Unlock Savings: The Ultimate Remote Control Supplier Guide (2025)

Introduction: Navigating the Global Market for remote control supplier

In today’s competitive landscape, sourcing reliable remote control suppliers can be a daunting task for international B2B buyers. The diversity in applications—ranging from consumer electronics to industrial machinery—demands a thorough understanding of the market. This guide serves as a comprehensive resource, addressing critical challenges faced by businesses in Africa, South America, the Middle East, and Europe, particularly when navigating the intricacies of remote control supply chains.

Buyers will find valuable insights on various types of remote controls, their specific applications, and essential criteria for supplier vetting. We delve into factors influencing cost, the latest trends in technology, and the importance of compliance with regional regulations. By equipping decision-makers with actionable knowledge, this guide empowers them to make informed purchasing decisions that align with their operational needs and budget constraints.

Moreover, understanding cultural nuances and market dynamics across different regions is crucial. Whether you are based in Egypt, Indonesia, or Brazil, the information provided will help you identify suitable suppliers, negotiate effectively, and establish long-term partnerships. This guide not only simplifies the sourcing process but also enhances your overall procurement strategy, ensuring that your business stays ahead in a rapidly evolving global marketplace.

Understanding remote control supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Infrared Remote Controls | Operate using infrared light; require line-of-sight | Consumer electronics, HVAC systems | Pros: Cost-effective; Cons: Limited range and directionality |

| Radio Frequency Remote Controls | Use radio waves; do not require line-of-sight | Industrial machinery, home automation | Pros: Greater range; Cons: Potential for interference |

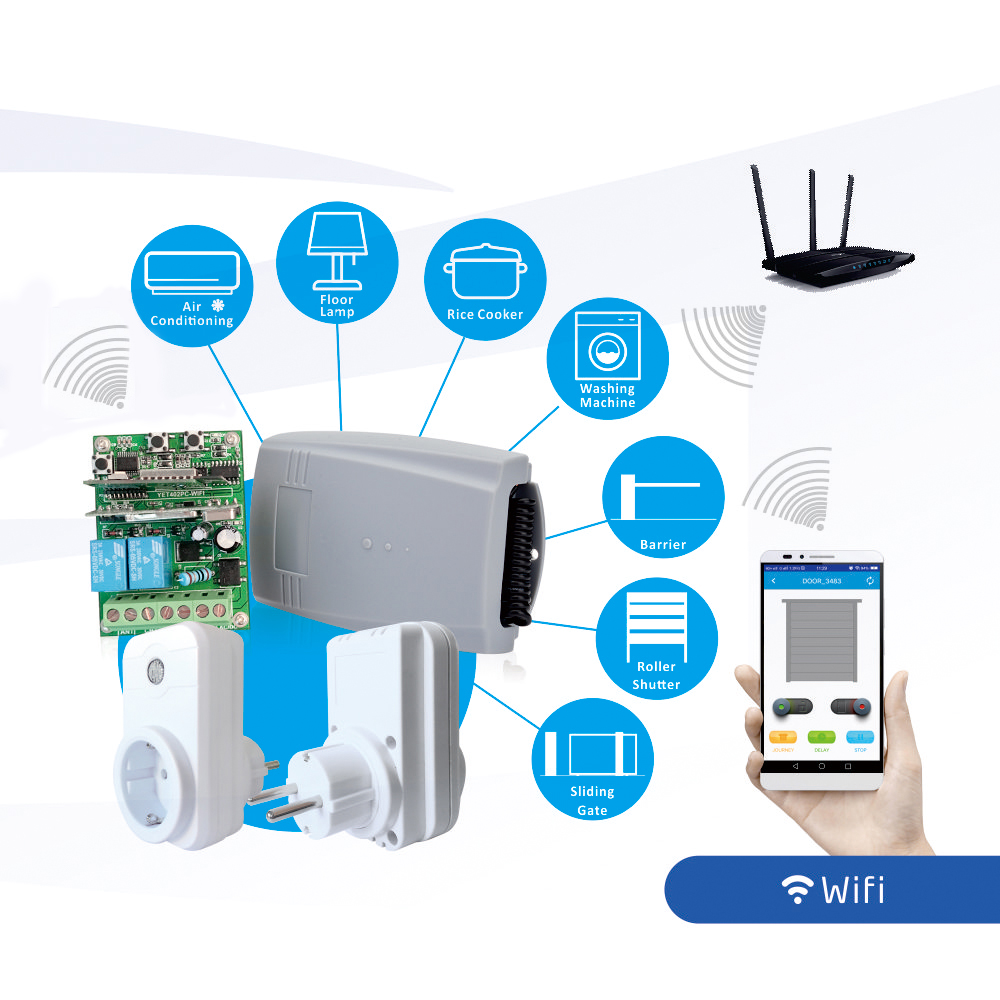

| Wi-Fi Remote Controls | Connect via Wi-Fi; allow for remote access over the internet | Smart home devices, commercial security | Pros: High flexibility; Cons: Dependence on stable internet |

| Bluetooth Remote Controls | Utilize Bluetooth technology; short-range communication | Personal devices, audio systems | Pros: Easy pairing; Cons: Limited range compared to RF |

| Custom Remote Solutions | Tailored designs for specific applications | Specialized industrial equipment | Pros: Designed for specific needs; Cons: Higher cost and lead time |

What Are Infrared Remote Controls and Their B2B Suitability?

Infrared (IR) remote controls are widely recognized for their simple operation, relying on infrared light to communicate with devices. They are most suitable for applications where direct line-of-sight is available, such as in consumer electronics and HVAC systems. When considering purchasing IR remotes, B2B buyers should weigh cost-effectiveness against limitations in range and directionality, especially in environments with obstructions.

How Do Radio Frequency Remote Controls Enhance Industrial Operations?

Radio frequency (RF) remote controls are favored in industrial settings due to their ability to operate without requiring a direct line of sight. This feature makes them ideal for controlling machinery and home automation systems. When selecting RF remotes, buyers should consider the potential for interference from other devices, which can impact performance, as well as their operational range that often exceeds that of IR remotes.

What Advantages Do Wi-Fi Remote Controls Offer for Commercial Applications?

Wi-Fi remote controls provide flexibility and remote access over the internet, making them particularly useful for smart home devices and commercial security systems. They allow for control from various locations, which is beneficial for businesses with multiple sites. However, buyers must consider the dependence on a stable internet connection, as any disruption can hinder functionality.

Why Choose Bluetooth Remote Controls for Personal Devices?

Bluetooth remote controls are popular in personal device applications, such as audio systems and smartphones. Their ease of pairing and user-friendly interface make them attractive for businesses looking to enhance customer experience. However, the limited range compared to RF remote controls may be a drawback in larger environments, so buyers should evaluate their specific application needs before purchasing.

When Are Custom Remote Solutions the Best Choice for B2B Buyers?

Custom remote solutions are designed to meet specific operational requirements and are often used in specialized industrial equipment. These tailored remotes can optimize functionality and enhance user experience. However, buyers should be prepared for potentially higher costs and longer lead times associated with custom solutions. Evaluating the long-term benefits against initial investments is crucial for making informed purchasing decisions.

Related Video: Control Systems Lectures – LTI Systems

Key Industrial Applications of remote control supplier

| Industry/Sector | Specific Application of Remote Control Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Machinery Control | Increases operational efficiency and reduces downtime. | Look for suppliers with robust technical support and customization options. |

| Construction | Heavy Equipment Operation | Enhances safety and improves project timelines. | Prioritize suppliers who comply with local safety regulations and offer durable products. |

| Agriculture | Drone Operations for Crop Monitoring | Optimizes yield through precise monitoring and data collection. | Ensure compatibility with local regulations and technology standards. |

| Entertainment and Events | Remote Lighting and Sound Control | Streamlines event management and enhances audience experience. | Seek suppliers that provide real-time support and flexible solutions for various event sizes. |

| Energy and Utilities | Remote Monitoring of Infrastructure | Reduces operational costs and improves response times. | Focus on suppliers with experience in energy sector challenges and compliance with international standards. |

How is Remote Control Technology Applied in Manufacturing?

In the manufacturing sector, remote control technology is primarily utilized for automating machinery operations. This application allows operators to control equipment from a distance, significantly increasing operational efficiency and minimizing downtime. For international B2B buyers, especially from Africa and South America, it is crucial to source suppliers that not only offer robust technical support but also customization options tailored to specific machinery needs. This ensures that the technology integrates seamlessly into existing operations, enhancing productivity and reducing the risk of human error.

A stock image related to remote control supplier.

What Role Does Remote Control Play in Construction?

In the construction industry, remote control suppliers facilitate the operation of heavy equipment, such as cranes and excavators, from a safe distance. This capability enhances safety on job sites, allowing operators to manage machinery without being exposed to potential hazards. For buyers in regions like the Middle East, where construction projects are often large-scale and complex, sourcing remote control solutions that comply with local safety regulations is essential. Additionally, durability and reliability are paramount, as equipment often operates in challenging environments.

How is Remote Control Technology Transforming Agriculture?

Agriculture is witnessing a significant transformation through the use of remote control technology, particularly in drone operations for crop monitoring. This application allows farmers to gather data on crop health and soil conditions efficiently, optimizing yield and resource management. For buyers in Europe and Africa, it is vital to ensure that the remote control systems comply with local regulations governing drone usage. Furthermore, compatibility with existing agricultural technology and ease of use are important factors to consider when sourcing these solutions.

In What Ways Does Remote Control Enhance Entertainment and Events?

In the entertainment sector, remote control technology is used for managing lighting and sound systems during events. This application streamlines event management, allowing technicians to adjust settings in real-time, which enhances the audience experience. For B2B buyers in South America and Europe, it is important to look for suppliers who offer flexible solutions that can adapt to various event sizes and types. Additionally, real-time technical support can be a significant value-add, ensuring that any issues can be swiftly addressed during live events.

How Does Remote Control Technology Benefit Energy and Utilities?

In the energy and utilities sector, remote control suppliers play a crucial role in the remote monitoring of infrastructure, such as power lines and water treatment facilities. This technology helps reduce operational costs by enabling proactive maintenance and improving response times to outages or failures. For international buyers, particularly from regions with developing infrastructure, sourcing suppliers with a proven track record in addressing energy sector challenges and compliance with international standards is key. This ensures that the solutions provided are not only effective but also sustainable in the long run.

Related Video: Robotics applications by Universal Robots – Easy Automation with Collaborative Robots [ 2020 ]

3 Common User Pain Points for ‘remote control supplier’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Remote Control Suppliers

The Problem:

International B2B buyers often struggle to identify reliable remote control suppliers who can meet their specific needs. This challenge is particularly pronounced in regions such as Africa and South America, where access to trustworthy suppliers may be limited. Buyers may encounter a plethora of options online, yet many lack certifications or proven track records, leading to uncertainty about quality and reliability. This situation can result in wasted time and resources, especially when urgent projects depend on timely deliveries and superior product performance.

The Solution:

To overcome this issue, buyers should prioritize sourcing suppliers with verifiable credentials, such as ISO certifications or industry-specific awards. Utilizing platforms like LinkedIn can help in vetting suppliers through professional networks and recommendations. Engaging in industry trade shows or virtual expos can also provide opportunities for face-to-face interaction, allowing buyers to assess the suppliers’ capabilities and product quality firsthand. Additionally, it’s advisable to request samples or conduct pilot tests before committing to larger orders, ensuring that the products meet the specified requirements and quality standards.

Scenario 2: Incompatibility Issues with Existing Systems

The Problem:

Many businesses face the challenge of remote control devices being incompatible with their existing systems. This is particularly common in industries such as hospitality and entertainment, where different remote control units must seamlessly integrate with various devices (TVs, projectors, etc.). Incompatibility can lead to operational disruptions, frustrated staff, and ultimately, a poor customer experience. This issue is often exacerbated in regions where tech support may not be readily available to assist with integration problems.

The Solution:

To mitigate compatibility issues, buyers should conduct a thorough needs assessment prior to sourcing remote controls. This involves mapping out the existing systems and identifying specific requirements for integration. When engaging with suppliers, it is crucial to inquire about compatibility with existing technologies, including details about protocols and standards used (e.g., IR, RF, Bluetooth). Additionally, buyers should consider suppliers that offer comprehensive customer support and technical documentation to facilitate smooth integration. Building a partnership with suppliers who have a proven track record in similar industries can also provide insights and solutions tailored to unique operational needs.

Scenario 3: Insufficient Customization Options for Remote Controls

The Problem:

Another common pain point for B2B buyers is the lack of customization options in remote controls. Many suppliers offer generic models that fail to meet specific branding or functional requirements, especially for businesses that wish to enhance their customer experience through tailored solutions. This limitation can hinder the ability to provide a cohesive brand experience, particularly in competitive markets such as the Middle East and Europe, where differentiation is key.

The Solution:

To address this concern, buyers should actively seek out suppliers that specialize in customizable remote control solutions. This includes options for branding, button configuration, and additional functionalities that cater to specific industry needs. When communicating with suppliers, clearly outline customization requirements, including design aesthetics and functional specifications. It may also be beneficial to collaborate with suppliers who have experience in your industry, as they can offer insights into best practices and innovative features that resonate with your target audience. Establishing a close working relationship with these suppliers can lead to more tailored solutions and ongoing product development that aligns with evolving business needs.

Strategic Material Selection Guide for remote control supplier

When selecting materials for remote controls, international B2B buyers must consider various factors that influence performance, durability, and cost. This guide analyzes four common materials used in remote control manufacturing: plastic, metal, rubber, and composite materials. Each material has distinct properties and implications for application, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Plastic in Remote Control Manufacturing?

Plastic is one of the most widely used materials in remote control production due to its versatility and cost-effectiveness. Common types include ABS (Acrylonitrile Butadiene Styrene) and polycarbonate, which offer good temperature resistance and impact strength. Plastics typically have a temperature rating up to 80°C and can withstand moderate pressure.

Pros & Cons:

The primary advantage of plastic is its lightweight nature, which reduces shipping costs and enhances user experience. However, it may not be as durable as metals, especially in harsh environments. Additionally, plastic can be susceptible to UV degradation, which is a critical consideration for outdoor applications.

Impact on Application:

Plastic is compatible with a range of electronic components, making it suitable for various remote control applications. However, buyers must ensure that the chosen plastic meets local compliance standards, such as ASTM or EN specifications.

How Does Metal Compare in Terms of Performance for Remote Controls?

Metal, particularly aluminum and stainless steel, is favored for its strength and durability. These materials can withstand higher temperatures (up to 150°C) and are resistant to corrosion, making them ideal for rugged applications.

Pros & Cons:

Metal offers superior durability and a premium feel, which can enhance the product’s marketability. However, it is generally heavier and more expensive than plastic, which could increase shipping costs. Manufacturing complexity is also higher, requiring specialized processes like machining or die-casting.

Impact on Application:

Metals are particularly effective in environments where remote controls are exposed to moisture or chemicals. Buyers must consider local regulations on metal usage and ensure compliance with industry standards.

What Role Does Rubber Play in Remote Control Design?

Rubber is often used in remote controls for buttons and grips due to its excellent tactile properties and resistance to wear. It can endure temperatures from -30°C to 70°C and provides good insulation against moisture.

Pros & Cons:

The main advantage of rubber is its ability to provide a comfortable grip and a quiet operation, enhancing user experience. However, rubber can degrade over time, especially if exposed to UV light or extreme temperatures, necessitating careful selection based on application.

Impact on Application:

Rubber’s compatibility with various electronic components makes it suitable for diverse remote control designs. Buyers should ensure that the rubber meets the necessary compliance standards, particularly in regions with stringent regulations.

Why Are Composite Materials Gaining Popularity in Remote Control Manufacturing?

Composite materials, such as fiberglass-reinforced plastics, combine the benefits of different materials to enhance performance. They can offer high strength-to-weight ratios and excellent thermal stability.

Pros & Cons:

Composites are lightweight and can be molded into complex shapes, providing design flexibility. However, they tend to be more expensive and may require specialized manufacturing techniques, which can complicate production.

Impact on Application:

Composites are particularly useful in high-performance applications where weight and strength are critical. Buyers should be aware of the specific standards applicable to composite materials in their region.

Summary Table of Material Selection for Remote Controls

| Material | Typical Use Case for remote control supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General consumer electronics | Lightweight and cost-effective | Less durable in harsh conditions | Low |

| Metal | Industrial and outdoor remote controls | High durability and corrosion resistance | Heavier and more expensive | High |

| Rubber | Remote control buttons and grips | Excellent tactile properties | Degrades over time | Medium |

| Composite | High-performance remote controls | High strength-to-weight ratio | More expensive and complex to manufacture | High |

This strategic material selection guide provides critical insights for international B2B buyers to make informed decisions when sourcing remote control components, ensuring compliance with local standards while balancing performance and cost.

In-depth Look: Manufacturing Processes and Quality Assurance for remote control supplier

What Are the Main Stages of Manufacturing Remote Controls?

The manufacturing process of remote controls involves several critical stages, each designed to ensure functionality, reliability, and quality. Understanding these stages is essential for B2B buyers looking to source high-quality remote control products.

Material Preparation

The first step in the manufacturing process is material preparation. This includes selecting high-quality plastics, metals, and electronic components that meet industry specifications. Suppliers often utilize advanced software to simulate the material properties and assess their suitability for the intended application. It’s crucial for buyers to inquire about the sourcing of materials, as this can impact both product quality and sustainability.

Forming Techniques

Once materials are prepared, the next stage is forming. This typically involves injection molding for plastic components, where melted plastic is injected into molds to create the desired shapes. In the case of metal components, techniques like stamping and die-casting are commonly used. Each technique has its advantages; for instance, injection molding allows for complex designs and high-volume production, making it ideal for remote controls.

Assembly Processes

The assembly phase is where the components come together to form the final product. This can be a manual or automated process, depending on the supplier’s capabilities. Automated assembly lines are increasingly popular as they enhance efficiency and reduce labor costs. B2B buyers should assess the assembly methods used by suppliers, as this can directly affect the consistency and quality of the final product.

Finishing Techniques

The final stage is finishing, which includes painting, coating, and applying decals. These processes not only enhance the aesthetic appeal but also provide protection against wear and tear. Advanced finishing techniques, such as UV coating, can improve durability and provide additional functionality, such as water resistance. Buyers should consider the types of finishes offered and how they align with their product requirements.

How Do Quality Assurance Practices Impact Remote Control Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each remote control meets the necessary standards before reaching the market. For international B2B buyers, understanding these QA practices is essential for making informed sourcing decisions.

What International Standards Should B2B Buyers Be Aware Of?

International standards like ISO 9001 are critical benchmarks in the manufacturing sector. This standard focuses on quality management systems and helps ensure consistent quality in products and services. Additionally, industry-specific certifications such as CE marking (for compliance with European safety, health, and environmental protection standards) and API standards (for electronic devices) are also vital. Buyers should ask suppliers about their certifications and how they ensure compliance with these standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in remote control manufacturing involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected before they are used in production. Suppliers should have rigorous IQC procedures to ensure that only high-quality materials are utilized.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to ensure that the manufacturing process adheres to established standards. IPQC helps catch defects early, reducing waste and rework.

-

Final Quality Control (FQC): Before shipping, final inspections are performed to verify that the finished product meets all specifications and quality standards. This includes functionality tests and aesthetic checks.

What Common Testing Methods Are Used in Remote Control Manufacturing?

Testing is a critical component of quality assurance, ensuring that remote controls perform as expected in various conditions. B2B buyers should be familiar with the following common testing methods:

-

Functional Testing: This involves testing the remote control’s buttons, range, and connectivity to ensure it operates correctly with the intended devices.

-

Environmental Testing: Products are subjected to various environmental conditions, such as extreme temperatures and humidity, to assess durability and performance.

-

Safety Testing: Ensures that the product complies with safety regulations, reducing the risk of electrical hazards or other safety issues.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is paramount. Here are actionable steps to ensure due diligence:

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s QC processes is through on-site audits. During these audits, buyers can evaluate the supplier’s manufacturing facilities, quality control procedures, and overall compliance with industry standards. This firsthand observation can provide invaluable insights.

Requesting Quality Reports

Buyers should request detailed quality assurance reports from suppliers. These reports should outline QC procedures, test results, and any corrective actions taken in response to identified issues. Analyzing these documents can help buyers gauge the supplier’s commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an additional layer of assurance. These independent entities can conduct inspections and testing to verify that products meet specified quality standards before shipment. This is particularly beneficial for buyers from regions like Africa and South America, where product standards may differ from local expectations.

What Nuances Should B2B Buyers Consider Regarding Quality Control Certifications?

Navigating the landscape of quality control certifications can be complex for international buyers. Here are key considerations:

-

Regional Differences: Quality standards can vary significantly between regions. For instance, European buyers may prioritize CE compliance, while Middle Eastern buyers might focus on local certification requirements. Understanding these differences is essential for ensuring product acceptance in target markets.

-

Supplier Capabilities: Not all suppliers are equipped to meet the same standards. It is crucial to verify that a supplier has the necessary certifications and capabilities to produce products that comply with your specific market requirements.

-

Continuous Improvement: Quality assurance is not a one-time effort. Suppliers should demonstrate a commitment to continuous improvement, regularly updating their processes and certifications in response to industry changes and customer feedback.

By understanding the manufacturing processes and quality assurance practices of remote control suppliers, B2B buyers can make informed decisions that align with their business needs, ensuring they source high-quality products that meet their market standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘remote control supplier’

The following guide provides a comprehensive checklist for international B2B buyers seeking to source remote control suppliers. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before beginning your supplier search, it’s essential to clearly outline the technical requirements for the remote controls you need. This includes specifications such as range, compatibility with devices, power supply options, and any necessary certifications (e.g., CE, FCC). A well-defined specification helps streamline communication with potential suppliers and ensures that you receive products that meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential remote control suppliers, focusing on those with experience in your specific industry. Utilize online directories, trade platforms, and industry associations to compile a list of candidates. Pay attention to suppliers that have a solid reputation and positive reviews from other buyers, particularly from your region.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist, assess each supplier’s capabilities. Look for details regarding their production capacity, technology used, and quality control processes. It’s beneficial to inquire about their experience with similar projects and request case studies or examples of past work. This evaluation helps ensure that the supplier can meet your volume and quality requirements.

Step 4: ✅ Verify Supplier Certifications

Certifications are a crucial aspect of supplier credibility. Ensure that the suppliers you consider hold relevant industry certifications, which can indicate adherence to quality and safety standards. For remote controls, look for certifications such as ISO 9001 for quality management and any specific electrical safety certifications applicable in your region.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the remote controls to test their functionality and quality. This step is critical as it allows you to evaluate the product firsthand and ensure it meets your technical specifications. Conduct thorough testing to assess performance, durability, and compatibility with your existing systems.

Step 6: Negotiate Terms and Conditions

Once you have identified a supplier that meets your criteria, enter into negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your expectations and any penalties for late deliveries or quality issues. A well-negotiated contract can protect your interests and establish a strong foundation for a long-term partnership.

Step 7: Establish Communication Channels

Effective communication is vital for successful supplier relationships. Establish clear channels for ongoing communication, including regular updates on production status and any potential issues. Consider using digital tools for project management and communication to enhance collaboration, especially when dealing with suppliers in different time zones.

By following this step-by-step checklist, international B2B buyers can streamline the sourcing process for remote control suppliers, ensuring that they select a partner that aligns with their business goals and technical requirements.

Comprehensive Cost and Pricing Analysis for remote control supplier Sourcing

What Are the Key Cost Components in Remote Control Supplier Sourcing?

When sourcing from remote control suppliers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials include plastics, metals, and electronic components. High-quality materials often lead to higher durability, which can be essential for certain applications.

-

Labor: Labor costs vary by region and can be influenced by local wage standards, skill levels, and workforce availability. In developing countries, labor might be cheaper, but it’s essential to consider the skills and expertise required for high-quality production.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, maintenance, and facility costs. Suppliers with efficient operations can offer competitive pricing while maintaining quality.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. These costs are often amortized over larger production runs, which can make higher volume orders more cost-effective.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with international standards. While these processes add to costs, they are essential for avoiding costly returns and reputational damage.

-

Logistics: Shipping and handling costs can fluctuate based on distance, shipping methods, and customs fees. Understanding Incoterms can help buyers anticipate these costs better.

-

Margin: Supplier profit margins vary widely based on market conditions and competition. A clear understanding of expected margins can aid in negotiating more favorable terms.

How Do Price Influencers Affect Remote Control Supplier Sourcing?

Several factors can influence the pricing of remote controls, particularly in international markets:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can greatly impact pricing. Larger orders typically yield lower per-unit costs, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Custom features or specifications will increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, CE) can affect both the cost and the perceived value of the product. Investing in higher-quality products may lead to long-term savings through reduced failure rates.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge a premium, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers in shipping. The chosen Incoterm can influence the total landed cost, affecting overall pricing.

What Are the Best Buyer Tips for Negotiating Prices with Remote Control Suppliers?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Volume Discounts: Leverage larger order sizes to negotiate better prices. Building a long-term relationship with suppliers can also yield favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the costs associated with shipping, storage, and potential failure rates. A slightly higher upfront cost may result in lower TCO if the product is more reliable.

-

Understand Pricing Nuances: Different regions may have varying cost structures due to local economic conditions. Buyers should conduct thorough market research to understand pricing trends and adjust their offers accordingly.

-

Evaluate Supplier Capabilities: Assessing a supplier’s production capabilities and quality assurance processes can provide insights into whether their pricing is justified. A supplier with robust QC measures might charge more, but the investment could lead to fewer issues down the line.

-

Be Aware of Currency Fluctuations: For buyers dealing with international suppliers, currency exchange rates can impact costs. Locking in prices when the currency is favorable can help manage expenses.

Disclaimer for Indicative Prices

It’s important to note that the pricing analysis provided is indicative and can vary widely based on specific circumstances, including market demand, geopolitical factors, and supplier negotiations. Always conduct a detailed cost analysis tailored to your unique sourcing needs.

Alternatives Analysis: Comparing remote control supplier With Other Solutions

In the landscape of remote control solutions, international B2B buyers are often faced with multiple options that can meet their operational needs. Evaluating alternatives to a traditional remote control supplier is essential for making informed decisions that align with business objectives. Below, we provide a comparative analysis of the traditional remote control supplier against two viable alternatives: smart device integration and programmable automation systems.

Comparison Table of Remote Control Solutions

| Comparison Aspect | Remote Control Supplier | Smart Device Integration | Programmable Automation Systems |

|---|---|---|---|

| Performance | High reliability for specific applications | Variable; depends on network stability | High; can be customized for specific tasks |

| Cost | Moderate initial investment | Varies; often lower setup cost, but ongoing fees may apply | Higher initial investment, but cost-effective in long run |

| Ease of Implementation | Straightforward; typically plug-and-play | Moderate; requires network setup | Complex; requires programming knowledge and integration |

| Maintenance | Low; typically minimal upkeep | Medium; regular updates needed | High; requires ongoing programming and troubleshooting |

| Best Use Case | Specific tasks requiring remote access | Home automation, small business operations | Large-scale industrial applications |

What are the Pros and Cons of Smart Device Integration?

Smart device integration leverages existing smart technologies, such as smartphones and tablets, to control devices remotely. The primary advantage of this alternative is its flexibility and lower initial cost compared to traditional remote control suppliers. Businesses can utilize devices they already own, reducing the need for additional hardware. However, the performance is highly dependent on network stability, and ongoing subscription fees for software and services can add up over time. This solution is ideal for small to medium-sized businesses looking to automate simple tasks without heavy upfront investments.

How Do Programmable Automation Systems Compare?

Programmable automation systems provide a robust alternative for businesses seeking comprehensive control over their operations. These systems are highly customizable, allowing companies to tailor solutions to their specific needs, especially in industrial settings. The high initial investment is offset by long-term savings through increased efficiency and reduced labor costs. However, the complexity of implementation can be a barrier for some organizations, as it often requires specialized programming skills and ongoing maintenance. This solution is best suited for large enterprises that require intricate control systems for complex operations.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right remote control solution hinges on a thorough understanding of your business needs, budget constraints, and operational scale. For businesses focused on specific tasks with low complexity, a traditional remote control supplier may offer the most reliable solution. In contrast, companies looking for flexibility and lower upfront costs might find smart device integration to be advantageous. Finally, organizations operating on a larger scale with specific automation needs should consider programmable automation systems, despite their complexity and higher initial costs. By assessing these alternatives carefully, B2B buyers can make strategic decisions that enhance operational efficiency and align with their long-term business goals.

Essential Technical Properties and Trade Terminology for remote control supplier

What are the Key Technical Properties of Remote Controls?

Understanding the essential technical properties of remote controls is crucial for B2B buyers looking to procure reliable and efficient devices. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality of the materials used in manufacturing remote controls. Common materials include plastics like ABS (Acrylonitrile Butadiene Styrene) for casings and silicone for buttons. High-grade materials enhance durability and resistance to wear and tear, which is vital for devices used in various environments, especially in regions with extreme climates like Africa or the Middle East.

2. Signal Range

Signal range indicates the maximum distance over which a remote can effectively communicate with its corresponding device. This specification is essential for buyers who require remote controls for large spaces, such as in commercial buildings or outdoor settings. A longer signal range can significantly enhance user experience and operational efficiency.

3. Battery Life

Battery life is a critical specification that affects the usability and maintenance of remote controls. B2B buyers should inquire about the expected battery duration under typical usage conditions. Longer battery life reduces the frequency of replacements, contributing to lower operational costs, particularly in environments where remote controls are frequently used.

4. Ergonomics

Ergonomics pertains to the design and usability of remote controls. A well-designed remote should fit comfortably in hand, with intuitively placed buttons for ease of use. For international buyers, especially those in diverse markets like South America and Europe, ergonomic considerations can influence user satisfaction and reduce training time for staff.

5. Compatibility

Compatibility refers to the ability of a remote control to work with various devices and systems. Buyers must ensure that the remote they choose is compatible with their existing technology, which can vary significantly across regions. This consideration is especially pertinent for businesses integrating new technology into their operations.

What Trade Terminology Should B2B Buyers Understand?

Familiarity with industry terminology is essential for effective communication and negotiation in the procurement process. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the remote control industry, understanding OEM relationships can help buyers identify reliable suppliers and gauge the quality of products based on the manufacturer’s reputation.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of MOQs, as they can impact inventory management and cash flow. Negotiating favorable MOQ terms can lead to cost savings and more flexible purchasing options.

3. RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. By issuing an RFQ for remote controls, buyers can obtain competitive pricing and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is crucial for international B2B buyers, as they dictate who is responsible for shipping, insurance, and tariffs. This knowledge helps avoid misunderstandings and ensures smooth logistics operations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for effective planning and inventory management, especially for businesses operating in fast-paced environments or those that rely on timely product availability.

By comprehending these technical specifications and trade terms, international B2B buyers can make informed decisions that enhance their procurement strategies, ultimately leading to better operational efficiency and cost-effectiveness in their organizations.

Navigating Market Dynamics and Sourcing Trends in the remote control supplier Sector

What are the Current Market Dynamics and Key Trends in the Remote Control Supplier Sector?

The remote control supplier sector is experiencing significant growth driven by technological advancements, evolving consumer preferences, and the increasing demand for automation across various industries. Global drivers such as the rise of smart home technologies and the Internet of Things (IoT) are shaping the market landscape. B2B buyers from Africa, South America, the Middle East, and Europe should be aware of these trends as they influence sourcing decisions.

Emerging technologies, including artificial intelligence and machine learning, are enhancing the functionality and efficiency of remote controls. Suppliers are increasingly offering customizable solutions that cater to specific industry needs, from consumer electronics to industrial automation. In addition, the demand for multi-functional remote controls that integrate with various devices is on the rise, providing opportunities for B2B buyers to source versatile products that can streamline operations.

Market dynamics are also influenced by competitive pricing and the need for reliable supply chains. International buyers must stay informed about geopolitical factors that may impact sourcing, such as trade tariffs and local regulations. Building relationships with suppliers who demonstrate agility and responsiveness can mitigate risks associated with supply chain disruptions.

How is Sustainability and Ethical Sourcing Reshaping the Remote Control Supplier Sector?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the remote control sector. The environmental impact of electronic waste and the importance of responsible manufacturing practices have prompted many companies to adopt greener approaches. International buyers, particularly from regions like Africa and the Middle East, are increasingly prioritizing suppliers who demonstrate a commitment to sustainability.

Ethical supply chains are crucial in building trust with customers and stakeholders. Buyers should seek suppliers that are transparent about their sourcing practices and can provide certifications such as ISO 14001 for environmental management. Utilizing recyclable materials and reducing carbon footprints are also key indicators of a supplier’s commitment to sustainability.

Incorporating ‘green’ certifications into procurement processes can enhance a company’s reputation and align with global sustainability goals. B2B buyers should consider engaging with suppliers who are innovating in sustainable practices, such as using energy-efficient manufacturing processes or developing remote controls that have a longer lifespan to reduce waste.

How Has the Remote Control Supplier Sector Evolved Over Time?

The evolution of the remote control supplier sector can be traced back to the introduction of basic infrared remote controls in the 1980s, which revolutionized consumer electronics. Initially designed for convenience, these devices have transformed significantly due to advancements in technology. The transition from analog to digital remote controls marked a pivotal moment, allowing for more complex functionalities and improved user experiences.

In recent years, the integration of smart technology has further propelled the industry forward. Today’s remote controls often come equipped with features such as voice recognition, smartphone connectivity, and compatibility with various smart home devices. This evolution reflects the broader trends of digitalization and automation that are reshaping industries globally, making it essential for B2B buyers to stay informed about the latest innovations and market shifts to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of remote control supplier

-

How do I find reliable remote control suppliers for my business?

To find reliable remote control suppliers, start by conducting thorough online research. Utilize platforms like Alibaba, Global Sources, and TradeIndia to explore supplier profiles and reviews. Attend industry trade shows and networking events to meet potential suppliers in person. Additionally, leverage local business directories and chambers of commerce in your region. Always request samples and verify certifications to ensure product quality and compliance with international standards. -

What are the key factors to consider when vetting a remote control supplier?

When vetting a remote control supplier, consider their experience, product range, and production capacity. Check for certifications that align with industry standards, such as ISO or CE markings. Evaluate their customer service and communication responsiveness, as these are critical for resolving issues. Additionally, request client references to gauge their reliability and performance. Finally, assess their logistics capabilities to ensure timely delivery and support. -

What customization options should I expect from remote control suppliers?

Most reputable remote control suppliers offer various customization options, including branding, color schemes, and functionality tailored to specific applications. Discuss your requirements upfront, including any unique features or designs you need. Be clear about minimum order quantities (MOQs) for customized products, as these can vary significantly between suppliers. Request prototypes to assess the quality and functionality before committing to a larger order. -

What is the typical minimum order quantity (MOQ) for remote controls?

The MOQ for remote controls can vary widely depending on the supplier and the complexity of the product. Generally, MOQs can range from 100 to 1,000 units for standard models. Custom products may require higher MOQs due to the increased costs associated with design and production. It’s crucial to discuss MOQs during initial negotiations to ensure they align with your business needs and budget. -

What payment terms are commonly offered by remote control suppliers?

Payment terms for remote control suppliers typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit (usually 30% to 50%) upfront, with the balance due before shipment. It’s essential to negotiate terms that provide you with security while ensuring the supplier feels confident about the transaction. Always review the payment options thoroughly and consider using escrow services for larger transactions. -

How can I ensure quality assurance when sourcing remote controls?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request samples for testing and evaluation. Many suppliers offer quality control inspections during production and before shipment. Consider hiring third-party inspection services to verify product quality independently. Additionally, discussing warranties and return policies upfront can provide further assurance regarding the reliability of your supplier. -

What logistics considerations should I keep in mind when importing remote controls?

Logistics is crucial when importing remote controls. Consider shipping methods (air vs. sea), as they impact cost and delivery time. Research customs regulations in your country to avoid unexpected delays or additional fees. Ensure that the supplier provides all necessary documentation, including packing lists, invoices, and certificates of origin. It’s also advisable to work with a freight forwarder who can assist with the logistics and help navigate international shipping complexities. -

How do I handle potential disputes with a remote control supplier?

To handle potential disputes with a remote control supplier, establish clear communication channels and document all agreements in writing. If issues arise, address them promptly through direct communication. If resolution is not possible, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration. Maintaining a professional relationship can often help mitigate conflicts and lead to satisfactory resolutions for both parties.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for remote control supplier

In today’s rapidly evolving marketplace, strategic sourcing of remote control suppliers is not just an operational necessity; it is a pivotal component for competitive advantage. By leveraging a well-defined sourcing strategy, international B2B buyers from Africa, South America, the Middle East, and Europe can unlock significant cost efficiencies, enhance product quality, and foster innovation. The analysis of supplier capabilities, market trends, and geographical advantages can lead to more informed decision-making, ensuring that buyers select partners who align with their long-term business goals.

How Can Strategic Sourcing Impact Your Bottom Line?

Investing time and resources into strategic sourcing can lead to improved supplier relationships and a deeper understanding of market dynamics. Buyers should prioritize building partnerships that not only fulfill immediate needs but also offer scalability and adaptability in a changing landscape. Furthermore, engaging with suppliers who possess local market expertise can facilitate smoother operations and enhance customer satisfaction.

What Should International Buyers Do Next?

A stock image related to remote control supplier.

As you move forward, consider implementing a robust supplier evaluation framework that encompasses quality, reliability, and sustainability. Explore diverse markets and leverage technology to facilitate communication and collaboration with potential suppliers across continents. The future of remote control supply is promising, and by acting strategically today, you position your business for success tomorrow. Embrace this opportunity to redefine your sourcing strategy and stay ahead in the competitive global marketplace.