Unlock Savings: The Ultimate Guide to Kitchen Equipment China (2025)

Introduction: Navigating the Global Market for kitchen equipment china

In today’s global marketplace, sourcing high-quality kitchen equipment from China presents both opportunities and challenges for international B2B buyers. Navigating the complexities of supply chains, varying standards, and cultural differences can be daunting, particularly for buyers in regions like Africa, South America, the Middle East, and Europe. This guide offers a comprehensive overview of the kitchen equipment landscape in China, equipping you with the insights needed to make informed purchasing decisions.

We will explore various types of kitchen equipment, including commercial appliances, utensils, and storage solutions, as well as their applications across different sectors such as hospitality, food service, and retail. Additionally, we will delve into effective strategies for vetting suppliers to ensure quality and reliability, along with tips on cost management and negotiation tactics to maximize your investment.

By providing a thorough understanding of the market dynamics and practical advice tailored to your region, this guide empowers you to confidently engage with suppliers and enhance your operational efficiency. Whether you are a buyer in Argentina seeking to outfit a new restaurant or a procurement officer in the UK looking to upgrade existing facilities, this resource is designed to streamline your sourcing process and drive your business success in the competitive kitchen equipment sector.

Understanding kitchen equipment china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial Dishware | Durable materials, various sizes, and designs for restaurants | Restaurants, hotels, catering services | Pros: High durability, aesthetic appeal. Cons: Higher initial cost. |

| Kitchen Utensils | Essential tools like spatulas, ladles, and knives | Food preparation in restaurants and catering | Pros: Essential for operations, easy to replace. Cons: Quality varies widely. |

| Cookware Sets | Includes pots, pans, and specialty items | Restaurants, food trucks, catering companies | Pros: Versatility, often sold in bulk. Cons: Requires proper maintenance. |

| Food Storage Containers | Airtight seals, stackable designs, various materials | Food prep and storage in restaurants | Pros: Helps reduce waste, keeps food fresh. Cons: Can be costly in large quantities. |

| Barware | Glassware and tools for beverage service | Bars, restaurants, event venues | Pros: Enhances customer experience, variety of styles. Cons: Fragility can lead to breakage. |

What are the Key Characteristics of Commercial Dishware?

Commercial dishware is designed for high durability and aesthetic appeal, making it essential for restaurants and catering services. These products are typically made from materials such as porcelain, stoneware, or melamine, which can withstand daily use and washing. When purchasing commercial dishware, B2B buyers should consider factors such as the style that aligns with their brand, the resistance to chipping, and the ease of cleaning. Investing in quality dishware can enhance the dining experience and reduce replacement costs over time.

How Do Kitchen Utensils Impact Food Preparation?

Kitchen utensils are the backbone of food preparation in any commercial kitchen. Essential tools such as spatulas, ladles, and knives play a crucial role in efficiency and safety. B2B buyers should prioritize ergonomics and material quality when selecting utensils, as these factors can affect kitchen staff productivity. While utensils are generally easy to replace, investing in high-quality options can improve workflow and reduce the risk of accidents.

Why Are Cookware Sets Important for Restaurants?

Cookware sets are vital for any kitchen, encompassing pots, pans, and specialty items that cater to various cooking techniques. These sets are often sold in bulk, making them a cost-effective choice for restaurants and catering companies. B2B buyers should consider the material (e.g., stainless steel, non-stick) and suitability for their cooking methods when purchasing cookware. Proper maintenance is essential to prolong the lifespan of these items, making it crucial to educate staff on care practices.

What Benefits Do Food Storage Containers Provide?

Food storage containers are essential for maintaining food safety and reducing waste in commercial kitchens. With features like airtight seals and stackable designs, these containers help keep ingredients fresh and organized. B2B buyers should evaluate the materials used (plastic, glass, etc.) and their ability to withstand temperature variations. While the upfront costs can be significant, the long-term benefits of reduced spoilage and improved kitchen organization can justify the investment.

How Does Barware Enhance Customer Experience?

Barware, including glassware and cocktail tools, is critical for enhancing the customer experience in bars and restaurants. The right barware not only adds to the aesthetic appeal but also influences the quality of service. B2B buyers should consider the style and durability of barware, as well as the types of beverages served. While glassware can be fragile, investing in high-quality products can minimize breakage and elevate the overall dining experience.

Related Video: 20 Types of Kitchen Tools & Equipment & Their Uses | Useful list of Essential Kitchen Utensils

Key Industrial Applications of kitchen equipment china

| Industry/Sector | Specific Application of Kitchen Equipment China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality and Catering | Commercial kitchen setups for hotels and restaurants | Enhanced efficiency and consistency in food preparation | Compliance with local health and safety regulations |

| Food Processing | Industrial food processing equipment | Increased production capacity and reduced waste | Durability and maintenance support |

| Retail and Supermarkets | Display and storage solutions for food products | Improved product visibility and extended shelf life | Energy efficiency and compliance with food safety standards |

| Education and Training Institutions | Kitchen labs for culinary schools | Hands-on training experience for students | Equipment adaptability to various culinary techniques |

| Healthcare | Kitchen equipment for hospitals and care facilities | Safe and nutritious meal preparation for patients | Hygiene standards and ease of cleaning |

How is Kitchen Equipment from China Used in Hospitality and Catering?

In the hospitality and catering sector, kitchen equipment from China is essential for establishing fully functional commercial kitchens in hotels and restaurants. These establishments require high-quality ovens, refrigerators, and cooking ranges that ensure food is prepared efficiently and consistently. B2B buyers from regions such as Africa and Europe must consider compliance with local health regulations and energy efficiency to maximize operational effectiveness and minimize costs.

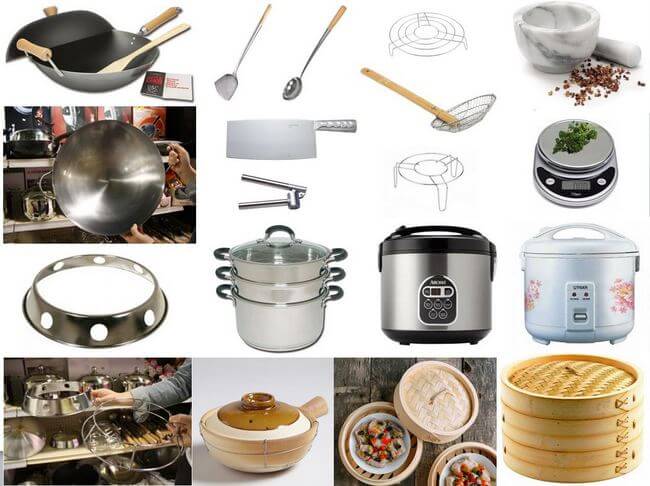

A stock image related to kitchen equipment china.

What Role Does Kitchen Equipment Play in Food Processing Industries?

In food processing, kitchen equipment from China is utilized to streamline production processes, from mixing and cooking to packaging. Such equipment enhances production capacity while minimizing waste, allowing businesses to meet high demand without compromising quality. International buyers should focus on the durability of the equipment and the availability of maintenance support to ensure long-term operational reliability.

How Can Kitchen Equipment Improve Retail and Supermarket Operations?

Retailers and supermarkets benefit from Chinese kitchen equipment through improved display and storage solutions. Proper refrigeration and display cases not only enhance product visibility but also extend the shelf life of perishable items. For B2B buyers in South America and the Middle East, sourcing energy-efficient equipment that complies with food safety standards is crucial for operational success and customer satisfaction.

Why is Kitchen Equipment Important for Educational Institutions?

Culinary schools and educational institutions utilize kitchen equipment from China to provide students with hands-on training in food preparation techniques. This equipment includes stoves, mixers, and utensils that mimic commercial kitchen environments, ensuring students are well-prepared for careers in the culinary field. Buyers should look for adaptable equipment that can accommodate various cooking methods to enhance the educational experience.

How Does Kitchen Equipment Impact Healthcare Facilities?

In healthcare settings, kitchen equipment from China plays a vital role in preparing safe and nutritious meals for patients. Hospitals and care facilities require specialized equipment that adheres to strict hygiene standards to ensure food safety. For international buyers in regions like Europe and the Middle East, the ease of cleaning and maintenance of kitchen equipment is a key consideration to ensure compliance with health regulations and patient care standards.

Related Video: COOKERY LESSON 2 -Classify the types of appropriate cleaning tools and equipment based on their uses

3 Common User Pain Points for ‘kitchen equipment china’ & Their Solutions

Scenario 1: Sourcing Quality Kitchen Equipment from China

The Problem:

B2B buyers often face the daunting challenge of sourcing high-quality kitchen equipment from China. Many international buyers are concerned about product authenticity, subpar materials, and whether the equipment will meet local health and safety regulations. In regions like Africa and South America, where quality assurance can be less stringent, this concern becomes even more pressing. A buyer may invest a significant amount of capital only to receive equipment that does not perform as expected or, worse, poses safety risks.

The Solution:

To overcome these challenges, it is essential to establish reliable connections with reputable manufacturers and suppliers. Start by conducting thorough research on potential vendors through platforms like Alibaba, Global Sources, or even industry-specific trade shows. Look for suppliers with verified certifications such as ISO, HACCP, or other relevant quality assurance standards that meet both Chinese and international regulations.

Consider engaging third-party inspection services to conduct quality checks before shipment. These services can verify that the kitchen equipment adheres to the specified standards, thus mitigating the risk of receiving defective products. Furthermore, initiate clear communication with suppliers to outline specifications, expectations, and after-sales support. By doing so, you can ensure that the equipment sourced not only meets quality standards but also aligns with your business needs.

Scenario 2: Navigating Cultural and Language Barriers in Procurement

The Problem:

Cultural differences and language barriers can create significant obstacles for B2B buyers looking to procure kitchen equipment from China. Misunderstandings can arise during negotiations, leading to incorrect orders, delays, and even damaged relationships with suppliers. For buyers from the Middle East and Europe, where negotiation styles and business etiquettes can vary widely, this can be particularly frustrating.

The Solution:

To navigate these complexities, it’s advisable to employ a local intermediary or a sourcing agent who understands both the Chinese market and your business culture. These professionals can facilitate communication, clarify product specifications, and negotiate better terms on your behalf. Additionally, consider using translation services or tools to ensure that both parties fully understand the agreements and specifications.

Investing time in understanding Chinese business customs can also be beneficial. This includes being aware of the importance of building relationships (Guanxi) and showing respect during negotiations. By fostering a good rapport with suppliers, you can enhance trust and improve the likelihood of favorable outcomes in future transactions.

Scenario 3: Ensuring Compliance with Local Regulations and Standards

The Problem:

One of the critical pain points for international B2B buyers is ensuring that imported kitchen equipment complies with local regulations and standards. For instance, buyers in Europe face stringent EU regulations regarding materials used in food preparation equipment, which may not be a requirement in China. Non-compliance can lead to legal issues, fines, and damaged reputations.

The Solution:

To effectively navigate these regulatory landscapes, buyers should familiarize themselves with local standards and compliance requirements before placing orders. This can involve researching regulations relevant to kitchen equipment in your specific market, such as CE marking in Europe or FDA compliance in the USA.

It’s also prudent to request documentation from suppliers that demonstrates compliance with these standards. This may include material safety data sheets, certifications, and test reports. Furthermore, consider consulting with local regulatory bodies or industry experts to ensure that you’re not only compliant at the time of import but also prepared for any future changes in regulations. By taking these proactive steps, buyers can minimize risks and ensure that their kitchen equipment is both safe and compliant for use in their markets.

Strategic Material Selection Guide for kitchen equipment china

When selecting materials for kitchen equipment from China, international B2B buyers must consider various factors that influence product performance, compliance, and overall suitability for their specific market needs. Below, we analyze four common materials used in kitchen equipment, focusing on their properties, advantages, disadvantages, and implications for buyers, especially from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel in Kitchen Equipment?

Stainless steel is a popular choice for kitchen equipment due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressure, making it suitable for various cooking applications. The most commonly used grades, such as 304 and 316, offer good mechanical properties and are relatively easy to clean, which is crucial in food preparation environments.

Pros: Stainless steel is highly durable, resistant to rust and staining, and offers a sleek appearance that is desirable in commercial kitchens. It is also compliant with food safety standards, making it a preferred choice for many international buyers.

Cons: The initial cost of stainless steel can be higher compared to other materials. Additionally, it can be prone to scratching and may require regular maintenance to keep its appearance.

Impact on Application: Stainless steel is compatible with a wide range of food media, including acidic and alkaline substances, which makes it versatile for various culinary tasks.

How Does Aluminum Perform in Kitchen Equipment Applications?

Aluminum is another common material used in kitchen equipment, known for its lightweight and excellent thermal conductivity. It heats up quickly and distributes heat evenly, which is ideal for cooking applications.

Pros: Aluminum is generally less expensive than stainless steel and is easier to manufacture into complex shapes. Its lightweight nature makes it easier to handle and transport.

Cons: While aluminum is resistant to corrosion, it is not as durable as stainless steel and can warp under high heat. It may also react with acidic foods, which can affect the taste and safety of the food.

Impact on Application: Aluminum is best suited for cooking equipment that requires quick heating, such as frying pans and baking trays. However, buyers should consider its limitations in applications involving acidic media.

What Are the Benefits of Using Cast Iron in Kitchen Equipment?

Cast iron is renowned for its excellent heat retention and even heating properties. It is often used in cookware such as skillets and Dutch ovens, providing a unique cooking experience.

Pros: Cast iron is extremely durable and can last for generations if properly maintained. It also adds a unique flavor to food, especially when seasoned.

Cons: The weight of cast iron can be a drawback, making it less convenient for some users. It also requires special care to prevent rusting and maintain its non-stick properties.

Impact on Application: Cast iron is ideal for slow cooking and high-heat applications, making it suitable for a variety of culinary techniques. However, its heavy nature may not appeal to all users.

Why Is Plastic Used in Kitchen Equipment?

Plastic is often used in kitchen equipment for items such as cutting boards, utensils, and storage containers. It is lightweight and can be molded into various shapes.

Pros: Plastic is generally low-cost and resistant to moisture, making it suitable for food storage. It is also available in a wide range of colors and designs.

Cons: Plastic can be less durable than metal options and may warp or stain over time. Some plastics may not be suitable for high-temperature applications.

Impact on Application: Plastic is compatible with a variety of food media but may not withstand extreme temperatures. Buyers should ensure that the plastic used meets food safety standards.

Summary Table of Material Selection for Kitchen Equipment

| Material | Typical Use Case for kitchen equipment china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Cookware, countertops, sinks | Highly durable and corrosion-resistant | Higher initial cost, maintenance required | High |

| Aluminum | Frying pans, baking trays | Lightweight and excellent heat conductivity | Less durable, can react with acidic foods | Medium |

| Cast Iron | Skillets, Dutch ovens | Excellent heat retention and durability | Heavy, requires special care | Medium |

| Plastic | Cutting boards, utensils, storage containers | Low-cost and moisture-resistant | Less durable, may warp under heat | Low |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for kitchen equipment from China, ensuring they make informed decisions that align with their specific needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for kitchen equipment china

What Are the Key Stages in the Manufacturing Process of Kitchen Equipment in China?

Manufacturing kitchen equipment in China involves a series of meticulous stages that ensure the final product meets the quality and functionality standards expected by international B2B buyers. The primary stages include:

-

Material Preparation: This initial phase involves sourcing and preparing high-quality materials such as stainless steel, aluminum, or plastics. Suppliers often provide material certifications to assure buyers of compliance with international standards. It’s critical for buyers to verify that materials are sourced responsibly, particularly in regions where sustainability is a growing concern.

-

Forming: After material preparation, the forming stage shapes the materials into the desired components using techniques like stamping, bending, and casting. Advanced machinery, such as CNC (Computer Numerical Control) machines, is commonly used to ensure precision in forming. Buyers should inquire about the technology used in this stage to gauge the potential for defects and overall product quality.

-

Assembly: In this phase, individual components are brought together to create the final product. Assembly lines often utilize automated systems to enhance efficiency and consistency. Understanding the assembly process can help buyers evaluate how labor costs and skills might affect the final product’s quality.

-

Finishing: The finishing stage includes processes such as polishing, coating, and painting to enhance the product’s aesthetics and durability. Surface treatments are essential for kitchen equipment, as they directly influence hygiene and longevity. B2B buyers should ask about the finishing techniques used and their compliance with food safety standards.

How Is Quality Assurance Implemented in Kitchen Equipment Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet established specifications and regulations. Several international and industry-specific standards guide this process:

-

International Standards: ISO 9001 is a widely recognized quality management standard that many manufacturers adhere to. Compliance indicates a commitment to quality management principles, including customer focus and continuous improvement.

-

Industry-Specific Standards: Certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for specific applications are crucial. These certifications signify that the products comply with specific safety and performance standards.

What Are the Key Quality Control Checkpoints in Kitchen Equipment Manufacturing?

Quality control (QC) is conducted at various checkpoints throughout the manufacturing process to ensure that each stage meets the required standards. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection checks the raw materials and components upon arrival at the manufacturing facility. Suppliers should provide documentation of material certifications and compliance with relevant standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC involves ongoing inspections and tests to identify any defects early in the process. This proactive approach minimizes waste and reduces the risk of defective products reaching the final stage.

-

Final Quality Control (FQC): After assembly and finishing, FQC ensures that the final products meet all specifications. This stage often includes functional testing and visual inspections, and documentation of the results should be made available to buyers.

Which Testing Methods Are Commonly Used for Kitchen Equipment Quality Assurance?

Various testing methods are employed to validate the quality of kitchen equipment. These methods include:

-

Performance Testing: Evaluating functionality under normal and extreme conditions to ensure durability and performance. This can include stress testing, temperature resistance, and load-bearing assessments.

-

Safety Testing: Ensuring that products comply with safety standards, particularly for electrical kitchen equipment. This may involve electrical safety tests, heat resistance tests, and checks for hazardous materials.

-

Hygiene Testing: Conducting microbiological tests to ensure that materials and surfaces meet food safety standards. This is particularly important for equipment used in commercial kitchens.

How Can International B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of suppliers is essential for B2B buyers to ensure they receive high-quality products. Here are actionable steps buyers can take:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and QC measures directly. This step can provide insight into the supplier’s capabilities and commitment to quality.

-

Quality Control Reports: Requesting regular QC reports can help buyers stay informed about the inspection outcomes and any corrective actions taken. Detailed reports should include data from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality control. Many international buyers prefer this method to ensure compliance with their standards.

What Are the QC and Certification Nuances for Buyers from Africa, South America, the Middle East, and Europe?

International B2B buyers must be aware of specific nuances related to quality control and certification based on their regions:

-

Africa: Buyers should consider local standards and regulations, which may differ from global norms. Establishing clear communication with suppliers about compliance can prevent issues.

-

South America: With growing emphasis on sustainability, buyers should ensure that suppliers adhere to environmental regulations, particularly in material sourcing and waste management.

-

Middle East: The Gulf Cooperation Council (GCC) has specific safety and quality standards. Buyers should verify that products comply with these standards, particularly for kitchen equipment used in hospitality.

-

Europe: The CE marking is crucial for entering European markets. Buyers should confirm that suppliers can provide the necessary documentation and certifications to avoid regulatory issues.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing kitchen equipment from China, ensuring high standards and compliance with their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kitchen equipment china’

In today’s globalized marketplace, sourcing kitchen equipment from China presents unique opportunities for international B2B buyers, especially from Africa, South America, the Middle East, and Europe. This step-by-step checklist will guide you through the essential stages of the sourcing process, ensuring you make informed decisions that align with your business needs.

1. Define Your Technical Specifications

Clearly outline the specifications and requirements for the kitchen equipment you need. This includes dimensions, materials, certifications, and functionalities.

– Why It Matters: A well-defined specification helps streamline the sourcing process and ensures that suppliers can meet your exact needs.

– What to Look For: Consider industry standards and local regulations that might affect your equipment choices.

2. Research and Identify Potential Suppliers

Conduct thorough research to identify reliable suppliers in China. Utilize trade platforms, industry directories, and trade shows to compile a list of potential partners.

– Why It Matters: A diverse supplier pool increases your chances of finding a manufacturer that fits your quality and price requirements.

– What to Look For: Focus on suppliers with a proven track record and positive reviews from other international buyers.

3. Verify Supplier Certifications and Compliance

Ensure that your selected suppliers hold the necessary certifications and comply with international standards, such as ISO or CE.

– Why It Matters: Compliance with safety and quality standards is critical to avoid legal issues and ensure the reliability of your kitchen equipment.

– What to Look For: Request copies of certifications and check their validity with the issuing authorities.

4. Request Samples and Conduct Quality Checks

Before placing a large order, request samples of the kitchen equipment to assess quality firsthand.

– Why It Matters: Evaluating samples allows you to verify that the products meet your specifications and quality expectations.

– What to Look For: Check for durability, functionality, and any aesthetic details that may be crucial for your brand image.

5. Negotiate Terms and Pricing

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Be prepared to discuss minimum order quantities (MOQs) and any additional costs, such as shipping and customs duties.

– Why It Matters: Clear and favorable terms can significantly impact your overall sourcing costs and cash flow.

– What to Look For: Aim for transparency in pricing to avoid hidden fees that could inflate your budget later.

6. Establish Clear Communication Channels

Set up effective communication channels with your supplier to facilitate ongoing dialogue throughout the sourcing process.

– Why It Matters: Open communication can help resolve any potential issues quickly and maintain a positive working relationship.

– What to Look For: Use platforms that allow for real-time updates and ensure both parties are aligned on expectations and timelines.

7. Plan for Logistics and Shipping

Finally, create a logistics plan that includes shipping methods, timelines, and customs processes. Consider working with a freight forwarder to navigate international shipping.

– Why It Matters: Proper logistics planning minimizes delays and ensures your equipment arrives in good condition.

– What to Look For: Ensure your logistics partner has experience with shipping kitchen equipment and understands the regulations in your country.

By following this structured checklist, international B2B buyers can effectively navigate the complexities of sourcing kitchen equipment from China, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for kitchen equipment china Sourcing

What Are the Key Cost Components in Kitchen Equipment Sourcing from China?

When sourcing kitchen equipment from China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects costs. Stainless steel, for instance, is more expensive than aluminum but offers better durability and resistance to corrosion. Buyers should consider the long-term benefits of material selection in relation to their budget.

-

Labor: Labor costs can vary significantly across different regions in China. While urban areas may have higher labor costs, they often provide better-skilled workers. Evaluating labor costs against the quality of output is essential for maintaining competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and administrative costs. A well-managed facility can offer lower overhead, translating into more competitive pricing for buyers.

-

Tooling: Custom tooling can be a significant upfront cost, especially for bespoke designs. However, these costs can be amortized over larger production runs, making them more manageable as order quantities increase.

-

Quality Control (QC): Implementing stringent QC processes ensures that products meet international standards, which can lead to higher initial costs but ultimately saves money by reducing returns and defects.

-

Logistics: Shipping costs from China to various international destinations can vary based on the chosen Incoterms. Understanding these terms is critical for budgeting and ensuring timely delivery.

-

Margin: Finally, supplier profit margins can vary based on the supplier’s market position and competition. Buyers should expect to negotiate these margins, especially for larger orders.

How Do Price Influencers Affect Kitchen Equipment Costs?

Several factors influence the pricing of kitchen equipment sourced from China:

-

Volume/MOQ: Minimum order quantities (MOQ) play a significant role in pricing. Larger orders often attract discounts, making it essential for buyers to evaluate their purchasing strategy to leverage volume effectively.

-

Specifications and Customization: Custom specifications can increase costs due to the additional resources required for design and production. Buyers must weigh the benefits of customization against the potential for increased expenditure.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or CE) can add to the cost. Buyers should consider the trade-off between initial costs and the long-term value of certified products.

-

Supplier Factors: The reputation and reliability of suppliers can impact prices. Established suppliers may charge more due to their experience and quality assurance processes, but they can also provide better reliability.

-

Incoterms: Understanding Incoterms is crucial for budgeting logistics. Different terms dictate the responsibilities of the buyer and seller, affecting total landed costs.

What Are the Best Buyer Tips for Cost-Efficiency in Kitchen Equipment Sourcing?

To ensure cost-efficiency when sourcing kitchen equipment from China, international buyers should consider the following strategies:

-

Negotiate Effectively: Engage in negotiations with suppliers to secure better pricing. Establishing a good relationship can lead to favorable terms and potential discounts.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the initial purchase price. This includes maintenance, operational costs, and potential savings from higher-quality products.

-

Understand Pricing Nuances: International buyers should be aware of local market conditions and pricing trends in China. This knowledge can empower them during negotiations and help avoid overpaying.

-

Leverage Local Expertise: Consider working with local agents or consultants familiar with the Chinese market. They can provide insights into sourcing strategies, quality control, and effective negotiation tactics.

Disclaimer on Indicative Prices

Prices for kitchen equipment can fluctuate based on market conditions, supplier changes, and economic factors. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure they are getting competitive pricing that aligns with their specific needs.

Alternatives Analysis: Comparing kitchen equipment china With Other Solutions

When considering kitchen equipment, it’s essential to evaluate various alternatives that can meet the needs of your business. The choice between different types of kitchen equipment can significantly impact operational efficiency, costs, and overall quality. Below, we present a comparison of ‘kitchen equipment china’ against two viable alternatives: stainless steel kitchen equipment and commercial-grade plastic kitchen equipment.

| Comparison Aspect | Kitchen Equipment China | Stainless Steel Kitchen Equipment | Commercial-Grade Plastic Kitchen Equipment |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Excellent durability and resistance to rust and corrosion | Good for light use, but less durable than metal |

| Cost | Moderate, varies by brand | Generally higher upfront cost | Lower initial investment and operational costs |

| Ease of Implementation | Simple to install, may require specific handling | Installation can be complex, but generally straightforward | Easy to install and handle |

| Maintenance | Requires careful cleaning to maintain appearance | Low maintenance, easy to clean | Requires regular cleaning but may stain over time |

| Best Use Case | Ideal for upscale dining establishments | Suitable for high-traffic kitchens and food processing | Best for casual dining and food prep areas |

What Are the Benefits and Drawbacks of Stainless Steel Kitchen Equipment?

Stainless steel kitchen equipment is renowned for its durability and resistance to corrosion and rust. This makes it an excellent choice for commercial kitchens that experience high traffic and require equipment that can withstand heavy use. The maintenance is relatively low, as stainless steel can be easily cleaned with standard cleaning agents. However, the initial investment is typically higher compared to kitchen equipment china, which may pose a budgetary concern for smaller businesses. Additionally, the installation process can be more complex, requiring professional assistance in some cases.

How Does Commercial-Grade Plastic Kitchen Equipment Compare?

Commercial-grade plastic kitchen equipment offers a cost-effective alternative for businesses looking to minimize their initial investment. This type of equipment is lightweight and easy to handle, making it ideal for casual dining establishments and food prep areas. However, while it is less expensive upfront, it may not provide the same level of durability as metal options, leading to potentially higher replacement costs over time. Regular cleaning is necessary to maintain hygiene, and there is a risk of staining, which could affect the presentation of food.

How Can B2B Buyers Choose the Right Kitchen Equipment Solution?

Selecting the right kitchen equipment solution involves assessing your specific operational needs, budget constraints, and maintenance capabilities. If your establishment focuses on fine dining or high-volume food processing, investing in stainless steel equipment may be worthwhile despite the higher initial cost. Conversely, if your operations are more casual, commercial-grade plastic may suffice, offering flexibility and lower costs. Kitchen equipment china can provide a balance of aesthetic appeal and durability, making it a strong contender for upscale environments. Ultimately, understanding the pros and cons of each option will empower B2B buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for kitchen equipment china

What Are the Key Technical Properties of Kitchen Equipment from China?

When sourcing kitchen equipment from China, understanding the technical specifications is vital for ensuring quality and reliability. Here are some essential technical properties to consider:

1. Material Grade: Why Is It Important?

Material grade refers to the quality and type of materials used in manufacturing kitchen equipment. Common materials include stainless steel, aluminum, and plastic. For instance, food-grade stainless steel (like 304 or 316) is highly resistant to corrosion and is ideal for commercial kitchens. Selecting the right material grade ensures durability, safety, and compliance with health regulations, which is crucial for B2B buyers aiming for long-term investments.

2. Tolerance Levels: How Do They Affect Performance?

Tolerance levels indicate the permissible limits of variation in a physical dimension. In kitchen equipment, tight tolerances ensure that parts fit together correctly, which is essential for functionality and safety. For example, a tolerance of ±0.5 mm in the dimensions of a cooking appliance can significantly affect its performance. Understanding tolerances helps buyers assess manufacturing precision, which is vital for operational efficiency.

3. Capacity: What Should Buyers Consider?

Capacity specifications determine the volume or weight of food that kitchen equipment can handle. For example, ovens may list capacities in liters, while refrigerators may specify cubic feet. Knowing the required capacity is essential for buyers to ensure that the equipment meets their operational demands, especially in high-volume settings like restaurants or catering services.

4. Power Ratings: Why Are They Critical?

Power ratings, typically expressed in watts or kilowatts, indicate the energy consumption and performance of kitchen appliances. For instance, a commercial dishwasher with a high power rating can clean larger loads more efficiently. Understanding power ratings helps buyers calculate operating costs and energy efficiency, which are crucial for budget management and sustainability goals.

5. Compliance Standards: How Do They Impact Sourcing?

Compliance standards refer to the regulations that kitchen equipment must meet to be sold in specific markets. Common certifications include CE in Europe and NSF in the United States. Ensuring that products meet these standards is essential for avoiding legal issues and ensuring customer safety, making it a critical consideration for international buyers.

What Common Trade Terms Should B2B Buyers Understand?

Navigating the trade landscape requires familiarity with specific jargon. Here are some essential terms that B2B buyers should know:

1. What Is OEM (Original Equipment Manufacturer)?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the kitchen equipment sector, buyers often deal with OEM suppliers who create customized products for brands. Understanding OEM can help buyers negotiate better terms and ensure quality control in the manufacturing process.

2. What Does MOQ (Minimum Order Quantity) Mean?

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for budgeting and inventory management. Buyers need to evaluate their needs against MOQ requirements to avoid excess inventory and ensure a steady supply of kitchen equipment.

3. What Is an RFQ (Request for Quotation)?

An RFQ is a document sent to suppliers requesting pricing and other relevant information for specific products. It is essential for buyers to understand how to create an effective RFQ to ensure they receive accurate and competitive quotes, which can aid in decision-making.

4. What Are Incoterms and Why Are They Important?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk management, and delivery points. Familiarity with Incoterms is crucial for B2B buyers to avoid misunderstandings and ensure smooth logistics.

5. What Is Lead Time and How Does It Impact Procurement?

Lead time refers to the time between placing an order and receiving it. Understanding lead times is vital for effective inventory management and planning. Buyers must consider lead times when sourcing kitchen equipment to ensure they meet their operational timelines and avoid disruptions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing kitchen equipment from China, ensuring they meet their operational needs while maximizing efficiency and compliance.

Navigating Market Dynamics and Sourcing Trends in the kitchen equipment china Sector

What Are the Current Market Dynamics and Key Trends in the Kitchen Equipment China Sector?

The kitchen equipment market in China is evolving rapidly, driven by several global factors. The increasing demand for high-quality kitchen appliances, fueled by urbanization and changing consumer lifestyles, has led to a surge in production and innovation. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are taking note of China’s competitive pricing and advanced manufacturing capabilities. Emerging technologies such as IoT-enabled kitchen appliances are gaining traction, allowing for smarter kitchens that can enhance operational efficiency and user experience.

Another significant trend is the shift towards e-commerce platforms for sourcing kitchen equipment. Buyers are increasingly relying on online marketplaces to access a broader range of products and suppliers, streamlining the procurement process. This trend is particularly pronounced in regions like South America and Africa, where traditional supply chains may be less established. Additionally, the emphasis on customization and localized production is becoming crucial for international buyers, as they seek to meet specific market demands and preferences.

How Is Sustainability and Ethical Sourcing Impacting B2B Buyers in the Kitchen Equipment Sector?

Sustainability has emerged as a cornerstone of sourcing strategies in the kitchen equipment sector. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility. This includes utilizing eco-friendly materials, reducing carbon footprints during production, and ensuring ethical labor practices throughout the supply chain. The impact of climate change is prompting buyers from Europe and the Middle East, in particular, to demand transparency in sourcing practices.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers looking to attract international clients. Moreover, the use of sustainable materials—such as recycled metals and biodegradable plastics—is gaining popularity among manufacturers in China. B2B buyers are encouraged to conduct thorough due diligence on potential suppliers, assessing their sustainability practices and certifications to align with their corporate social responsibility (CSR) goals.

What Is the Brief Evolution and History of the Kitchen Equipment Sector in China?

The kitchen equipment sector in China has undergone significant transformations over the past few decades. Initially dominated by low-cost manufacturing, the industry has shifted towards innovation and quality improvement, particularly since China joined the World Trade Organization in 2001. This integration into the global market spurred investments in advanced manufacturing technologies, enabling Chinese companies to produce a wider range of high-quality kitchen equipment.

Today, China’s kitchen equipment manufacturers are not only focusing on domestic needs but are also increasingly targeting international markets. The rise of e-commerce and digital marketing has further accelerated this trend, allowing Chinese suppliers to reach B2B buyers across the globe. As the industry continues to evolve, international buyers can expect greater competition, enhanced product offerings, and a focus on sustainability in sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of kitchen equipment china

-

How do I ensure the quality of kitchen equipment sourced from China?

To ensure quality, start by researching potential suppliers through platforms like Alibaba or Global Sources. Look for manufacturers with ISO certifications and positive reviews. Request samples to assess the materials and craftsmanship firsthand. Additionally, consider hiring third-party inspection services to conduct quality checks before shipment. Establish clear quality assurance (QA) protocols in your purchase agreement to safeguard your interests. -

What are the typical payment terms for purchasing kitchen equipment from China?

Payment terms can vary significantly, but common arrangements include a 30% deposit upon order confirmation and the balance before shipment. Some suppliers may offer letters of credit or trade insurance for added security. It’s essential to negotiate terms that protect your investment, especially for large orders. Always ensure that payment methods are secure and that you have a clear contract outlining the terms. -

What is the minimum order quantity (MOQ) for kitchen equipment from Chinese suppliers?

Minimum order quantities can differ by supplier and product type. Generally, MOQs for kitchen equipment range from 100 to 1,000 units. Smaller businesses should seek suppliers willing to accommodate lower MOQs or consider group purchasing with other buyers. Always clarify the MOQ before proceeding, as this impacts your overall budgeting and inventory management. -

How can I customize kitchen equipment sourced from China to meet my specific needs?

Most Chinese manufacturers are open to customization. Start by discussing your specific requirements, such as dimensions, materials, or branding. Provide detailed specifications and, if possible, design mockups. Be prepared for potential additional costs and longer lead times for custom orders. Establish clear communication channels to ensure that your expectations are met throughout the process. -

What logistics considerations should I keep in mind when importing kitchen equipment from China?

Consider shipping methods, such as sea freight for large orders or air freight for urgent needs. Factor in lead times, customs duties, and local regulations in your destination country. Partnering with a reliable freight forwarder can streamline the import process and help navigate complex logistics. Always ensure that you have the necessary documentation, such as bills of lading and customs declarations, to avoid delays. -

How do I vet suppliers for kitchen equipment to ensure reliability?

Vetting suppliers involves several steps: check their business licenses, certifications, and years of operation. Request references from previous clients and conduct background checks through platforms like Dun & Bradstreet. Attend trade shows or virtual exhibitions to meet suppliers in person and assess their capabilities. Building a strong relationship with your supplier can also enhance trust and reliability. -

What are the common challenges faced when sourcing kitchen equipment from China?

Challenges include language barriers, cultural differences, and varying quality standards. Miscommunication can lead to errors in orders or specifications. To mitigate these issues, work with suppliers who have experience dealing with international clients. Establish clear contracts, maintain open communication, and consider using translation services if necessary.

A stock image related to kitchen equipment china.

- How can I stay updated on market trends for kitchen equipment in international markets?

To stay informed, subscribe to industry publications, attend trade shows, and join relevant online forums or associations. Utilize market research reports to gain insights into consumer preferences and emerging trends. Networking with industry professionals and suppliers can also provide valuable information on new products and innovations in kitchen equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for kitchen equipment china

As international B2B buyers navigate the complex landscape of sourcing kitchen equipment from China, strategic sourcing emerges as a critical factor for success. By aligning procurement strategies with market trends, buyers can enhance operational efficiency and optimize cost savings. Understanding the nuances of the Chinese supply chain, including supplier capabilities and quality standards, is essential for mitigating risks associated with sourcing.

How Can Buyers Leverage Strategic Sourcing for Kitchen Equipment?

Strategic sourcing not only facilitates access to a diverse range of high-quality kitchen equipment but also fosters long-term partnerships with reliable suppliers. Buyers from Africa, South America, the Middle East, and Europe should prioritize building relationships that extend beyond transactional interactions, allowing for collaborative innovation and improved supply chain resilience.

What Is the Future Outlook for Sourcing Kitchen Equipment from China?

Looking ahead, the kitchen equipment sector will likely witness increased competition and innovation, driven by technological advancements and evolving consumer preferences. International buyers must stay proactive and adaptable to these changes. By leveraging strategic sourcing practices, you can position your business for success in this dynamic market landscape.

In conclusion, embrace the opportunities that strategic sourcing presents. Connect with suppliers who understand your unique needs and can support your growth objectives. This proactive approach will not only enhance your supply chain but also solidify your competitive advantage in the global marketplace.