Unlock Savings: The Ultimate Lamp Custom Guide (2025)

Introduction: Navigating the Global Market for lamp custom

In today’s fast-paced global market, sourcing custom lamps that meet specific business needs can be a daunting challenge for international B2B buyers. The complexity of selecting the right designs, materials, and suppliers can lead to confusion and costly mistakes. This guide aims to demystify the process of navigating the custom lamp market, providing essential insights into various types of lamps, their applications, and how to effectively vet suppliers.

From understanding the latest trends in sustainable lighting solutions to evaluating the best manufacturing practices in regions like Africa, South America, the Middle East, and Europe, this comprehensive resource is designed to empower informed purchasing decisions. Buyers will find actionable strategies to assess costs, quality, and supplier reliability, ensuring that they can confidently procure custom lamps that align with their brand identity and operational requirements.

By leveraging the insights presented in this guide, B2B buyers can streamline their sourcing processes, mitigate risks, and enhance their overall product offerings. Whether you are looking to illuminate a corporate space or add flair to retail environments, understanding the nuances of the custom lamp market is crucial for achieving business success in a competitive landscape.

Understanding lamp custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Custom Lamps | Energy-efficient, long lifespan, various designs | Retail, hospitality, office lighting | Pros: Low energy costs, diverse styles. Cons: Initial investment may be higher. |

| Smart Custom Lamps | Integrates with IoT, adjustable settings, remote control | Smart homes, modern offices, exhibitions | Pros: Enhanced control, energy savings. Cons: Requires technical setup and compatibility. |

| Vintage Custom Lamps | Retro designs, unique materials, handcrafted options | Boutique stores, themed restaurants | Pros: Distinctive aesthetics, high demand. Cons: Potentially higher maintenance and costs. |

| Industrial Custom Lamps | Robust construction, minimalist design, often metal | Warehouses, factories, loft-style spaces | Pros: Durability, unique style. Cons: Limited design options may not suit all tastes. |

| Eco-friendly Custom Lamps | Sustainable materials, low environmental impact | Green buildings, eco-conscious businesses | Pros: Appeals to sustainability-focused clients. Cons: May have limited availability and higher costs. |

What are the Characteristics and Suitability of LED Custom Lamps?

LED custom lamps are known for their energy efficiency and longevity, making them an excellent choice for various B2B applications. They come in a multitude of designs, allowing businesses to select options that align with their branding or aesthetic preferences. When purchasing LED lamps, B2B buyers should consider the initial investment versus long-term energy savings, as well as the potential for customization in terms of color and brightness.

How Do Smart Custom Lamps Enhance Business Operations?

Smart custom lamps are at the forefront of modern lighting solutions, integrating seamlessly with Internet of Things (IoT) technology. These lamps allow businesses to control lighting remotely, adjust settings based on occupancy, and even schedule lighting for optimal energy usage. B2B buyers should evaluate the technical compatibility of these lamps with existing systems and consider the long-term operational efficiencies they can offer, despite the need for initial setup and potential training.

Why Choose Vintage Custom Lamps for a Unique Aesthetic?

Vintage custom lamps provide a unique charm that can significantly enhance the ambiance of retail spaces and themed restaurants. Often handcrafted from distinctive materials, these lamps stand out in a crowded marketplace. However, buyers should be mindful of the potential for higher maintenance costs and the need for sourcing from specialized suppliers. Understanding the demand for vintage aesthetics can also help businesses position themselves effectively in their respective markets.

What Makes Industrial Custom Lamps Ideal for Certain Environments?

Industrial custom lamps are characterized by their robust construction and minimalist design, making them suitable for warehouses and factories. Their unique style often appeals to businesses looking for a modern yet functional aesthetic. When considering industrial lamps, B2B buyers should assess their durability and how well they can withstand harsh environments, alongside the limited variety in design options that may not cater to every business’s branding needs.

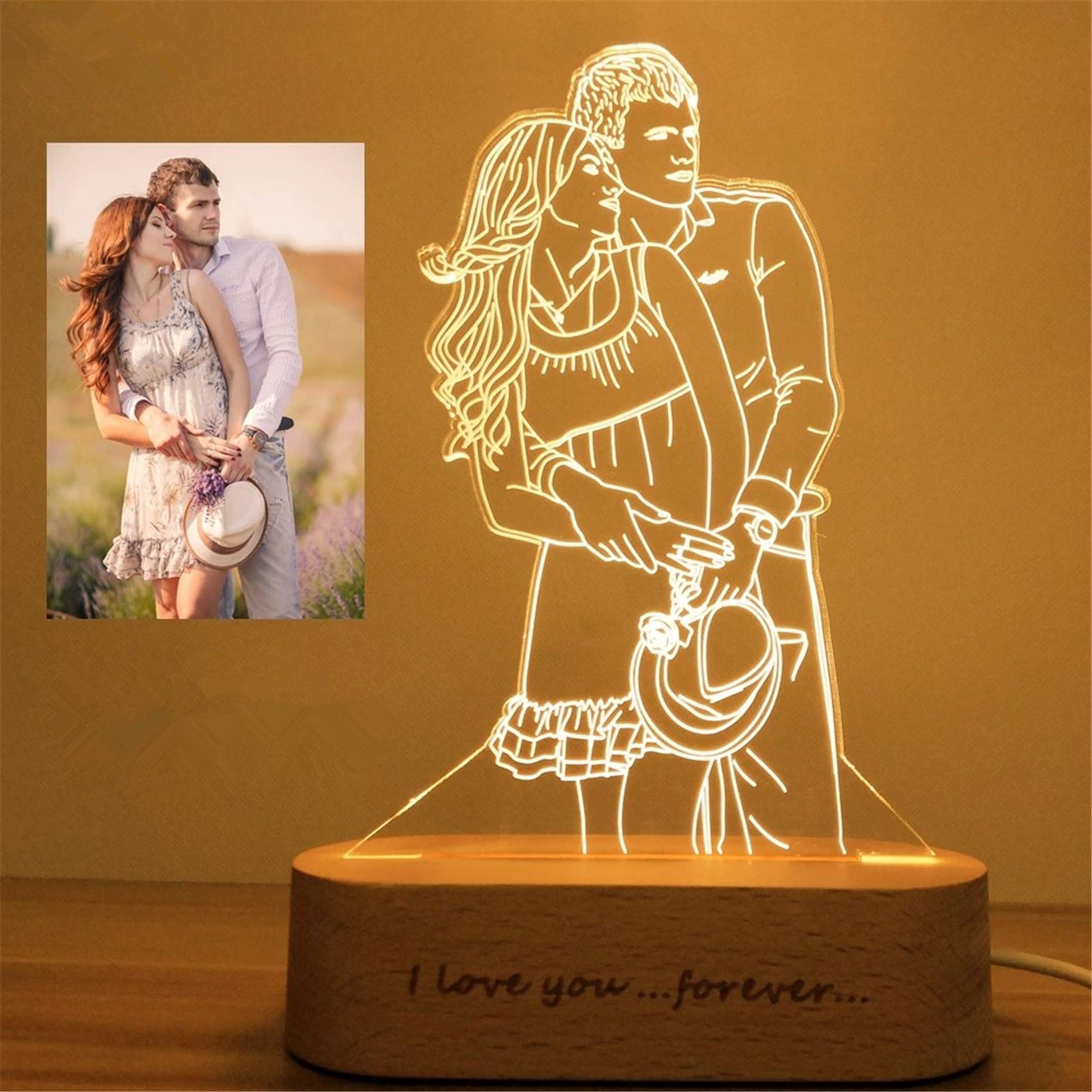

A stock image related to lamp custom.

How Do Eco-friendly Custom Lamps Align with Sustainable Business Practices?

Eco-friendly custom lamps are designed using sustainable materials and are focused on reducing environmental impact, making them ideal for green buildings and eco-conscious businesses. These lamps not only appeal to clients who prioritize sustainability but also enhance corporate responsibility initiatives. B2B buyers should consider the availability of these products and the potential for higher costs, as well as the marketing advantages of aligning with eco-friendly practices.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of lamp custom

| Industry/Sector | Specific Application of lamp custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Custom decorative lighting for hotels | Enhances guest experience and brand image | Quality materials, energy efficiency, and design options |

| Automotive | Tailored lighting for vehicle interiors | Improves safety and aesthetic appeal | Compliance with automotive standards and durability |

| Retail | Bespoke display lighting solutions | Increases product visibility and sales | Versatility in design and compatibility with fixtures |

| Manufacturing | Specialized industrial lighting systems | Boosts productivity and safety in workspaces | Compliance with safety regulations and energy efficiency |

| Healthcare | Custom lighting for medical facilities | Supports patient well-being and operational efficiency | Hygiene standards and adaptability to various environments |

How is Custom Lighting Used in the Hospitality Industry?

In the hospitality sector, custom decorative lighting plays a crucial role in enhancing the ambiance of hotels and restaurants. By integrating unique designs, businesses can create memorable experiences that align with their brand identity. For international buyers, particularly from regions like Africa and the Middle East, sourcing high-quality, energy-efficient lighting that adheres to local aesthetic preferences is essential. Additionally, considerations around installation and maintenance can impact long-term value.

What Are the Benefits of Custom Lighting in the Automotive Sector?

Custom lighting solutions in the automotive industry focus on enhancing vehicle interiors with tailored ambient lighting. This not only improves safety by illuminating critical areas but also elevates the overall aesthetic appeal of the vehicle. Buyers from South America and Europe must ensure that their sourcing partners comply with stringent automotive standards, focusing on durability and resistance to environmental factors. A strong emphasis on innovation can also lead to competitive advantages in this rapidly evolving market.

How Does Custom Lighting Impact Retail Environments?

In retail, bespoke display lighting solutions are vital for increasing product visibility and driving sales. Custom lights can highlight merchandise effectively, creating an engaging shopping experience that attracts customers. For B2B buyers in Europe and Africa, it’s crucial to consider the versatility of designs and compatibility with existing fixtures. Additionally, sourcing energy-efficient options can significantly reduce operational costs, enhancing profitability over time.

Why is Specialized Industrial Lighting Important in Manufacturing?

Specialized industrial lighting systems are essential for boosting productivity and ensuring safety in manufacturing environments. Custom lighting can be tailored to specific workspaces, reducing eye strain and improving visibility for tasks requiring precision. Buyers from the Middle East and South America should prioritize suppliers who understand compliance with safety regulations and energy efficiency standards. This approach not only enhances worker safety but also contributes to overall operational efficiency.

How is Custom Lighting Beneficial for Healthcare Facilities?

A stock image related to lamp custom.

In healthcare, custom lighting solutions are designed to support patient well-being and operational efficiency in medical facilities. Proper lighting can influence mood, promote healing, and facilitate better medical procedures. International buyers, particularly in regions with diverse healthcare needs like Africa and Europe, must ensure that sourcing partners meet stringent hygiene standards while also providing adaptable lighting solutions for various healthcare environments. This focus on quality can lead to improved patient outcomes and satisfaction.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘lamp custom’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Custom Lamp Orders

The Problem: B2B buyers often face significant challenges when it comes to ensuring the quality of custom lamps. This issue is particularly pronounced when sourcing from international suppliers in regions like Asia or Europe. Language barriers, different quality standards, and varying manufacturing practices can lead to products that do not meet expectations, resulting in costly returns or project delays.

The Solution: To mitigate these risks, buyers should establish a rigorous quality assurance process. Start by creating a detailed specification sheet that outlines the exact requirements for the custom lamps, including materials, dimensions, and finish. Next, engage in thorough supplier vetting, which includes visiting manufacturing sites if possible or requesting product samples. Implementing a third-party quality control service can also be beneficial. This service can conduct inspections at various stages of production, ensuring that the final product aligns with your specifications before shipping. Additionally, building a strong relationship with suppliers through regular communication can enhance transparency and improve product quality.

Scenario 2: Meeting Diverse Regulatory Compliance Requirements for Custom Lamps

The Problem: International buyers often struggle to navigate the complex landscape of regulatory compliance when ordering custom lamps. Different regions, such as the EU, Middle East, and Africa, have varying safety and environmental standards. This can lead to delays in the importation process, potential fines, and the risk of having products that cannot be sold in the target market.

The Solution: To avoid compliance issues, it is crucial for buyers to conduct thorough research on the regulatory requirements specific to their markets. This includes understanding certifications such as CE marking in Europe or SASO standards in Saudi Arabia. Collaborating with a knowledgeable local partner or hiring compliance consultants can provide valuable insights into local regulations. When sourcing custom lamps, ensure that suppliers are familiar with and can comply with these regulations. Request detailed documentation and certifications before placing orders. Additionally, maintaining an open line of communication with customs officials can help preemptively address any compliance-related concerns.

Scenario 3: Managing Lead Times and Supply Chain Disruptions in Custom Lamp Production

The Problem: Another common pain point for B2B buyers is managing lead times and potential supply chain disruptions, particularly when dealing with custom lamp orders. Factors such as raw material shortages, shipping delays, or sudden changes in demand can lead to extended lead times, which can significantly impact project timelines and customer satisfaction.

The Solution: To effectively manage lead times, buyers should adopt a proactive approach by developing a robust supply chain strategy. Start by diversifying your supplier base to reduce dependency on a single source. This allows for greater flexibility in times of disruption. Implementing just-in-time inventory practices can also help manage stock levels while keeping costs down. Regularly communicate with suppliers about market trends and potential disruptions, and consider establishing safety stock levels for critical components. Additionally, using project management tools to track timelines and milestones can help identify potential delays early and allow for timely adjustments to project plans. By fostering strong relationships with suppliers and maintaining transparency, buyers can better navigate the complexities of custom lamp production and delivery.

Strategic Material Selection Guide for lamp custom

When selecting materials for custom lamps, international B2B buyers must consider various factors that influence the performance, durability, and compliance of the final product. Below, we analyze four common materials used in lamp custom manufacturing: aluminum, glass, plastic, and steel. Each material comes with its unique properties, advantages, disadvantages, and implications for specific applications.

What Are the Key Properties of Aluminum in Lamp Custom Manufacturing?

Aluminum is a lightweight, corrosion-resistant metal that is often used in lamp custom designs. Its excellent thermal conductivity allows for efficient heat dissipation, making it suitable for high-temperature applications. Additionally, aluminum can be anodized to enhance its surface properties, increasing durability and aesthetic appeal.

Pros & Cons: Aluminum is relatively easy to manufacture and can be shaped into complex designs, which is advantageous for custom lamp applications. However, it may not be as durable as other metals like steel, particularly in high-impact environments. The cost of aluminum is moderate, making it a popular choice among manufacturers.

Impact on Application: Aluminum is compatible with various media and is often used in outdoor lighting due to its resistance to corrosion. However, buyers should consider local climate conditions, as extreme temperatures may affect the longevity of aluminum components.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is crucial, particularly in Europe and the UK. Buyers should also be aware of local regulations regarding the recycling of aluminum products, as sustainability is becoming increasingly important.

How Does Glass Perform as a Material for Custom Lamps?

Glass is a traditional choice for lamp custom applications, known for its aesthetic qualities and versatility. It can withstand high temperatures and is available in various forms, including tempered and frosted glass, which can enhance light diffusion.

Pros & Cons: The main advantage of glass is its ability to provide a high-quality aesthetic finish, making it ideal for decorative lamps. However, glass is fragile and can break easily, which may not be suitable for all environments. The manufacturing process for glass can also be complex and costly, especially for custom shapes.

Impact on Application: Glass is compatible with various light sources, including LED and incandescent bulbs. However, it is essential to ensure that the glass used can withstand the heat generated by the specific light source.

Considerations for International Buyers: Buyers should ensure compliance with safety standards, particularly regarding the use of tempered glass in regions with stringent regulations. In markets like the Middle East, where high temperatures are common, selecting the right type of glass is critical.

What Are the Advantages and Limitations of Plastic in Lamp Customization?

Plastic is increasingly popular in lamp custom applications due to its lightweight nature and versatility. It can be molded into intricate designs and is available in various colors and finishes.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, making it ideal for mass production. However, plastics can be less durable than metals or glass, particularly in high-temperature applications, and may degrade over time when exposed to UV light.

Impact on Application: Plastic is suitable for indoor applications and can be used in various lighting fixtures. However, its compatibility with specific light sources should be evaluated, as some plastics may not withstand high temperatures.

Considerations for International Buyers: Buyers should be aware of the different types of plastics available and their respective compliance with international standards. In regions like South America, where environmental regulations are evolving, selecting recyclable plastics may enhance marketability.

How Does Steel Compare as a Material for Custom Lamps?

Steel is a robust and durable material that is often used in industrial-style lamp designs. It offers excellent strength and can withstand high impacts, making it suitable for both indoor and outdoor applications.

Pros & Cons: The key advantage of steel is its durability and resistance to wear and tear. However, it is heavier than aluminum and can be more expensive to manufacture, particularly if intricate designs are required. Steel also requires protective coatings to prevent rusting, which can add to the cost.

Impact on Application: Steel is compatible with various lighting technologies and is often used in commercial and industrial settings. Buyers should consider the environment in which the lamp will be used, as untreated steel may corrode in humid or coastal areas.

Considerations for International Buyers: Compliance with standards such as JIS in Japan or DIN in Germany is essential. In the Middle East, where humidity can be high, selecting stainless steel or coated options may be necessary to ensure longevity.

Summary Table of Material Selection for Lamp Custom

| Material | Typical Use Case for lamp custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Outdoor lighting fixtures | Lightweight and corrosion-resistant | Less durable in high-impact situations | Medium |

| Glass | Decorative lamps | High aesthetic quality | Fragile and can break easily | High |

| Plastic | Indoor lighting | Low cost and easy to manufacture | Less durable and UV degradation | Low |

| Steel | Industrial lamp designs | Excellent durability | Heavy and requires protective coating | High |

In conclusion, the strategic selection of materials for custom lamps is critical for ensuring product performance and compliance with international standards. By understanding the properties, advantages, and limitations of each material, B2B buyers can make informed decisions that align with their specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for lamp custom

What Are the Main Stages in the Manufacturing Process for Custom Lamps?

The manufacturing of custom lamps involves a series of well-defined stages, each critical for ensuring the final product meets both aesthetic and functional standards. Understanding these stages can help B2B buyers identify the capabilities of potential suppliers and the quality of the products they offer.

Material Preparation: What Materials Are Used in Custom Lamp Manufacturing?

The first stage of manufacturing custom lamps is material preparation. Common materials include metals, plastics, glass, and ceramics. Buyers should inquire about the sourcing of these materials, as the quality can significantly affect the durability and performance of the lamps. For instance, high-grade aluminum or stainless steel is often preferred for frames due to their strength and corrosion resistance.

In addition to raw materials, buyers should also consider the sustainability of the materials used. Many manufacturers now offer eco-friendly options that can appeal to environmentally conscious markets, particularly in regions like Europe and parts of Africa.

Forming: How Are Custom Lamp Components Shaped?

The forming stage involves shaping the prepared materials into specific components of the lamp. Techniques can vary widely based on the material used. For metals, processes such as stamping, bending, and extrusion are common. For glass, methods like blowing and molding are prevalent.

Buyers should look for manufacturers who utilize advanced forming techniques, as these can lead to more intricate designs and better overall quality. Additionally, technologies such as CNC machining and laser cutting can enhance precision and reduce waste, aligning with sustainability goals.

Assembly: What Are the Key Steps in Assembling Custom Lamps?

Once individual components are formed, the next step is assembly. This process often includes wiring, fitting electrical components, and ensuring that all parts fit together seamlessly. B2B buyers should ensure that suppliers have skilled labor and automated processes in place to guarantee consistency and efficiency during assembly.

Quality assurance during assembly is crucial. Suppliers should have protocols to check for defects in electrical connections and physical assembly, which can impact the lamp’s safety and performance.

Finishing: How Does the Finishing Process Affect Quality?

The final stage, finishing, involves painting, polishing, or applying coatings to enhance the lamp’s aesthetic appeal and durability. Techniques such as powder coating and anodizing can provide protective layers that resist wear and tear, making the lamps suitable for various environments.

Buyers should ask about the finishing processes used by suppliers, as high-quality finishes can greatly enhance the product’s marketability. Additionally, manufacturers should comply with relevant environmental regulations, especially in Europe, where strict standards apply.

What Quality Assurance Measures Are Essential for Custom Lamps?

Quality assurance (QA) is a critical aspect of the manufacturing process for custom lamps, ensuring that products meet both international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 play a significant role in quality assurance for lamp manufacturers. This standard focuses on quality management systems and is essential for ensuring consistent quality in production processes.

In addition to ISO standards, specific certifications like CE marking in Europe and API certifications in certain markets can be crucial. These certifications often indicate compliance with safety and performance standards that are recognized globally, offering buyers assurance about the quality and safety of the products.

What Are the Key Quality Control Checkpoints in Lamp Manufacturing?

Quality control in lamp manufacturing typically involves several critical checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified quality standards. This initial check can prevent defects from entering the production process.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections to monitor the production line. This step helps identify issues early, allowing for corrective actions before the final product is assembled.

-

Final Quality Control (FQC): Once the lamps are assembled, FQC ensures that each unit meets the established quality criteria before shipment. This may involve functional testing and visual inspections.

What Testing Methods Are Commonly Used in Lamp Quality Assurance?

Various testing methods are employed to ensure that custom lamps meet safety and performance standards. Common methods include:

-

Electrical Testing: This involves checking the lamp’s electrical components for proper functioning, ensuring they meet safety standards to prevent hazards.

-

Durability Testing: Manufacturers may conduct tests to assess the lamp’s resistance to wear and tear, including exposure to different environmental conditions.

-

Light Output Testing: Measuring the brightness and efficiency of the lamp ensures it meets the specified performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can help buyers assess the manufacturing processes and quality control measures in place. Buyers should look for suppliers with transparent practices and a commitment to quality.

-

Request Quality Control Reports: Suppliers should be willing to provide documentation detailing their quality control measures, including inspection results and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. This is particularly valuable for buyers in regions where they cannot easily visit suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances based on regional standards and practices. For instance, buyers in Europe may face stricter compliance requirements compared to those in Africa or South America.

Additionally, cultural differences may influence communication regarding quality expectations. Buyers should ensure clear communication of their quality standards and expectations from the outset to avoid misunderstandings later in the process.

By understanding the manufacturing processes and quality assurance measures associated with custom lamps, international B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lamp custom’

Introduction

Sourcing custom lamps for your business can be a complex process, especially when navigating different markets and suppliers. This practical sourcing guide provides a step-by-step checklist designed to help international B2B buyers streamline their procurement process. By following these actionable steps, you can ensure that you select the right supplier and secure high-quality products tailored to your specific needs.

Step 1: Define Your Technical Specifications

Clearly defining your technical specifications is crucial for successful sourcing. This includes understanding the materials, dimensions, design features, and functionality of the custom lamps you need.

- Consider: Energy efficiency ratings, types of bulbs, and compliance with local regulations.

- Outcome: A well-defined specification will help suppliers provide accurate quotes and samples, reducing misunderstandings.

Step 2: Research Potential Suppliers

Conducting thorough research on potential suppliers is essential to identify reliable partners. Look for manufacturers who specialize in custom lamp production and have a proven track record.

- Where to look: Trade shows, industry directories, and online marketplaces such as Alibaba or Global Sources.

- Key factors: Evaluate suppliers based on their experience, product range, and customer reviews.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, ensure they possess the necessary certifications and standards relevant to your market. This is particularly important for safety and quality assurance.

- Important certifications: ISO 9001 for quality management and CE marking for compliance in Europe.

- Why it matters: Certifications provide assurance that the supplier adheres to international quality and safety standards, reducing risks associated with subpar products.

Step 4: Request Samples and Prototypes

Once you’ve shortlisted suppliers, request samples or prototypes of the custom lamps. This step allows you to evaluate the quality and craftsmanship firsthand.

- What to assess: Material quality, finish, and adherence to your specifications.

- Outcome: Sampling helps to mitigate risks and ensures that the final product meets your expectations.

Step 5: Negotiate Pricing and Terms

Effective negotiation can lead to favorable pricing and contract terms. Be prepared to discuss not only the cost but also payment terms, lead times, and minimum order quantities.

- Tips for negotiation: Establish a clear budget and be upfront about your needs to foster transparent discussions.

- Considerations: Factor in shipping costs and potential tariffs, especially if sourcing from different regions.

Step 6: Verify Production Capabilities

Understanding a supplier’s production capabilities is vital to ensure they can meet your order volume and deadlines.

- Questions to ask: What is their production capacity? Do they have contingency plans for delays?

- Why this matters: Reliable production capabilities can significantly impact your supply chain and inventory management.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership. Establish a clear communication plan that outlines how you will interact with the supplier throughout the sourcing process.

- Components of the plan: Regular updates, preferred communication channels, and points of contact.

- Goal: Ensuring that both parties are aligned on expectations and timelines, fostering a collaborative relationship.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing custom lamps more effectively, minimizing risks and maximizing value in their procurement efforts.

Comprehensive Cost and Pricing Analysis for lamp custom Sourcing

What Are the Key Cost Components in Lamp Custom Sourcing?

When sourcing custom lamps, understanding the cost structure is critical for international B2B buyers. The major cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals, glass, or sustainable options can elevate the price but also improve durability and aesthetic appeal. Buyers should consider the trade-off between cost and quality when selecting materials.

-

Labor: Labor costs vary by region and can affect the pricing of custom lamps. In regions with higher labor costs, such as parts of Europe, manufacturers may charge more. Buyers should investigate labor practices and consider suppliers that offer competitive labor rates while maintaining quality standards.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses incurred during production. Understanding these costs can help buyers gauge the pricing strategies of different suppliers.

-

Tooling: Custom lamp designs often require specialized tooling, which can add to the initial cost. It’s essential to factor in tooling costs when negotiating with suppliers, as these may be amortized over larger orders.

-

Quality Control (QC): Implementing QC processes ensures that the final products meet specified standards. Buyers should inquire about the QC measures employed by suppliers, as robust QC can prevent costly returns and dissatisfaction.

-

Logistics: Shipping costs can vary widely based on the shipping method, distance, and Incoterms. Buyers should account for logistics when evaluating total costs, as these can significantly affect the final price.

-

Margin: Suppliers will add their profit margin to the total production cost. Understanding the typical margins in the industry can provide leverage during negotiations.

How Do Price Influencers Affect Custom Lamp Sourcing?

Several factors influence the pricing of custom lamps:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically reduce the per-unit cost due to economies of scale. Buyers should evaluate their purchasing capacity to negotiate better pricing.

-

Specifications and Customization: More intricate designs or specific functionalities can increase costs. Buyers should clearly outline their specifications to avoid unexpected price hikes.

-

Materials: The selection of premium materials will naturally increase costs. Buyers should balance their desire for high-quality materials with budget constraints.

-

Quality Certifications: Compliance with international quality standards may add costs, but it can enhance the product’s marketability and safety. Buyers in regions like Europe often prioritize certified products.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge more due to their track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the chosen Incoterms is vital, as they dictate the responsibilities for shipping costs and risks. Buyers should negotiate terms that minimize their exposure to unforeseen costs.

What Are Effective Buyer Tips for Cost-Efficient Lamp Custom Sourcing?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

-

Negotiate Wisely: Establish a clear understanding of cost components and leverage this knowledge during negotiations. Being well-informed can lead to more favorable pricing.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, durability, and energy efficiency. A higher upfront cost may be justified by lower operational costs over time.

-

Understand Pricing Nuances: Different regions may have unique pricing structures influenced by local economic conditions, tariffs, and supply chain dynamics. Buyers should be aware of these nuances to make informed decisions.

-

Build Relationships with Suppliers: Developing strong relationships with suppliers can lead to better pricing and priority service. Open communication can foster trust and lead to more favorable terms.

Disclaimer on Indicative Prices

Prices for custom lamps can vary widely based on the aforementioned factors and regional market conditions. Therefore, it is essential for buyers to conduct thorough research and obtain quotes from multiple suppliers to ensure they are making informed decisions.

Alternatives Analysis: Comparing lamp custom With Other Solutions

When considering the best lighting solutions for your business, evaluating alternatives to ‘lamp custom’ is essential for informed decision-making. Custom lamps offer unique designs tailored to specific needs, but there are other viable options that may suit various requirements and budgets. This section explores alternative solutions, comparing them across several critical aspects.

| Comparison Aspect | Lamp Custom | LED Fixtures | Smart Lighting Solutions |

|---|---|---|---|

| Performance | High versatility in design | Excellent energy efficiency | Adaptive lighting settings |

| Cost | Higher initial investment | Moderate upfront costs | Higher upfront costs, but savings on energy bills over time |

| Ease of Implementation | Requires skilled artisans | Simple installation | May require smart home integration |

| Maintenance | Varies by design | Low maintenance | Moderate, depends on technology |

| Best Use Case | Unique ambiance projects | General lighting needs | Dynamic environments needing flexibility |

What Are the Benefits and Drawbacks of LED Fixtures Compared to Lamp Custom?

LED fixtures represent a popular alternative to lamp custom. They are known for their energy efficiency and long lifespan, making them a cost-effective option in the long run. Their performance is consistent, providing bright and clear illumination suitable for various settings, from offices to retail spaces. However, the aesthetic options can be limited compared to custom designs, which may not fulfill specific branding needs. Additionally, while installation is relatively straightforward, ensuring optimal placement for maximum effect may require some planning.

How Do Smart Lighting Solutions Compare to Lamp Custom in Terms of Functionality?

Smart lighting solutions have gained traction, especially in environments that require adaptability and control. These systems allow users to adjust brightness, color, and even scheduling through apps or voice commands, catering to dynamic business needs. While they offer advanced functionality, the initial investment can be higher than that of lamp custom or LED fixtures, and integration with existing systems may pose challenges. Maintenance may also be more complex due to the technology involved, which could require specialized knowledge.

What Factors Should B2B Buyers Consider When Choosing Between These Options?

Choosing the right lighting solution involves assessing your specific business requirements. If your priority is unique design and ambiance, lamp custom may be the best fit despite higher costs and maintenance needs. For businesses focused on energy efficiency and lower long-term costs, LED fixtures are an excellent alternative. Meanwhile, if your operations require flexibility and advanced control, smart lighting solutions could enhance productivity and adaptability.

Conclusion: Making an Informed Decision for Your Business’s Lighting Needs

B2B buyers must evaluate their specific needs, budget constraints, and desired outcomes when comparing lamp custom to alternative solutions like LED fixtures and smart lighting. By understanding the distinct advantages and limitations of each option, decision-makers can select a lighting solution that not only meets their functional requirements but also aligns with their overall business strategy.

Essential Technical Properties and Trade Terminology for lamp custom

What Are the Key Technical Properties for Custom Lamps?

When considering custom lamps, understanding the essential technical properties is crucial for ensuring product quality and compatibility with your specific requirements. Here are some critical specifications to keep in mind:

-

Material Grade

The material grade refers to the quality of the materials used in lamp construction, including metals, plastics, and glass. Common materials include aluminum for its lightweight properties and durability, and glass for its aesthetic appeal. Choosing the right material grade affects not only the lamp’s appearance but also its longevity and performance, which are vital considerations for B2B buyers seeking reliable products. -

Tolerance

Tolerance indicates the allowable deviation from specified dimensions in the manufacturing process. In lamp customizations, precise tolerances are essential for ensuring that components fit together seamlessly. Understanding tolerance levels helps buyers avoid issues related to assembly and functionality, which can lead to costly delays and rework. -

Wattage and Lumens

Wattage measures the energy consumption of the lamp, while lumens quantify the light output. A higher lumen count indicates brighter illumination, which is important for applications requiring specific lighting conditions. For B2B buyers, selecting the right wattage and lumens can enhance energy efficiency and meet regulatory standards, making it a critical aspect of the purchasing decision. -

Color Temperature

Color temperature, measured in Kelvin (K), describes the hue of the light emitted by the lamp. Warm white light (around 2700K) is often preferred for residential settings, while cooler temperatures (5000K and above) are suitable for commercial environments. Understanding color temperature helps buyers choose lamps that create the desired ambiance and meet the specific needs of their target market. -

IP Rating (Ingress Protection)

The IP rating indicates the level of protection a lamp has against dust and water ingress. For instance, an IP65 rating means the lamp is dust-tight and can withstand low-pressure water jets. This specification is particularly crucial for outdoor or industrial applications, as it impacts the durability and safety of the lighting solution.

What Are Common Trade Terms in the Lamp Custom Industry?

Familiarity with industry terminology is vital for smooth communication and efficient transactions in the lamp custom market. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the lamp industry, buyers may choose to work with OEMs to create custom designs that align with their branding and specifications. Understanding OEM relationships can streamline the procurement process and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to assess whether a supplier meets their order volume needs. This term is particularly relevant for international buyers, as it can impact overall costs and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for specific products or services. It is a key step in the procurement process, allowing buyers to compare offers and negotiate terms. Crafting a clear and detailed RFQ can lead to better pricing and terms, benefiting the buyer. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who bears the risk and costs associated with shipping, delivery, and customs clearance. Familiarity with Incoterms is crucial for B2B buyers to ensure smooth logistics and avoid misunderstandings. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is vital for project planning and inventory management, especially for international buyers who may face longer shipping durations. Accurate lead time estimates help businesses align their operations with customer expectations. -

Certification Standards

Certification standards, such as CE or UL, indicate that a lamp has met specific safety and performance criteria. These certifications are important for compliance with local regulations and can influence a buyer’s decision, especially in regions with stringent safety laws. Understanding these standards can help buyers mitigate risks associated with product liability.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom lamps, ultimately enhancing their business operations and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the lamp custom Sector

What Are the Current Market Dynamics and Sourcing Trends in the Lamp Custom Sector?

The lamp custom sector is experiencing a transformative phase driven by technological advancements and changing consumer preferences. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several key trends shaping the market.

Firstly, the integration of smart technology into lighting solutions is on the rise. Smart lamps that can be controlled via mobile apps or voice-activated systems are gaining traction, catering to both commercial and residential markets. This trend reflects a broader shift toward automation and IoT (Internet of Things) in various industries. Buyers should consider suppliers who offer customizable smart lighting options that can be tailored to specific client needs.

Secondly, sustainability is becoming a crucial factor in sourcing decisions. With increasing awareness about climate change and energy consumption, many businesses are looking for suppliers who prioritize eco-friendly practices. This includes the use of energy-efficient LED technology and sustainable materials in lamp production. Buyers should actively seek partners who demonstrate a commitment to environmental responsibility, as this can enhance brand reputation and meet the growing demand for green products.

Lastly, the global supply chain dynamics are evolving. The COVID-19 pandemic highlighted vulnerabilities in sourcing, prompting businesses to rethink their strategies. Many companies are diversifying their supplier base and considering local sourcing to mitigate risks. International buyers should evaluate potential suppliers not only based on cost but also on their reliability and ability to adapt to changing market conditions.

How Is Sustainability Impacting the Lamp Custom Sector?

In today’s market, the environmental impact of products is under scrutiny, making sustainability a pivotal consideration for B2B buyers in the lamp custom sector. The production and disposal of lamps can significantly affect the environment, from resource extraction to energy consumption during use. As a result, ethical sourcing has become essential for businesses looking to align with consumer values and regulatory standards.

Buyers should prioritize suppliers who adopt sustainable practices, such as using recycled materials and minimizing waste in the production process. Certifications like Energy Star and CE mark can serve as indicators of a supplier’s commitment to energy efficiency and safety standards. Furthermore, sourcing from manufacturers that utilize sustainable materials—such as bamboo, recycled metals, or biodegradable plastics—can help reduce the overall carbon footprint associated with lamp production.

Another aspect of ethical sourcing involves transparency in supply chains. B2B buyers should inquire about the sourcing origins of materials and the labor practices employed in production. Ensuring that suppliers adhere to fair labor practices not only aligns with corporate social responsibility goals but also enhances brand reputation in the market.

What Is the Evolution of the Lamp Custom Sector?

The lamp custom sector has undergone significant evolution over the past few decades, influenced by technological advancements and shifting consumer preferences. Initially dominated by traditional incandescent bulbs, the industry saw a rapid transition towards compact fluorescent lamps (CFLs) and now, predominantly, to LED technology. This evolution is marked by a focus on energy efficiency, longevity, and versatility in design.

The rise of customization in the lamp sector reflects broader trends in consumer behavior, with buyers increasingly seeking unique and tailored solutions for their lighting needs. This shift has prompted manufacturers to invest in innovative design capabilities and flexible production techniques, allowing for greater personalization in lamp offerings.

As B2B buyers navigate this dynamic landscape, understanding these historical trends can provide valuable insights into current market demands and future opportunities in the lamp custom sector.

Frequently Asked Questions (FAQs) for B2B Buyers of lamp custom

-

How do I solve supply chain issues when sourcing custom lamps?

To mitigate supply chain issues when sourcing custom lamps, start by establishing strong relationships with multiple suppliers across different regions. Diversifying your supplier base can help reduce the risk of disruptions. Additionally, consider using technology for real-time tracking of shipments and inventory levels. Regular communication with suppliers about lead times and production schedules will also help you anticipate potential delays. Lastly, maintaining a buffer stock of essential components can provide a safety net during unforeseen supply chain interruptions. -

What is the best approach to vetting suppliers for custom lamps?

The best approach to vetting suppliers involves a multi-step process: first, check their certifications and compliance with international standards. Next, review their portfolio and client testimonials to gauge their expertise and reliability. Conduct on-site visits or virtual audits to assess their manufacturing capabilities and quality control processes. Additionally, request samples of their products to evaluate craftsmanship. Finally, consider their financial stability and responsiveness to inquiries, as these factors reflect their ability to meet your business needs consistently. -

What customization options are available for lamp designs?

Customization options for lamp designs are extensive and can include variations in size, shape, materials, and finishes. Many manufacturers offer bespoke solutions tailored to your specifications, allowing you to choose unique elements such as color schemes, lighting technology (e.g., LED), and additional features like dimmers or smart controls. It’s essential to communicate your vision clearly and provide detailed specifications to the supplier to ensure the final product aligns with your expectations. -

What are the typical minimum order quantities (MOQs) for custom lamps?

Minimum order quantities (MOQs) for custom lamps can vary significantly based on the supplier and the complexity of the design. Generally, MOQs may range from 50 to several hundred units. When negotiating, be sure to discuss your specific needs and explore options for lower MOQs, especially if you are a new buyer. Some suppliers might offer flexibility based on the design or may allow for combined orders of different styles to meet MOQ requirements. -

What payment terms should I expect when ordering custom lamps?

Payment terms for custom lamp orders typically include a deposit upfront, usually ranging from 30% to 50%, with the balance due upon completion or before shipment. It’s crucial to negotiate terms that align with your cash flow needs. Some suppliers may offer payment through letters of credit, which can provide additional security. Always clarify the terms in the contract, including penalties for late payments or conditions for refunds in case of defects. -

How can I ensure quality assurance for custom lamps?

To ensure quality assurance for custom lamps, establish clear quality standards and specifications before production begins. Request regular updates and samples during the manufacturing process to verify that the product meets your requirements. Implement a final inspection procedure upon receipt of the goods, either through third-party quality inspectors or by your team. Additionally, consider including quality assurance clauses in your contract to protect against defects or non-compliance with agreed-upon standards. -

What logistics considerations should I keep in mind when importing custom lamps?

When importing custom lamps, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder who understands the complexities of international shipping. Be aware of any tariffs or duties that may apply to your products upon arrival in your country, as these can significantly impact your overall costs. Lastly, ensure you have appropriate insurance coverage during transit to protect against potential damages or losses. -

How do I handle communication barriers with international suppliers?

To handle communication barriers with international suppliers, first, establish clear and concise communication channels. Utilize tools like video calls, emails, and instant messaging for regular updates. If language is a concern, consider hiring a translator or using translation software to facilitate discussions. Always document conversations and agreements to avoid misunderstandings. Additionally, be patient and culturally sensitive, as different regions may have varying communication styles and business practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lamp custom

What Are the Key Takeaways for Strategic Sourcing in Lamp Customization?

Strategic sourcing in the lamp customization industry is essential for international B2B buyers seeking to optimize their supply chains and enhance product offerings. By prioritizing relationships with reliable suppliers, companies can ensure consistent quality and innovation in their custom lamp designs. Leveraging local resources and understanding regional market dynamics, particularly in Africa, South America, the Middle East, and Europe, can lead to significant cost savings and improved delivery timelines.

How Can Buyers Leverage Strategic Sourcing for Competitive Advantage?

Buyers should consider adopting a data-driven approach to sourcing, which includes analyzing market trends and consumer preferences. This insight allows companies to anticipate shifts in demand and adjust their sourcing strategies accordingly. Additionally, embracing sustainable practices in sourcing not only meets growing consumer expectations but can also yield long-term operational efficiencies.

What Should International B2B Buyers Do Next?

As the demand for customized lighting solutions continues to rise, now is the opportune time for international B2B buyers to refine their sourcing strategies. By focusing on strategic partnerships and innovative sourcing techniques, businesses can stay ahead of the competition. Engage with suppliers who share your vision for quality and sustainability, and explore new markets to expand your reach. Your proactive approach today will position your company for success in the evolving landscape of lamp customization.