Unlock Savings with Oakleys Custom: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for oakleys custom

Navigating the global market for Oakleys custom products presents a unique set of challenges for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality customized eyewear can be daunting, especially when considering factors such as supplier reliability, product authenticity, and cost-effectiveness. This guide aims to provide a comprehensive overview of the various types of Oakleys custom offerings, their applications across different industries, and essential tips for vetting suppliers to ensure quality and compliance.

By delving into the nuances of the Oakleys custom market, this guide empowers B2B buyers to make informed purchasing decisions. It covers critical aspects, including the latest trends in customization, pricing strategies, and potential pitfalls to avoid during the procurement process. Whether you are based in the bustling markets of Nairobi or the vibrant business hubs of Milan, understanding the landscape of Oakleys custom products is crucial for maintaining a competitive edge.

In an increasingly interconnected world, navigating these complexities not only enhances your purchasing strategy but also fosters long-term partnerships with reputable suppliers. Equip yourself with the insights and knowledge necessary to thrive in this dynamic market, ensuring that your business meets the growing demand for customized eyewear solutions.

Understanding oakleys custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Oakley Sunglasses | Personalized lens colors and frame styles | Corporate gifts, promotional events | Pros: Unique branding; Cons: Higher cost |

| Custom Oakley Apparel | Tailored designs and company logos | Employee uniforms, sponsorships | Pros: Enhanced brand visibility; Cons: Limited sizes |

| Custom Oakley Accessories | Specialized cases, straps, and cleaning kits | Retail partnerships, bundled sales | Pros: Increased product value; Cons: Inventory risk |

| Custom Oakley Sports Gear | Performance enhancements and team logos | Sports teams, events, and tournaments | Pros: Improved team morale; Cons: Seasonal demand |

| Custom Oakley Tech Gear | Integration of tech features (e.g., audio) | Tech companies, event giveaways | Pros: Innovative appeal; Cons: Higher price point |

What Are Custom Oakley Sunglasses and Their B2B Relevance?

Custom Oakley sunglasses allow businesses to personalize lens colors and frame styles, making them a popular choice for corporate gifts and promotional events. This type of customization not only enhances brand visibility but also creates a unique identity for the company. When considering B2B purchases, buyers should evaluate the cost versus the potential for brand recognition, as these sunglasses can be a higher investment but may offer a significant return through increased brand loyalty and customer engagement.

How Can Custom Oakley Apparel Benefit Businesses?

Custom Oakley apparel, including tailored designs and company logos, is ideal for employee uniforms and sponsorships. This type of customization helps improve brand visibility in various settings, from corporate events to sports activities. Buyers should consider the quality and fit of the apparel, as well as the potential for bulk discounts, ensuring that they receive a product that represents their brand effectively while maintaining employee comfort.

What Are the Advantages of Custom Oakley Accessories?

Custom Oakley accessories, such as specialized cases, straps, and cleaning kits, are valuable additions for businesses looking to enhance their product offerings. These accessories can be used in retail partnerships and bundled sales, increasing the perceived value of the primary product. When purchasing, B2B buyers should assess the compatibility of accessories with existing products and consider inventory management, as these items can sometimes carry a risk of overstock.

Why Choose Custom Oakley Sports Gear for Teams?

Custom Oakley sports gear, featuring performance enhancements and team logos, is essential for sports teams and events. This type of customization not only boosts team morale but also creates a sense of unity among players. B2B buyers in the sports industry should evaluate the durability and performance of the gear, as well as the potential for sponsorship opportunities, ensuring that the investment aligns with the team’s goals and budget.

What Is the Appeal of Custom Oakley Tech Gear?

Custom Oakley tech gear, which integrates advanced features like audio capabilities, appeals to tech companies and event organizers looking for innovative giveaways. This customization offers a modern twist on traditional products, making them attractive to a tech-savvy audience. Buyers should weigh the innovative appeal against the higher price point, ensuring that the investment aligns with their target market’s preferences and the overall branding strategy.

Related Video: Oakley Custom Sutro Sunglasses Unboxing & Review

Key Industrial Applications of oakleys custom

| Industry/Sector | Specific Application of oakleys custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom Eyewear Designs | Enhances brand identity and customer engagement | Quality of materials, customization options, lead times |

| Sports & Recreation | Performance-Enhancing Eyewear | Improves athlete performance and safety | Durability, UV protection, comfort, and fit |

| Automotive & Transportation | Functional Eyewear for Drivers | Increases visibility and reduces glare | Compliance with safety standards, lens technology |

| Healthcare & Safety | Protective Eyewear for Medical Personnel | Ensures safety and compliance in medical settings | Anti-fog properties, durability, comfort for extended use |

| Industrial & Manufacturing | Safety Glasses for Industrial Workers | Protects workers from hazards, enhancing safety | Compliance with safety regulations, impact resistance |

How is Oakleys Custom Used in Fashion & Apparel?

In the fashion and apparel sector, Oakleys custom eyewear is utilized to create unique designs that resonate with brand identity. By offering personalized styles, businesses can enhance customer engagement and loyalty. For international B2B buyers, particularly from regions like Europe and Africa, sourcing considerations include the quality of materials used in the eyewear, the range of customization options available, and the lead times for production. This ensures that the products meet market demands and aesthetic preferences.

What Role Does Oakleys Custom Play in Sports & Recreation?

In sports and recreation, Oakleys custom eyewear is tailored to enhance performance and safety for athletes. This includes designs that provide superior visibility, reduce glare, and offer UV protection. B2B buyers in South America and the Middle East should consider factors such as durability and comfort, as well as the specific requirements of different sports. This ensures that the eyewear not only meets performance standards but also caters to the specific needs of athletes.

How Can Oakleys Custom Benefit the Automotive Industry?

For the automotive and transportation sector, Oakleys custom eyewear serves as functional eyewear for drivers, significantly increasing visibility and reducing glare during driving. This is particularly important in regions with varying light conditions, such as Europe and Africa. Key sourcing considerations include compliance with safety standards and lens technology that enhances visual clarity. Buyers should ensure that the eyewear meets the specific needs of drivers for both comfort and functionality.

Why is Oakleys Custom Important in Healthcare & Safety?

In healthcare, Oakleys custom eyewear is crucial for medical personnel who require protective eyewear to ensure safety and compliance in clinical settings. Features such as anti-fog properties and durability are essential for medical professionals who may wear these glasses for extended periods. B2B buyers from the Middle East and Europe must prioritize comfort and compliance with safety regulations to guarantee that their workforce remains protected while performing their duties.

How Does Oakleys Custom Enhance Safety in Industrial Settings?

In industrial and manufacturing environments, Oakleys custom eyewear is vital for protecting workers from potential hazards. These safety glasses are designed to meet stringent impact resistance standards, ensuring that employees are safeguarded against workplace dangers. International B2B buyers, particularly those in Africa and South America, should focus on sourcing eyewear that complies with local safety regulations while also considering the comfort and fit for prolonged use. This approach minimizes workplace injuries and promotes a culture of safety.

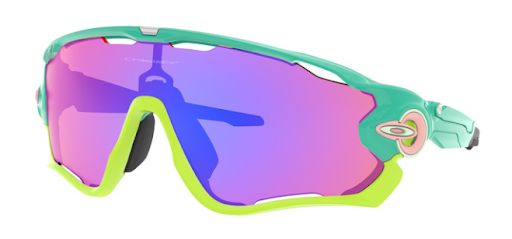

A stock image related to oakleys custom.

Related Video: Uses of Metals – Science 9

3 Common User Pain Points for ‘oakleys custom’ & Their Solutions

Scenario 1: Customization Delays in Production

The Problem: International B2B buyers often face significant delays when ordering custom products like Oakleys. These delays can arise from miscommunication regarding specifications, production bottlenecks, or logistical issues. Buyers in regions such as Africa and South America may find that the time taken to finalize orders can lead to missed market opportunities, especially in fast-paced industries like fashion and sports.

The Solution: To mitigate production delays, buyers should establish clear communication channels with manufacturers right from the outset. Creating a detailed specification document that outlines every aspect of the order—from design elements to materials and quantities—can help minimize misunderstandings. Additionally, utilizing project management tools to track the production timeline and regularly check in with the supplier can ensure that any potential delays are identified early. For buyers, it’s crucial to build a strong relationship with suppliers who have a proven track record of timely deliveries, and to incorporate buffer time into their planning to accommodate any unforeseen issues.

Scenario 2: Quality Assurance Issues with Custom Orders

The Problem: Quality assurance is a common concern for B2B buyers, particularly when sourcing custom products like Oakleys. Buyers may receive items that do not meet the promised specifications or quality standards, leading to dissatisfaction and potential financial losses. This issue is exacerbated when buyers are located in regions where they cannot physically inspect the products before purchasing.

The Solution: To ensure high quality in custom orders, buyers should implement a robust quality assurance process. This could include requesting samples before placing a full order, which allows for direct evaluation of materials and craftsmanship. Buyers should also inquire about the manufacturer’s quality control protocols, including any certifications they hold. Establishing a quality checklist that aligns with the buyer’s specific requirements can provide a framework for evaluating the products upon delivery. Furthermore, engaging third-party inspection services can add an additional layer of assurance, particularly for international transactions where on-site inspections may not be feasible.

Scenario 3: Complicated Import Regulations and Duties

The Problem: Navigating the complex landscape of import regulations and duties can be a daunting task for B2B buyers, especially when ordering custom products like Oakleys from different countries. Buyers from regions such as the Middle East and Europe may encounter unexpected tariffs, customs paperwork, and varying regulations that can complicate the import process, leading to increased costs and delays.

The Solution: To successfully navigate import regulations, buyers should conduct thorough research on the customs requirements of their respective countries. Collaborating with customs brokers or freight forwarders who specialize in international trade can significantly streamline the process. These professionals can provide insights into tariff classifications, necessary documentation, and compliance regulations that must be adhered to. Buyers should also consider incorporating these potential costs into their pricing strategy to avoid surprises. Developing a comprehensive checklist that includes all required documentation (like commercial invoices, packing lists, and certificates of origin) can help ensure that shipments clear customs smoothly and efficiently.

Strategic Material Selection Guide for oakleys custom

What Are the Key Materials for Oakleys Custom Products?

When selecting materials for Oakleys custom products, international B2B buyers must consider various factors, including performance properties, cost, and regional compliance standards. Below, we analyze four common materials used in Oakleys custom applications, providing insights into their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

How Does Polycarbonate Perform in Oakleys Custom Applications?

Polycarbonate is a popular choice for Oakleys custom products, particularly for lenses and protective gear. This thermoplastic material boasts excellent impact resistance, making it ideal for eyewear that requires durability against physical stress. Polycarbonate lenses can withstand high temperatures, typically rated up to 120°C, and offer UV protection.

Pros: Polycarbonate is lightweight, highly shatter-resistant, and provides clear optical quality. Its manufacturing process is relatively straightforward, allowing for complex shapes and designs.

Cons: While polycarbonate is durable, it can scratch more easily than other materials unless treated with a hard coating. Additionally, its cost can be higher than traditional glass lenses.

Impact on Application: Polycarbonate is compatible with various coatings, enhancing its scratch resistance and UV protection. For B2B buyers, this means that products can be tailored to specific use cases, such as sports eyewear or safety goggles.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for optical clarity and impact resistance. In regions like Europe, adherence to EU regulations regarding chemical safety is crucial.

What Are the Benefits of Using Nylon in Oakleys Custom Products?

Nylon is another versatile material used in Oakleys custom applications, particularly for frames and straps. Known for its flexibility and strength, nylon can endure a wide range of temperatures and is resistant to wear and tear.

Pros: Nylon is lightweight, resistant to chemicals, and offers good tensile strength, making it suitable for active use. Its flexibility allows for comfort and fit in custom designs.

Cons: Nylon can absorb moisture, potentially affecting its performance in humid environments. Additionally, its colorfastness can be a concern if exposed to sunlight for prolonged periods.

Impact on Application: Nylon’s compatibility with various dyes allows for vibrant color options, appealing to a diverse customer base. This adaptability is particularly beneficial for brands targeting active lifestyles.

Considerations for International Buyers: Buyers from regions such as Africa and South America should consider nylon’s performance in local climates. Compliance with local standards for materials used in consumer products is also essential.

Why Choose Aluminum for Oakleys Custom Products?

A stock image related to oakleys custom.

Aluminum is often selected for Oakleys custom products due to its lightweight yet robust nature. This metal is commonly used in frames and components where strength is paramount.

Pros: Aluminum offers excellent corrosion resistance, making it suitable for various environmental conditions. It is also recyclable, aligning with sustainability goals.

Cons: While aluminum is durable, it can be prone to scratches and dents if not properly treated. The manufacturing complexity can also increase costs compared to plastic alternatives.

Impact on Application: Aluminum’s strength-to-weight ratio makes it ideal for products that require durability without added weight. This is particularly relevant for high-performance eyewear.

Considerations for International Buyers: Buyers should be aware of international standards for metal products, such as ASTM and ISO certifications. In Europe, compliance with REACH regulations regarding chemical safety is also critical.

What Role Does Glass Play in Oakleys Custom Products?

Glass remains a traditional choice for Oakleys custom lenses, especially for high-end products. It offers superior optical clarity and scratch resistance compared to plastic alternatives.

Pros: Glass lenses provide excellent visual quality and are less prone to scratching. They also offer high resistance to UV rays.

Cons: Glass is heavier than plastic options and can shatter upon impact, posing safety concerns. The manufacturing process can be more complex and costly.

Impact on Application: Glass is particularly suitable for applications requiring high optical performance, such as prescription eyewear. However, the weight may limit its use in sports or active wear.

Considerations for International Buyers: Buyers must ensure that glass products meet safety standards in their respective regions, such as EN and ANSI standards. Additionally, awareness of shipping regulations for fragile materials is crucial.

Summary of Material Selection for Oakleys Custom Products

| Material | Typical Use Case for Oakleys Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Lenses, protective gear | Lightweight and impact-resistant | Scratches easily without coating | Medium |

| Nylon | Frames, straps | Flexible and strong | Absorbs moisture | Low |

| Aluminum | Frames, components | Corrosion-resistant | Prone to scratches | High |

| Glass | High-end lenses | Superior optical clarity | Heavier and can shatter | Medium |

This guide provides a comprehensive overview of material options for Oakleys custom products, enabling international B2B buyers to make informed decisions that align with their specific market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for oakleys custom

What Are the Main Stages of Manufacturing Oakleys Custom Products?

The manufacturing process for Oakleys custom products involves several key stages that ensure the quality and durability of the final product. Understanding these stages is crucial for B2B buyers looking to source high-quality custom eyewear.

Material Preparation

The first step in the manufacturing process is material preparation. Oakleys custom products typically use high-grade materials such as polycarbonate and Trivex for lenses, and various plastics or metals for frames.

- Material Selection: Buyers should inquire about the sourcing of materials, ensuring they meet international standards for safety and performance.

- Pre-Treatment: Materials may undergo treatments to enhance durability and resistance to UV light and scratches, which are essential features for eyewear.

Forming Techniques

Once the materials are prepared, the next stage is forming. This process shapes the lenses and frames into their desired forms.

- Injection Molding: This technique is often used for plastic frames, allowing for complex designs and lightweight structures.

- Cutting and Grinding: Lenses are cut to precise specifications using high-precision machinery, ensuring clarity and fit.

How Is Assembly Conducted in Oakleys Custom Manufacturing?

The assembly stage is where the different components come together to create the final product.

- Component Assembly: Frames and lenses are assembled using automated and manual processes. Quality checks at this stage are crucial to ensure alignment and fitting.

- Customization Options: B2B buyers can specify features such as color, lens tint, and personalized engraving, which can be integrated during this stage.

What Finishing Techniques Are Used in Oakleys Custom Products?

Finishing techniques enhance the aesthetic and functional qualities of the eyewear.

- Coatings: Anti-reflective coatings and hydrophobic treatments are applied to lenses to improve performance.

- Quality Inspection: Each finished product undergoes a thorough inspection to ensure it meets design specifications and quality standards.

What International Quality Assurance Standards Should B2B Buyers Know?

Understanding the relevant quality assurance standards is vital for B2B buyers looking to ensure that the products they source meet international quality benchmarks.

ISO 9001 Certification

ISO 9001 is an internationally recognized standard for quality management systems. Suppliers should be able to provide documentation verifying their compliance with this standard, ensuring a consistent approach to quality across their operations.

CE Marking

For buyers in Europe, CE marking is crucial as it indicates compliance with EU safety and health regulations. This is particularly important for eyewear, where consumer safety is paramount.

API and Other Industry-Specific Standards

In addition to ISO and CE, buyers should also be aware of other relevant industry-specific standards such as API (American Petroleum Institute) for certain materials used in lens manufacturing. This is particularly relevant if the eyewear is intended for specific industrial applications.

What Are the Key Quality Control Checkpoints in Oakleys Custom Manufacturing?

Quality control (QC) is integrated into the manufacturing process at various checkpoints to ensure that every product meets the highest standards.

Incoming Quality Control (IQC)

The first checkpoint involves inspecting incoming materials for quality and compliance with specifications. This includes testing the materials for defects and ensuring they meet the required standards.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves monitoring various stages of production to identify any potential issues. This can include checks on the precision of cutting and molding processes.

Final Quality Control (FQC)

Once the products are assembled and finished, FQC checks for overall quality, including visual inspections and functional testing. This step is crucial to ensure that all products meet the buyer’s specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is essential for B2B buyers to ensure reliability and consistency in their orders.

Supplier Audits

Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should request to see their quality management documentation and any certifications they hold.

Quality Assurance Reports

Requesting quality assurance reports can help buyers understand the supplier’s history of quality control and any issues that have arisen in the past. These reports often detail the results of various quality checks performed during the manufacturing process.

Third-Party Inspections

Engaging third-party inspection services can add an additional layer of assurance. These independent entities can conduct inspections at various stages of the manufacturing process to ensure compliance with quality standards.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances that can impact quality control:

- Cultural Differences: Understanding the cultural approach to quality and business practices in different regions can help buyers navigate negotiations and expectations.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers should ensure their suppliers comply with both local and international standards.

- Language Barriers: Effective communication is crucial for quality assurance. Buyers may need to utilize translation services or bilingual representatives to ensure clarity in specifications and requirements.

By understanding the manufacturing processes and quality assurance protocols involved in Oakleys custom products, B2B buyers can make informed decisions, ensuring they source high-quality eyewear that meets their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oakleys custom’

In the competitive landscape of B2B procurement, especially for specialized products like custom Oakleys, having a structured sourcing approach is essential. This guide serves as a practical checklist to help international buyers streamline their purchasing process, ensuring they make informed decisions that align with their business needs.

Step 1: Define Your Customization Requirements

Before reaching out to suppliers, clearly outline what you need from the custom Oakleys. Consider factors like design, materials, branding elements, and order volume. This clarity not only helps suppliers understand your needs better but also sets the foundation for a successful partnership.

- Design Elements: Specify colors, logos, and styles.

- Material Quality: Determine the level of durability and comfort required.

Step 2: Research Potential Suppliers

Thoroughly research suppliers that specialize in custom eyewear. Look for companies with a solid reputation, positive reviews, and experience in your target market. This step is crucial to ensure you partner with reliable manufacturers who can deliver quality products.

- Check Online Reviews: Platforms like Google and industry-specific forums can provide insights.

- Evaluate Their Portfolio: A strong portfolio demonstrates their capability and experience.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that your potential suppliers adhere to industry standards and regulations. Certifications such as ISO or compliance with local laws are indicators of a supplier’s commitment to quality and safety.

- Request Documentation: Ask for copies of relevant certifications.

- Verify Compliance: Research if they meet specific regulations in your region (e.g., CE marking in Europe).

Step 4: Request Samples

Before placing a large order, request samples of the custom Oakleys. This allows you to assess the quality, craftsmanship, and overall design. Samples can also help you gauge how well the supplier can execute your specific requirements.

- Assess Quality: Check for defects, comfort, and overall aesthetics.

- Test Durability: If possible, conduct stress tests to ensure longevity.

Step 5: Understand Pricing Structures

Discuss pricing models with suppliers to understand all costs involved. This includes unit prices, shipping, potential customs fees, and any additional costs for customization. Having a clear understanding of the pricing structure helps you avoid unexpected expenses.

- Negotiate Terms: Don’t hesitate to negotiate for better pricing or terms.

- Request a Detailed Quotation: Ensure the quote outlines all costs associated with the order.

Step 6: Establish Communication Protocols

Effective communication is critical for successful sourcing. Establish clear protocols for updates, timelines, and feedback throughout the procurement process. This ensures everyone is on the same page and can address issues promptly.

- Set Expectations: Define how often you will receive updates.

- Use Reliable Channels: Ensure that both parties are comfortable with the communication tools used.

Step 7: Finalize and Monitor the Order

Once you have chosen a supplier, finalize the order with a written contract that details all agreed terms. After placing the order, monitor the production and shipping processes to ensure timelines are adhered to and quality standards are met.

- Regular Check-Ins: Schedule updates during production.

- Inspect Upon Arrival: Conduct a thorough inspection of the received goods to ensure they meet your specifications.

By following this step-by-step checklist, B2B buyers can enhance their procurement process for custom Oakleys, leading to better partnerships and satisfactory products that meet their business needs.

Comprehensive Cost and Pricing Analysis for oakleys custom Sourcing

What are the Key Cost Components in Oakleys Custom Sourcing?

When sourcing Oakleys custom products, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality or specialized materials will naturally raise expenses, so it’s essential to assess the trade-off between quality and price.

-

Labor: Labor costs can vary greatly depending on the region of production. Countries with lower labor costs may offer a competitive edge, but this can also affect quality and lead times.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient production processes can help reduce overhead costs.

-

Tooling: The initial investment in tooling for custom designs can be substantial. Understanding the tooling costs upfront can help you gauge the total investment required for a specific project.

-

Quality Control (QC): Implementing effective QC processes can incur additional costs but is essential for maintaining product standards. Investing in QC can prevent costly errors down the line.

-

Logistics: Shipping costs can vary significantly based on the chosen logistics partner and the Incoterms agreed upon. International shipping often entails customs duties, which should be factored into the overall cost.

-

Margin: Suppliers will typically add a profit margin to their costs. Understanding the margin expectations in different markets can help in negotiations.

How Do Price Influencers Affect Oakleys Custom Sourcing?

Several factors can influence the pricing of Oakleys custom products:

-

Volume/MOQ (Minimum Order Quantity): Higher volumes often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing capabilities and inventory strategies.

-

Specifications and Customization: The complexity of custom designs can significantly affect pricing. More intricate specifications usually require additional resources, increasing costs.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or CE marks) often come at a higher price. Buyers must balance the need for quality with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: The terms of shipment (FOB, CIF, DDP, etc.) can greatly affect the final cost. Buyers should clearly define responsibilities and costs to avoid unexpected charges.

What Are Effective Buyer Tips for Sourcing Oakleys Custom Products?

To maximize cost-efficiency when sourcing Oakleys custom products, consider the following tips:

-

Negotiate Effectively: Always approach negotiations with a clear understanding of your budget and the market. Leverage multiple quotes to create competitive pressure among suppliers.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider ongoing costs such as maintenance, warranty, and potential shipping fees. A lower upfront cost may not always translate to the best long-term value.

-

Understand Pricing Nuances for International Buyers: Familiarize yourself with local market conditions, currency fluctuations, and import/export regulations specific to your region (e.g., Italy, Kenya). This knowledge can provide leverage in negotiations.

-

Build Strong Supplier Relationships: Establishing long-term partnerships with suppliers can yield better pricing and priority service. Consistent orders and open communication can lead to favorable terms.

Disclaimer on Indicative Prices

Prices for Oakleys custom sourcing can vary widely based on the factors discussed. It is essential for buyers to conduct thorough market research and obtain multiple quotations to ensure they receive fair pricing aligned with their specifications and needs.

Alternatives Analysis: Comparing oakleys custom With Other Solutions

Understanding Alternatives to Oakley’s Custom Solutions

When evaluating solutions for custom eyewear or accessories, it’s essential to consider alternatives that can meet similar needs. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must assess various options based on performance, cost, and usability. This comparison will help determine the most suitable choice for specific business requirements.

Comparison Table of Oakley’s Custom and Alternatives

| Comparison Aspect | Oakley’s Custom | Alternative 1: Ray-Ban Custom | Alternative 2: Maui Jim Custom |

|---|---|---|---|

| Performance | High durability; UV protection | Good durability; UV protection | Excellent UV protection; polarized lenses |

| Cost | Moderate to high pricing | Moderate pricing | High pricing |

| Ease of Implementation | Easy online customization | User-friendly interface | Requires in-store fitting |

| Maintenance | Low; easy to clean | Low; standard care required | Moderate; care for polarized lenses |

| Best Use Case | Sports and outdoor activities | Casual and fashion use | Outdoor sports and activities |

Detailed Breakdown of Alternatives

Alternative 1: Ray-Ban Custom

Ray-Ban offers a customizable eyewear solution that appeals to a broad audience. The customization interface is user-friendly, allowing users to choose frame styles, colors, and lens types. The performance of Ray-Ban products is commendable, providing good durability and UV protection. However, while the pricing is moderate, it may still be higher than some other brands. Ray-Ban is best suited for buyers looking for stylish yet functional eyewear, particularly in casual settings.

Alternative 2: Maui Jim Custom

Maui Jim is renowned for its high-quality polarized lenses, which provide excellent UV protection and clarity, making them ideal for outdoor sports and activities. The customization process typically requires a visit to a store for fitting, which can be inconvenient for some buyers. Additionally, Maui Jim products tend to be on the higher end of the pricing spectrum. Despite this, their superior lens technology and durability make them an attractive option for businesses focused on outdoor activities, especially in sunny climates.

Conclusion: How to Choose the Right Custom Eyewear Solution

Selecting the right custom eyewear solution requires a thorough assessment of your specific business needs. Consider factors such as budget, intended use, and the level of customization required. While Oakley’s custom offerings provide a robust solution for sports enthusiasts, alternatives like Ray-Ban and Maui Jim may cater better to different market segments. By weighing the pros and cons of each option, B2B buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for oakleys custom

What Are the Key Technical Properties of Oakleys Custom Products?

When considering the procurement of Oakleys custom products, understanding their essential technical properties is crucial. Here are some critical specifications that international B2B buyers should be familiar with:

-

Material Grade

The material grade of Oakleys custom products typically refers to the quality and type of materials used in manufacturing. This can include various alloys, plastics, or composites. For B2B buyers, knowing the material grade is vital for assessing durability, performance, and suitability for specific applications. Higher-grade materials often correlate with better performance and longevity, which can minimize replacement costs over time. -

Tolerance Levels

Tolerance levels indicate the permissible limits of variation in a manufactured component’s dimensions. In the context of Oakleys custom products, tighter tolerances often lead to higher precision and better fit, which is essential for functionality. B2B buyers should prioritize suppliers that can consistently meet specified tolerances, as this directly impacts product quality and operational efficiency. -

Surface Finish

The surface finish is a critical property that affects both aesthetics and performance. It refers to the texture and smoothness of the product’s surface, which can influence factors such as corrosion resistance and ease of cleaning. Buyers should consider the required surface finish based on the intended use and environment of the product, ensuring it meets both functional and aesthetic expectations. -

Mechanical Properties

Mechanical properties such as tensile strength, hardness, and ductility define how a material behaves under various forces. For Oakleys custom products, these properties are crucial for determining their suitability for specific applications. B2B buyers should assess these properties to ensure the product can withstand operational stresses without failure. -

Weight Considerations

The weight of Oakleys custom products can significantly affect their usability, transport, and installation. For industries where weight is a critical factor, such as aerospace or automotive, understanding the weight specifications can help in making informed purchasing decisions.

Which Trade Terminology Should B2B Buyers Know for Oakleys Custom?

Familiarity with industry-specific terminology can enhance communication and negotiation processes in B2B transactions. Here are some common trade terms relevant to Oakleys custom products:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the quality and reliability of products, as well as ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management. B2B buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or insufficient supply. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. For international buyers, submitting an RFQ helps clarify project requirements and facilitates competitive pricing, ensuring better value for procurement. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international B2B transactions, as they clarify who bears the risk and costs associated with shipping goods. -

Lead Time

Lead time refers to the amount of time between the initiation of an order and the fulfillment of that order. Understanding lead times is vital for effective supply chain management, allowing buyers to plan accordingly and maintain operational efficiency. -

Customization Options

This term refers to the various modifications available for a product to meet specific customer needs. For buyers interested in Oakleys custom, understanding available customization options can provide a competitive edge by ensuring the products align closely with operational requirements.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies and ensure they make informed decisions in sourcing Oakleys custom products.

Navigating Market Dynamics and Sourcing Trends in the oakleys custom Sector

What are the Current Market Dynamics and Key Trends in the Oakleys Custom Sector?

The oakleys custom sector is experiencing significant transformations driven by globalization, technological advancements, and shifting consumer preferences. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly looking for personalized products that cater to local tastes while ensuring quality and reliability. The rise of e-commerce platforms has made it easier for international buyers to connect with suppliers, allowing them to access a broader range of custom oakleys options.

Emerging trends include the integration of advanced manufacturing technologies such as 3D printing, which enables rapid prototyping and customization. This technology not only reduces lead times but also minimizes waste, appealing to cost-conscious buyers. Additionally, data analytics is becoming a crucial tool for businesses to understand market demands and optimize inventory management, further enhancing the sourcing process.

Another important trend is the emphasis on transparency in the supply chain. Buyers are increasingly demanding information about the origins of materials and the processes involved in creating custom oakleys. This shift is driven by a growing awareness of ethical considerations and the need for businesses to align with sustainability goals.

How is Sustainability and Ethical Sourcing Impacting the Oakleys Custom Sector?

Sustainability has become a cornerstone of modern B2B sourcing strategies. In the oakleys custom sector, the environmental impact of production processes is under scrutiny, prompting buyers to seek out suppliers who prioritize eco-friendly practices. This includes using sustainable materials, such as recycled plastics and biodegradable components, which not only reduce waste but also appeal to environmentally conscious consumers.

Ethical sourcing is equally important, as businesses aim to build trust and credibility with their clients. Buyers are increasingly looking for suppliers that adhere to ethical labor practices, ensuring fair wages and safe working conditions. Certifications such as Fair Trade and ISO 14001 can provide assurance that suppliers are committed to maintaining ethical standards.

Incorporating sustainability and ethical sourcing into business strategies not only enhances brand reputation but also meets regulatory requirements in many regions. Buyers who prioritize these factors are likely to establish stronger partnerships and gain competitive advantages in the marketplace.

What is the Brief Evolution and History of the Oakleys Custom Sector?

The oakleys custom sector has evolved significantly over the past few decades, transitioning from a niche market to a mainstream offering. Initially, customization was limited to a small selection of products, primarily driven by high-end consumers seeking unique designs. However, advancements in technology, particularly digital printing and online platforms, have democratized customization, making it accessible to a wider audience.

As consumer preferences shifted towards personalized experiences, brands began to recognize the value of custom offerings in driving customer loyalty and satisfaction. This evolution was further accelerated by the rise of social media, where consumers showcase their unique purchases, creating a demand for more tailored products.

Today, the oakleys custom sector stands at the intersection of technology, consumerism, and sustainability, reflecting broader trends in global commerce. International B2B buyers must stay attuned to these changes to effectively navigate the evolving landscape and leverage new opportunities for growth.

Frequently Asked Questions (FAQs) for B2B Buyers of oakleys custom

-

How do I ensure the quality of custom Oakleys when sourcing internationally?

To guarantee the quality of custom Oakleys, it is essential to conduct thorough supplier vetting. Start by requesting samples to assess craftsmanship and materials. Look for suppliers with certifications such as ISO standards and positive reviews from previous clients. Establish clear quality assurance protocols, including detailed specifications for customization, to ensure that the final product meets your standards. Regular communication and on-site inspections can further enhance quality control throughout the production process. -

What are the minimum order quantities (MOQs) for custom Oakleys?

Minimum order quantities for custom Oakleys can vary significantly based on the supplier and the level of customization. Generally, MOQs range from 100 to 500 units. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your budget and inventory capabilities. Some suppliers may offer flexibility on MOQs for first-time buyers or for bulk orders, so exploring multiple options can lead to better terms. -

What payment terms should I expect when ordering custom Oakleys?

Payment terms for custom Oakleys often depend on the supplier’s policies and the scale of your order. Common practices include a deposit (typically 30-50%) upfront, with the balance due upon completion or before shipment. For larger orders, suppliers may offer more favorable terms, such as net 30 or net 60 payment options. Ensure that all payment terms are clearly outlined in the contract to avoid any misunderstandings.

-

How can I customize Oakleys to meet my branding requirements?

Customizing Oakleys involves selecting specific features such as lens colors, frame styles, and logo placements. Most suppliers offer design templates to help you visualize your customizations. When working with a supplier, clearly communicate your brand identity and any specific requirements. Request prototypes to review before final production to ensure that the final product aligns with your branding strategy. -

What logistics considerations should I keep in mind when importing custom Oakleys?

When importing custom Oakleys, consider logistics factors such as shipping methods, customs duties, and lead times. Choose a reliable freight forwarder who understands international regulations, especially if you’re shipping to regions like Africa or the Middle East, where customs can be complex. Plan for potential delays by allowing extra time for customs clearance and ensure that all necessary documentation is in order to prevent issues at the border. -

How do I handle disputes with suppliers of custom Oakleys?

To manage disputes effectively, maintain open communication with your supplier from the outset. Establish a clear contract outlining terms and conditions, including quality expectations and delivery timelines. If a dispute arises, try to resolve it amicably through negotiation. If necessary, involve a third-party mediator or consult legal counsel familiar with international trade regulations to help navigate the issue. -

What are the best practices for vetting suppliers of custom Oakleys?

Effective supplier vetting includes researching their reputation, production capabilities, and compliance with international standards. Request references from previous clients and check online reviews. Consider conducting factory audits to assess their manufacturing processes firsthand. Additionally, verify their certifications, such as ISO or other relevant industry standards, to ensure they meet your quality and ethical sourcing requirements. -

What should I know about the market trends for custom Oakleys in different regions?

Understanding market trends is crucial for B2B buyers. In regions like Europe, there is a growing demand for eco-friendly and sustainable products, influencing customization options. In Africa and South America, pricing sensitivity may drive the need for cost-effective customization without compromising quality. Regularly analyze market reports and consumer preferences to adjust your offerings accordingly, ensuring they resonate with your target audience in each region.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for oakleys custom

What Are the Key Takeaways for Strategic Sourcing of Oakleys Custom?

In the realm of strategic sourcing for Oakleys Custom products, international B2B buyers must recognize the importance of building strong supplier relationships and leveraging data analytics to inform purchasing decisions. Buyers should prioritize suppliers who demonstrate reliability, quality, and compliance with international standards, particularly when sourcing from diverse regions such as Africa, South America, the Middle East, and Europe. Understanding local market dynamics and cultural nuances can significantly enhance negotiation strategies and partnership outcomes.

How Can B2B Buyers Position Themselves for Future Success?

As global supply chains evolve, B2B buyers must remain agile and proactive in adapting to market changes. Investing in technology that enables real-time inventory management and data analysis will provide a competitive edge. Furthermore, exploring sustainable sourcing practices is becoming increasingly essential, not only to meet regulatory requirements but also to cater to the growing demand for eco-friendly products.

What Should International Buyers Do Next?

Moving forward, international B2B buyers are encouraged to initiate discussions with potential suppliers, focusing on transparency and long-term collaboration. Attend industry events, engage in online platforms, and utilize resources such as auction sites to discover unique offerings. By taking these steps, buyers can effectively position themselves at the forefront of the Oakleys Custom market, ensuring both immediate and lasting success.