Unlock Savings: The Ultimate Guide to Li Ion Battery Pack China (2025)

Introduction: Navigating the Global Market for li ion battery pack china

In an increasingly electrified world, sourcing reliable lithium-ion battery packs from China presents both opportunities and challenges for international B2B buyers. With the demand for energy storage solutions surging across various industries—from renewable energy to electric vehicles—understanding the dynamics of this global market is essential. This guide offers a comprehensive overview of the types of lithium-ion battery packs available, their diverse applications, and the nuances of supplier vetting. It also delves into cost considerations and logistics, ensuring that your purchasing decisions are both informed and strategic.

For businesses in Africa, South America, the Middle East, and Europe—especially in countries like Spain and France—navigating the complexities of international sourcing can be daunting. This guide is designed to empower you with actionable insights, enabling you to make educated decisions that align with your operational needs and budget constraints. By exploring the critical aspects of supplier selection, quality assurance, and market trends, you will be equipped to mitigate risks and capitalize on the advantages that come with sourcing lithium-ion battery packs from China. Whether you’re looking to enhance your product offerings or streamline your supply chain, this resource serves as your roadmap to successfully engaging with this vital market.

Understanding li ion battery pack china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium Cobalt Oxide (LCO) | High energy density, compact size | Smartphones, laptops | Pros: Excellent performance; Cons: Expensive and less stable. |

| Lithium Iron Phosphate (LFP) | Long cycle life, thermal stability | Electric vehicles, energy storage systems | Pros: Safe and durable; Cons: Lower energy density. |

| Lithium Nickel Manganese Cobalt (NMC) | Balanced performance, good thermal stability | Electric vehicles, power tools | Pros: Versatile; Cons: Higher manufacturing costs. |

| Lithium Polymer (LiPo) | Flexible form factor, lightweight | Drones, portable electronics | Pros: Lightweight and customizable; Cons: More expensive and sensitive to punctures. |

| Lithium Nickel Cobalt Aluminum Oxide (NCA) | High energy density, good thermal stability | Electric vehicles, aerospace applications | Pros: High performance; Cons: Costly and complex manufacturing. |

What are the Characteristics of Lithium Cobalt Oxide (LCO) Batteries?

Lithium Cobalt Oxide (LCO) batteries are known for their high energy density and compact size, making them ideal for applications where space is limited, such as smartphones and laptops. They typically offer a voltage of about 3.7V and have a cycle life of around 500-1000 cycles. When considering LCO batteries, B2B buyers should evaluate the cost against performance needs, especially in consumer electronics where weight and size are critical.

How Does Lithium Iron Phosphate (LFP) Compare in Terms of Suitability?

Lithium Iron Phosphate (LFP) batteries stand out due to their long cycle life and thermal stability. With a lower energy density compared to LCO, LFP batteries are more suitable for applications like electric vehicles and energy storage systems, where safety and longevity are paramount. Buyers should prioritize LFP for projects requiring high safety standards and lower maintenance costs, despite the initial investment being relatively high.

What Advantages Does Lithium Nickel Manganese Cobalt (NMC) Offer?

Lithium Nickel Manganese Cobalt (NMC) batteries provide a balanced performance that combines high energy density with good thermal stability. This makes them versatile for various applications, including electric vehicles and power tools. B2B buyers should consider NMC when looking for a battery that offers a good trade-off between performance and cost, especially in industries where reliability is crucial.

Why Choose Lithium Polymer (LiPo) Batteries for Portable Electronics?

Lithium Polymer (LiPo) batteries are characterized by their lightweight and flexible form factor, making them ideal for drones and portable electronics. They can be manufactured in various shapes and sizes, allowing for greater design flexibility. However, B2B buyers should be aware of their sensitivity to punctures and higher costs, which may impact the overall project budget.

What Makes Lithium Nickel Cobalt Aluminum Oxide (NCA) a High-Performance Option?

Lithium Nickel Cobalt Aluminum Oxide (NCA) batteries are recognized for their high energy density and thermal stability, making them a popular choice in electric vehicles and aerospace applications. While they offer exceptional performance, their complex manufacturing process and higher costs can be a barrier for some buyers. When considering NCA, B2B purchasers should weigh the performance benefits against budget constraints and potential supply chain complexities.

Related Video: Lithium Ion Battery Pack Architecture

Key Industrial Applications of li ion battery pack china

| Industry/Sector | Specific Application of li ion battery pack china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Energy Storage Systems for Solar and Wind Power | Enhances grid stability and energy efficiency | Ensure compatibility with existing systems and local regulations. |

| Electric Vehicles (EVs) | Powering Electric Cars and Buses | Reduces carbon footprint and operational costs | Consider battery range, charging times, and lifecycle. |

| Consumer Electronics | Portable Electronics (Laptops, Smartphones) | Increases product performance and user satisfaction | Focus on battery capacity, weight, and safety certifications. |

| Industrial Automation | Robotics and Automated Machinery | Improves operational efficiency and reduces downtime | Assess battery management systems and integration capabilities. |

| Medical Devices | Portable Medical Equipment | Ensures reliability and mobility in healthcare | Verify compliance with medical standards and longevity. |

How Are Li-Ion Battery Packs Used in Renewable Energy Applications?

Li-ion battery packs from China are increasingly utilized in energy storage systems for solar and wind power applications. These batteries store excess energy generated during peak production times and release it when demand is high, thereby enhancing grid stability and energy efficiency. For international B2B buyers, especially in Africa and South America, sourcing these batteries requires an understanding of local regulations and compatibility with existing renewable energy systems. Buyers should also consider the environmental impact and lifecycle of the batteries to ensure sustainability.

What Role Do Li-Ion Battery Packs Play in Electric Vehicles?

In the electric vehicle (EV) sector, Chinese li-ion battery packs are critical for powering electric cars and buses. These batteries provide the necessary energy density to achieve longer ranges and faster acceleration, which are essential for consumer acceptance and operational efficiency. International buyers, particularly from Europe and the Middle East, should focus on the battery’s range, charging times, and lifecycle costs when sourcing. Additionally, they must ensure that the batteries comply with international safety and environmental standards to avoid regulatory challenges.

How Do Li-Ion Battery Packs Enhance Consumer Electronics?

Li-ion battery packs are fundamental in powering portable electronics such as laptops and smartphones. The high energy density and lightweight nature of these batteries enable longer usage times and improved device performance, which directly influences consumer satisfaction. B2B buyers in Europe and Africa should prioritize battery capacity, weight, and safety certifications when sourcing. Understanding the specific requirements of their target markets, including energy efficiency and product reliability, can also help in selecting the right battery solutions.

How Are Li-Ion Battery Packs Used in Industrial Automation?

In industrial automation, li-ion battery packs power robotics and automated machinery, significantly improving operational efficiency and reducing downtime. These batteries provide a reliable power source that supports continuous operations, crucial in manufacturing settings. For B2B buyers from South America and the Middle East, it’s vital to assess battery management systems and integration capabilities to ensure seamless operation with existing machinery. Additionally, buyers should consider after-sales support and warranty conditions when sourcing these advanced battery solutions.

What Are the Applications of Li-Ion Battery Packs in Medical Devices?

Li-ion battery packs are essential in portable medical equipment, providing the necessary power for devices like infusion pumps and diagnostic tools. The reliability and mobility offered by these batteries can significantly enhance patient care in various healthcare settings. International B2B buyers, particularly in Europe, should verify compliance with medical standards and focus on the longevity and safety features of the batteries. Ensuring that the supplier has a robust quality assurance process can mitigate risks associated with medical applications.

3 Common User Pain Points for ‘li ion battery pack china’ & Their Solutions

Scenario 1: Quality Assurance and Reliability Issues

The Problem:

International B2B buyers often face significant concerns regarding the quality and reliability of lithium-ion battery packs sourced from China. With numerous manufacturers in the market, distinguishing between high-quality products and subpar alternatives can be challenging. Buyers from regions such as Africa and South America may encounter products that do not meet their specifications, leading to operational inefficiencies and increased costs due to frequent replacements or repairs. The inconsistency in battery performance can also adversely affect the end products, causing reputational harm and customer dissatisfaction.

The Solution:

To mitigate quality assurance issues, B2B buyers should implement a rigorous supplier evaluation process. This includes requesting detailed product specifications and certifications (such as ISO 9001) from potential suppliers. Additionally, conducting factory audits, either in person or through third-party services, can provide insights into manufacturing practices and quality control measures. Establishing clear quality benchmarks in the contract can also ensure accountability. Finally, consider sourcing samples for extensive testing before committing to larger orders. This proactive approach will help buyers secure reliable lithium-ion battery packs that meet their operational needs.

Scenario 2: Navigating Import Regulations and Compliance

The Problem:

Another prevalent pain point for international buyers is navigating the complex landscape of import regulations and compliance standards associated with lithium-ion batteries. Different countries have varying safety and environmental regulations, and failing to comply can lead to shipment delays, hefty fines, or even the rejection of goods at customs. Buyers in Europe, for instance, must adhere to the EU’s Battery Directive, while those in the Middle East might face different regulatory challenges, complicating the import process.

The Solution:

B2B buyers should invest time in understanding the specific regulations that apply to their markets. This involves researching the local laws concerning battery imports, including safety standards, labeling requirements, and disposal regulations. Collaborating with a logistics partner who specializes in hazardous materials can provide valuable insights and streamline the shipping process. Additionally, maintaining open communication with suppliers in China about compliance requirements is crucial. Buyers should request documentation that confirms adherence to international standards, such as UN38.3 for transport safety, which can facilitate smoother customs clearance.

Scenario 3: High Shipping Costs and Lead Times

The Problem:

The shipping costs and lead times associated with importing lithium-ion battery packs from China can pose significant challenges for B2B buyers. Fluctuating freight rates and extended transit times can impact inventory management and ultimately affect the supply chain. Buyers from regions with less established shipping routes may find themselves facing exorbitant costs and unpredictable delivery schedules, disrupting their operations and leading to potential revenue loss.

The Solution:

To combat high shipping costs and long lead times, buyers should consider establishing long-term relationships with reliable freight forwarders who can negotiate better rates based on volume. Additionally, exploring alternative shipping methods, such as rail or consolidated shipping, can reduce costs significantly. Implementing a just-in-time inventory strategy can also help manage stock levels efficiently, allowing businesses to order smaller quantities more frequently. Lastly, buyers should communicate openly with their suppliers about their shipping expectations and timelines, potentially negotiating favorable shipping terms that align with their operational needs.

Strategic Material Selection Guide for li ion battery pack china

What Are the Key Materials Used in Li-ion Battery Packs from China?

When sourcing lithium-ion (Li-ion) battery packs from China, international B2B buyers must consider the materials used in their construction. The choice of materials can significantly impact performance, cost, and compliance with regional standards. Below, we analyze four common materials used in Li-ion battery packs, highlighting their properties, advantages, disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

How Does Lithium Cobalt Oxide (LCO) Benefit Li-ion Battery Packs?

Key Properties: Lithium cobalt oxide is known for its high energy density and stability at elevated temperatures, making it suitable for applications requiring compact energy storage. It typically operates effectively within a temperature range of -20°C to 60°C.

Pros & Cons: The primary advantage of LCO is its high capacity, allowing for smaller battery sizes without sacrificing performance. However, it is relatively expensive and can be less durable over time, particularly under high-stress conditions. Additionally, LCO is sensitive to overcharging, which can lead to safety concerns.

Impact on Application: LCO is commonly used in consumer electronics and electric vehicles, where space and weight are critical. However, its cost may limit its use in more price-sensitive markets.

Considerations for International Buyers: Buyers should be aware of compliance with safety standards such as IEC 62133 and UN 38.3 for transport safety. Additionally, European buyers may need to consider RoHS compliance for hazardous substances.

What Role Does Lithium Iron Phosphate (LFP) Play in Battery Performance?

Key Properties: Lithium iron phosphate is recognized for its excellent thermal stability and long cycle life. It operates effectively at temperatures ranging from -20°C to 60°C and has a lower risk of thermal runaway compared to other chemistries.

Pros & Cons: The main advantage of LFP is its safety and longevity, making it suitable for applications that require high reliability. However, it has a lower energy density than LCO, which can result in larger battery sizes. The manufacturing process can also be more complex, affecting cost.

Impact on Application: LFP is often used in electric buses, stationary energy storage, and applications where safety is paramount. Its robustness makes it ideal for harsh environments.

Considerations for International Buyers: Buyers from regions with stringent safety regulations, such as Europe, should ensure that LFP batteries meet local compliance standards. Additionally, LFP’s growing popularity in renewable energy applications may align with sustainability goals in these markets.

How Does Nickel Manganese Cobalt (NMC) Enhance Battery Versatility?

Key Properties: Nickel manganese cobalt offers a balanced performance profile with good thermal stability and energy density. It typically operates effectively between -20°C and 60°C, making it versatile for various applications.

Pros & Cons: NMC’s primary advantage is its ability to provide a good balance between energy density, cost, and safety. However, it can be more expensive than LFP and may require more complex manufacturing processes.

Impact on Application: NMC is widely used in electric vehicles and energy storage systems, where a balance of performance and cost is critical. Its adaptability makes it a popular choice for manufacturers looking to optimize battery performance.

Considerations for International Buyers: Buyers should ensure that NMC batteries comply with international standards, such as ISO 9001 for quality management. Additionally, understanding the supply chain for raw materials is crucial, as geopolitical factors can impact availability and pricing.

What Advantages Does Graphite Provide in Li-ion Battery Packs?

Key Properties: Graphite is commonly used as an anode material in Li-ion batteries due to its excellent conductivity and stability. It can handle high charge and discharge rates, typically operating within a temperature range of -20°C to 60°C.

Pros & Cons: The key advantage of graphite is its cost-effectiveness and availability. However, it has a lower theoretical capacity compared to silicon-based alternatives, which may limit its performance in high-demand applications.

Impact on Application: Graphite is widely used in consumer electronics and electric vehicles, where cost and performance are balanced. Its established supply chain makes it a reliable choice for manufacturers.

Considerations for International Buyers: Buyers should consider the sourcing of graphite, particularly in light of environmental regulations and ethical sourcing practices. Compliance with standards like ASTM D7868 for battery materials is also essential.

Summary Table of Materials for Li-ion Battery Packs

| Material | Typical Use Case for li ion battery pack china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Cobalt Oxide (LCO) | Consumer electronics, electric vehicles | High energy density | Expensive, sensitive to overcharging | High |

| Lithium Iron Phosphate (LFP) | Electric buses, stationary energy storage | Excellent thermal stability, long cycle life | Lower energy density, complex manufacturing | Medium |

| Nickel Manganese Cobalt (NMC) | Electric vehicles, energy storage systems | Balanced performance profile | More expensive, complex manufacturing | Medium to High |

| Graphite | Consumer electronics, electric vehicles | Cost-effective, widely available | Lower theoretical capacity compared to silicon | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling them to make informed decisions when sourcing Li-ion battery packs from China. Understanding the properties, advantages, and compliance considerations of each material is crucial for optimizing performance and ensuring regulatory adherence.

In-depth Look: Manufacturing Processes and Quality Assurance for li ion battery pack china

What Are the Key Manufacturing Processes for Lithium-Ion Battery Packs in China?

The manufacturing of lithium-ion (Li-ion) battery packs involves several critical stages that ensure the final product meets both performance and safety standards. Understanding these stages can help international B2B buyers make informed decisions when sourcing battery packs from Chinese manufacturers.

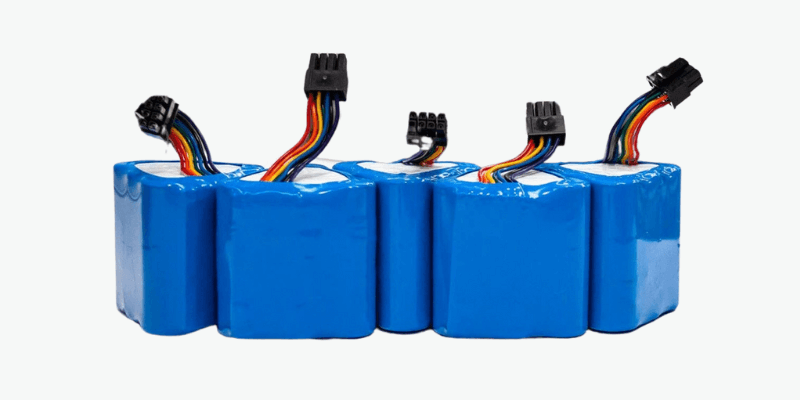

A stock image related to li ion battery pack china.

1. Material Preparation: What Raw Materials Are Used?

The first stage in manufacturing Li-ion battery packs is material preparation. This involves sourcing high-quality raw materials, including:

- Cathode Materials: Common options include lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), and lithium nickel manganese cobalt oxide (NMC).

- Anode Materials: Graphite is predominantly used, although silicon-based anodes are gaining traction for their superior energy density.

- Electrolytes: Liquid electrolytes, typically a lithium salt dissolved in organic solvents, are essential for efficient ion transfer.

B2B buyers should verify the source and quality of these materials, as they directly impact the battery’s performance, lifespan, and safety.

2. Forming: How Are Battery Cells Constructed?

Once the materials are prepared, the forming process begins, which includes:

- Mixing: The active materials are mixed with binders and solvents to create a slurry.

- Coating: This slurry is then coated onto metal foils (copper for anodes and aluminum for cathodes).

- Drying: The coated foils are dried to remove solvents, resulting in a solid electrode layer.

- Cutting: The electrodes are cut into specific sizes to fit the battery cells.

Understanding the techniques used in forming can help buyers assess the technological capabilities of a supplier. Advanced techniques, such as roll-to-roll coating, can enhance efficiency and reduce waste.

3. Assembly: What Are the Steps in Battery Pack Assembly?

The assembly process involves several steps:

- Cell Assembly: Individual cells are stacked or wound together, depending on the design.

- Tab Welding: Connections are made between cells using ultrasonic welding or laser welding, ensuring low resistance and high conductivity.

- Module Formation: Multiple cells are combined into modules that will make up the final battery pack.

B2B buyers should inquire about the assembly methods used, as different techniques can affect the battery pack’s reliability and performance. Automation in assembly can also signal a manufacturer’s commitment to quality.

4. Finishing: What Final Steps Ensure Quality?

The finishing stage is crucial for ensuring the battery pack meets safety and performance standards. Key processes include:

- Encapsulation: The cells and modules are encased in protective housings to prevent damage and leakage.

- Battery Management System (BMS) Integration: A BMS is installed to monitor the battery’s health, charge levels, and temperature, ensuring safe operation.

- Labeling and Packaging: Final products are labeled with essential information and packaged for shipment.

This stage is vital for B2B buyers to understand, as the quality of finishing can influence both safety and user experience.

How Is Quality Assurance Implemented in Lithium-Ion Battery Manufacturing?

Quality assurance (QA) is a critical component of the Li-ion battery manufacturing process. It ensures that the final products meet international standards and customer expectations.

International Standards: What Certifications Should Buyers Look For?

Chinese manufacturers often adhere to international quality standards, which can provide assurance to B2B buyers. Key certifications include:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to maintain high-quality products.

- CE Marking: This indicates compliance with European health, safety, and environmental protection standards.

- UN 38.3 Certification: This is vital for the transport of lithium batteries and ensures they meet safety requirements.

Buyers should prioritize suppliers with these certifications, as they demonstrate a commitment to quality and safety.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various stages of production. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to identify and rectify defects early in the process.

- Final Quality Control (FQC): Before shipment, finished products undergo rigorous testing to ensure they meet specifications.

Understanding these checkpoints helps buyers evaluate a manufacturer’s commitment to quality and consistency.

What Common Testing Methods Are Used to Ensure Battery Safety and Performance?

Testing methods play a crucial role in quality assurance for lithium-ion batteries. Common methods include:

- Electrical Testing: This checks voltage, capacity, and internal resistance.

- Thermal Testing: Batteries are subjected to temperature cycling to assess performance under extreme conditions.

- Safety Testing: Short-circuit tests, overcharge tests, and drop tests are performed to ensure the battery can withstand various scenarios without failing.

B2B buyers should request detailed testing reports from suppliers to verify the performance and safety of the products.

How Can B2B Buyers Verify Supplier Quality Control?

Given the complexity of battery manufacturing and the importance of quality, B2B buyers should implement strategies to verify supplier QC practices:

1. Conduct Supplier Audits

Regular audits can help buyers assess a supplier’s manufacturing processes, quality control measures, and compliance with international standards. This can be done through:

- On-site Visits: Directly visiting the manufacturing facility allows buyers to evaluate production conditions and quality practices.

- Third-Party Audits: Engaging third-party firms for impartial assessments can provide an additional layer of verification.

2. Request Documentation and Reports

Buyers should ask for comprehensive documentation, including:

- Quality Assurance Reports: These should detail the results of IQC, IPQC, and FQC.

- Certification Copies: Request copies of all relevant certifications to ensure compliance.

3. Leverage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased evaluation of product quality before shipment. This step can significantly reduce risks associated with quality and compliance.

What Are the Unique QC and Certification Nuances for International Buyers?

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances when dealing with Chinese manufacturers:

- Regulatory Compliance: Different regions have varying regulations regarding battery imports. Understanding these can help in selecting compliant suppliers.

- Cultural Considerations: Communication and expectations may differ across regions, affecting the clarity of quality agreements. Establishing clear channels for feedback and expectations is essential.

- Supply Chain Reliability: Consider suppliers that demonstrate strong logistics capabilities to ensure timely delivery and compliance with local regulations.

By focusing on these aspects, international buyers can navigate the complexities of sourcing lithium-ion battery packs from China with greater confidence and success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘li ion battery pack china’

Introduction

Sourcing lithium-ion battery packs from China can be a complex process, especially for international B2B buyers. This guide provides a practical step-by-step checklist to streamline your procurement process. By following these steps, you can ensure that you select the right suppliers, negotiate favorable terms, and receive high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Before you start searching for suppliers, it’s crucial to have a clear understanding of your technical requirements. This includes battery capacity, voltage, size, weight, and any specific safety standards you must adhere to.

– Why It Matters: Precise specifications help you avoid misunderstandings with suppliers and ensure that the batteries will meet your operational needs.

– What to Look For: Create a detailed document outlining all specifications and relevant certifications, such as IEC or UL standards.

Step 2: Conduct Market Research

Gather intelligence on the current market landscape for lithium-ion battery packs in China. Look into the latest technologies, trends, and pricing structures.

– Why It Matters: Understanding the market can help you identify competitive pricing and innovative products, giving you leverage in negotiations.

– What to Look For: Use industry reports, trade publications, and online forums to gather insights.

Step 3: Evaluate Potential Suppliers

It’s essential to vet suppliers thoroughly before making a commitment. Request company profiles, case studies, and references from previous clients.

– Why It Matters: A reliable supplier can significantly affect your supply chain’s efficiency and product quality.

– What to Look For: Check their manufacturing capabilities, production capacity, and quality control processes. Consider visiting the facility if possible.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications for quality and safety, such as ISO 9001 and ISO 14001.

– Why It Matters: Certifications provide assurance that the supplier adheres to international quality standards, which is critical for compliance and safety.

– What to Look For: Request copies of certifications and confirm their validity through official channels.

Step 5: Request Samples for Testing

Before placing a large order, ask for samples of the lithium-ion battery packs. This allows you to evaluate their quality and performance in real-world conditions.

– Why It Matters: Testing samples can reveal potential issues that might not be apparent from specifications alone.

– What to Look For: Assess the samples for compatibility with your products, performance metrics, and any safety concerns.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms of your purchase, including pricing, lead times, payment terms, and warranty conditions.

– Why It Matters: Clear agreements help prevent disputes and ensure that both parties understand their obligations.

– What to Look For: Aim for favorable payment terms (e.g., letters of credit) and ensure that warranties cover defects and performance issues.

Step 7: Plan for Logistics and Compliance

Consider the logistics of shipping and customs regulations when importing lithium-ion batteries from China.

– Why It Matters: Proper logistics planning ensures timely delivery and compliance with international shipping regulations, especially for hazardous materials like batteries.

– What to Look For: Work with logistics partners experienced in handling battery shipments and understand the local regulations in your region regarding battery imports.

By following these steps, you can navigate the complexities of sourcing lithium-ion battery packs from China more effectively, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for li ion battery pack china Sourcing

What Are the Key Cost Components of Li-ion Battery Pack Sourcing from China?

When sourcing Li-ion battery packs from China, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

-

Materials: The primary materials used in Li-ion batteries include lithium, cobalt, nickel, and graphite. Prices for these raw materials can fluctuate significantly based on global demand and supply conditions. Buyers should monitor commodity markets to anticipate changes in material costs.

-

Labor: Labor costs in China have been rising, but they still remain competitive compared to other regions. The complexity of battery pack assembly can influence labor costs, with more intricate designs requiring higher skilled labor.

-

Manufacturing Overhead: This encompasses the operational costs of running a manufacturing facility, including utilities, rent, and administrative expenses. Efficient manufacturing practices can help in keeping these overheads lower.

-

Tooling: Custom tooling for battery packs can be a significant upfront investment. This cost can vary depending on the complexity and specifications of the battery design. Buyers should consider how tooling costs will affect the overall budget.

-

Quality Control (QC): Implementing rigorous QC processes is essential to ensure product reliability and compliance with international standards. The costs associated with QC can vary based on the supplier’s capabilities and the certifications required.

-

Logistics: Shipping and handling costs from China to the buyer’s location can vary based on the chosen Incoterms. This includes freight charges, insurance, and customs duties.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and supplier relationships.

How Do Price Influencers Impact Li-ion Battery Pack Sourcing?

Several factors influence the pricing of Li-ion battery packs, which international buyers should carefully consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to lower per-unit costs, making it advantageous for buyers to consolidate their orders if possible.

-

Specifications and Customization: Customized battery packs that meet specific performance or size requirements may incur higher costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials directly impacts the performance and lifespan of the battery. Higher-quality materials may cost more but can lead to better performance and lower Total Cost of Ownership (TCO). Certifications such as ISO or UL can also add to the cost but are essential for market acceptance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to their proven track record.

-

Incoterms: The choice of Incoterms can affect overall costs. Terms like FOB (Free On Board) may require buyers to handle shipping logistics, potentially increasing costs if not managed properly.

What Are Effective Buyer Tips for Negotiating Li-ion Battery Pack Prices?

To secure favorable pricing and terms when sourcing Li-ion battery packs from China, consider the following tips:

-

Negotiate Terms and Prices: Engage in open discussions with suppliers about pricing structures and potential discounts for larger orders. Don’t hesitate to negotiate terms that can provide better value.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, maintenance, and expected lifespan. A lower initial cost may not always result in the best overall value.

-

Understand Pricing Nuances: Be aware of the seasonal trends in raw material prices, which can affect battery costs. Timing your orders can lead to significant savings.

-

Build Strong Supplier Relationships: Cultivating a good relationship with suppliers can lead to better pricing and priority service. Long-term partnerships often yield better terms and reliability.

-

Conduct Thorough Market Research: Analyze the market to identify various suppliers and their offerings. This can give you leverage during negotiations and help you understand the competitive landscape.

Conclusion

By comprehensively understanding the cost structure and pricing influences, international B2B buyers can make informed decisions when sourcing Li-ion battery packs from China. Careful negotiation and strategic planning can lead to significant cost savings and a more favorable purchasing experience. Always keep in mind that prices can vary widely based on numerous factors, and it’s advisable to consult multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing li ion battery pack china With Other Solutions

In the competitive landscape of energy storage solutions, international B2B buyers must carefully evaluate various options to determine the best fit for their specific needs. While ‘Li Ion Battery Pack China’ is a prominent choice due to its efficiency and widespread availability, several alternative technologies also merit consideration. This analysis will compare lithium-ion battery packs manufactured in China with two viable alternatives: lead-acid batteries and solid-state batteries.

Comparison Table of Energy Storage Solutions

| Comparison Aspect | Li Ion Battery Pack China | Lead-Acid Batteries | Solid-State Batteries |

|---|---|---|---|

| Performance | High energy density, long cycle life | Lower energy density, shorter cycle life | Higher energy density, longer cycle life |

| Cost | Moderate initial cost, cost-effective for large-scale | Lower initial cost, but higher total cost over time | High initial cost, but decreasing with advancements |

| Ease of Implementation | Simple integration, established supply chains | Familiar technology, widely available | Emerging technology, requires specialized knowledge |

| Maintenance | Low maintenance requirements | Requires regular maintenance | Minimal maintenance needed |

| Best Use Case | Electric vehicles, renewable energy storage | Backup power, automotive applications | Next-gen electronics, electric vehicles, grid storage |

What Are the Advantages and Disadvantages of Lead-Acid Batteries?

A stock image related to li ion battery pack china.

Lead-acid batteries are one of the oldest and most commonly used energy storage solutions. They offer a lower initial cost compared to lithium-ion packs, making them attractive for short-term projects or applications with limited budgets. However, their overall lifespan is significantly shorter, leading to higher long-term costs. They also have a lower energy density, which means they take up more space and weigh more than lithium-ion solutions. Their maintenance requirements can be a drawback, as they need regular checks to ensure optimal performance, particularly in extreme temperatures.

How Do Solid-State Batteries Compare to Lithium-Ion Packs?

Solid-state batteries represent the cutting edge of energy storage technology, offering several advantages over traditional lithium-ion packs. They boast a higher energy density, which can lead to longer-lasting power and reduced weight, making them ideal for applications like electric vehicles and portable electronics. However, they currently come with a high initial investment and are still in the early stages of commercial deployment. Additionally, their manufacturing processes require specialized knowledge, which can complicate integration for businesses not already familiar with the technology.

How Can B2B Buyers Choose the Right Energy Storage Solution?

When selecting the best energy storage solution, B2B buyers should consider several factors specific to their operational needs. Key considerations include the performance requirements of their application, budget constraints, and the importance of maintenance. For instance, businesses in sectors with rapid technological advancements may prioritize the high performance and longevity of lithium-ion or solid-state batteries, despite their higher costs. Conversely, companies focused on short-term projects or backup systems might find lead-acid batteries to be a more economical choice. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for li ion battery pack china

What Are the Essential Technical Properties of Li-ion Battery Packs from China?

When sourcing Li-ion battery packs from China, understanding the technical specifications is critical for making informed purchasing decisions. Here are some essential properties that B2B buyers should consider:

-

Material Grade

The quality of the materials used in Li-ion battery packs, such as lithium cobalt oxide (LCO) or lithium iron phosphate (LFP), directly impacts performance and safety. High-grade materials ensure better energy density, longevity, and thermal stability. For international buyers, selecting the appropriate material grade is essential to meet specific application requirements and to comply with regional regulations. -

Capacity (Ah)

Capacity, measured in ampere-hours (Ah), indicates the amount of energy a battery can store. Higher capacity allows for longer usage times, which is crucial for devices requiring sustained power. B2B buyers must assess their energy needs to determine the right capacity for their applications, ensuring they select a battery pack that provides sufficient power without over-specifying, which can lead to increased costs. -

Voltage (V)

The nominal voltage of a Li-ion battery pack, typically ranging from 3.2V to 3.7V per cell, determines its suitability for various applications. Understanding voltage requirements is vital for ensuring compatibility with existing systems and for optimizing performance. Buyers should confirm that the voltage aligns with the specifications of their devices to prevent operational issues. -

Cycle Life

Cycle life refers to the number of complete charge and discharge cycles a battery can undergo before its capacity significantly degrades. A longer cycle life translates to lower replacement costs and improved sustainability, appealing to buyers focused on long-term investments. Evaluating cycle life is essential for industries such as renewable energy, electric vehicles, and consumer electronics, where battery longevity is critical. -

Tolerance Levels

Tolerance levels indicate the acceptable deviation from specified measurements in dimensions and performance. In B2B transactions, understanding tolerance is crucial to ensuring that battery packs fit seamlessly within products and operate as intended. Buyers should request tolerance specifications to avoid compatibility issues that could arise during integration.

What Are Common Trade Terms Used in Li-ion Battery Pack Transactions?

Navigating the trade landscape for Li-ion battery packs involves familiarity with specific jargon. Here are several key terms that international buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that may be marketed by another company. In the context of Li-ion batteries, partnering with an OEM can provide tailored solutions that meet specific requirements. Buyers should look for OEM partnerships that offer customization options to ensure product compatibility. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and overall cost. Buyers should negotiate MOQs that align with their production needs while ensuring they do not overcommit to large orders that may lead to excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the Li-ion battery market, submitting an RFQ can help buyers receive competitive pricing and detailed specifications. It is advisable to include comprehensive details in the RFQ to obtain accurate quotes that reflect all technical requirements. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and to clarify who bears the risk and cost at various stages of the transportation process. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). -

Certification Standards

Certification standards, such as CE, UL, or RoHS, ensure that battery packs meet specific safety and environmental regulations. Buyers should verify that the products they source comply with relevant certification standards in their region to avoid legal issues and ensure consumer safety. This is particularly important for buyers in regulated markets like Europe.

By understanding these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Li-ion battery packs from China, ensuring compatibility, safety, and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the li ion battery pack china Sector

What Are the Current Market Dynamics and Key Trends in the Li-Ion Battery Pack Sector in China?

The global demand for lithium-ion (Li-ion) battery packs is experiencing exponential growth, driven by the accelerating adoption of electric vehicles (EVs), renewable energy systems, and consumer electronics. In 2023, the market is projected to reach unprecedented levels, particularly in regions like Africa, South America, the Middle East, and Europe. B2B buyers should be aware of key trends such as the increasing integration of artificial intelligence (AI) in manufacturing processes, which enhances production efficiency and quality control. Additionally, the rise of battery-as-a-service (BaaS) models is transforming how companies approach energy storage solutions, presenting new opportunities for sourcing partnerships.

International buyers should also consider the geographic diversification of suppliers. While China remains a dominant player, emerging markets in Southeast Asia and Africa are gaining traction, offering competitive pricing and innovative solutions. It’s crucial for B2B buyers to establish robust supplier relationships that focus on transparency and reliability, as fluctuating raw material prices and geopolitical tensions can affect supply chain stability.

Furthermore, regulatory frameworks, especially in Europe, are tightening, emphasizing the need for compliance with safety and environmental standards. Buyers must stay informed about these regulations to avoid potential disruptions in sourcing and to enhance their competitive edge.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy for Li-Ion Battery Packs?

As environmental concerns become paramount, sustainability is no longer optional for B2B buyers in the Li-ion battery sector. The ecological impact of lithium extraction and battery disposal raises significant ethical questions, urging companies to seek suppliers committed to sustainable practices. Ethical sourcing encompasses selecting materials and partners who prioritize environmental stewardship, which can enhance brand reputation and consumer trust.

Buyers should look for suppliers that obtain certifications like ISO 14001 for environmental management or those involved in circular economy initiatives. These certifications demonstrate a commitment to reducing carbon footprints and promoting resource recycling. Additionally, sourcing from manufacturers who use recycled materials in their battery production can not only lower costs but also align with global sustainability goals.

Incorporating sustainability into sourcing strategies can provide a competitive advantage in markets increasingly favoring environmentally friendly products. Buyers should also engage with suppliers who disclose their environmental impact and improvement plans, fostering transparency in the supply chain.

How Has the Li-Ion Battery Pack Industry Evolved Over Time?

The evolution of the Li-ion battery pack industry in China has been marked by rapid technological advancements and shifts in market demand. Initially developed in the early 1990s, Li-ion technology has undergone significant improvements in energy density, charge times, and overall lifespan. China’s strategic investments in battery technology and manufacturing infrastructure have positioned it as a leader in the global market.

Historically, the focus was primarily on consumer electronics, but the paradigm shifted with the rise of electric vehicles and renewable energy storage solutions. As international demand surged, Chinese manufacturers adapted by scaling production capabilities and investing in R&D to enhance battery performance and sustainability.

This evolution underscores the importance of staying informed about market shifts and technological innovations, allowing B2B buyers to make informed decisions when sourcing Li-ion battery packs. Understanding these historical contexts can help in identifying reliable suppliers who are not only responsive to current trends but are also future-ready in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of li ion battery pack china

-

How do I ensure the quality of lithium-ion battery packs sourced from China?

To ensure the quality of lithium-ion battery packs, it’s essential to conduct thorough supplier vetting. Start by requesting samples to evaluate performance and safety standards. Verify the manufacturer’s certifications, such as ISO 9001 and relevant safety certifications like UL and CE. Additionally, consider hiring third-party inspection services to conduct audits or on-site inspections before bulk purchases. Engaging in regular communication with suppliers can also help monitor production processes and maintain quality assurance. -

What are the key factors to consider when selecting a supplier for lithium-ion battery packs?

When selecting a supplier, consider their manufacturing capabilities, experience in the industry, and reputation. Look for suppliers with proven track records in producing high-quality lithium-ion batteries. Evaluate their technical support and after-sales service, as these can be crucial for resolving issues post-purchase. Additionally, assess their financial stability and production capacity to ensure they can meet your demand without compromising on quality. -

What customization options are available for lithium-ion battery packs from Chinese suppliers?

Many Chinese manufacturers offer customization options for lithium-ion battery packs, including size, shape, capacity, and voltage. You can also request specific features such as built-in battery management systems (BMS) or enhanced thermal management solutions. When approaching a supplier, provide detailed specifications and requirements to facilitate the customization process. Keep in mind that extensive customizations may affect lead times and minimum order quantities (MOQs). -

What are the typical minimum order quantities (MOQs) for lithium-ion battery packs in China?

MOQs for lithium-ion battery packs can vary significantly among suppliers, often ranging from 100 to 1,000 units or more, depending on the product type and customization level. Larger orders typically lead to lower per-unit costs, so it’s beneficial to assess your demand accurately before placing an order. If your needs fall below the MOQ, some suppliers may offer flexibility or charge a premium for smaller quantities. -

What payment terms should I expect when sourcing lithium-ion battery packs from China?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer payment via letters of credit or other secure methods to protect both parties. Ensure you clarify payment terms upfront to avoid misunderstandings. It’s also advisable to consider using escrow services for large transactions to safeguard your investment. -

How do I manage logistics and shipping for lithium-ion battery packs from China?

Managing logistics for lithium-ion battery packs involves selecting reliable shipping partners experienced with hazardous materials. Lithium-ion batteries are classified as dangerous goods, which can complicate shipping processes. Work with your supplier to determine the best shipping method (air freight, sea freight, etc.) based on cost and urgency. Additionally, consider using a freight forwarder to streamline customs clearance and ensure compliance with international shipping regulations. -

What are the common challenges faced when importing lithium-ion battery packs from China?

Common challenges include navigating complex import regulations, ensuring compliance with safety and environmental standards, and managing lead times. Additionally, fluctuations in shipping costs and potential delays in customs can impact delivery schedules. To mitigate these risks, it’s crucial to conduct thorough research on regulations in your target market and maintain open communication with your supplier and logistics provider. -

How can I stay informed about the latest trends in lithium-ion battery technology?

To stay updated on the latest trends in lithium-ion battery technology, engage with industry publications, attend trade shows, and participate in relevant webinars. Joining industry associations or forums can also provide valuable insights and networking opportunities. Additionally, consider subscribing to newsletters or following reputable manufacturers and technology companies on social media for real-time updates on innovations and market developments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for li ion battery pack china

The landscape of strategic sourcing for lithium-ion battery packs from China is evolving rapidly, driven by technological advancements and increasing global demand. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of this market is crucial. Key takeaways include the importance of establishing strong relationships with reliable suppliers, leveraging local expertise to navigate regulatory frameworks, and continuously assessing supply chain risks to mitigate disruptions.

Investing in strategic sourcing not only enhances procurement efficiency but also positions companies to capitalize on the competitive pricing and innovation offered by Chinese manufacturers. As the demand for sustainable energy solutions continues to rise, buyers should prioritize suppliers that demonstrate commitment to environmental standards and quality certifications.

Looking ahead, the potential for growth in emerging markets presents a significant opportunity. B2B buyers are encouraged to explore partnerships with Chinese manufacturers that align with their strategic goals, ensuring they remain competitive in an increasingly electrified world. Embrace the future of energy storage by integrating strategic sourcing practices that drive both profitability and sustainability.