Unlock Savings: The Ultimate Liquid Custom Guide (2025)

Introduction: Navigating the Global Market for liquid custom

In an increasingly interconnected world, international B2B buyers face the daunting challenge of sourcing liquid custom solutions that meet diverse regional needs. Whether you are in the bustling markets of Argentina or the thriving economies of the Middle East, navigating the complexities of supplier selection and product specifications can be overwhelming. This guide aims to streamline that process by providing a comprehensive overview of liquid custom options, including types, applications, and key factors to consider when vetting suppliers.

Understanding the nuances of liquid custom is essential for making informed purchasing decisions. This guide will explore various types of liquid custom products, from specialized formulations to tailored packaging solutions. It will also delve into the specific applications of these products across different industries, ensuring that you can align your sourcing strategy with your business objectives. Additionally, we will provide actionable insights on cost considerations and supplier evaluation criteria, equipping you with the knowledge needed to forge successful partnerships.

For B2B buyers from Africa, South America, the Middle East, and Europe, this guide serves as a valuable resource, empowering you to navigate the global market with confidence. By leveraging the insights provided here, you can mitigate risks, optimize your procurement strategy, and ultimately enhance your operational efficiency in sourcing liquid custom solutions that resonate with your unique market demands.

Understanding liquid custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Liquid Custom Formulas | Tailored mixtures based on specific client requirements | Cosmetics, Pharmaceuticals | Pros: Highly personalized; Cons: Longer lead times. |

| Liquid Custom Packaging | Unique packaging solutions for liquid products | Food & Beverage, Personal Care | Pros: Enhances brand identity; Cons: Higher costs. |

| Liquid Custom Blending | Combining different liquid components for specific outcomes | Industrial Chemicals, Food Products | Pros: Optimizes product performance; Cons: Complexity in sourcing. |

| Liquid Custom Labeling | Customized labeling solutions for compliance and branding | Pharmaceuticals, Food & Beverage | Pros: Ensures regulatory compliance; Cons: Additional design costs. |

| Liquid Custom Concentrates | High-concentration liquids designed for dilution | Cleaning Products, Beverages | Pros: Cost-effective shipping; Cons: Requires precise dilution knowledge. |

What Are Liquid Custom Formulas and Their B2B Relevance?

Liquid custom formulas are bespoke mixtures created to meet specific customer needs. They are particularly prevalent in industries such as cosmetics and pharmaceuticals, where unique compositions can significantly enhance product efficacy. For B2B buyers, key purchasing considerations include the supplier’s ability to meet regulatory standards and the flexibility of formulations. Buyers should also evaluate lead times, as custom formulations may require extended development periods, impacting production schedules.

How Does Liquid Custom Packaging Benefit Businesses?

Liquid custom packaging involves designing unique containers tailored to specific liquid products. This approach is highly beneficial in sectors like food and beverage and personal care, where packaging can influence consumer perception and brand loyalty. Buyers should assess the packaging’s compatibility with their products and its ability to protect contents while also enhancing visual appeal. However, custom packaging often comes with higher costs, necessitating a clear ROI analysis.

What Is Liquid Custom Blending and Why Is It Important?

Liquid custom blending refers to the process of combining various liquid components to achieve desired attributes, commonly utilized in industrial chemicals and food products. This method allows businesses to optimize product performance while ensuring consistency. B2B buyers should consider the supplier’s expertise in blending processes and their ability to maintain quality standards. The complexity of sourcing various components can pose challenges, making reliable partnerships essential for success.

Why Choose Liquid Custom Labeling Solutions?

Liquid custom labeling is crucial for compliance and branding in industries such as pharmaceuticals and food and beverage. Customized labels ensure that products meet regulatory requirements and convey necessary information to consumers. B2B buyers must evaluate the costs associated with custom labeling, including design and production, while also considering the potential for increased marketability. Effective labeling can differentiate products in competitive markets, making it a strategic investment.

What Are Liquid Custom Concentrates and Their Advantages?

Liquid custom concentrates are high-concentration solutions designed for dilution before use. They are widely used in cleaning products and beverages, offering significant shipping cost savings due to reduced volume. B2B buyers need to understand the precise dilution requirements to ensure product effectiveness and safety. While these concentrates can be cost-effective, they require careful handling and knowledge of proper usage, making supplier education and support critical in the purchasing process.

Related Video: The Calculus of Variations and the Euler-Lagrange Equation

Key Industrial Applications of liquid custom

| Industry/Sector | Specific Application of Liquid Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom Engine Oil Formulations | Enhanced engine performance and longevity | Compliance with regional regulations and quality standards |

| Food & Beverage | Custom Flavoring Solutions | Improved product differentiation and consumer appeal | Sourcing from certified suppliers to ensure safety and quality |

| Pharmaceuticals | Tailored Drug Delivery Systems | Increased efficacy and patient compliance | Need for stringent quality control and regulatory compliance |

| Agriculture | Customized Fertilizer Solutions | Optimized crop yield and reduced environmental impact | Availability of local suppliers and sustainability certifications |

| Chemical Manufacturing | Specialized Chemical Mixtures for Production Processes | Enhanced efficiency and cost savings in production | Understanding of local chemical regulations and safety protocols |

How is Liquid Custom Used in the Automotive Sector?

In the automotive industry, liquid custom is primarily utilized for formulating specialized engine oils that cater to specific vehicle requirements. By customizing the viscosity, additives, and performance characteristics, manufacturers can enhance engine performance and longevity. For B2B buyers in Africa, South America, and the Middle East, sourcing high-quality engine oils that comply with regional standards is essential. Buyers must consider local regulations and the supplier’s ability to provide consistent quality and performance.

What Role Does Liquid Custom Play in Food & Beverage Applications?

In the food and beverage sector, liquid custom is integral for creating tailored flavoring solutions that meet diverse consumer preferences. By developing unique flavors, companies can differentiate their products in a competitive market. B2B buyers, especially in Europe and South America, should prioritize sourcing from suppliers with the necessary certifications to ensure product safety and quality. Additionally, understanding local taste profiles can significantly enhance product acceptance and market success.

A stock image related to liquid custom.

How is Liquid Custom Transforming Pharmaceuticals?

Liquid custom applications in the pharmaceutical industry focus on developing tailored drug delivery systems that improve medication efficacy and patient compliance. By customizing formulations, companies can address specific therapeutic needs, resulting in better treatment outcomes. International B2B buyers must ensure that their suppliers adhere to strict quality control measures and regulatory compliance, particularly in regions with stringent pharmaceutical regulations. This focus on quality is critical for maintaining market trust and effectiveness.

In What Ways Does Liquid Custom Benefit Agriculture?

In agriculture, customized liquid fertilizers are designed to optimize crop yield while minimizing environmental impact. By formulating fertilizers that meet specific nutrient requirements, farmers can enhance productivity and sustainability. B2B buyers in regions like Africa and South America should consider sourcing from local suppliers who understand the regional agricultural landscape and can provide sustainable solutions. Ensuring that suppliers hold relevant sustainability certifications is also crucial for long-term viability.

How is Liquid Custom Enhancing Chemical Manufacturing?

Liquid custom plays a vital role in chemical manufacturing by enabling the formulation of specialized chemical mixtures tailored for various production processes. These custom solutions can enhance efficiency and reduce costs, making them attractive to businesses looking to optimize operations. For international B2B buyers, particularly in Europe and the Middle East, understanding local chemical regulations and safety protocols is essential when sourcing these products. Establishing relationships with suppliers who have a proven track record in compliance can mitigate risks and ensure operational continuity.

Related Video: Types Of Flowmeters And Their Industrial Applications.

3 Common User Pain Points for ‘liquid custom’ & Their Solutions

Scenario 1: Inconsistent Product Quality Leading to Supply Chain Disruptions

The Problem:

International B2B buyers often face the challenge of inconsistent product quality when sourcing liquid custom products. This is particularly relevant for businesses in Africa and South America, where local suppliers may not have the same quality control measures as established manufacturers in Europe or the Middle East. For example, a beverage manufacturer might receive a batch of custom flavoring that varies significantly in taste and viscosity, leading to production delays and dissatisfied customers.

The Solution:

To mitigate the risk of inconsistent quality, it is crucial to establish strong partnerships with reputable suppliers who prioritize quality assurance. Start by conducting a thorough vetting process that includes checking references and reviewing certifications. Implement a clear specification document that outlines your quality expectations, including viscosity, flavor concentration, and shelf-life. Additionally, consider arranging for third-party quality inspections before shipments are dispatched. This proactive approach not only helps ensure that the products meet your standards but also builds a reliable supply chain that enhances overall business performance.

Scenario 2: Complicated Regulatory Compliance for Custom Liquids

The Problem:

Navigating the regulatory landscape can be daunting for B2B buyers, especially when dealing with liquid custom formulations that may fall under various regulations depending on the region. For instance, a cosmetics company in Europe might struggle to comply with EU regulations while trying to source a unique custom formulation from a supplier in South America. Failing to meet these compliance requirements can result in costly fines or product recalls.

The Solution:

To successfully navigate regulatory compliance, invest in legal counsel or consultancy services that specialize in the regulations of both the supplier’s and your own country. Create a compliance checklist tailored to your specific product category, ensuring that all necessary documentation, such as safety data sheets and ingredient lists, are prepared ahead of time. Furthermore, maintain open communication with your suppliers about their compliance capabilities and ask for their documentation to streamline the process. This diligence not only minimizes risks but also fosters a transparent relationship with your suppliers.

Scenario 3: High Costs Associated with Low Minimum Order Quantities

The Problem:

Many international B2B buyers encounter high costs when sourcing liquid custom products due to suppliers’ minimum order quantities (MOQs). This issue is prevalent in the Middle East and Africa, where smaller businesses may need to order more than they can sell, leading to excess inventory and cash flow constraints. For example, a small beverage startup might find itself locked into a large order of a custom syrup that it cannot afford or sell within a reasonable timeframe.

The Solution:

To address high costs linked to MOQs, consider collaborating with other businesses to consolidate orders. Forming purchasing groups can help you meet suppliers’ MOQs while also reducing individual costs. Additionally, negotiate with suppliers to explore flexible ordering options, such as tiered pricing based on order size, which can make smaller orders more financially viable. Lastly, evaluate alternative suppliers who may offer more favorable MOQs or even custom formulations that allow for lower minimum orders. By taking these steps, you can optimize your purchasing strategy and maintain better control over your inventory and cash flow.

Strategic Material Selection Guide for liquid custom

When selecting materials for liquid custom applications, international B2B buyers must consider a variety of factors, including the properties of the materials, their suitability for specific applications, and compliance with regional standards. Here, we analyze four common materials used in liquid custom applications, highlighting their key properties, advantages, limitations, and important considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel in Liquid Custom Applications?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures. Its typical temperature rating can exceed 800°C (1472°F), making it suitable for a wide range of applications, including food and beverage processing, pharmaceuticals, and chemical manufacturing.

Pros & Cons: The durability of stainless steel is one of its significant advantages, as it can last for decades with minimal maintenance. However, its higher cost compared to other materials can be a drawback, especially for startups or smaller businesses. Manufacturing complexity can also be an issue, as stainless steel components often require specialized machining.

Impact on Application: Stainless steel is compatible with a wide variety of media, including corrosive chemicals, making it a versatile choice for many industries.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM A240 and EN 10088, as well as local regulations in their respective regions. In countries like Brazil and Argentina, it’s essential to consider local sourcing options to mitigate import costs.

How Does Polypropylene Perform in Liquid Custom Applications?

Polypropylene is a thermoplastic polymer known for its chemical resistance, lightweight nature, and cost-effectiveness. It typically operates effectively at temperatures up to 100°C (212°F) and has a good pressure rating, making it suitable for various applications, particularly in the chemical and agricultural sectors.

Pros & Cons: The primary advantage of polypropylene is its low cost and ease of manufacturing, allowing for rapid prototyping and production. However, it has lower temperature and mechanical strength compared to metals, which can limit its use in high-pressure applications.

Impact on Application: Polypropylene is compatible with many acids and bases, making it ideal for chemical handling. However, it may not be suitable for high-temperature liquids.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM D4101 and consider the availability of polypropylene in their region. In the Middle East, for example, local suppliers may offer competitive pricing.

What Are the Benefits of Using PTFE in Liquid Custom Applications?

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is celebrated for its exceptional chemical resistance and low friction properties. It can withstand temperatures up to 260°C (500°F) and is often used in applications involving aggressive chemicals.

Pros & Cons: The key advantage of PTFE is its unparalleled chemical resistance, making it suitable for highly corrosive environments. However, it is relatively expensive and can be challenging to machine, which may increase manufacturing complexity.

Impact on Application: PTFE is ideal for applications involving strong acids and bases, as well as high-purity environments like pharmaceuticals.

Considerations for International Buyers: Compliance with standards such as ASTM D4894 is crucial. Buyers in Europe should also consider the REACH regulations regarding chemical safety.

How Does PVC Compare in Liquid Custom Applications?

Polyvinyl Chloride (PVC) is a widely used plastic known for its durability and versatility. It can handle temperatures up to 60°C (140°F) and is often used in piping, fittings, and tanks.

Pros & Cons: PVC is cost-effective and easy to work with, making it a popular choice for many applications. However, its lower temperature tolerance and potential for brittleness at low temperatures can be significant drawbacks.

Impact on Application: PVC is suitable for water and wastewater applications but may not be suitable for high-temperature or highly corrosive liquids.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM D1784 and be aware of local regulations regarding plastic materials, particularly in regions with stringent environmental laws.

Summary Table of Material Selection for Liquid Custom Applications

| Material | Typical Use Case for liquid custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Polypropylene | Chemical handling, agricultural uses | Low cost, easy to manufacture | Limited temperature/pressure rating | Low |

| PTFE | Chemical processing, high-purity applications | Exceptional chemical resistance | Expensive, machining challenges | High |

| PVC | Water and wastewater applications | Cost-effective, versatile | Lower temperature tolerance | Low |

By carefully evaluating these materials and their properties, international B2B buyers can make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for liquid custom

What Are the Main Stages in the Manufacturing Process for Liquid Custom Products?

The manufacturing process for liquid custom products typically involves several key stages that ensure the final product meets the desired specifications and quality standards. Understanding these stages is essential for B2B buyers looking to source reliable suppliers.

-

Material Preparation: The first stage involves sourcing high-quality raw materials. This includes selecting appropriate liquids, additives, and packaging materials. Buyers should inquire about the supplier’s sourcing practices to ensure that materials comply with regional regulations and industry standards.

-

Forming: In this stage, the liquid is processed and mixed according to specific formulations. Techniques such as blending, emulsification, and homogenization are commonly used. For instance, in the cosmetics industry, emulsifiers are crucial for creating stable creams and lotions. B2B buyers should request detailed formulation documents to verify that the processes align with their requirements.

-

Assembly: For products requiring packaging, the assembly stage involves filling containers, labeling, and sealing. Automated systems are often used for efficiency, but manual processes may be employed for specialized products. Buyers should assess the supplier’s capabilities in terms of production scale and flexibility to accommodate custom orders.

-

Finishing: This final stage includes quality checks, packaging, and preparation for shipment. Processes such as sterilization, if applicable, ensure the product’s safety and longevity. B2B buyers should confirm the supplier’s finishing processes, especially if they require specific certifications.

How Do Quality Assurance Practices Ensure Product Reliability?

Quality assurance (QA) is a critical component of the manufacturing process for liquid custom products. It encompasses a range of practices and standards aimed at maintaining product integrity and safety. International B2B buyers should pay close attention to the following aspects:

-

International Standards: Many suppliers adhere to ISO 9001 standards, which focus on quality management systems. This certification indicates that the supplier consistently meets customer and regulatory requirements. Additionally, industry-specific standards like CE marking for Europe or API standards for petroleum products are crucial for compliance.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints:

– Incoming Quality Control (IQC): This initial inspection checks raw materials for conformity to specifications before production begins.

– In-Process Quality Control (IPQC): Ongoing assessments during manufacturing help catch any deviations from the established processes.

– Final Quality Control (FQC): This stage involves comprehensive testing of the finished product, including physical, chemical, and microbiological assessments. -

Common Testing Methods: Various testing methods are employed to ensure product quality, including:

– Spectroscopy: Used for analyzing the composition of liquids.

– Viscosity Testing: Essential for products like paints and coatings.

– Microbial Testing: Critical for cosmetics and food products to ensure safety.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control practices is paramount. Here are actionable steps to ensure that potential suppliers meet required standards:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing process firsthand. This includes reviewing documentation, observing operations, and assessing compliance with quality standards.

-

Quality Control Reports: Requesting detailed QC reports from suppliers helps buyers understand the outcomes of various quality checks. These reports should include data on testing results, corrective actions taken, and any non-conformance issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality practices. This is particularly useful for international buyers who may not have the resources to conduct audits themselves.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing liquid custom products from suppliers in different regions, B2B buyers must be aware of specific nuances related to quality control and certifications:

-

Regional Regulations: Different regions may have varying regulations and standards. For example, the European Union has strict regulations for cosmetic products under the EU Cosmetics Regulation, while some South American countries may have less stringent rules. Buyers should familiarize themselves with the regulatory landscape of their target market.

-

Cultural Considerations: Understanding cultural differences can impact quality perceptions. For instance, buyers from Africa may prioritize different aspects of product quality compared to those in Europe. Building strong relationships with suppliers can help bridge these gaps.

-

Documentation and Traceability: Ensuring proper documentation and traceability of products is essential. Buyers should demand that suppliers maintain comprehensive records of all manufacturing processes, quality checks, and certifications. This is especially important for industries like pharmaceuticals, where traceability is critical for compliance.

Conclusion

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for liquid custom products is crucial. By focusing on the key stages of manufacturing, verifying quality control practices, and recognizing regional nuances, buyers can make informed decisions and ensure the reliability of their suppliers. Establishing strong partnerships with manufacturers who adhere to international standards and demonstrate robust quality assurance processes will ultimately lead to successful sourcing outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘liquid custom’

The purpose of this guide is to provide international B2B buyers with a structured approach to sourcing ‘liquid custom’ solutions effectively. By following this checklist, you can ensure that you make informed decisions and partner with reliable suppliers that meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the type of liquid custom you need, its intended use, and any industry-specific regulations that apply. A detailed specification will help you communicate your needs effectively and filter out suppliers who cannot meet your standards.

Step 2: Conduct Market Research

Research the market landscape for liquid custom products in your target regions, such as Africa, South America, the Middle East, and Europe. Identify key players, market trends, and pricing benchmarks. Understanding the market will empower you to negotiate better terms and choose suppliers that align with your budget and quality expectations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering liquid custom solutions that meet your specifications.

- Key Considerations:

- Check online reviews and testimonials.

- Assess their experience in your specific market or industry.

Step 4: Request Samples and Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of their liquid custom products. This step allows you to assess quality firsthand and ensure that the products meet your specifications. Evaluating samples can save time and prevent costly mistakes later on.

Step 5: Verify Compliance and Certifications

Ensure that your potential suppliers comply with relevant industry standards and regulations. Certifications can provide assurance regarding the quality and safety of the products. Verify that they have the necessary certifications for your market, such as ISO, GMP, or other relevant standards.

Step 6: Negotiate Terms and Conditions

After selecting a supplier, engage in negotiations regarding pricing, delivery timelines, payment terms, and after-sales support. Clear agreements help prevent misunderstandings and ensure that both parties are aligned on expectations. Pay attention to the fine print, especially regarding warranties and liability clauses.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Establish clear channels for ongoing dialogue with your supplier, including points of contact and regular updates. This will facilitate problem-solving and ensure that any issues are addressed promptly.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing liquid custom products with confidence, ultimately leading to successful partnerships and better procurement outcomes.

Comprehensive Cost and Pricing Analysis for liquid custom Sourcing

When considering the cost structure for liquid custom sourcing, several key components play a crucial role in determining the final price. Understanding these components can empower international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

What Are the Key Cost Components in Liquid Custom Sourcing?

-

Materials: The type of materials used significantly impacts the cost. High-quality or specialized materials will increase expenses, while bulk purchasing may yield discounts. Buyers should analyze material choices based on their specific needs and budget constraints.

-

Labor: Labor costs can vary widely based on the supplier’s location. Regions with lower labor costs might offer more competitive pricing, but this could also affect quality. Buyers should consider the skill level of the labor force and ensure that it aligns with their quality expectations.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment maintenance. Understanding the supplier’s operational efficiency can help buyers gauge how overhead might influence the overall pricing.

-

Tooling: Custom tooling can represent a significant upfront investment. Buyers should inquire about tooling costs, especially for unique designs, and consider these when calculating total expenses.

-

Quality Control (QC): Implementing rigorous QC processes ensures product quality but adds to overall costs. Buyers should weigh the importance of quality against the associated costs, as poor quality can lead to higher long-term expenses.

-

Logistics: Shipping costs, including freight and insurance, must be factored into the total cost. The choice of Incoterms can greatly influence these logistics expenses, as they determine who bears the responsibility for shipping and insurance.

-

Margin: Finally, suppliers will include their profit margin in the pricing structure. Understanding typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Liquid Custom Sourcing?

Several factors can influence the price of liquid custom products:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs. Buyers should assess their needs against minimum order requirements to optimize costs.

-

Specifications and Customization: Highly customized products may incur additional costs. Buyers should clarify their needs upfront and consider whether customization is essential or if standard options suffice.

-

Materials and Quality Certifications: The presence of quality certifications can enhance trust but may also increase costs. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: Supplier reputation, experience, and location can all affect pricing. Building strong relationships with reputable suppliers can lead to better pricing and terms.

-

Incoterms: Different Incoterms can significantly impact the total cost, as they dictate shipping responsibilities. Buyers should familiarize themselves with these terms to negotiate favorable conditions.

What Are the Best Buyer Tips for Cost-Efficiency?

-

Negotiation Strategies: Effective negotiation can lead to significant savings. Buyers should prepare by researching industry standards and be ready to discuss volume commitments or long-term contracts for better rates.

-

Understanding Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should consider maintenance, operational costs, and potential wastage when evaluating suppliers. This holistic view can lead to more cost-effective decisions.

-

Pricing Nuances for International Buyers: Currency fluctuations and import duties can greatly affect pricing for buyers in Africa, South America, the Middle East, and Europe. It’s crucial to factor these into the budget and seek suppliers that offer stable pricing options.

-

Due Diligence on Suppliers: Conducting thorough due diligence on potential suppliers can uncover hidden costs or risks. Requesting references and conducting site visits can provide deeper insights into their operations.

Conclusion and Disclaimer

While this analysis provides a comprehensive overview of the cost structure and pricing factors for liquid custom sourcing, it is important to note that prices can vary widely based on specific circumstances and market conditions. Buyers should use this information as a guideline and conduct further research tailored to their unique needs and situations.

Alternatives Analysis: Comparing liquid custom With Other Solutions

In the rapidly evolving landscape of B2B solutions, understanding the alternatives to any technology or method is crucial for making informed decisions. For international buyers, particularly those from Africa, South America, the Middle East, and Europe, evaluating options like ‘liquid custom’ against other viable solutions can optimize operational efficiency and cost-effectiveness.

| Comparison Aspect | Liquid Custom | Alternative 1: Standard Liquid Solution | Alternative 2: Solid Custom Solution |

|---|---|---|---|

| Performance | High adaptability and customization | Moderate performance, less flexibility | High durability but limited customization |

| Cost | Higher initial investment but lower long-term costs | Lower upfront costs but higher operational costs | Moderate costs with potential hidden expenses |

| Ease of Implementation | Requires specialized knowledge | User-friendly and quick to implement | Complicated setup with steep learning curve |

| Maintenance | Low maintenance needs | Moderate maintenance requirements | High maintenance and monitoring needed |

| Best Use Case | Complex, variable environments | Simple applications with stable conditions | Long-term, stable use cases where durability is key |

What Are the Pros and Cons of Standard Liquid Solutions?

Standard liquid solutions are widely used across industries due to their ease of implementation. They are cost-effective upfront, making them attractive for businesses with limited budgets. However, they often lack the flexibility and adaptability that many modern operations require. In dynamic environments where changes are frequent, relying solely on standard solutions can lead to inefficiencies and increased costs over time.

How Does a Solid Custom Solution Compare?

Solid custom solutions offer exceptional durability and are ideal for long-term applications. They are particularly beneficial in industries where robustness is crucial, such as manufacturing and construction. However, their complexity can be a drawback, as they often require extensive training and setup time. Additionally, the maintenance costs can accumulate, making them less favorable for businesses looking for a low-maintenance option.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate solution, B2B buyers should evaluate their specific operational requirements, budget constraints, and long-term goals. If flexibility and adaptability are critical, ‘liquid custom’ may be the best option despite the higher initial costs. On the other hand, if the application is straightforward and cost is a primary concern, standard liquid solutions could suffice. For industries prioritizing durability, solid custom solutions are worth considering, but buyers should be mindful of the associated complexity and maintenance needs. Ultimately, the right choice will depend on a thorough analysis of these factors in relation to the unique demands of the business.

Essential Technical Properties and Trade Terminology for liquid custom

What Are the Key Technical Properties for Liquid Custom?

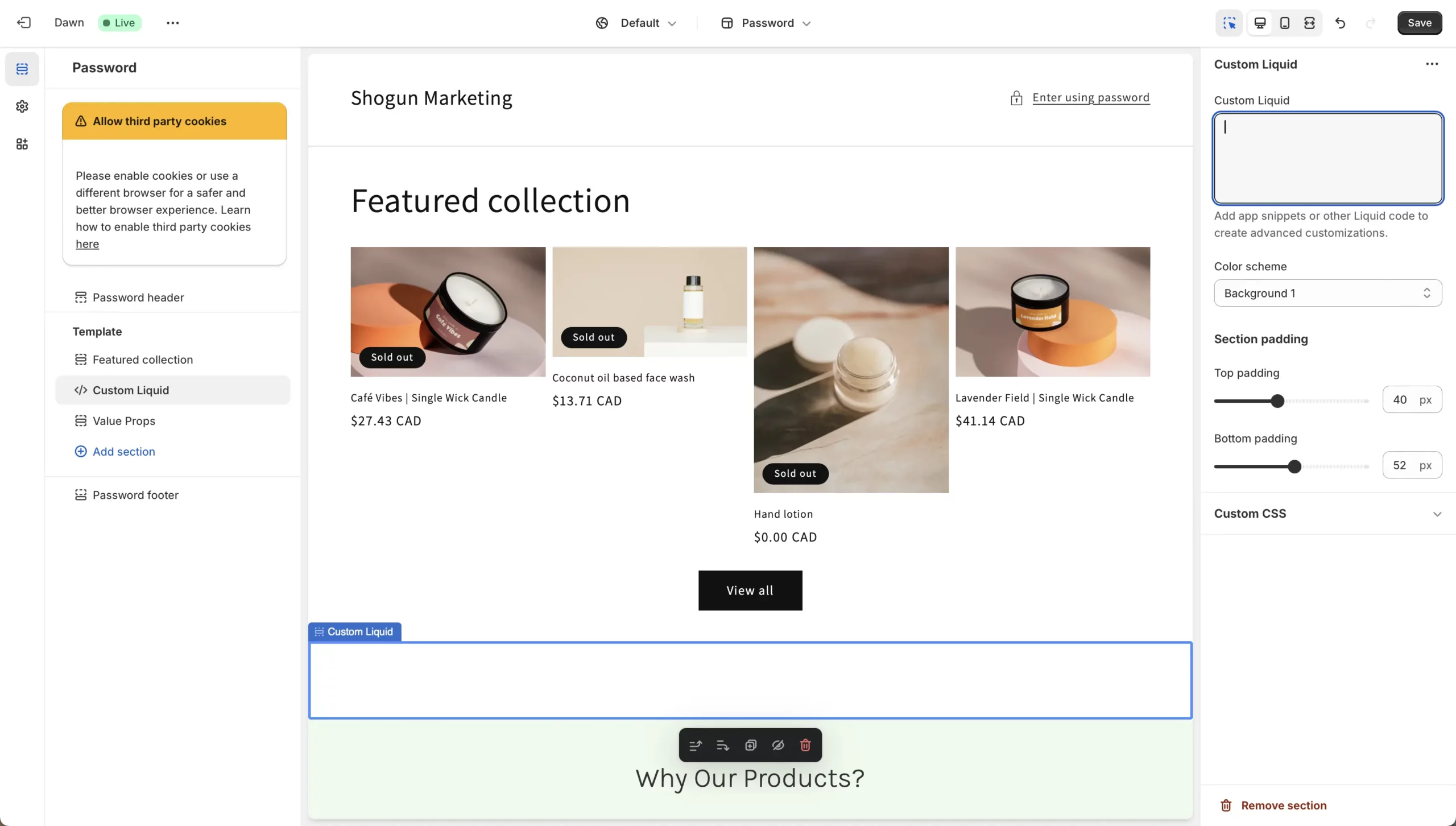

A stock image related to liquid custom.

When sourcing liquid custom products, understanding the technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties that international B2B buyers should consider:

-

Material Grade

– The material grade refers to the specific classification of the raw materials used in the product. For liquid custom applications, the grade affects durability, resistance to corrosion, and overall performance. Buyers should ensure that the material meets industry standards, as this can influence both longevity and safety in various applications. -

Viscosity

– Viscosity measures a liquid’s resistance to flow, which is critical in determining how a liquid custom product will perform under different conditions. High-viscosity liquids may require special handling and equipment, while low-viscosity products may be easier to transport. Understanding viscosity helps buyers select the right product for their specific application needs. -

Temperature Resistance

– Temperature resistance indicates the range of temperatures the liquid can withstand without degrading. This property is vital for applications exposed to extreme heat or cold. Buyers should assess the operating conditions to ensure that the liquid custom product will maintain its integrity and performance throughout its expected lifecycle. -

Chemical Compatibility

– Chemical compatibility refers to how well a liquid interacts with other materials, including packaging, storage containers, and other chemicals. Buyers must consider the environment in which the liquid will be used to prevent reactions that could compromise safety or efficacy. -

Density

– Density is the mass per unit volume of the liquid, affecting how it behaves during transport and storage. Higher-density liquids may require different handling techniques, while lower-density products can offer advantages in certain applications. Understanding density is essential for logistics planning and cost estimation.

What Are Common Trade Terms in the Liquid Custom Industry?

Familiarity with industry jargon can streamline communication and negotiations in the liquid custom market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces components or products that are marketed by another company. In the context of liquid custom, understanding OEM relationships can help buyers identify reliable suppliers who can meet specific design and quality requirements. -

MOQ (Minimum Order Quantity)

– MOQ is the minimum quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it affects inventory management and cost efficiency. Knowing the MOQ can help buyers gauge whether a supplier aligns with their purchasing capabilities and budget. -

RFQ (Request for Quotation)

– An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. Crafting a detailed RFQ can help ensure that buyers receive accurate and comparable pricing, leading to better purchasing decisions. It’s important to include specific technical properties and quantities in the RFQ to avoid misunderstandings. -

Incoterms (International Commercial Terms)

– Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for buyers to clarify shipping, insurance, and risk management. For example, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total costs. -

Lead Time

– Lead time refers to the time taken from placing an order to the delivery of the product. This term is particularly important in the liquid custom industry where timely delivery can be critical for production schedules. Buyers should always inquire about lead times when negotiating contracts to ensure alignment with their operational timelines.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the liquid custom Sector

What Are the Key Market Dynamics and Trends in the Liquid Custom Sector?

The liquid custom sector is witnessing significant transformation driven by globalization, technological advancements, and evolving consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must be aware of these dynamics to make informed sourcing decisions.

One of the primary global drivers is the increasing demand for customized liquid formulations across various industries, including food and beverage, cosmetics, and pharmaceuticals. Buyers are increasingly seeking suppliers that can provide tailored solutions to meet specific market needs. Emerging technologies such as artificial intelligence and machine learning are enhancing product development and supply chain efficiencies, allowing for more agile responses to market demands.

Additionally, the rise of e-commerce platforms is reshaping the sourcing landscape. Buyers can now access a broader range of suppliers globally, facilitating competitive pricing and diverse product options. However, this also means that B2B buyers must conduct thorough due diligence to ensure reliability and quality. Trends towards automation in manufacturing processes are also becoming prominent, reducing lead times and costs, which is crucial for buyers looking to optimize their operations.

How Is Sustainability Influencing Sourcing in the Liquid Custom Sector?

Sustainability is no longer a secondary consideration in sourcing; it has become a fundamental aspect of the supply chain. The environmental impact of production processes is a growing concern for B2B buyers, particularly in regions facing stricter regulations and increasing consumer awareness. Buyers from Africa, South America, the Middle East, and Europe are now prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical sourcing is vital in ensuring that supply chains do not contribute to environmental degradation or social injustices. Buyers should seek out partners who are transparent about their sourcing practices and can provide certifications such as Fair Trade, Rainforest Alliance, or ISO 14001. These certifications not only signify a commitment to sustainability but also enhance brand reputation and consumer trust.

Furthermore, the adoption of green materials in the production of liquid custom products is gaining traction. Buyers should look for suppliers who utilize biodegradable, recyclable, or sustainably sourced ingredients. This shift not only mitigates environmental impact but can also lead to cost savings in the long run as regulatory pressures mount and consumer preferences evolve.

How Has the Liquid Custom Sector Evolved Over Time?

The liquid custom sector has evolved significantly over the past few decades, driven by technological innovations and changing market demands. Initially focused on standard formulations, the industry has shifted towards providing customized solutions that cater to specific consumer needs. This evolution has been fueled by advancements in manufacturing technologies, allowing for greater flexibility and faster turnaround times in product development.

Moreover, the globalization of trade has opened up new markets for liquid custom products, enabling suppliers to reach a broader audience. As international trade barriers continue to diminish, B2B buyers are now better positioned to source high-quality products from various regions, enhancing their competitive advantage.

In summary, understanding the market dynamics and sourcing trends in the liquid custom sector is essential for international B2B buyers. Emphasizing sustainability and ethical sourcing will not only align with global standards but also cater to the growing consumer demand for responsible business practices. By leveraging technology and staying informed about market trends, buyers can optimize their sourcing strategies and drive business growth.

Frequently Asked Questions (FAQs) for B2B Buyers of liquid custom

-

How do I solve quality assurance issues when sourcing liquid custom?

To address quality assurance issues, establish a clear set of specifications and standards before engaging with suppliers. Conduct thorough research on potential suppliers, including their certifications and past performance. Request samples of the liquid custom product to evaluate quality firsthand. Additionally, consider using third-party quality assurance services to perform inspections and ensure compliance with international standards, particularly when dealing with suppliers in regions like Africa and South America. -

What is the best way to vet suppliers for liquid custom products?

The best approach to vet suppliers involves a multi-step process. Start by checking their business credentials, including registration and compliance with local regulations. Look for reviews or testimonials from other B2B buyers. Utilize platforms like Alibaba or Global Sources to find verified suppliers. Additionally, schedule virtual meetings to discuss your requirements and gauge their responsiveness and expertise. Finally, if feasible, conduct site visits to build trust and ensure their facilities meet your standards. -

What are the common minimum order quantities (MOQ) for liquid custom?

Minimum order quantities (MOQ) for liquid custom can vary significantly based on the supplier, product type, and customization level. Typically, MOQs can range from a few hundred liters to several thousand liters. It’s essential to communicate your needs clearly with potential suppliers and negotiate terms that suit your purchasing capacity. Some suppliers may offer lower MOQs for first-time orders or trial runs, especially if you express long-term partnership intentions. -

How can I negotiate favorable payment terms for liquid custom orders?

Negotiating payment terms involves understanding the supplier’s policies while asserting your needs. Start by discussing payment options, such as letters of credit, escrow services, or partial payments upon order confirmation. Aim for terms that provide security for both parties, like a 30% upfront payment with the balance upon delivery. Be transparent about your payment capabilities and timelines, especially if you’re sourcing from regions with different financial practices, such as the Middle East or South America. -

What logistics considerations should I keep in mind when importing liquid custom?

When importing liquid custom, consider the entire logistics chain, including shipping methods, transit times, and regulatory compliance. Research customs requirements in your country to avoid delays. Choose reliable freight forwarders experienced in handling liquid products, as they can provide valuable insights into the best shipping routes and methods. Additionally, factor in storage solutions upon arrival, as some liquid products may require specific handling or temperature controls. -

How do I ensure product customization meets my specifications?

To ensure that product customization aligns with your specifications, begin by providing detailed design and formulation documents to your supplier. Engage in iterative communication throughout the development process, including regular updates and sample testing. Utilize prototypes to assess whether the customization meets your expectations before mass production. Establishing a clear timeline for revisions and approvals can also help streamline the process and mitigate misunderstandings. -

What are the risks associated with sourcing liquid custom internationally?

Sourcing liquid custom internationally carries several risks, including supply chain disruptions, quality inconsistencies, and regulatory challenges. Political instability in certain regions, such as parts of Africa or South America, can also impact delivery timelines. To mitigate these risks, conduct thorough due diligence on suppliers, secure comprehensive contracts that outline responsibilities and liabilities, and consider diversifying your supplier base to avoid reliance on a single source. -

How can I maintain a strong relationship with liquid custom suppliers?

Building and maintaining a strong relationship with suppliers is crucial for long-term success. Regular communication is key; schedule check-ins to discuss performance and address any issues promptly. Show appreciation for their efforts, whether through timely payments or positive feedback. Additionally, consider collaborating on new product developments or improvements to foster loyalty. A partnership mindset, where both parties benefit, often leads to better service, pricing, and innovation in future projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for liquid custom

As we conclude our exploration of liquid custom sourcing, it is imperative to recognize the strategic advantages that informed decision-making can provide for international B2B buyers. By prioritizing strategic sourcing, businesses can not only enhance their supply chain resilience but also optimize costs and improve product quality. This is particularly relevant for markets in Africa, South America, the Middle East, and Europe, where diverse economic landscapes present unique opportunities and challenges.

What Are the Key Takeaways for International Buyers?

-

Understand Local Market Dynamics: Tailoring sourcing strategies to regional specifics can yield significant benefits. For instance, leveraging local suppliers in South America can reduce lead times and shipping costs.

-

Emphasize Supplier Relationships: Building strong partnerships with suppliers enhances collaboration and innovation. This is crucial in regions where trust and long-term commitments drive business success.

-

Leverage Technology: Utilizing data analytics and supply chain management tools can optimize sourcing processes, leading to more informed purchasing decisions and efficiency gains.

How Can International B2B Buyers Prepare for Future Trends?

The landscape of liquid custom sourcing is evolving rapidly. As sustainability and digital transformation become focal points, international buyers must stay agile and informed. Embracing these trends will not only secure competitive advantages but also foster long-term business growth.

In conclusion, the path forward for international B2B buyers is clear: invest in strategic sourcing practices that align with both global trends and local needs. By doing so, businesses can position themselves for success in an increasingly interconnected market. Engage with industry experts, explore new technologies, and forge meaningful supplier relationships to navigate the future of liquid custom sourcing effectively.