Unlock Savings: The Ultimate Guide to 1950 Chevy Truck Custom (2025)

Introduction: Navigating the Global Market for 1950 chevy truck custom

Navigating the global market for a 1950 Chevy truck custom presents unique challenges for international B2B buyers. Whether you are sourcing specialized parts or seeking customization services, understanding regional suppliers and their capabilities is crucial. This guide delves into the diverse aspects of customizing a 1950 Chevy truck, including the types of modifications available, potential applications in various industries, and key considerations for supplier vetting.

By exploring cost structures, shipping logistics, and quality assurance processes, this comprehensive resource equips buyers from Africa, South America, the Middle East, and Europe—such as Egypt and Brazil—with the knowledge needed to make informed purchasing decisions. The growing demand for vintage vehicles, coupled with the trend of custom modifications, underscores the importance of selecting the right partners to enhance vehicle performance and aesthetics.

This guide aims to empower B2B buyers by providing actionable insights into the customization landscape of the 1950 Chevy truck. From identifying reliable suppliers to understanding market trends, you will gain valuable information to optimize your procurement strategy and ensure successful transactions in the competitive automotive sector.

Understanding 1950 chevy truck custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Restoration Custom | Original parts, vintage aesthetics, and factory specifications. | Classic car dealerships, collectors. | Pros: Authenticity and resale value. Cons: Higher costs and longer timelines. |

| Hot Rod Custom | Performance upgrades, modern engines, and unique body modifications. | Racing events, automotive shows. | Pros: Enhanced performance and customization. Cons: May not retain original value. |

| Rat Rod Custom | Raw, unfinished look with a focus on creativity and personality. | Custom shows, art installations. | Pros: Unique style and lower cost. Cons: Less appeal for traditional buyers. |

| Utility Custom | Enhanced functionality with modern features like towing packages. | Construction, logistics companies. | Pros: Practicality and improved performance. Cons: May compromise classic aesthetics. |

| Show Custom | High-end finishes, intricate detailing, and show-ready designs. | Car shows, exhibitions. | Pros: Eye-catching appeal and high resale potential. Cons: High investment and maintenance costs. |

What Are the Key Characteristics of Restoration Custom 1950 Chevy Trucks?

Restoration custom trucks focus on preserving the original essence of the 1950 Chevy while using authentic parts to maintain vintage aesthetics. These vehicles are ideal for classic car dealerships and collectors who value authenticity and historical accuracy. Buyers should consider the availability of original parts and the potential for higher resale value, although restoration can be costly and time-consuming.

How Do Hot Rod Customs Enhance Performance?

Hot rod customs are designed for performance enthusiasts, featuring modern engines and significant modifications that enhance speed and handling. These trucks are popular in racing events and automotive shows where performance is key. B2B buyers should consider the balance between performance upgrades and the potential impact on the vehicle’s original value, as these modifications may not appeal to traditional collectors.

Why Choose a Rat Rod Custom for Creative Expression?

Rat rod customs embrace a raw, unfinished aesthetic that allows for creative expression and individuality. They are often seen in custom shows and art installations, appealing to a niche market of buyers looking for unique vehicles. While they can be less expensive to create, B2B buyers should note that their unconventional style may have limited appeal compared to more traditional restorations.

What Are the Benefits of Utility Custom 1950 Chevy Trucks?

Utility custom trucks enhance functionality, incorporating modern features like towing packages and improved suspensions. These vehicles are particularly suited for construction and logistics companies looking for reliable workhorses. Buyers should weigh the practicality and performance improvements against any compromises to the classic aesthetic, as this may affect their appeal in the collector market.

What Makes Show Custom Trucks Stand Out?

Show custom trucks are meticulously crafted to achieve high-end finishes and intricate detailing, making them perfect for car shows and exhibitions. Their eye-catching designs attract attention and can lead to high resale potential. However, B2B buyers must be prepared for significant investment and ongoing maintenance costs to preserve the stunning appearance and performance of these vehicles.

Key Industrial Applications of 1950 chevy truck custom

| Industry/Sector | Specific Application of 1950 Chevy Truck Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Custom farm utility vehicle | Enhanced operational efficiency for farm tasks | Availability of parts for customization and repair |

| Construction | Heavy-duty transport for materials | Reliable transportation of tools and materials | Durability of modifications and ease of maintenance |

| Event Management | Mobile event setup and service | Versatile use for transporting equipment and staff | Customization options for branding and utility |

| Logistics & Delivery | Customized delivery truck | Improved logistics for last-mile delivery | Sourcing reliable suppliers for parts and retrofitting |

| Tourism & Recreation | Vintage tour vehicle | Unique customer experience enhancing brand image | Compliance with local regulations and safety standards |

How is the 1950 Chevy Truck Custom Used in Agriculture?

In the agriculture sector, the 1950 Chevy truck custom serves as a versatile utility vehicle. Farmers often modify these trucks to handle various tasks, such as transporting produce, tools, and livestock. The customization allows for specific adaptations, such as enhanced towing capabilities and storage solutions, which are crucial for efficiency in farming operations. International buyers, especially from regions like Africa and South America, should consider sourcing durable parts to withstand challenging terrains and climates.

What Role Does the 1950 Chevy Truck Custom Play in Construction?

In the construction industry, the 1950 Chevy truck custom is often utilized as a heavy-duty transport vehicle. Its robust frame and customizable features enable it to carry heavy materials and tools to job sites. This truck can be modified with features like reinforced beds or specialized racks to suit specific construction needs. Buyers from the Middle East and Europe should focus on sourcing high-quality components to ensure reliability and longevity, particularly in demanding construction environments.

How Can Event Management Benefit from a Customized 1950 Chevy Truck?

Event management companies find the 1950 Chevy truck custom to be an ideal mobile setup for events. The truck can be tailored to transport equipment, booths, and staff efficiently, making it a multifunctional asset. Custom branding options can also enhance visibility at events, creating a unique experience for attendees. B2B buyers in Europe and South America should prioritize sourcing customization services that comply with local branding regulations and ensure the vehicle meets logistical needs.

Why is the 1950 Chevy Truck Custom Valuable for Logistics & Delivery?

In logistics and delivery, the 1950 Chevy truck custom can be adapted into an efficient last-mile delivery vehicle. Its customization allows for optimized cargo space and loading capabilities, which are vital for timely deliveries. This adaptability can significantly enhance operational efficiency and customer satisfaction. Buyers from Africa and the Middle East should consider local regulations regarding vehicle modifications and sourcing reliable parts to maintain the truck’s performance.

How Does the 1950 Chevy Truck Custom Enhance Tourism & Recreation?

Tourism and recreation businesses leverage the 1950 Chevy truck custom as a vintage tour vehicle to attract customers. Its classic design and customizable features can create a memorable experience, enhancing the brand’s appeal. Customization options can include seating arrangements and entertainment systems, making it versatile for various tours. Buyers in regions like Europe should ensure that their modifications comply with local safety standards while enhancing the aesthetic appeal of the vehicle.

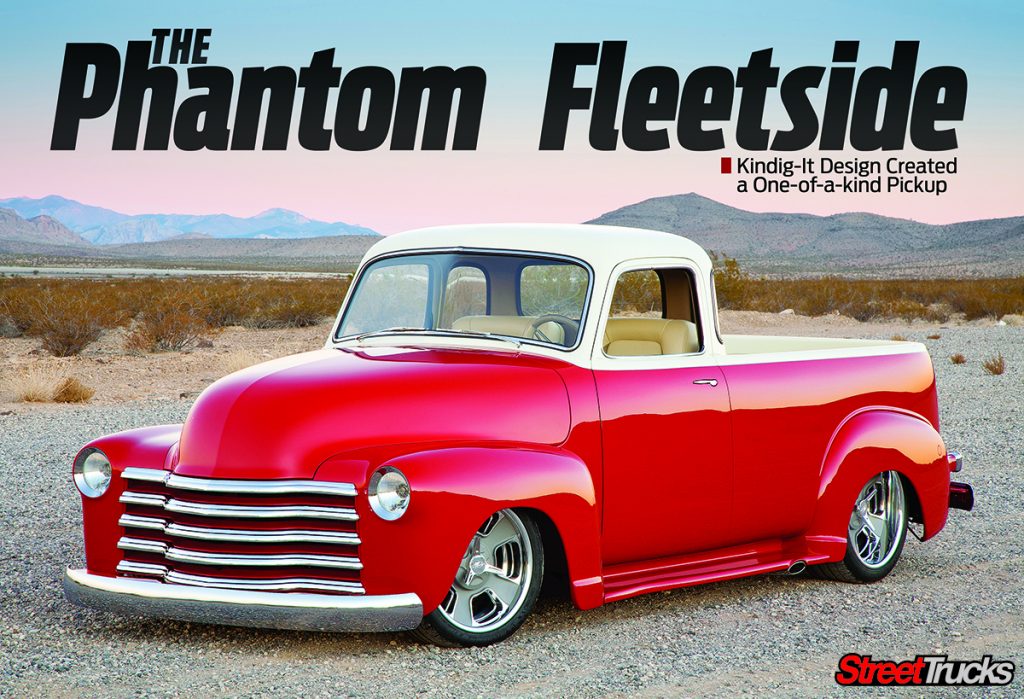

A stock image related to 1950 chevy truck custom.

Related Video: 1950 Chevy truck on S10 chassis build compilation

3 Common User Pain Points for ‘1950 chevy truck custom’ & Their Solutions

Scenario 1: Difficulty Sourcing Authentic Parts for Customization

The Problem: B2B buyers, particularly those involved in the restoration or customization of vintage vehicles like the 1950 Chevy Truck, often face challenges in sourcing authentic and high-quality parts. This can be exacerbated by the geographical location of buyers in regions like Africa or South America, where access to genuine parts may be limited. The risk of purchasing counterfeit or substandard components can lead to additional costs and delays in project timelines, ultimately affecting the bottom line.

The Solution: To effectively source authentic parts for a 1950 Chevy Truck, buyers should establish relationships with reputable suppliers who specialize in vintage vehicle parts. Begin by conducting thorough research to identify suppliers with positive reviews and a proven track record in international shipping. Utilize online platforms, forums, and networks dedicated to classic car enthusiasts to gather recommendations. Additionally, consider attending international auto shows or trade fairs, where suppliers often showcase their products. Building a network of trusted suppliers will not only ensure access to genuine parts but also facilitate better negotiation terms and support services.

Scenario 2: Navigating Customization Regulations and Compliance

The Problem: Customizing a vintage truck like the 1950 Chevy can often involve navigating a complex landscape of local regulations and compliance standards, especially in regions such as the Middle East and Europe. B2B buyers may struggle to understand the legal requirements related to emissions, safety, and vehicle modifications. Non-compliance can lead to fines, project rework, or even the inability to register the vehicle for use, which can be a significant setback for businesses focusing on vehicle customization.

The Solution: To navigate these regulations effectively, it is essential for buyers to conduct comprehensive research on local vehicle customization laws before commencing any project. Collaborating with legal experts or consultants specializing in automotive regulations can provide clarity and guidance on compliance issues. Additionally, buyers should engage with local automotive clubs or associations that may offer insights into the latest regulations and best practices. Keeping abreast of changes in legislation will help ensure that all modifications are compliant, thus minimizing risks and ensuring project success.

Scenario 3: Ensuring Quality in Custom Fabrication and Upgrades

The Problem: When customizing a 1950 Chevy Truck, B2B buyers often encounter the challenge of ensuring the quality and durability of fabricated parts and upgrades. Many buyers have reported issues with poorly manufactured components that do not meet performance expectations, leading to operational inefficiencies and increased maintenance costs. This problem is particularly pronounced when working with international suppliers, where quality control can vary significantly.

The Solution: To mitigate quality concerns, buyers should implement a stringent vetting process for any fabrication partners or suppliers. This includes requesting samples of materials and finished products, as well as reviewing certifications and quality assurance processes. Establishing clear specifications and standards upfront will also help ensure that all parties are aligned on expectations. Furthermore, consider integrating quality audits into the procurement process, where buyers can assess the manufacturing facilities and processes before placing large orders. By prioritizing quality assurance, businesses can enhance the reliability of their customizations, ultimately leading to better performance and customer satisfaction.

Strategic Material Selection Guide for 1950 chevy truck custom

What Are the Key Materials for Customizing a 1950 Chevy Truck?

When selecting materials for customizing a 1950 Chevy truck, international B2B buyers must consider various factors, including performance, cost, and compliance with local standards. Here are some of the most common materials used in custom builds, along with their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions like Africa, South America, the Middle East, and Europe.

Which Metal Offers the Best Performance for Custom Truck Parts?

Steel

Steel is a popular choice for structural components due to its strength and durability. It typically has a high tensile strength and excellent wear resistance, making it suitable for high-stress applications.

- Key Properties: High tensile strength, good weldability, and moderate corrosion resistance.

- Pros: Cost-effective, widely available, and easy to fabricate. It can withstand significant loads and impacts.

- Cons: Prone to rust if not properly treated, heavier than alternative materials, and may require additional coatings for corrosion resistance.

- Impact on Application: Ideal for chassis and frame components where strength is critical. However, it may not be suitable for parts exposed to harsh environments without proper treatment.

- Considerations for International Buyers: Compliance with ASTM standards is crucial for quality assurance. Buyers should also consider local availability and the cost of protective coatings to prevent corrosion.

What Are the Benefits of Using Aluminum in Custom Builds?

Aluminum

Aluminum is increasingly favored for its lightweight properties and corrosion resistance. It is particularly beneficial for components where weight savings are essential.

- Key Properties: Lightweight, excellent corrosion resistance, and good thermal conductivity.

- Pros: Reduces overall vehicle weight, enhancing fuel efficiency and handling. It is also resistant to rust, requiring less maintenance.

- Cons: Generally more expensive than steel, less strong in tension, and can be challenging to weld without specialized equipment.

- Impact on Application: Suitable for body panels and decorative elements. Its lightweight nature can improve performance but may require reinforcements in high-stress areas.

- Considerations for International Buyers: Compliance with JIS (Japanese Industrial Standards) may be relevant for buyers in Asia. Additionally, the cost factor should be weighed against the benefits of weight reduction.

How Does Composite Material Enhance Customization Options?

Composite Materials

Composites, such as fiberglass and carbon fiber, are becoming popular for custom parts due to their unique properties.

- Key Properties: High strength-to-weight ratio, excellent fatigue resistance, and customizable properties.

- Pros: Can be molded into complex shapes, lightweight, and resistant to corrosion and environmental degradation.

- Cons: Higher manufacturing complexity and costs, requiring specialized skills for repair and installation.

- Impact on Application: Ideal for custom bodywork and aerodynamic enhancements. They can significantly improve aesthetics and performance.

- Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding material use and safety standards. The availability of skilled labor for installation and repair is also a factor.

What Role Does Plastic Play in Custom Truck Components?

High-Density Polyethylene (HDPE)

HDPE is often used for non-structural components such as fuel tanks and interior fittings.

- Key Properties: High impact resistance, good chemical resistance, and low moisture absorption.

- Pros: Lightweight, cost-effective, and easy to mold into various shapes. It is also resistant to many chemicals and UV light.

- Cons: Limited temperature resistance compared to metals and may not be suitable for high-stress applications.

- Impact on Application: Best for components that require chemical resistance and lightweight properties, such as fuel tanks and storage compartments.

- Considerations for International Buyers: Compliance with local environmental regulations regarding plastic use is essential. Understanding the local market for HDPE products will aid in sourcing.

Summary Table of Material Selection for 1950 Chevy Truck Customization

| Material | Typical Use Case for 1950 Chevy Truck Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and frame components | Cost-effective and strong | Prone to rust without treatment | Low |

| Aluminum | Body panels and decorative elements | Lightweight and corrosion resistant | More expensive than steel | Med |

| Composite Materials | Custom bodywork and aerodynamic parts | High strength-to-weight ratio | Higher manufacturing complexity | High |

| High-Density Polyethylene (HDPE) | Fuel tanks and interior fittings | Lightweight and cost-effective | Limited temperature resistance | Low |

This guide provides a comprehensive overview of material options for customizing a 1950 Chevy truck, focusing on the needs and considerations of international B2B buyers. By understanding the properties and implications of each material, buyers can make informed decisions that align with their project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 1950 chevy truck custom

What Are the Key Manufacturing Processes for Customizing a 1950 Chevy Truck?

Manufacturing a custom 1950 Chevy truck involves several intricate processes that ensure both aesthetic appeal and functionality. Understanding these processes is essential for B2B buyers looking to source parts or services for customization.

Material Preparation: What Materials Are Used in Custom Truck Manufacturing?

The first stage in the manufacturing process is material preparation. Common materials include:

- Steel: Primarily used for the frame and body due to its strength and durability.

- Aluminum: Often selected for components where weight reduction is critical, such as wheels and engine parts.

- Fiberglass: Used in body kits for aesthetic enhancements.

- Leather and Upholstery Fabrics: For interior customization.

Before manufacturing begins, materials undergo rigorous inspections to ensure they meet specific standards. This may involve checking for surface defects, chemical composition, and dimensional accuracy.

What Techniques Are Commonly Used in Forming Custom Truck Parts?

Once materials are prepared, the forming stage commences. Key techniques include:

- CNC Machining: Computer Numerical Control (CNC) technology allows for precise cutting, shaping, and milling of components. This technique is particularly beneficial for creating custom parts that fit specific design requirements.

- Sheet Metal Fabrication: Techniques like laser cutting and bending are employed to shape the steel or aluminum sheets into the desired forms for the truck’s body and frame.

- Welding: MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are commonly used to join metal components. Quality welding is crucial for structural integrity and durability.

How Is Assembly Conducted in the Customization Process?

The assembly stage brings together all manufactured components. This process involves:

- Sub-assembly: Components such as the engine, transmission, and suspension are assembled separately before being integrated into the main chassis.

- Main Assembly: The truck’s body is fitted onto the frame, and various systems (electrical, hydraulic) are connected. Skilled technicians ensure that all parts fit correctly and function as intended.

What Finishing Techniques Are Used for Custom Chevy Trucks?

The finishing stage is vital for both aesthetics and protection. Techniques include:

- Painting: High-quality paints and finishes are applied to achieve the desired color and gloss. This may involve multiple layers, including primers and clear coats.

- Plating: Chrome or nickel plating can enhance the look of various components while providing corrosion resistance.

- Interior Finishing: Upholstery work involves fitting leather, fabric, and other materials to create a comfortable and stylish interior.

How Is Quality Assurance Implemented in Custom Truck Manufacturing?

Quality assurance (QA) is crucial in ensuring that the final product meets both international and industry-specific standards.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with the following international standards:

- ISO 9001: This standard emphasizes a quality management system that ensures consistent quality in products and services.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: While more common in oil and gas, API standards can apply to specific components like pumps and valves used in custom trucks.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure compliance with standards:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to verify they meet specifications.

- In-Process Quality Control (IPQC): Monitors the production process at various stages to catch defects early.

- Final Quality Control (FQC): Conducted before the product is shipped, ensuring that it meets all quality standards and specifications.

What Common Testing Methods Are Used for Custom Truck Parts?

Testing methods vary based on the component being manufactured but typically include:

- Dimensional Inspection: Verifying that parts meet specified measurements using tools like calipers and gauges.

- Functional Testing: Ensuring that components like the engine and electrical systems operate correctly under simulated conditions.

- Stress Testing: Assessing the durability of components by subjecting them to extreme conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits can provide insights into the manufacturing processes and QC measures in place. Look for compliance with ISO 9001 and other relevant standards.

- Quality Reports: Requesting detailed QC reports can help assess a supplier’s commitment to quality.

- Third-Party Inspections: Engaging an independent inspection agency can provide an unbiased evaluation of the manufacturing process and final products.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification:

- Documentation: Ensure that all necessary certifications, such as ISO and CE, are documented and available for review.

- Local Regulations: Understand any local regulations that may affect the importation and use of customized vehicles.

- Cultural Considerations: Different regions may have varying expectations regarding quality and customization. Tailoring your approach based on cultural insights can enhance supplier relationships.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing parts or services for customizing a 1950 Chevy truck. This knowledge not only helps in selecting reliable suppliers but also ensures that the final product meets the high standards expected in today’s market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1950 chevy truck custom’

In the realm of sourcing components and customizations for a 1950 Chevy truck, international B2B buyers face unique challenges and opportunities. This guide serves as a practical checklist to streamline the procurement process, ensuring you find the best suppliers and products tailored to your specific needs.

1. Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications for your custom Chevy truck. This includes dimensions, materials, and functionality of the parts needed. Having a detailed specification sheet helps in communicating effectively with suppliers and ensures you receive accurate quotes.

- Considerations: Think about whether you require OEM (Original Equipment Manufacturer) parts or aftermarket modifications. Specify any custom designs or features to avoid misunderstandings later.

2. Research Potential Suppliers Thoroughly

Invest time in researching potential suppliers who specialize in custom parts for classic vehicles. A thorough vetting process is crucial for quality assurance and reliability.

- Actions: Look for suppliers with a proven track record in the automotive sector, particularly those experienced with vintage models. Check online reviews, industry forums, and ask for recommendations from fellow enthusiasts or businesses.

3. ✅ Verify Supplier Certifications

Ensure that your chosen suppliers have relevant certifications and compliance with international quality standards. Certifications like ISO 9001 can indicate a commitment to quality management systems.

- Importance: Certifications can provide assurance that the supplier adheres to established quality protocols, which is vital for custom parts where precision is essential.

4. Request Samples Before Bulk Orders

Before finalizing any large orders, request samples of the parts you intend to purchase. This step allows you to assess the quality and fit of the components firsthand.

- Benefits: Evaluating samples helps prevent costly mistakes associated with ordering large quantities of parts that may not meet your expectations or specifications.

5. Discuss Customization Options

Engage in detailed discussions with potential suppliers about customization options available for the 1950 Chevy truck. Understanding the range of modifications they can offer is key to achieving your desired outcomes.

- Key Points: Ask about the supplier’s ability to accommodate unique requests and their experience with similar projects. This will provide insight into their flexibility and capability to meet your needs.

6. Evaluate Pricing Structures and Payment Terms

Understanding the pricing structure and payment terms is essential to ensure the financial feasibility of your project. Compare quotes from multiple suppliers to identify competitive pricing.

- Considerations: Look out for hidden costs, including shipping, tariffs, or taxes, especially when dealing with international suppliers. Negotiating favorable payment terms can also enhance cash flow management.

7. Establish Clear Communication Channels

Effective communication is critical throughout the sourcing process. Establish clear lines of communication with suppliers to ensure smooth collaboration.

- Best Practices: Utilize tools like emails, video calls, and project management software to maintain transparency. Regular updates on production timelines and any potential issues will help build a trustworthy relationship.

A stock image related to 1950 chevy truck custom.

By following this checklist, international B2B buyers can streamline their sourcing process for custom parts and upgrades for the 1950 Chevy truck, ensuring a successful procurement experience that meets their specific needs.

Comprehensive Cost and Pricing Analysis for 1950 chevy truck custom Sourcing

What Are the Key Cost Components for Customizing a 1950 Chevy Truck?

When considering the customization of a 1950 Chevy Truck, it is essential to break down the overall cost structure into distinct components. The primary cost components include:

-

Materials: This encompasses all raw materials required for the build, such as sheet metal, upholstery, paint, and mechanical parts. The choice of materials significantly impacts both the aesthetic and functional aspects of the truck.

-

Labor: Skilled labor is a critical factor in customization projects. The complexity of the modifications will determine the number of labor hours required. In regions like Africa and South America, labor costs may vary, so understanding local wage standards is crucial for budgeting.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility costs. Manufacturers often allocate a portion of these costs to each project, affecting the final pricing.

-

Tooling: Custom jobs may require specialized tools or dies, which can add significant costs, especially for unique modifications. Buyers should inquire about tooling fees upfront to avoid unexpected expenses.

-

Quality Control (QC): Ensuring that the final product meets the required specifications involves quality assurance processes. The costs associated with QC can vary based on the complexity and the quality standards set by the buyer.

-

Logistics: Shipping costs can be substantial, particularly for international buyers. Factors such as distance, mode of transport, and customs duties play a significant role in the overall logistics cost.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary based on the supplier’s reputation, market demand, and the complexity of the customizations.

What Influences Pricing for Custom 1950 Chevy Trucks?

Several factors can influence the pricing of custom 1950 Chevy Trucks, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better prices, especially if they plan multiple purchases.

-

Specifications and Customization: Unique designs or specifications can increase costs significantly. It is advisable for buyers to have clear specifications to avoid miscommunication that could lead to costly changes.

-

Material Choices: Premium materials will naturally increase costs. Buyers should assess their quality requirements against their budget, particularly when sourcing from different regions.

-

Quality and Certifications: Suppliers with recognized quality certifications may charge higher prices but can offer better reliability and performance. International buyers should ensure that suppliers meet the necessary standards for their respective markets.

-

Supplier Factors: The supplier’s experience, location, and capabilities can significantly affect pricing. Established suppliers may offer higher quality but at a premium price.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is critical for buyers. This will define the responsibilities of both parties regarding shipping costs and risks, ultimately impacting the total cost of ownership.

What Are Some Negotiation Tips for International B2B Buyers?

-

Understand Total Cost of Ownership: Beyond the initial price, consider ongoing maintenance, potential repairs, and operational costs. A lower upfront cost might lead to higher long-term expenses.

-

Leverage Local Insights: Buyers from Africa, South America, the Middle East, and Europe should utilize local knowledge to negotiate better terms. Familiarity with local markets can provide leverage in discussions.

-

Be Clear About Specifications: Clearly outline your requirements to prevent misunderstandings that could lead to additional costs. This clarity aids in accurate quotations and timely deliveries.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and service. Long-term partnerships often yield more favorable terms.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Gathering multiple proposals allows for comparison and can lead to better negotiation outcomes.

Disclaimer on Indicative Prices

Pricing for custom 1950 Chevy Trucks can vary widely based on numerous factors, including but not limited to those discussed above. It is essential for buyers to conduct thorough research and obtain detailed quotes from multiple suppliers to get a clear understanding of potential costs.

Alternatives Analysis: Comparing 1950 chevy truck custom With Other Solutions

When considering a custom vehicle like the 1950 Chevy Truck, it’s essential to evaluate alternative solutions that can meet similar needs. Whether the goal is aesthetic appeal, functionality, or reliability, comparing different options can help international B2B buyers make informed decisions.

Comparison Table of Customization Alternatives

| Comparison Aspect | 1950 Chevy Truck Custom | Classic Ford F-100 Custom | Electric Pickup Trucks (e.g., Rivian R1T) |

|---|---|---|---|

| Performance | Strong traditional engine, but limited by age | Comparable power with newer tech | Superior torque and range with electric motors |

| Cost | Moderate to high; depends on customization level | Generally similar, but parts may be cheaper | Higher initial investment, but lower running costs |

| Ease of Implementation | Requires skilled labor for custom work | Easier to find parts and labor | Complex installation but less labor-intensive once set up |

| Maintenance | High due to age and customization | Moderate; newer models are easier to maintain | Low; fewer moving parts and high reliability |

| Best Use Case | Classic car enthusiasts, show vehicles | Daily drivers, classic car fans | Eco-conscious businesses, modern fleets |

What are the Advantages and Disadvantages of Classic Ford F-100 Custom?

The Classic Ford F-100 is a viable alternative for those seeking a vintage truck experience. Its performance is on par with the 1950 Chevy Truck, offering a reliable engine and good handling. The cost is comparable, but parts for the F-100 may be easier to source, leading to potentially lower maintenance costs. However, it may not have the same aesthetic appeal to Chevy enthusiasts, which could be a drawback for those prioritizing style over practicality.

How Do Electric Pickup Trucks Compare to Custom Classics?

Electric pickup trucks, such as the Rivian R1T, are rapidly gaining popularity due to their environmental benefits and advanced technology. They outperform traditional vehicles in torque and range, making them suitable for heavy-duty tasks. While the initial investment is higher, the long-term running costs can be significantly lower due to savings on fuel and maintenance. However, the complexity of installation and the need for charging infrastructure can be barriers for traditionalists or businesses in regions with limited access to such facilities.

Conclusion: How to Choose the Right Customization Solution?

Selecting the right customization solution for a vehicle like the 1950 Chevy Truck requires careful consideration of your specific needs. Factors such as performance, cost, ease of implementation, and maintenance should be evaluated in the context of your target market. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider local availability of parts and services, as well as the cultural significance of vehicle choice. Ultimately, the best option will align with both business objectives and customer preferences.

Essential Technical Properties and Trade Terminology for 1950 chevy truck custom

What Are the Essential Technical Properties for Customizing a 1950 Chevy Truck?

When considering the customization of a 1950 Chevy truck, understanding its essential technical properties is crucial for B2B buyers. Here are some key specifications that influence both performance and aesthetics.

1. Material Grade

Material grade refers to the quality and composition of the materials used in the vehicle’s construction and upgrades. Common materials include steel, aluminum, and composites. For instance, high-strength steel is often preferred for structural components due to its durability and resilience, while aluminum may be chosen for lightweight applications. For international buyers, selecting the right material grade can impact shipping costs and compatibility with local regulations.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension in manufacturing. In the context of custom parts for a 1950 Chevy truck, tight tolerances ensure that components fit together correctly, enhancing performance and safety. For B2B buyers, understanding tolerance levels is crucial when placing orders to ensure that parts meet specific requirements and work seamlessly with existing systems.

3. Finish Type

The finish type refers to the surface treatment of components, such as paint, powder coating, or chrome plating. The choice of finish not only affects the vehicle’s appearance but also its resistance to corrosion and wear. B2B buyers should consider the environmental conditions in their market (e.g., humidity, UV exposure) when selecting finishes, as this can significantly affect long-term durability.

4. Weight Distribution

Weight distribution is a critical aspect of vehicle handling and performance. Custom modifications can alter the truck’s weight balance, which affects stability and maneuverability. For buyers, understanding how modifications impact weight distribution can help in making informed decisions about performance enhancements, especially if the truck will be used in demanding conditions.

5. Powertrain Compatibility

Powertrain compatibility involves ensuring that any upgrades, such as new engines or transmissions, are compatible with the existing drivetrain. This includes understanding the specifications of the original engine and any aftermarket components. For international buyers, ensuring compatibility can mitigate costly modifications and ensure smoother operations.

What Are Common Trade Terms in the 1950 Chevy Truck Customization Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. Using OEM parts can ensure quality and compatibility, which is especially important for buyers looking to maintain the authenticity of the 1950 Chevy truck.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it affects inventory management and cash flow. Buyers in markets like Africa and South America should negotiate MOQs that align with their operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. This process is essential for B2B buyers to compare options and make informed purchasing decisions. Crafting a clear RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping. Understanding Incoterms is crucial for international B2B transactions, as they outline who pays for shipping, insurance, and tariffs, which can significantly affect total costs.

5. Aftermarket

The aftermarket refers to parts and accessories that are not supplied by the OEM but are available for customization and upgrades. For buyers looking to enhance their 1950 Chevy truck, knowing the aftermarket landscape can open up various options for performance and aesthetics.

By grasping these technical properties and trade terms, B2B buyers can navigate the customization process for the 1950 Chevy truck with greater confidence and efficiency, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the 1950 chevy truck custom Sector

What Are the Key Market Trends in the 1950 Chevy Truck Custom Sector?

The 1950 Chevy Truck custom sector is experiencing a revival, driven by a growing demand for vintage vehicles and customizations that enhance performance and aesthetics. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking unique modifications to stand out in the market. Key trends include the integration of modern technology, such as electric drivetrains and advanced suspension systems, which appeal to a younger demographic interested in sustainability and performance.

Additionally, digital platforms are reshaping sourcing strategies. B2B buyers are leveraging e-commerce platforms and online marketplaces to connect with suppliers and manufacturers globally. This shift facilitates the procurement of custom parts, such as precision sheet metal components and specialized accessories, essential for the restoration and enhancement of 1950 Chevy Trucks. Notably, suppliers in regions with established automotive manufacturing, like Europe and Brazil, are emerging as key players, offering competitive pricing and innovative solutions tailored to specific buyer needs.

How Is Sustainability Impacting the Sourcing of Custom Parts for 1950 Chevy Trucks?

Sustainability is becoming a pivotal consideration in the sourcing of custom parts for 1950 Chevy Trucks. The environmental impact of traditional manufacturing processes has prompted many B2B buyers to prioritize suppliers who adhere to sustainable practices. This includes utilizing recycled materials, minimizing waste, and implementing energy-efficient manufacturing techniques.

Ethical supply chains are also gaining importance. Buyers are increasingly demanding transparency regarding the sourcing of materials and the labor practices of manufacturers. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance supplier credibility and appeal to conscientious buyers. Moreover, the use of “green” materials, like bio-based composites and eco-friendly finishes, is on the rise, allowing buyers to market their custom vehicles as environmentally responsible.

What Is the Historical Context of the 1950 Chevy Truck Custom Sector?

The 1950 Chevy Truck has a storied history that has significantly influenced its custom sector. Originally designed for utility, the truck quickly gained popularity due to its robust build and versatility. Over the decades, it has evolved into a canvas for customization, reflecting personal style and modern automotive trends.

The custom scene began gaining traction in the late 20th century, driven by car enthusiasts looking to blend classic aesthetics with modern performance. Today, the 1950 Chevy Truck stands as a symbol of nostalgia, with a dedicated community that values both restoration and innovation. This historical context provides B2B buyers with a rich narrative that can enhance branding and marketing strategies when sourcing custom parts and services.

In conclusion, understanding the market dynamics and sourcing trends in the 1950 Chevy Truck custom sector allows international B2B buyers to navigate the complexities of this vibrant industry effectively. By focusing on sustainability, leveraging technology, and appreciating the vehicle’s historical significance, buyers can make informed decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of 1950 chevy truck custom

-

How do I ensure the quality of a custom 1950 Chevy truck?

To ensure the quality of a custom 1950 Chevy truck, it is essential to conduct thorough supplier vetting. Look for manufacturers with a solid reputation, verified certifications, and extensive experience in automotive customization. Request samples of their previous work and ensure they adhere to international quality standards. Additionally, consider visiting the production facility if feasible or engaging a third-party quality assurance service to inspect the vehicle before shipment. This proactive approach minimizes risks and guarantees that you receive a product that meets your expectations. -

What is the best customization for a 1950 Chevy truck to enhance performance?

The best customization for enhancing performance in a 1950 Chevy truck includes upgrading the engine, suspension, and braking systems. Consider installing a modern V8 engine for better horsepower and fuel efficiency. Upgrading to a disc brake system improves stopping power and safety, while a new suspension system can enhance handling and ride comfort. Additionally, consider retrofitting with modern technology, such as fuel injection and electronic ignition systems, for improved reliability and performance. -

What are the common challenges in sourcing custom 1950 Chevy trucks internationally?

Common challenges in sourcing custom 1950 Chevy trucks internationally include language barriers, varying quality standards, and different regulatory requirements. Additionally, logistical issues such as shipping delays and customs clearance can pose significant hurdles. It is advisable to partner with reliable freight forwarders and customs brokers familiar with the automotive industry. Establishing clear communication and documentation standards with suppliers can mitigate these challenges and ensure a smoother transaction process. -

What are the minimum order quantities (MOQ) for custom 1950 Chevy trucks?

Minimum order quantities (MOQ) for custom 1950 Chevy trucks can vary significantly based on the supplier and the specific customization requirements. Some manufacturers may have a MOQ of one unit, while others may require larger orders to justify production costs. It is crucial to discuss these details upfront with potential suppliers to understand their policies and negotiate terms that align with your business needs. Always confirm whether the MOQ includes all customization options or if different components have separate MOQs. -

How should I handle payments for international purchases of custom trucks?

Handling payments for international purchases of custom trucks requires careful planning to mitigate risks. Common payment methods include letters of credit, bank transfers, or escrow services, which provide security for both parties. It’s essential to agree on payment terms before finalizing any contract. Consider negotiating a payment schedule based on project milestones, which can help manage cash flow and ensure satisfaction with the work completed at each stage. -

What logistics considerations should I keep in mind when importing a 1950 Chevy truck?

When importing a 1950 Chevy truck, logistics considerations include shipping methods, customs clearance, and compliance with local regulations. Choose a reliable shipping method, such as container shipping, to protect the vehicle during transit. Familiarize yourself with your country’s import regulations to ensure compliance with safety and emissions standards. Engage a knowledgeable customs broker to navigate documentation and duties, streamlining the import process and reducing potential delays. -

What are the best practices for supplier vetting when sourcing custom trucks?

Best practices for supplier vetting when sourcing custom trucks include conducting background checks, reviewing customer testimonials, and verifying certifications. Request references from previous clients to gauge their satisfaction and reliability. Additionally, assess the supplier’s production capabilities and quality control processes. If possible, visit the facility to inspect operations firsthand. Establish clear communication about expectations and timelines to ensure alignment with your project goals. -

How can I ensure compliance with international trade regulations when sourcing trucks?

To ensure compliance with international trade regulations when sourcing trucks, familiarize yourself with both your country’s and the supplier’s regulations. This includes understanding tariffs, import duties, and safety standards. Utilize resources such as trade associations and government websites for up-to-date information. Engaging with legal experts or trade consultants can also provide valuable insights into navigating complex regulations, ensuring that your transactions remain compliant and avoiding costly penalties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 1950 chevy truck custom

What Are the Key Takeaways for International B2B Buyers in Customizing a 1950 Chevy Truck?

The journey of customizing a 1950 Chevy truck presents a wealth of opportunities for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. Strategic sourcing is essential to ensure that you acquire high-quality parts and services while optimizing costs. Engaging with reliable suppliers not only enhances product quality but also fosters innovation, enabling you to offer unique customizations that meet local market demands.

How Can Strategic Sourcing Enhance Your Customization Projects?

By prioritizing strategic sourcing, buyers can mitigate risks associated with international procurement, such as fluctuating prices and supply chain disruptions. Establishing relationships with manufacturers who specialize in custom parts—like precision sheet metal and advanced automotive components—can lead to improved turnaround times and better pricing structures. This approach allows businesses to stay competitive in a niche market that values distinctiveness and quality.

What Does the Future Hold for Custom 1950 Chevy Truck Projects?

Looking ahead, the market for vintage truck customization is poised for growth, driven by the increasing popularity of classic vehicles as both functional and collectible assets. International buyers should seize this momentum by investing in partnerships with innovative suppliers and custom shops. Embrace the opportunity to create customized vehicles that resonate with your target market, and position your business as a leader in the automotive customization space. Take action today and explore the possibilities that strategic sourcing can unlock for your 1950 Chevy truck projects.