Unlock Savings: The Ultimate Guide to Contacting Manufacturers (2025)

Introduction: Navigating the Global Market for contactor manufacturer

Navigating the complexities of sourcing the right contactor manufacturer can be a daunting task for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. With an ever-expanding array of suppliers and products available, it’s critical to identify manufacturers that align not only with your technical requirements but also your strategic business goals. This guide aims to demystify the procurement process by providing detailed insights into the various types of contactors, their applications, and the essential criteria for evaluating suppliers.

In the following sections, we will explore the key factors influencing the selection of a contactor manufacturer, including product specifications, market trends, and pricing structures. We will also delve into the importance of supplier vetting, offering practical strategies to assess quality, reliability, and compliance with international standards. By equipping B2B buyers with actionable knowledge, this guide empowers you to make informed purchasing decisions that enhance operational efficiency and reduce risks in your supply chain.

Whether you are a procurement manager in Nigeria seeking to streamline your electrical components sourcing or a business leader in Italy looking to expand your supplier network, our comprehensive analysis will provide the tools you need to navigate the global market effectively. Embrace the opportunity to enhance your purchasing strategy and drive your business forward in today’s competitive landscape.

Understanding contactor manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electromechanical Contactors | Operate using electromagnetic coils; reliable in high-load applications. | Motor control, lighting systems. | Pros: High durability, cost-effective. Cons: Slower switching speed compared to electronic types. |

| Solid State Contactors | Use semiconductor materials for switching; no moving parts. | Industrial automation, HVAC systems. | Pros: Faster switching, longer lifespan. Cons: Higher initial cost, sensitivity to overheating. |

| Relay Contactors | Combine contactor features with relay functions; versatile. | Automation systems, control panels. | Pros: Compact design, flexibility in applications. Cons: Limited load capacity compared to pure contactors. |

| Smart Contactors | Integrate IoT capabilities for remote monitoring and control. | Energy management, smart buildings. | Pros: Enhanced control, data analytics. Cons: Complexity in installation, higher cost. |

| Miniature Contactors | Smaller size for limited space applications; lower load ratings. | Residential installations, small machinery. | Pros: Space-saving, cost-effective. Cons: Not suitable for high-power applications. |

What are the characteristics of Electromechanical Contactors?

Electromechanical contactors are widely recognized for their reliability in high-load applications. These devices operate using electromagnetic coils to open and close the circuit, making them a staple in industrial settings such as motor control and lighting systems. When purchasing, B2B buyers should consider the contactor’s voltage and current ratings, as well as its durability under continuous operation. The cost-effectiveness and robust nature of these contactors make them a popular choice, despite their slower switching speeds compared to electronic alternatives.

How do Solid State Contactors differ in functionality?

Solid State Contactors (SSCs) utilize semiconductor materials to achieve switching without moving parts, providing significant advantages in terms of speed and longevity. They are ideal for applications in industrial automation and HVAC systems where quick switching is essential. Buyers should assess the thermal management capabilities of SSCs, as they can be sensitive to overheating. While the initial investment may be higher, the long lifespan and reduced maintenance needs often justify the cost for businesses seeking efficiency and reliability.

Why choose Relay Contactors for diverse applications?

Relay Contactors combine the functionalities of relays and contactors, making them versatile components in automation systems and control panels. Their compact design allows for easy integration into various applications, but they generally have a limited load capacity compared to traditional contactors. B2B buyers should evaluate the specific load requirements and environmental conditions when selecting relay contactors. The flexibility and adaptability of these devices make them an attractive option for companies looking to optimize space and functionality.

What are the benefits of Smart Contactors in modern systems?

Smart Contactors are designed with IoT capabilities, enabling remote monitoring and control, which is increasingly vital in energy management and smart building applications. These contactors offer enhanced control and valuable data analytics that can significantly improve operational efficiency. However, the complexity of installation and higher upfront costs may deter some buyers. Companies focused on future-proofing their operations should consider investing in smart contactors to leverage the benefits of automation and data-driven decision-making.

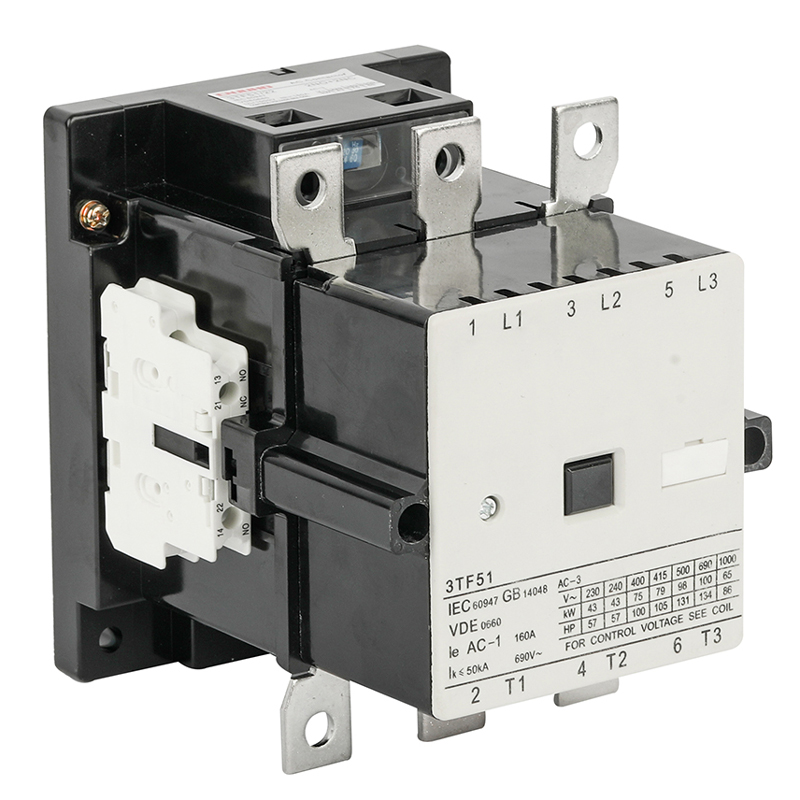

A stock image related to contactor manufacturer.

When to consider Miniature Contactors for your projects?

Miniature Contactors are specifically designed for applications where space is at a premium, such as in residential installations and small machinery. They typically have lower load ratings, making them unsuitable for high-power applications. B2B buyers should carefully assess the load requirements and ensure that the miniature contactors can meet their operational needs. The space-saving design and cost-effectiveness of these contactors make them an appealing choice for businesses looking to maximize efficiency in compact environments.

Related Video: Electronics How-To: Relays and Contactor Basics

Key Industrial Applications of contactor manufacturer

| Industry/Sector | Specific Application of contactor manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Motor Control in Production Lines | Enhanced efficiency and reduced downtime | Compliance with local electrical standards and certifications |

| Renewable Energy | Solar Panel Array Management | Optimized energy output and system reliability | Availability of support for integration with existing systems |

| HVAC Systems | Automation of Heating and Cooling Units | Improved energy efficiency and cost savings | Compatibility with various HVAC control systems |

| Construction | Control of Heavy Machinery | Increased safety and operational reliability | Robustness and durability to withstand harsh environments |

| Water Treatment | Pump Control and Monitoring | Ensured water quality and regulatory compliance | Adaptability to different pump types and environmental conditions |

How is Contactor Manufacturing Applied in the Manufacturing Sector?

In the manufacturing industry, contactors are primarily used for motor control in production lines. They enable the safe and efficient operation of electric motors that power machinery. By automating the start and stop processes, contactors reduce manual intervention, thus enhancing operational efficiency and minimizing downtime. For international buyers, particularly in regions like Africa and South America, it is crucial to ensure that contactors meet local electrical standards and certifications to avoid compliance issues and ensure safety.

What Role Do Contactors Play in Renewable Energy Applications?

In the renewable energy sector, contactors are vital for managing solar panel arrays. They help in controlling the flow of electricity generated by solar panels, ensuring optimal energy output and system reliability. By automating the connection and disconnection of solar arrays to the grid, contactors contribute to maximizing energy efficiency. Buyers from the Middle East and Europe should consider the availability of manufacturer support for integrating contactors with existing renewable energy systems to enhance overall performance.

How Are Contactors Used in HVAC Systems?

Contactor manufacturers provide essential components for automating heating, ventilation, and air conditioning (HVAC) systems. These devices control the electrical components of HVAC units, improving energy efficiency and reducing operational costs. For B2B buyers, particularly in Europe where energy regulations are stringent, compatibility with various HVAC control systems is a critical consideration to ensure seamless integration and compliance with energy efficiency standards.

Why Are Contactors Important for Construction Machinery Control?

In the construction industry, contactors are crucial for controlling heavy machinery, such as cranes and excavators. They enhance safety by providing reliable electrical control, allowing operators to manage machinery effectively. The robustness and durability of contactors are essential, especially in harsh construction environments. International buyers must prioritize sourcing contactors that can withstand extreme conditions to maintain operational reliability and safety.

How Do Contactors Facilitate Water Treatment Processes?

A stock image related to contactor manufacturer.

Contactor manufacturers play a significant role in water treatment facilities by controlling pumps and monitoring water quality. They help ensure that pumps operate efficiently, thereby maintaining regulatory compliance for water quality standards. For buyers in regions like Africa, where water treatment infrastructure may be developing, adaptability to different pump types and environmental conditions is a vital consideration when sourcing contactors to ensure functionality and reliability in diverse settings.

Related Video: CHINT NXC-12 230V, 380V AC Contactor

3 Common User Pain Points for ‘contactor manufacturer’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Contactor for Specific Applications

The Problem:

International B2B buyers often struggle with identifying the right contactor for their specific industrial applications. This challenge is heightened by the variety of voltage ratings, current capacities, and environmental conditions that different contactors are designed to withstand. For instance, a manufacturing plant in Nigeria may require contactors that can operate effectively in high humidity and temperature conditions, whereas a facility in Italy may need ones that comply with stricter European Union electrical standards. Misalignment in specifications can lead to equipment failures, increased operational costs, and safety hazards.

The Solution:

To effectively source the right contactor, buyers should engage in a comprehensive needs assessment before making a purchase. This includes evaluating the electrical load requirements, environmental factors, and compliance with local regulations. Collaborating with a reputable contactor manufacturer that offers customizable solutions can also be beneficial. They often provide technical support and guidance tailored to specific industry needs. Additionally, leveraging tools such as product selection software or online configurators offered by manufacturers can simplify the selection process. Be sure to request detailed product datasheets and certifications to ensure the chosen contactor meets both operational and regulatory demands.

Scenario 2: Concerns Over Product Quality and Reliability

The Problem:

Quality assurance is a paramount concern for B2B buyers, particularly when sourcing contactors from manufacturers in different regions. Instances of subpar products can lead to costly downtime, safety incidents, and reputational damage. Buyers from regions like South America may face challenges in validating the quality of imported contactors, especially if there is a lack of established local suppliers. The fear of receiving counterfeit or inferior products can create hesitance in decision-making, impacting project timelines and budgets.

The Solution:

To mitigate these concerns, buyers should prioritize suppliers that have a proven track record and industry certifications. Look for manufacturers with ISO certifications or those that comply with international quality standards. It is also beneficial to request references or case studies from previous clients in similar industries or regions. Establishing a direct line of communication with the manufacturer can facilitate transparency; inquire about their quality control processes and warranty policies. Furthermore, consider visiting the manufacturing facility or engaging a third-party quality assurance service to validate the product before finalizing large orders.

Scenario 3: Challenges with After-Sales Support and Service

The Problem:

After-sales support is often overlooked, yet it can be a critical pain point for B2B buyers. In regions such as the Middle East and Africa, where technical expertise may be limited, buyers may find themselves without adequate support for installation, maintenance, or troubleshooting of contactors. This lack of support can lead to prolonged downtimes and increased operational risks, ultimately affecting productivity and profitability.

The Solution:

To address these challenges, buyers should thoroughly evaluate the after-sales service offered by contactor manufacturers before making a purchase. Look for suppliers that provide comprehensive technical support, including installation guides, troubleshooting documentation, and access to trained technicians. It can be advantageous to choose manufacturers that offer on-site training for staff, ensuring that the local team is equipped to handle any issues that arise. Establishing a service level agreement (SLA) that outlines response times and support availability can also help manage expectations and ensure prompt assistance when needed. Engaging with manufacturers that have a local presence or partnerships with regional distributors can further enhance support capabilities.

Strategic Material Selection Guide for contactor manufacturer

When selecting materials for contactor manufacturing, it’s crucial to consider the properties and performance characteristics that align with specific applications. Below, we analyze four common materials used in contactor manufacturing, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Copper in Contactor Manufacturing?

Copper is widely recognized for its excellent electrical conductivity and thermal properties. With a high melting point of around 1,085°C, it can withstand substantial heat without degrading. Additionally, copper exhibits good corrosion resistance, particularly when coated or alloyed.

Pros & Cons:

Copper’s primary advantage is its superior conductivity, making it ideal for electrical components. However, it can be relatively expensive compared to alternatives like aluminum, and its susceptibility to corrosion in certain environments can limit its application without protective coatings.

Impact on Application:

Copper is highly compatible with various media, including air and non-corrosive liquids, making it suitable for a range of electrical applications.

Considerations for International Buyers:

For buyers in regions such as Africa and South America, where humidity and corrosion can be significant concerns, understanding local environmental conditions is essential. Compliance with standards like ASTM B187 for copper products is also critical.

How Does Aluminum Compare for Use in Contactors?

Aluminum is another popular choice due to its lightweight nature and good conductivity, though it is not as conductive as copper. It has a melting point of approximately 660°C and offers decent corrosion resistance, especially when anodized.

Pros & Cons:

The primary advantage of aluminum is its cost-effectiveness and lightweight nature, which can reduce shipping and handling costs. However, its lower conductivity compared to copper can lead to increased energy losses in high-performance applications.

Impact on Application:

Aluminum is suitable for applications where weight is a critical factor, such as in mobile or portable equipment. However, it may not perform as well in high-temperature environments without proper thermal management.

Considerations for International Buyers:

In Europe, compliance with EN 573 standards for aluminum alloys is vital. Buyers from the Middle East should consider the effects of high temperatures and humidity on aluminum’s performance.

What Are the Benefits of Using Steel in Contactor Manufacturing?

Steel, particularly stainless steel, is known for its strength and durability. With a melting point of around 1,370°C, it can withstand high temperatures and is resistant to deformation under stress.

Pros & Cons:

Steel’s primary advantage is its mechanical strength, making it suitable for heavy-duty applications. However, its weight can be a disadvantage in applications where reducing weight is essential. Additionally, while stainless steel offers corrosion resistance, it can be more expensive than carbon steel.

Impact on Application:

Steel is often used in environments where mechanical stress and durability are crucial, such as in industrial machinery. Its compatibility with various media is generally good, but it may corrode in highly acidic or basic environments.

Considerations for International Buyers:

For buyers in regions like Nigeria, where industrial applications are growing, ensuring compliance with ASTM A240 for stainless steel is important. Understanding local availability and pricing can also impact procurement decisions.

Why Is Plastic a Viable Option for Contactor Components?

Plastics, such as polycarbonate and nylon, are increasingly used in contactor manufacturing due to their insulating properties and resistance to corrosion. They can withstand temperatures up to about 120°C, depending on the type.

Pros & Cons:

The main advantage of plastics is their lightweight nature and excellent electrical insulation properties. However, they may not withstand high mechanical stress and can degrade over time when exposed to UV light or extreme temperatures.

Impact on Application:

Plastics are suitable for non-load-bearing components in contactors, such as housings and insulators. Their compatibility with various chemicals makes them versatile for different applications.

Considerations for International Buyers:

European buyers should ensure compliance with RoHS directives regarding hazardous substances in plastics. In South America, understanding local regulations on plastic waste management can influence material choice.

Summary Table of Material Selection for Contactor Manufacturing

| Material | Typical Use Case for contactor manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical contacts and conductors | Superior electrical conductivity | High cost and corrosion susceptibility | High |

| Aluminum | Lightweight components in portable devices | Cost-effective and lightweight | Lower conductivity than copper | Medium |

| Steel | Heavy-duty applications in industrial settings | High strength and durability | Weight can be a disadvantage | Medium |

| Plastic | Insulating housings and non-load-bearing parts | Excellent insulation and lightweight | Limited mechanical strength | Low |

This strategic material selection guide aims to provide international B2B buyers with actionable insights to make informed decisions that align with their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for contactor manufacturer

What Are the Key Stages in the Manufacturing Process of Contactors?

Manufacturing contactors involves several critical stages that ensure the final product meets both functional and safety standards. Understanding these stages can help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when sourcing contactors.

-

Material Preparation

The manufacturing process begins with the selection and preparation of raw materials, primarily copper and plastic components. High-quality copper is essential for effective electrical conductivity, while durable plastics are used for the housing. Suppliers often source these materials from verified providers to ensure compliance with international standards. -

Forming

Once materials are prepared, they undergo forming processes such as stamping and molding. Stamping is commonly used for metal parts, where sheets of copper are cut into precise shapes. For plastic components, injection molding is the preferred technique, allowing for complex designs and high production volumes. Buyers should inquire about the machinery and technology used in these processes, as advanced equipment typically results in better precision and lower defect rates. -

Assembly

The assembly stage involves the integration of various components into a complete contactor unit. This includes installing electrical coils, contacts, and other essential parts. Automated assembly lines are increasingly common, enhancing speed and consistency. International B2B buyers should consider suppliers with experience in high-volume production to ensure timely delivery and reduced lead times. -

Finishing

Finishing processes, such as coating and labeling, are vital for both aesthetics and functionality. Coatings can protect against corrosion and improve durability, while labels provide essential information for users. Quality finishing is essential for compliance with international regulations, particularly in regions where environmental standards are stringent.

How Is Quality Assurance Implemented in Contactor Manufacturing?

Quality assurance (QA) is a crucial component of the manufacturing process, ensuring that each contactor meets stringent performance and safety criteria. B2B buyers should understand the various QA measures in place to safeguard their investments.

-

What Are the Relevant International Standards for Quality Assurance?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification is crucial for B2B buyers looking for reliable suppliers. Additionally, industry-specific standards like CE marking in Europe and API certifications for oil and gas applications can further validate a manufacturer’s commitment to quality. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify defects early. This includes regular inspections and testing of components as they are assembled.

– Final Quality Control (FQC): The final product undergoes comprehensive testing to confirm it meets all specifications before shipment. -

What Testing Methods Are Commonly Used?

Various testing methods are employed to ensure the quality of contactors. These include:

– Electrical Testing: To verify the operational performance and safety of the contactors under load.

– Mechanical Testing: Ensures structural integrity and durability, particularly for components under stress.

– Environmental Testing: Assesses how contactors perform under extreme conditions, such as temperature fluctuations or humidity.

How Can B2B Buyers Verify Supplier Quality Assurance?

Due diligence is essential when selecting a contactor manufacturer. Here are actionable strategies for B2B buyers to verify a supplier’s quality assurance practices:

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should establish a checklist that includes compliance with ISO and other relevant standards, inspection records, and employee training practices. -

Request Quality Reports and Certifications

Buyers should ask suppliers for documentation of their quality assurance processes, including ISO certifications, test results, and any third-party audits. This documentation can be critical in assessing the reliability of the supplier’s claims. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing capabilities. These services can conduct both pre-shipment inspections and random audits to ensure compliance with quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with suppliers from different regions, B2B buyers must consider several nuances in quality control:

-

Understanding Regional Standards

Quality standards can vary significantly by region. For instance, European buyers may prioritize CE certification, while buyers in Africa might focus more on local compliance requirements. Understanding these differences is vital for ensuring that products are suitable for their intended markets. -

Cultural and Operational Differences

Cultural attitudes toward quality can influence manufacturing processes. Buyers should be aware of the operational maturity of suppliers in different regions, as this can impact their adherence to quality standards. -

Logistics and Supply Chain Considerations

Supply chain complexities can affect product quality. Buyers should evaluate the logistics capabilities of suppliers, including their ability to manage inventory and respond to quality issues swiftly. A robust supply chain can mitigate risks associated with quality failures.

Conclusion

Understanding the manufacturing processes and quality assurance practices of contactor manufacturers is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions that not only enhance their supply chain efficiency but also ensure compliance with international standards. Prioritizing suppliers that demonstrate robust quality control measures will ultimately lead to a more reliable and successful partnership.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘contactor manufacturer’

The purpose of this guide is to provide international B2B buyers with a structured approach to sourcing contactor manufacturers effectively. By following these actionable steps, buyers can ensure they are making informed decisions that align with their technical requirements and business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your specific technical requirements for contactors. This includes voltage ratings, current capacity, and environmental conditions. A clear specification helps suppliers understand your needs and reduces the risk of miscommunication.

- Consider application requirements: Different industries may have unique needs, so be sure to tailor your specifications accordingly.

- Document your requirements: Create a detailed list to share with potential suppliers, which can streamline the evaluation process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential contactor manufacturers. Utilize online directories, trade shows, and industry forums to compile a list of candidates. This step is crucial as it lays the foundation for your supplier evaluation.

- Focus on geographic relevance: Consider suppliers from regions that align with your market, such as Africa or Europe, to facilitate logistics and communication.

- Evaluate market presence: Look for manufacturers with a proven track record in your industry to ensure reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This evaluation process helps mitigate risks and ensures you partner with reputable manufacturers.

- Check financial stability: A financially sound supplier is less likely to face disruptions that could affect your supply chain.

- Assess technical capabilities: Ensure the supplier has the necessary technology and expertise to meet your requirements.

Step 4: Verify Supplier Certifications

Ensure that the manufacturers you are considering hold relevant certifications, such as ISO 9001 or CE marking. Certifications indicate compliance with industry standards and quality assurance processes.

- Request documentation: Don’t hesitate to ask for copies of certifications to verify their authenticity.

- Understand regulatory requirements: Familiarize yourself with local regulations in your market to ensure compliance.

Step 5: Request Samples and Prototypes

Once you have narrowed down your list of suppliers, request samples or prototypes of the contactors. This step allows you to assess the quality and functionality of the products before making a larger commitment.

- Conduct performance testing: Evaluate the samples under real-world conditions to ensure they meet your specifications.

- Engage your technical team: Involve engineers or technicians in the evaluation process to gain insights into product suitability.

Step 6: Negotiate Terms and Conditions

Effective negotiation is vital for securing favorable terms with your chosen supplier. Discuss pricing, payment terms, lead times, and warranty conditions clearly.

- Be transparent about your needs: Share your volume requirements and timelines to help the supplier provide a competitive offer.

- Consider long-term partnerships: If you foresee ongoing needs, negotiate terms that reflect a long-term relationship, which can lead to better pricing and service.

Step 7: Establish Communication Protocols

Once a supplier is selected, establish clear communication protocols to ensure a smooth working relationship. Define points of contact, preferred communication channels, and frequency of updates.

- Set expectations for response times: Clearly outline how quickly you expect feedback on inquiries or issues.

- Utilize technology: Consider using project management tools to track progress and maintain transparency throughout the procurement process.

By following this checklist, international B2B buyers can enhance their sourcing strategies for contactor manufacturers, ensuring they select partners that meet their specific needs and contribute to their overall business success.

Comprehensive Cost and Pricing Analysis for contactor manufacturer Sourcing

When sourcing contactors from manufacturers, understanding the comprehensive cost structure is critical for making informed purchasing decisions. This section delves into the various cost components, price influencers, and practical tips that can aid international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing Contactors?

-

Materials: The cost of raw materials is the most significant component in the pricing of contactors. Common materials include copper, aluminum, and various plastics. Prices can fluctuate based on market demand and supply chain dynamics. Buyers should stay informed about global commodity prices to anticipate changes in costs.

-

Labor: Labor costs vary significantly by region. For instance, manufacturers in countries with lower labor costs may offer more competitive pricing. Understanding the local labor market can help buyers assess the potential for cost savings when sourcing from different regions.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Overhead costs can vary based on the manufacturer’s operational efficiency and location. Buyers should inquire about these factors when evaluating potential suppliers.

-

Tooling: The initial investment in tooling for specific contactor designs can be substantial. Custom tooling may increase upfront costs but can lead to lower per-unit costs in larger production runs.

-

Quality Control (QC): Ensuring product quality is essential, especially for electrical components. Quality control processes can add to costs but are crucial for minimizing defects and ensuring compliance with international standards.

-

Logistics: Shipping and handling costs can greatly influence the total cost of procurement. Factors such as distance, shipping method, and customs duties play significant roles. Buyers should consider local logistics capabilities and potential delays when sourcing internationally.

-

Margin: The manufacturer’s profit margin will also affect pricing. Higher margins may indicate premium products or added services, while lower margins may suggest more competitive pricing strategies.

What Factors Influence the Pricing of Contactors?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Understanding a manufacturer’s MOQ policy can help buyers negotiate better pricing.

-

Specifications and Customization: Custom specifications may lead to higher costs due to additional design and manufacturing efforts. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) may result in increased prices. However, investing in higher-quality products can lead to lower failure rates and longer product lifespans.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can impact pricing. Established manufacturers with a proven track record may charge a premium but often provide better assurance of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international sourcing. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect the total landed cost of products.

What Are the Best Buyer Tips for Negotiating Pricing?

-

Negotiate Terms: Engage in discussions about payment terms, delivery schedules, and return policies. Flexibility on both sides can lead to better pricing and cooperation.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the total cost of ownership, including maintenance, warranty, and potential downtime. This broader perspective can help justify higher upfront costs for superior products.

-

Stay Informed About Market Trends: Keeping abreast of industry trends, regional supply chain issues, and material price fluctuations can provide leverage in negotiations.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring local suppliers may reduce logistics costs and lead times, making it a viable option to consider.

Conclusion

Understanding the cost structure and pricing dynamics of contactor manufacturing is essential for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can make informed decisions that align with their operational and financial goals. Keep in mind that prices can vary widely based on numerous factors, and it’s advisable to conduct thorough research and seek multiple quotes before finalizing any agreements.

Alternatives Analysis: Comparing contactor manufacturer With Other Solutions

Understanding the Importance of Evaluating Alternatives in Contactor Solutions

In the realm of industrial automation and electrical control systems, selecting the right solution is crucial for optimizing performance and cost-efficiency. While contactor manufacturers provide reliable products for managing electrical loads, there are alternative technologies and methods worth considering. Each option presents unique advantages and disadvantages, which international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must evaluate based on their specific operational needs.

Comparison Table of Contactor Manufacturer and Alternatives

| Comparison Aspect | Contactor Manufacturer | Solid State Relay (SSR) | Relay Module |

|---|---|---|---|

| Performance | High reliability in switching heavy loads | Fast switching, less wear and tear | Good for low voltage and current applications |

| Cost | Moderate to high initial investment | Higher upfront cost but lower long-term costs | Lower initial cost, but may require more frequent replacements |

| Ease of Implementation | Requires careful wiring and setup | Simple installation, often plug-and-play | Can be easily integrated into existing systems |

| Maintenance | Low maintenance, but periodic checks needed | Minimal maintenance required | Moderate maintenance; potential for frequent replacements |

| Best Use Case | Industrial machinery, HVAC systems | Applications requiring high-speed switching | Basic control applications in consumer electronics |

What Are the Advantages and Disadvantages of Solid State Relays?

Solid State Relays (SSRs) are an alternative to traditional contactors, utilizing semiconductor devices to switch loads. Their main advantage lies in their ability to switch faster than mechanical contactors, which can enhance the performance of automation systems. SSRs also have a longer lifespan since they lack moving parts, resulting in less wear and tear. However, they typically come with a higher upfront cost and may not be suitable for all types of loads, particularly inductive loads that require a contactor’s robustness.

How Do Relay Modules Compare for Electrical Control Needs?

Relay modules offer a more cost-effective solution for simpler electrical control applications. They are particularly suited for low voltage and current operations, making them ideal for consumer electronics and light industrial uses. The initial cost of relay modules is lower compared to contactors and SSRs, making them attractive for budget-conscious projects. However, their lifespan can be shorter, necessitating more frequent replacements, which may increase long-term costs. Additionally, relay modules may require more maintenance and attention than their solid-state counterparts.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between a contactor manufacturer and its alternatives, B2B buyers should consider their specific application needs, budget constraints, and long-term operational goals. For heavy-duty industrial applications, contactors remain a robust choice due to their reliability and performance. However, for applications requiring rapid switching and minimal maintenance, SSRs could be more advantageous. Relay modules may serve well for basic control needs where cost is a primary concern. Ultimately, a thorough evaluation of the operational environment and expected load characteristics will guide buyers in making an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for contactor manufacturer

What Are the Key Technical Properties of Contactors That B2B Buyers Should Know?

When engaging with contactor manufacturers, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

The material used in the construction of contactors significantly affects their durability and performance. Common materials include copper for electrical conductors and various grades of steel for the housing. The choice of material impacts not only the lifespan of the contactor but also its resistance to environmental factors such as humidity and temperature fluctuations. B2B buyers should ensure that the materials meet industry standards for their specific applications. -

Rated Current

This specification indicates the maximum continuous current the contactor can handle without overheating. Rated current is a vital factor in ensuring the safety and efficiency of electrical systems. Buyers must select contactors with a rated current that exceeds the operational requirements of their applications to avoid failures and ensure reliability. -

Coil Voltage

The coil voltage refers to the voltage required to energize the contactor’s coil. It’s essential for buyers to match the coil voltage with the power supply of their system. A mismatch can lead to inadequate performance or damage to the contactor. Understanding the coil voltage is critical for ensuring seamless integration into existing electrical setups. -

Mechanical Life and Electrical Life

Mechanical life refers to the number of operations a contactor can perform without electrical load, while electrical life pertains to the lifespan under actual load conditions. These metrics are essential for assessing the long-term reliability and maintenance needs of contactors. Buyers should evaluate both aspects to determine the total cost of ownership and expected performance over time. -

Tolerance

Tolerance levels dictate how much variation is acceptable in the dimensions of contactor components. This specification is crucial for ensuring proper fit and function within electrical panels. Buyers must consider the tolerance levels required for their applications, as tighter tolerances can lead to enhanced performance but may also increase costs.

What Are Common Trade Terms in the Contactor Manufacturing Industry?

Understanding industry jargon can help B2B buyers navigate the procurement process more effectively. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of contactors, it’s essential for buyers to know if they are sourcing directly from OEMs, which often ensures higher quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a buyer must purchase from a manufacturer. This term is critical for buyers who are budgeting for large projects or looking to optimize inventory costs. Understanding MOQs can help in negotiating better terms and managing stock effectively. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. For contactors, submitting an RFQ can facilitate competitive pricing and help buyers gather necessary information for decision-making. It’s a common practice that can lead to better supplier relationships and cost savings. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international B2B transactions, especially for buyers in regions like Africa and South America, where shipping logistics can be complex. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the context of contactors, understanding lead times is crucial for project planning and inventory management. Buyers should ask manufacturers for estimated lead times to ensure timely delivery in alignment with project deadlines.

By familiarizing themselves with these essential technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right contactors for their needs while optimizing costs and project timelines.

Navigating Market Dynamics and Sourcing Trends in the contactor manufacturer Sector

What Are the Key Market Dynamics Affecting International B2B Buyers in the Contactor Manufacturer Sector?

The contractor manufacturing sector is currently experiencing significant shifts due to various global drivers. One of the foremost trends is the increasing demand for automation and control systems in industries such as renewable energy, manufacturing, and construction. This is particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe, where infrastructure development is rapidly evolving. Furthermore, advancements in B2B technology are transforming procurement processes, enabling buyers to leverage digital platforms for better sourcing decisions.

Emerging trends such as Industry 4.0 and the Internet of Things (IoT) are prompting manufacturers to innovate their product offerings. For instance, smart contactors that can communicate with other devices are becoming increasingly popular. Buyers should be aware of these technologies to ensure they are sourcing the most efficient and future-proof products. Additionally, the ongoing global supply chain disruptions have led to a push for local sourcing, which can reduce lead times and logistics costs. This trend is especially pertinent for buyers in regions like Nigeria and Italy, where local suppliers are becoming more competitive.

How Important Is Sustainability and Ethical Sourcing in the Contactor Manufacturing Sector?

The focus on sustainability and ethical sourcing is reshaping the contractor manufacturing landscape. As environmental concerns rise, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes reducing carbon footprints, minimizing waste, and utilizing recyclable materials in their products. For instance, many manufacturers are now seeking ‘green’ certifications, which can serve as a reliable indicator of a supplier’s environmental performance.

International buyers should also consider the social implications of their sourcing decisions. Ethical supply chains that ensure fair labor practices and transparency are becoming non-negotiable criteria for many organizations. By aligning with suppliers who prioritize ethical sourcing, buyers not only mitigate risks but also enhance their brand reputation. Additionally, investing in sustainable products can lead to long-term cost savings and compliance with regulatory standards, particularly in Europe, where environmental legislation is stringent.

How Has the Contactor Manufacturing Sector Evolved Over Time?

The contractor manufacturing sector has undergone considerable evolution over the last few decades. Initially focused on basic electrical components, the industry has expanded to incorporate advanced technologies and smart systems. This shift has been driven by the need for greater efficiency and the integration of renewable energy sources. As industries globally embrace digital transformation, the demand for sophisticated contactor solutions has surged.

This evolution has implications for B2B buyers who must now navigate a more complex landscape. Understanding the historical context of the sector can provide insights into current trends and future directions. For instance, the rise of automation and smart technologies reflects a broader industrial trend towards enhanced operational efficiency. Buyers who stay informed about these changes can make better sourcing decisions, ensuring they remain competitive in a rapidly changing market.

By keeping these insights in mind, international B2B buyers can better navigate the contractor manufacturing sector’s complexities, ensuring that their sourcing strategies are not only effective but also aligned with global trends.

Frequently Asked Questions (FAQs) for B2B Buyers of contactor manufacturer

-

How do I choose the right contactor manufacturer for my business needs?

Selecting the right contactor manufacturer involves assessing several key factors. First, consider their industry experience and reputation. Look for manufacturers with a proven track record in producing reliable and high-quality contactors. Additionally, evaluate their certifications and compliance with international standards, which ensure product quality and safety. It’s also vital to review their ability to provide customization options that meet your specific requirements and their capacity to handle your order volume. -

What are the key features to look for in contactors for industrial applications?

When sourcing contactors for industrial applications, prioritize features such as voltage rating, current capacity, and coil type. Ensure the contactors can handle the electrical load of your equipment and are suitable for the specific operational environment (e.g., temperature, humidity). Furthermore, consider the contactor’s durability and lifespan, as well as additional functionalities like overload protection and auxiliary contacts that may enhance operational efficiency. -

How can I verify the credibility of a contactor manufacturer?

To verify the credibility of a contactor manufacturer, start by researching their business history and customer reviews. Request references from other businesses that have worked with them. Check for industry certifications, such as ISO 9001, which indicate adherence to quality management standards. Additionally, consider visiting their facilities if possible, or request virtual tours, to assess their manufacturing processes and quality control measures directly. -

What minimum order quantities (MOQ) should I expect from contactor manufacturers?

Minimum order quantities (MOQ) can vary significantly between manufacturers. Typically, MOQs for contactors range from 100 to 1,000 units, depending on the complexity and customization of the product. When negotiating, clarify the MOQ and explore options for smaller trial orders if you’re uncertain about committing to a larger purchase. Some manufacturers may offer flexible MOQ options, especially if you establish a long-term partnership. -

What payment terms are common when sourcing contactors internationally?

Common payment terms for international B2B transactions often include options like Letter of Credit (LC), Advance Payment, and Net 30 or Net 60 days. It’s essential to discuss and negotiate these terms upfront to ensure both parties are comfortable. Be cautious with upfront payments, and consider using escrow services for larger transactions to minimize risk. Ensure that payment terms are clearly outlined in your contract to avoid misunderstandings. -

How do I ensure quality assurance in contactor manufacturing?

To ensure quality assurance, request detailed information about the manufacturer’s quality control processes. Inquire about their testing methods, inspection protocols, and certifications. Additionally, consider conducting third-party audits or inspections before shipping. Establishing a clear quality agreement that outlines your expectations can also help maintain standards. Regular communication with the manufacturer regarding quality concerns can foster a proactive approach to quality assurance. -

What logistics considerations should I keep in mind when importing contactors?

When importing contactors, consider factors such as shipping methods, lead times, and customs regulations in your country. Evaluate the total landed cost, including shipping, duties, and taxes, to avoid unexpected expenses. Collaborate with a reliable freight forwarder who understands the nuances of international shipping and can help navigate customs documentation. Also, plan for possible delays due to customs clearance, especially in regions with stringent import regulations. -

How can I customize contactors to fit my specific operational requirements?

Customization options for contactors can include modifications in size, voltage ratings, and additional features like timers or relays. When discussing customization with manufacturers, clearly communicate your specific needs and operational environment. Request prototypes or samples to test functionality before placing a full order. Some manufacturers may also offer design assistance to help you create a product that meets your unique specifications effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for contactor manufacturer

What Are the Key Takeaways for International B2B Buyers in Strategic Sourcing?

In summary, strategic sourcing for contactor manufacturers is essential for international B2B buyers seeking competitive advantage. The integration of local suppliers, particularly in regions like Africa and South America, can optimize supply chains while fostering community relationships. Buyers should prioritize manufacturers who demonstrate reliability, innovative technology, and compliance with international standards, which not only ensures product quality but also mitigates risks associated with cross-border transactions.

How Can Strategic Sourcing Enhance Competitive Advantage?

By leveraging strategic sourcing practices, buyers can significantly reduce costs and improve procurement efficiency. Understanding the nuances of different markets—from the regulatory environments of Europe to the emerging economies of the Middle East—enables businesses to make informed sourcing decisions. Furthermore, establishing long-term partnerships with reputable contactor manufacturers can lead to enhanced product customization and responsiveness to market changes.

What Is the Future Outlook for B2B Buyers in the Contactor Manufacturing Sector?

Looking ahead, the demand for sustainable and innovative electrical solutions will drive the contactor manufacturing sector. International B2B buyers should remain proactive, adapting their sourcing strategies to align with technological advancements and sustainability goals. Engaging with manufacturers who prioritize green practices not only enhances corporate responsibility but also appeals to a growing market of eco-conscious consumers.

As you embark on your sourcing journey, take the time to evaluate your options meticulously. Building strong relationships with contactor manufacturers will position your business for success in an increasingly competitive landscape.