Unlock Savings: The Ultimate Rice Mill Supplier Guide (2025)

Introduction: Navigating the Global Market for rice mill supplier

In the ever-evolving landscape of global trade, sourcing a reliable rice mill supplier presents a unique challenge for international B2B buyers. With varying quality standards, technological advancements, and regional market dynamics, understanding how to effectively navigate this complex market is crucial. This guide aims to provide an exhaustive overview of what to consider when selecting a rice mill supplier, from the types of mills available and their applications to essential supplier vetting processes and cost considerations.

This comprehensive resource empowers B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including Turkey and the UK—by delivering actionable insights and strategic guidance. Whether you are looking to invest in modern milling technology or seeking to optimize your existing operations, understanding the nuances of supplier selection can lead to more informed purchasing decisions.

By exploring key factors such as quality assurance, after-sales support, and technological compatibility, this guide will help you mitigate risks and enhance your supply chain efficiency. As you navigate the intricate waters of the global rice milling market, let this guide be your trusted companion, ensuring that you make choices that align with your business goals and operational needs.

Understanding rice mill supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Rice Mills | Manual operations with minimal automation; often local. | Small-scale rice processing, local markets | Pros: Low initial investment; local sourcing. Cons: Lower efficiency and output. |

| Modern Fully Automated Mills | High-tech machinery; fully automated processes; scalable. | Large-scale rice production, export markets | Pros: High efficiency; consistent quality. Cons: Significant initial investment; requires skilled maintenance. |

| Mobile Rice Mills | Compact and transportable; designed for remote areas. | Rural processing, disaster relief efforts | Pros: Flexibility; cost-effective for small communities. Cons: Limited capacity; may lack advanced features. |

| Custom Rice Mill Suppliers | Tailored solutions based on specific buyer needs; varied machinery. | Specialty rice processing, niche markets | Pros: Meets unique requirements; optimized production. Cons: Potentially higher costs; longer lead times. |

| Integrated Rice Processing Plants | Combines milling with packaging and distribution; large facilities. | Comprehensive rice production and supply chain management | Pros: Streamlined operations; reduces supply chain costs. Cons: High capital investment; complex management. |

What are Traditional Rice Mills and Their Suitability for B2B Buyers?

Traditional rice mills are characterized by their manual operations and minimal automation. Often found in rural areas, these mills cater primarily to small-scale rice processing and local markets. For B2B buyers, especially in developing regions, the appeal lies in their low initial investment and the ability to source rice locally. However, buyers must consider the trade-off in efficiency and output, as these mills typically produce lower volumes and may not meet the demands of larger markets.

How Do Modern Fully Automated Mills Enhance Rice Processing Efficiency?

Modern fully automated rice mills utilize advanced technology to streamline the milling process, significantly increasing production capacity and consistency in quality. These mills are ideal for large-scale rice producers and export markets, as they can handle higher volumes with minimal labor costs. While the initial investment can be substantial, the long-term benefits often outweigh the costs, making them a suitable choice for B2B buyers looking to scale operations. Buyers should also consider the need for skilled maintenance, as the complexity of the machinery requires trained personnel.

What Advantages Do Mobile Rice Mills Offer for Remote Processing?

Mobile rice mills are compact, transportable solutions designed to cater to rural and remote areas. They are particularly valuable for small communities that may not have access to traditional milling facilities. For B2B buyers, these mills provide flexibility and cost-effectiveness, making them suitable for rural processing and disaster relief efforts. However, potential buyers should be aware of the limited capacity and the absence of advanced features that may be present in larger, stationary mills.

Why Choose Custom Rice Mill Suppliers for Niche Markets?

Custom rice mill suppliers offer tailored solutions that address specific buyer needs, providing varied machinery options and configurations. This type of supplier is particularly beneficial for businesses operating in specialty rice processing or niche markets. While the ability to meet unique requirements is a significant advantage, buyers should be prepared for potentially higher costs and longer lead times associated with custom orders. Assessing the overall return on investment is crucial for making informed purchasing decisions.

What are the Benefits of Integrated Rice Processing Plants?

Integrated rice processing plants combine milling with packaging and distribution, creating a comprehensive solution for rice production and supply chain management. These large facilities are designed for significant output and streamlined operations, which can help reduce supply chain costs for B2B buyers. However, the high capital investment and complexity of managing such operations may pose challenges. Buyers should evaluate their operational capabilities and market demands to determine if this option aligns with their business strategy.

Related Video: Pattabhi Agro Foods – Advance Rice Mill in India. India’s leading Rice Exporter & Rice Supplier

Key Industrial Applications of rice mill supplier

| Industry/Sector | Specific Application of rice mill supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Milling of high-quality rice for packaged food products | Enhanced product quality, consistency, and shelf life | Supplier reliability, milling capacity, and technology used |

| Export and Trade | Bulk processing for export markets | Increased competitiveness in international markets | Compliance with international standards and certifications |

| Agriculture and Farming | Custom milling services for local farmers | Tailored solutions that meet specific crop needs | Local sourcing options, flexibility in production volumes |

| Hospitality and Catering | Provision of specialty rice types for restaurants and hotels | Unique offerings that attract diverse clientele | Variety of rice types, packaging options, and delivery timelines |

| Retail and Supermarkets | Supply of packaged rice products for retail distribution | Increased sales through premium product offerings | Branding options, supply chain efficiency, and market trends |

How is Rice Mill Supplier Used in Food Processing?

In the food processing industry, rice mill suppliers play a crucial role in milling high-quality rice for packaged food products. These suppliers provide advanced milling technologies that ensure the rice retains its nutritional value and flavor, addressing common issues such as grain breakage and inconsistent quality. For international buyers, especially those in Africa and South America, it is essential to consider the supplier’s reliability and the milling capacity to meet production demands. Additionally, understanding the technology used can help ensure the final product meets consumer expectations.

What Role Does Rice Mill Supplier Play in Export and Trade?

In the export and trade sector, rice mill suppliers facilitate bulk processing of rice, enabling businesses to meet international market standards. This application is vital for companies looking to enhance their competitiveness in global markets, particularly in regions like the Middle East and Europe. Buyers must consider compliance with international standards and certifications when sourcing rice mill suppliers, as these factors can significantly impact market access and product acceptance.

How Can Rice Mill Suppliers Support Local Agriculture and Farming?

Rice mill suppliers provide custom milling services that cater specifically to local farmers, helping them process their crops efficiently. This application addresses the unique needs of different rice varieties and helps farmers maximize their yields. For international buyers, especially in regions like Africa, it is crucial to evaluate local sourcing options and the flexibility of suppliers in adjusting production volumes based on seasonal demands. This adaptability can lead to better resource management and increased profitability for farmers.

What Benefits Do Rice Mill Suppliers Offer to Hospitality and Catering Industries?

In the hospitality and catering sectors, rice mill suppliers provide specialty rice types that enhance the culinary experience in restaurants and hotels. This application allows establishments to offer unique rice dishes that can attract a diverse clientele. Buyers from Europe and the Middle East should focus on the variety of rice types available, packaging options, and delivery timelines to ensure they can meet their customers’ demands effectively. These considerations are key to maintaining a competitive edge in a crowded market.

How Do Rice Mill Suppliers Impact Retail and Supermarkets?

Rice mill suppliers are essential for retail and supermarket chains as they supply packaged rice products that appeal to consumers. This application helps retailers increase sales through premium product offerings that meet evolving consumer preferences. International B2B buyers must consider branding options and supply chain efficiency when sourcing rice mill suppliers, as these elements can significantly influence market trends and consumer purchasing decisions. Understanding these dynamics is crucial for maximizing profitability in the retail space.

Related Video: NEW MINI RICE MILL

3 Common User Pain Points for ‘rice mill supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Rice Milling Equipment

The Problem: B2B buyers often encounter a significant challenge when sourcing rice milling equipment from suppliers. Variability in quality can lead to operational inefficiencies, product losses, and increased maintenance costs. For instance, a rice mill supplier might provide machinery that does not meet specified standards, resulting in subpar milling processes that affect the overall quality of the rice produced. This issue is particularly pressing for buyers in regions like Africa and South America, where local markets demand high-quality products but may have limited access to reliable suppliers.

The Solution: To mitigate quality inconsistencies, B2B buyers should conduct thorough due diligence before finalizing a supplier. This includes requesting detailed specifications and performance data for the milling equipment. Engage with suppliers who offer product demonstrations or trial periods, allowing for firsthand evaluation of their machinery’s performance. Additionally, checking supplier certifications and customer reviews can provide insights into their reliability. Establishing a clear set of quality benchmarks and ensuring the supplier can meet them is crucial. Forming partnerships with suppliers who emphasize quality control in their manufacturing processes can help ensure consistent product quality.

Scenario 2: Unforeseen Delays in Delivery Times

The Problem: Delivery delays are a common pain point for B2B buyers, particularly in international transactions. Buyers in Europe or the Middle East may experience extended lead times due to logistical issues or customs clearance, disrupting their production schedules and leading to financial losses. For example, a rice mill supplier may promise quick shipping but fail to account for port congestion or regulatory hurdles, leaving buyers in a bind.

The Solution: To address potential delivery delays, buyers should prioritize suppliers with a proven track record of timely deliveries. Establishing clear communication channels with suppliers can facilitate transparency regarding shipping timelines. Buyers should also consider incorporating buffer periods into their project schedules to account for potential delays. It is advisable to negotiate delivery terms that include penalties for late shipments, incentivizing suppliers to adhere to agreed timelines. Finally, leveraging local suppliers or those with regional distribution centers can significantly reduce delivery times and enhance reliability.

Scenario 3: Limited Technical Support and After-Sales Service

The Problem: After purchasing rice milling equipment, many B2B buyers face challenges related to inadequate technical support and after-sales service. This can be particularly troublesome for buyers who lack in-house expertise to troubleshoot machinery issues. For instance, a buyer in Africa may find that their supplier offers little to no support once the equipment is installed, leading to prolonged downtimes during critical production periods.

The Solution: To overcome this challenge, buyers should thoroughly evaluate the after-sales service offerings of potential rice mill suppliers before making a purchase. Prioritize suppliers that provide comprehensive technical support, including training for operators, maintenance guidelines, and readily available spare parts. Buyers should also inquire about the availability of remote support options, which can be critical for quick troubleshooting. Establishing a Service Level Agreement (SLA) with the supplier can ensure that response times for support inquiries are well-defined. Furthermore, seeking out suppliers with a local presence or partnerships with local service providers can enhance the level of support and minimize downtime for mill operations.

Strategic Material Selection Guide for rice mill supplier

What Are the Key Materials Used in Rice Mill Manufacturing?

When selecting materials for rice mill components, it’s essential to consider their properties, advantages, and limitations. This analysis will focus on four common materials: stainless steel, carbon steel, aluminum, and polyethylene. Each material has unique characteristics that can significantly impact the performance and longevity of rice milling equipment.

How Does Stainless Steel Benefit Rice Mill Suppliers?

Stainless steel is a popular choice for rice mill suppliers due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for various milling processes. The material’s non-reactive nature ensures that it does not contaminate the rice, which is crucial for maintaining product quality.

Pros: Stainless steel is highly durable, resistant to rust and corrosion, and easy to clean, which is vital for food safety. It also has a long lifespan, reducing the need for frequent replacements.

Cons: The primary drawback is the cost; stainless steel is generally more expensive than other materials. Additionally, its manufacturing process can be complex, requiring specialized equipment and techniques.

Impact on Application: Stainless steel is ideal for components that come into direct contact with rice and water, such as hoppers, silos, and milling machinery. Its compatibility with food-grade standards makes it a preferred choice in many regions.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with local food safety standards, such as the FDA in the U.S. or EFSA in Europe. Familiarity with ASTM and ISO standards can also be beneficial.

What Are the Advantages of Carbon Steel in Rice Mills?

Carbon steel is another common material used in rice milling equipment. It is known for its strength and toughness, making it suitable for structural applications within the mill.

Pros: Carbon steel is relatively inexpensive and offers good mechanical properties. It can be heat-treated to enhance its strength, making it suitable for high-stress applications.

Cons: The main disadvantage is its susceptibility to corrosion, which can lead to premature failure if not properly maintained. It may also require additional coatings or treatments to improve its resistance to rust.

Impact on Application: Carbon steel is often used in frames, supports, and other non-food-contact areas of the rice mill. Its strength is beneficial for structural components that must withstand significant loads.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to extend the lifespan of carbon steel components. Compliance with local standards for structural materials, such as DIN or JIS, is also essential.

Why is Aluminum a Viable Option for Rice Mill Components?

Aluminum is lightweight and corrosion-resistant, making it a viable option for various rice mill applications. Its excellent thermal conductivity is advantageous for heat-sensitive processes.

Pros: The lightweight nature of aluminum allows for easier handling and installation. It is also resistant to corrosion, which reduces maintenance costs over time.

Cons: Aluminum is generally less strong than stainless or carbon steel, which may limit its use in high-stress applications. It can also be more expensive than carbon steel.

Impact on Application: Aluminum is suitable for components like covers, guards, and lightweight frames that do not bear heavy loads. Its compatibility with food products makes it a good choice for non-contact areas.

Considerations for International Buyers: Buyers should verify that aluminum components meet local food safety regulations. Understanding the differences in alloy grades is crucial for ensuring the right material is selected for specific applications.

What Role Does Polyethylene Play in Rice Mill Manufacturing?

Polyethylene is a versatile plastic material often used for various applications in rice mills, particularly for storage and handling.

Pros: Polyethylene is lightweight, resistant to chemicals, and has good impact resistance. It is also cost-effective, making it an attractive option for bulk purchasing.

Cons: The primary limitation is its lower temperature resistance compared to metals, which may restrict its use in high-heat applications. It can also degrade over time when exposed to UV light.

Impact on Application: Polyethylene is commonly used for storage bins, chutes, and other non-structural components. Its chemical resistance makes it suitable for handling various materials without contamination.

Considerations for International Buyers: Buyers should ensure that the polyethylene used complies with local regulations regarding food safety and material specifications. Understanding the differences in grades and their applications is essential for optimal performance.

Summary Table of Material Selection for Rice Mill Suppliers

| Material | Typical Use Case for rice mill supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Hoppers, silos, milling machinery | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Structural frames and supports | Good strength and toughness | Susceptible to corrosion | Low |

| Aluminum | Covers, guards, lightweight frames | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Polyethylene | Storage bins, chutes | Cost-effective and chemical-resistant | Limited temperature resistance | Low |

This strategic material selection guide provides international B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in rice milling equipment. Understanding these factors will enable buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for rice mill supplier

What are the Main Stages of Manufacturing Rice Mills?

The manufacturing process for rice mills typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can help international B2B buyers identify the capabilities of potential suppliers and ensure that they meet their quality standards.

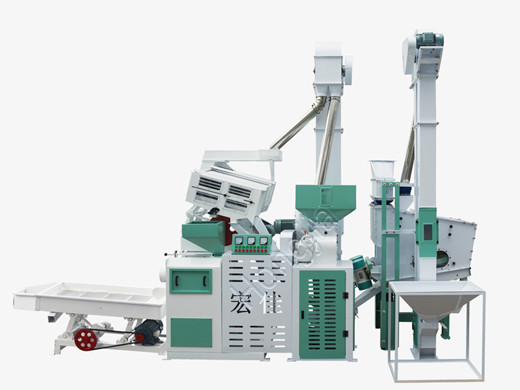

A stock image related to rice mill supplier.

Material Preparation

This initial stage focuses on sourcing high-quality raw materials such as steel, cast iron, and other components essential for constructing rice mills. Suppliers often prioritize materials that meet specific mechanical properties to withstand the rigors of milling operations. For B2B buyers, it’s crucial to inquire about the source of materials and whether they conform to international standards, such as ASTM or ISO.

Forming Techniques

Forming processes involve shaping the raw materials into components. Techniques such as casting, forging, and machining are commonly employed. Each technique has its advantages; for instance, casting can create complex shapes, while machining ensures precision. Buyers should assess suppliers’ capabilities in these techniques, as they significantly impact the performance and durability of the rice mill.

Assembly Process

The assembly stage combines all manufactured components into a complete rice milling unit. This process often includes aligning various parts, such as the milling chamber, motors, and control systems. Effective assembly is critical to ensure operational efficiency. B2B buyers should ask suppliers about their assembly protocols and whether they adhere to standardized procedures to minimize defects.

Finishing Touches

Finishing involves surface treatments, painting, and quality checks before the product is dispatched. This stage not only enhances the aesthetics of the rice mill but also protects it from environmental factors such as corrosion. Buyers should look for suppliers that use high-quality finishes and provide certifications for their coatings.

How is Quality Assurance Implemented in Rice Mill Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process for rice mills, ensuring that products meet both domestic and international standards. For international B2B buyers, understanding the QA practices of suppliers is essential for risk mitigation.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 are fundamental in the quality assurance process. This standard focuses on quality management systems and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for machinery components can also be significant. Buyers should verify that suppliers possess relevant certifications to ensure compliance with market requirements.

What are Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product before shipping ensures that it meets all specifications.

B2B buyers should request documentation of these QC checkpoints to assess the rigor of the supplier’s QA processes.

What Common Testing Methods are Used in Rice Mill Quality Control?

Testing methods play a vital role in quality assurance for rice mills. Common methods include:

- Dimensional Inspection: Ensuring that components are manufactured to specified tolerances.

- Material Testing: Assessing the mechanical properties of materials, such as tensile strength and hardness.

- Operational Testing: Running the rice mill under simulated conditions to verify performance and reliability.

Understanding these testing methods allows buyers to gauge the thoroughness of a supplier’s quality assurance measures.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is essential for mitigating risks associated with product quality. Here are several strategies B2B buyers can employ:

Conducting Audits

Regular audits of suppliers can provide insights into their manufacturing and QC processes. Buyers should establish audit protocols that assess compliance with international standards and quality benchmarks.

Requesting Quality Reports

Suppliers should be willing to provide quality reports detailing their QC processes, testing outcomes, and any corrective actions taken. These reports can help buyers evaluate the supplier’s commitment to quality.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can verify that suppliers adhere to industry standards and deliver products that meet buyers’ expectations.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing from suppliers in different regions, B2B buyers must navigate various quality control nuances. Factors such as regional regulations, cultural attitudes toward quality, and varying standards can affect procurement decisions.

Understanding Regional Regulations

Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with regional regulations that may impact the import and use of rice mills. For instance, European buyers must ensure compliance with EU regulations, while Middle Eastern buyers might need to adhere to specific local standards.

Cultural Considerations in Quality Perception

Cultural attitudes toward quality can vary significantly. For example, suppliers in Europe may have a different approach to quality assurance compared to those in Africa or South America. Understanding these differences can help buyers communicate more effectively and set realistic expectations.

Conclusion

In conclusion, the manufacturing processes and quality assurance measures for rice mills are critical considerations for international B2B buyers. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier capabilities, buyers can make informed decisions that align with their operational needs and market demands. Prioritizing these aspects will not only enhance the reliability of the rice mills sourced but also foster stronger supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rice mill supplier’

A stock image related to rice mill supplier.

The purpose of this guide is to provide international B2B buyers with a clear, actionable checklist for sourcing rice mill suppliers. By following these steps, buyers can ensure they choose a reliable partner that meets their operational needs and quality standards.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is essential before reaching out to suppliers. Define the capacity of the rice mill, the types of rice you intend to process, and any additional functionalities, such as parboiling or whitening. This clarity will help narrow down your options and communicate effectively with potential suppliers.

Step 2: Conduct Market Research

Before selecting a supplier, invest time in researching the market landscape. Identify key players in the rice milling industry, focusing on those with a strong presence in Africa, South America, the Middle East, and Europe. Utilize platforms like trade shows, industry reports, and online directories to gather insights about their reputation and product offerings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for:

– Track Record: Suppliers with a history of successful projects demonstrate reliability.

– Customer Feedback: Reviews and testimonials can provide insights into product performance and service quality.

Step 4: Verify Supplier Certifications

Certifications ensure that the supplier adheres to industry standards and regulations. Check for relevant certifications such as ISO, CE, or local quality assurance marks. These certifications not only reflect quality but also compliance with safety and environmental regulations, which is critical for long-term operational sustainability.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. Ensure that the quotations cover all aspects, including equipment specifications, pricing, warranty terms, and delivery timelines. Comparing these details will help you assess the value proposition of each supplier and identify any hidden costs.

Step 6: Assess After-Sales Support and Service

After-sales support is a vital aspect of your partnership with a rice mill supplier. Inquire about service agreements, maintenance support, and availability of spare parts. A supplier that provides robust after-sales service can significantly reduce downtime and enhance operational efficiency.

Step 7: Visit Supplier Facilities (If Possible)

If feasible, arrange a visit to the supplier’s manufacturing facilities. This step allows you to assess the production processes, quality control measures, and overall operational capabilities. Seeing the machinery and the production environment firsthand can provide valuable insights that are not apparent through documentation alone.

By following this checklist, international B2B buyers can make informed decisions when sourcing rice mill suppliers, ensuring they select a partner that aligns with their business goals and operational needs.

Comprehensive Cost and Pricing Analysis for rice mill supplier Sourcing

What Are the Key Cost Components in Sourcing Rice Mill Suppliers?

When sourcing rice mill suppliers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The cost of raw materials, such as steel, machinery parts, and electrical components, significantly impacts the overall price. Suppliers often source materials locally or internationally, which can affect pricing based on availability and market conditions.

-

Labor: Labor costs vary widely by region. Countries with lower labor costs can offer competitive pricing, but it’s essential to consider the skill level and expertise of the workforce, as this affects the quality of the final product.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and administrative expenses. Suppliers with efficient operations may have lower overhead costs, allowing them to offer more competitive pricing.

-

Tooling: The cost of tooling, including molds and dies used in manufacturing, is another significant component. Custom tooling can increase upfront costs but may lead to better efficiency and quality in the long run.

-

Quality Control (QC): Effective QC processes ensure that products meet specific standards, which can add to the cost. However, investing in quality control can reduce long-term costs associated with defects and returns.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and customs duties can greatly influence the final price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and their positioning.

How Do Price Influencers Affect Rice Mill Supplier Costs?

Several factors can influence the pricing of rice mill suppliers, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate MOQs that provide cost savings.

-

Specifications and Customization: Customization can significantly affect pricing. Buyers should clearly define their specifications to avoid unexpected costs during production.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (like ISO or CE) can impact costs. Higher quality materials may lead to higher upfront costs but can reduce maintenance and replacement expenses over time.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven track record, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. These terms dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, which can affect overall costs.

What Buyer Tips Can Help in Negotiating Prices for Rice Mill Suppliers?

When negotiating with rice mill suppliers, consider the following actionable tips:

-

Conduct Thorough Market Research: Understand the market rates for rice mills and compare multiple suppliers. This knowledge will empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Instead of just considering the purchase price, evaluate the TCO, which includes maintenance, operational costs, and potential downtime. A higher initial investment might yield lower long-term costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Consider long-term partnerships instead of one-time transactions.

-

Be Transparent About Your Needs: Clearly communicate your requirements and constraints. This transparency can foster trust and lead to more favorable pricing.

-

Negotiate Payment Terms: Flexible payment terms can alleviate cash flow concerns. Discuss options such as installment payments or deferred payment schedules.

Why Is It Important to Understand Pricing Nuances for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of pricing is vital. Currency fluctuations, import tariffs, and regional regulations can significantly impact costs. Additionally, varying cultural expectations around negotiations can affect how deals are closed. Being aware of these factors will enable buyers to make more strategic decisions and optimize their sourcing processes.

Disclaimer

The prices mentioned throughout this analysis are indicative and can vary based on numerous factors, including market conditions, supplier negotiations, and specific buyer requirements. Always conduct due diligence and consult multiple suppliers to obtain accurate pricing information tailored to your needs.

Alternatives Analysis: Comparing rice mill supplier With Other Solutions

Understanding Alternatives in Rice Milling Solutions

In the competitive landscape of rice production and processing, choosing the right milling solution is crucial for efficiency and profitability. While traditional rice mill suppliers provide a direct means of processing, there are alternative technologies and methods that can also meet the demands of international B2B buyers. This section evaluates rice mill suppliers against two viable alternatives: mobile rice milling units and automated rice processing systems.

Comparison Table of Rice Milling Solutions

| Comparison Aspect | Rice Mill Supplier | Mobile Rice Milling Unit | Automated Rice Processing System |

|---|---|---|---|

| Performance | High throughput, consistent quality | Moderate throughput, flexibility in location | Very high throughput, precision milling |

| Cost | Moderate initial investment, ongoing costs | Lower initial investment, variable operating costs | High initial investment, lower long-term operational costs |

| Ease of Implementation | Requires infrastructure setup | Quick setup, minimal infrastructure | Complex setup, requires specialized training |

| Maintenance | Regular maintenance needed, parts availability | Low maintenance, easy repairs | High maintenance, specialized technicians required |

| Best Use Case | Large-scale processing facilities | Small-scale or remote operations | Large-scale operations with high demand |

What Are the Pros and Cons of Mobile Rice Milling Units?

Mobile rice milling units offer flexibility and adaptability, making them ideal for small-scale farmers or regions with limited access to milling facilities. They can be transported to remote locations, reducing the need for extensive logistics. The initial investment is generally lower compared to traditional rice mills, which can be appealing for startups or smaller operations. However, these units typically have a moderate throughput and may not achieve the same quality consistency as larger suppliers. Additionally, they may require more frequent manual intervention, which can slow down processing times.

How Do Automated Rice Processing Systems Enhance Efficiency?

Automated rice processing systems represent the pinnacle of technological advancement in rice milling. These systems offer very high throughput rates and precision milling, significantly reducing waste and improving overall product quality. While the initial capital expenditure is substantial, the long-term operational costs can be lower due to reduced labor needs and enhanced efficiency. However, the complexity of these systems can be a barrier, as they require skilled technicians for both setup and maintenance. This makes them best suited for large-scale operations with a consistent demand for rice products.

Conclusion: How Should B2B Buyers Choose the Right Rice Milling Solution?

When selecting the ideal rice milling solution, international B2B buyers should evaluate their specific operational needs, budget constraints, and production goals. For businesses focused on large-scale production and consistent quality, traditional rice mill suppliers or automated systems may be the best fit. Conversely, those operating in remote areas or with lower volumes might find mobile rice milling units to be a more practical choice. Understanding the unique benefits and limitations of each option will empower buyers to make informed decisions that align with their business strategies.

Essential Technical Properties and Trade Terminology for rice mill supplier

What Are the Essential Technical Properties for Rice Mill Suppliers?

When selecting a rice mill supplier, understanding the technical properties of the equipment is crucial for ensuring quality, efficiency, and reliability in production. Here are some key specifications to consider:

1. Material Grade

The material grade of the rice mill components, such as stainless steel or carbon steel, significantly impacts durability and resistance to wear and corrosion. For instance, higher-grade stainless steel (like 304 or 316) is preferred for its longevity and ability to withstand harsh cleaning processes. B2B buyers should verify that suppliers use appropriate material grades to ensure the longevity of their equipment, especially in diverse environments across Africa, South America, the Middle East, and Europe.

2. Tolerance Levels

Tolerance refers to the allowable deviation in dimensions of the components, which can affect the machine’s performance. Precision in manufacturing is essential for components like rollers and hoppers to ensure uniformity in rice processing. Buyers should inquire about the tolerance levels offered by suppliers, as tighter tolerances typically mean better quality and efficiency in operation.

3. Capacity

The capacity of a rice mill, usually measured in tons per hour, is a critical specification that determines how much rice can be processed within a given timeframe. Buyers must align their production needs with the mill’s capacity to avoid bottlenecks or excess inventory. Suppliers often provide various models with different capacities, allowing buyers to select equipment that best fits their operational requirements.

4. Power Consumption

Power consumption is an essential factor in determining operational costs. Efficient rice mills are designed to minimize energy usage while maximizing output. Buyers should ask suppliers about the energy efficiency ratings of their equipment, as this can significantly impact long-term operating expenses.

5. Automation Level

The level of automation in rice milling equipment can greatly enhance productivity and reduce labor costs. Fully automated systems can streamline processes, from husking to polishing. Understanding the automation features available will help buyers select a supplier that meets their technological needs and budget constraints.

What Are Common Trade Terms Used in Rice Milling Supply?

Familiarity with trade terminology is vital for effective communication and negotiation with rice mill suppliers. Here are some commonly used terms in the industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of rice milling, buyers should understand whether they are purchasing from an OEM or a reseller, as this can affect warranty, service, and pricing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to gauge whether a supplier can meet their order size requirements without incurring excessive costs or being left with surplus inventory.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This is an essential step in the procurement process, allowing buyers to compare offers and make informed decisions based on cost and specifications.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, insurance responsibilities, and risk during transportation, which is critical when sourcing from international suppliers.

5. Lead Time

Lead time refers to the duration from the placement of an order to the delivery of the product. Understanding lead times is essential for buyers to plan their production schedules effectively and avoid disruptions in their supply chain.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they partner with reliable rice mill suppliers that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the rice mill supplier Sector

What Are the Key Market Dynamics and Trends Influencing Rice Mill Suppliers?

The global rice mill supplier sector is experiencing a transformation driven by several key factors. One major driver is the increasing demand for rice, particularly in developing regions like Africa and South America, where rice is a staple food. Simultaneously, the Middle East and Europe are witnessing a growing interest in premium rice varieties, leading to an uptick in quality-focused suppliers.

Emerging technologies are also shaping sourcing trends. Automation and the Internet of Things (IoT) are enabling rice mills to enhance efficiency and reduce costs. B2B buyers are increasingly looking for suppliers that leverage these technologies to provide real-time data on production and inventory. This trend not only streamlines operations but also improves transparency, a critical factor for international buyers.

Moreover, the rise of e-commerce platforms and digital marketplaces is facilitating access to suppliers across borders. Buyers from Turkey, the UK, and other European nations can now easily compare prices and specifications, leading to more competitive sourcing strategies. Understanding these dynamics is essential for international B2B buyers to navigate the complexities of the rice mill supplier sector effectively.

How Is Sustainability Shaping the Rice Mill Supplier Sector?

Sustainability is becoming a cornerstone of the rice mill supplier landscape. The environmental impact of rice production is significant, with water usage and methane emissions being critical concerns. Buyers are increasingly prioritizing suppliers that adopt sustainable practices, such as using energy-efficient machinery and sourcing rice from environmentally responsible farms.

Ethical sourcing is equally important. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to fair labor practices and community engagement. Certifications such as Fair Trade and Rainforest Alliance can serve as indicators of a supplier’s dedication to ethical standards.

Incorporating ‘green’ materials and technologies in rice milling processes not only reduces environmental footprints but also appeals to socially conscious consumers. For international buyers, aligning with suppliers who prioritize sustainability can enhance brand reputation and meet the growing consumer demand for ethically sourced products.

How Has the Rice Mill Supplier Sector Evolved Over Time?

The rice mill supplier sector has undergone significant evolution over the decades, transitioning from manual processes to highly mechanized operations. Historically, rice milling was a labor-intensive endeavor, with small-scale operations dominating the market. However, with advancements in technology and increased global demand, large-scale, automated rice mills have emerged.

This evolution has enabled suppliers to meet the growing needs of international markets, offering a variety of rice types and processing capabilities. As a result, the sector has not only expanded in scale but also in sophistication, with a greater emphasis on quality control and efficiency. Understanding this historical context can help B2B buyers appreciate the current landscape and identify suppliers that are well-equipped to meet their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of rice mill supplier

-

How do I solve the challenge of selecting a reliable rice mill supplier?

To select a reliable rice mill supplier, start by researching potential suppliers in your target regions, focusing on their reputation, certifications, and years of experience. Request references from other international buyers who have previously engaged with them. Utilize platforms like Alibaba or Global Sources to verify their legitimacy. Conduct video calls to assess their facilities and operational capabilities. Finally, ensure that they comply with international quality standards, such as ISO certifications, which can significantly reduce the risk of poor product quality. -

What is the best rice mill machine for small-scale operations?

For small-scale operations, a compact rice mill with a capacity of 200-500 kg per hour is often the best choice. Look for machines that offer multiple functions, such as husking, polishing, and grading, to maximize efficiency. Brands like Satake and Buhler are renowned for their quality and durability. Additionally, consider factors such as ease of maintenance, energy consumption, and the availability of spare parts in your region, which can significantly affect your operational costs and downtime. -

What are the minimum order quantities (MOQ) I should expect from rice mill suppliers?

Minimum order quantities (MOQ) can vary significantly depending on the supplier and the type of machinery. Generally, MOQs for rice mills range from one unit for high-end suppliers to several units for budget manufacturers. It’s important to clarify MOQs during initial communications to avoid misunderstandings. If you are a small business, some suppliers may offer flexibility on MOQs for first-time orders or pilot projects, especially if you can demonstrate potential for larger future orders. -

What payment terms should I negotiate with rice mill suppliers?

Payment terms can vary widely, but common arrangements include 30% upfront and 70% upon delivery, or a letter of credit for larger transactions. It’s advisable to negotiate terms that safeguard your investment while providing the supplier with sufficient assurance. Consider utilizing escrow services for additional security, especially when dealing with new suppliers. Always ensure that payment terms align with your cash flow needs and that they are clearly outlined in the contract to avoid disputes. -

How can I ensure quality assurance when sourcing rice mills?

To ensure quality assurance, request detailed product specifications and quality control processes from the supplier. Consider conducting pre-shipment inspections through third-party services that specialize in quality assurance for machinery. Additionally, inquire about the supplier’s return policy and warranty terms, as these can provide insight into their confidence in product quality. Regular communication and visits to the production facility, if feasible, can also help maintain quality standards throughout the manufacturing process. -

What logistics considerations should I keep in mind when importing rice mills?

Logistics is a critical factor when importing rice mills. You should evaluate shipping methods, including sea freight and air freight, based on your budget and urgency. Consider the total landed cost, which includes freight, customs duties, and insurance. Ensure that your supplier can provide all necessary shipping documentation, including the Bill of Lading and commercial invoice. Collaborating with a reliable freight forwarder can streamline the process and help navigate customs regulations specific to your country. -

How do I vet rice mill suppliers for international trade compliance?

Vetting suppliers for compliance with international trade regulations involves checking their export licenses and ensuring they adhere to both local and international standards. Utilize resources such as the Export Administration Regulations (EAR) for the U.S. or similar regulations in your country. Request documentation that proves their compliance with safety and environmental standards. Additionally, consider conducting background checks and reviewing their history with international buyers to assess their reliability and adherence to trade agreements. -

What customization options are typically available for rice mill machinery?

Many rice mill suppliers offer customization options to meet specific operational needs. Customizations may include variations in processing capacity, additional features such as color sorting technology, or modifications for local grain types. Discuss your requirements upfront and inquire about the supplier’s ability to adapt their equipment. Customization can sometimes extend lead times, so plan accordingly and ensure that any modifications do not compromise the machine’s quality or performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for rice mill supplier

In the evolving landscape of global rice supply chains, strategic sourcing emerges as a vital approach for international B2B buyers. Understanding the nuances of sourcing rice mill suppliers can significantly impact operational efficiency and cost-effectiveness. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers who demonstrate reliability, quality, and sustainability. Evaluating supplier capabilities through comprehensive assessments and leveraging technology for procurement processes can enhance the decision-making experience.

What are the key benefits of strategic sourcing in rice milling? By focusing on long-term supplier relationships and implementing robust risk management strategies, businesses can mitigate supply disruptions and ensure consistent product quality. Additionally, engaging with suppliers who adopt sustainable practices not only aligns with global trends but can also improve brand reputation and customer loyalty.

As we look ahead, the demand for rice will continue to grow, driven by population increases and changing dietary preferences. International B2B buyers must remain proactive in identifying and collaborating with innovative rice mill suppliers who can meet these evolving needs. Embrace strategic sourcing today to secure a competitive edge in the marketplace, ensuring your operations are future-ready and resilient.