Unlock Savings with Pocket Custom Solutions (2025)

Introduction: Navigating the Global Market for pocket custom

In today’s fast-paced global economy, international B2B buyers face the significant challenge of sourcing high-quality pocket custom solutions that meet diverse business needs. Whether you are in Colombia looking for innovative packaging options or in Saudi Arabia seeking durable and customizable promotional items, the quest for reliable suppliers can be overwhelming. This guide is designed to demystify the complexities of the pocket custom market, providing a comprehensive overview that covers various types, applications, and critical factors such as supplier vetting and cost considerations.

Understanding the nuances of pocket custom products is essential for making informed purchasing decisions. This guide will explore the different categories of pocket custom solutions, ranging from personalized accessories to practical business tools, along with their applications across various industries. Additionally, we will delve into effective strategies for identifying reputable suppliers, ensuring quality assurance, and negotiating favorable terms, all tailored for buyers from Africa, South America, the Middle East, and Europe.

By equipping yourself with actionable insights and a structured approach, you will be empowered to navigate the global market confidently. This resource aims to enhance your procurement strategies, enabling you to select the best pocket custom options that align with your business objectives and customer expectations. As you embark on this journey, let this guide serve as your trusted companion in unlocking the potential of pocket custom solutions for your organization.

Understanding pocket custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Pocket Bags | Tailored sizes and materials, branding options | Retail, promotional giveaways | Pros: High visibility; customizable. Cons: Higher production costs. |

| Pocket Folders | Multi-pocket designs, various finishes | Document management, presentations | Pros: Professional appearance; functional. Cons: Limited branding space. |

| Pocket Notebooks | Customizable covers, various sizes and page types | Corporate gifts, training sessions | Pros: Practical for note-taking; versatile. Cons: May lack uniqueness. |

| Pocket Organizers | Modular designs, multiple compartments | Event planning, project management | Pros: Highly functional; keeps items organized. Cons: Can be bulky. |

| Pocket Envelopes | Various sizes, security features, custom printing | Shipping, marketing materials | Pros: Secure; customizable. Cons: May require higher minimum orders. |

What Are the Key Characteristics of Custom Pocket Bags?

Custom pocket bags are designed to meet specific client needs, offering tailored sizes and materials along with branding options. These bags are ideal for retail environments and promotional giveaways, allowing businesses to enhance their visibility through customized designs. When considering a purchase, B2B buyers should evaluate the production costs against the marketing benefits, as these bags can be more expensive than standard options but offer a higher return on investment through brand exposure.

How Do Pocket Folders Enhance Document Management?

Pocket folders feature multi-pocket designs and a variety of finishes, making them a staple in document management and presentation settings. They provide a professional appearance while effectively organizing materials. Buyers should consider the balance between aesthetic appeal and functionality, as some designs may offer limited branding space. Custom printing options can enhance brand recognition, making pocket folders a valuable addition to corporate identity kits.

Why Are Pocket Notebooks Popular Among B2B Buyers?

Pocket notebooks are favored for their customizable covers and various sizes, making them versatile tools for corporate gifts and training sessions. They are practical for note-taking and can be easily branded to reflect a company’s identity. When purchasing, B2B buyers should assess the range of page types and the potential for personalization, as these factors can impact the perceived value and usefulness of the notebooks in professional settings.

What Functional Benefits Do Pocket Organizers Provide?

Pocket organizers are characterized by their modular designs and multiple compartments, making them ideal for event planning and project management. These organizers help maintain order and efficiency, ensuring that essential items are readily accessible. Buyers should consider the size and bulkiness of these products, as they may affect portability. The high functionality of pocket organizers often justifies their investment, especially for businesses that prioritize organization.

How Do Pocket Envelopes Offer Security and Customization?

Pocket envelopes come in various sizes and feature security options alongside custom printing capabilities. They are commonly used for shipping and marketing materials, providing a secure way to transport sensitive documents. B2B buyers should be aware of the potential for higher minimum order quantities, as this can influence overall budget considerations. The ability to customize envelopes enhances brand visibility, making them an essential tool for many businesses engaged in direct mail campaigns.

Related Video: Golang Tutorial #20 – Structs and Custom Types

Key Industrial Applications of pocket custom

| Industry/Sector | Specific Application of Pocket Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Tooling and Fixtures | Enhances precision and efficiency in production processes | Consider material quality and supplier certifications |

| Retail | Branded Promotional Merchandise | Strengthens brand recognition and customer loyalty | Evaluate production timelines and customization options |

| Automotive | Custom Vehicle Components | Improves vehicle performance and meets specific needs | Ensure compliance with industry standards and regulations |

| Healthcare | Custom Medical Devices | Tailors solutions to patient needs, improving outcomes | Focus on regulatory approvals and quality assurance |

| Construction | Custom Safety Gear | Ensures worker safety and compliance with regulations | Assess durability and comfort for various working conditions |

How is ‘Pocket Custom’ Used in Manufacturing and What Problems Does It Solve?

In the manufacturing sector, pocket custom is primarily utilized for custom tooling and fixtures. These bespoke tools are designed to enhance precision in production processes, thereby reducing waste and minimizing errors. For international B2B buyers, particularly those in Africa and South America, the challenge often lies in sourcing high-quality materials that meet local standards. Buyers must prioritize suppliers who can demonstrate certifications and quality control processes to ensure that the tooling aligns with their production needs.

What are the Benefits of Using ‘Pocket Custom’ in Retail?

In retail, pocket custom finds its application in creating branded promotional merchandise. This strategy not only strengthens brand recognition but also fosters customer loyalty. For businesses in the Middle East and Europe, the key consideration is the ability to produce customized items within tight timelines, especially during peak seasons. Buyers should assess suppliers based on their production capabilities and flexibility to adapt designs to meet specific marketing campaigns.

How Does ‘Pocket Custom’ Enhance Automotive Performance?

The automotive industry leverages pocket custom for the development of custom vehicle components. These components can significantly improve vehicle performance by addressing specific engineering challenges. For B2B buyers in regions like Saudi Arabia, it is crucial to ensure that the custom parts comply with international automotive standards. Buyers should prioritize suppliers who can provide detailed documentation of compliance and testing results to mitigate risks associated with performance and safety.

In What Ways Does ‘Pocket Custom’ Improve Healthcare Solutions?

In healthcare, pocket custom is vital for creating custom medical devices tailored to specific patient needs. This customization can lead to improved patient outcomes and enhanced operational efficiency in healthcare facilities. For international buyers, especially in Africa, understanding the regulatory landscape is essential. Buyers must focus on sourcing from manufacturers who have a proven track record of obtaining necessary regulatory approvals and can ensure quality assurance throughout the production process.

How is ‘Pocket Custom’ Essential for Construction Safety?

In the construction sector, pocket custom is used to produce custom safety gear that meets the unique requirements of various job sites. This customization is crucial for ensuring worker safety and compliance with local regulations. B2B buyers should consider factors such as the durability and comfort of the gear, particularly in diverse working conditions found across Europe and South America. It’s important to partner with suppliers who specialize in safety gear and can provide evidence of compliance with relevant safety standards.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘pocket custom’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often face the challenge of inconsistent product quality when sourcing ‘pocket custom’ items from different suppliers. For companies in Africa or South America, fluctuating quality can lead to brand damage, increased returns, and customer dissatisfaction. This inconsistency can stem from varying production standards, inadequate quality control measures, or miscommunication regarding specifications.

The Solution: To mitigate this issue, it is crucial to establish strong relationships with suppliers who have a proven track record. Begin by conducting thorough due diligence; request samples from potential suppliers and evaluate their products against your specifications. It’s advisable to implement a comprehensive quality assurance process that includes regular audits and clear communication of quality standards. Consider leveraging technology, such as collaborative platforms, to maintain ongoing dialogue about quality expectations and receive real-time feedback on product performance. Additionally, establish a set of benchmarks that suppliers must meet, ensuring that all parties have a clear understanding of what constitutes acceptable quality.

Scenario 2: Complex Customization Processes

The Problem: Many B2B buyers encounter frustration with the complexity of the customization process for ‘pocket custom’ items. This is particularly evident in regions like the Middle East, where cultural nuances and specific market preferences must be taken into account. Buyers may find it difficult to communicate their exact needs, leading to misunderstandings and suboptimal products that do not meet market demand.

The Solution: To streamline the customization process, it’s essential to engage in detailed discussions with suppliers right from the outset. Use visual aids and prototypes to convey your ideas more effectively. Establish a clear set of requirements and preferences, and encourage suppliers to provide feedback on feasibility and potential challenges. Additionally, consider collaborating with local design experts who understand the market dynamics and consumer preferences in your region. This can enhance communication and ensure that the final product aligns with local tastes. Utilizing project management tools can also help track the progress of custom orders, ensuring that every step of the process is transparent and accountable.

Scenario 3: High Shipping Costs and Delays

The Problem: International B2B buyers often struggle with high shipping costs and unpredictable delivery times when sourcing ‘pocket custom’ products. This issue can be particularly acute for companies in Europe and South America, where logistical challenges can lead to increased expenses and delayed market entry, adversely affecting competitiveness.

The Solution: To address shipping challenges, buyers should consider consolidating orders to maximize shipping efficiency. By ordering in bulk or partnering with other businesses to share freight costs, you can significantly reduce per-unit shipping expenses. Additionally, work closely with logistics providers who specialize in international shipping and understand the complexities involved. They can provide insights on the best shipping routes and methods to minimize costs and delays. It’s also prudent to stay informed about customs regulations in both the exporting and importing countries to prevent unexpected holdups. Finally, consider using alternative shipping methods like air freight for urgent orders, while planning regular shipments via sea freight for less time-sensitive needs. This strategy balances cost and delivery speed effectively.

Strategic Material Selection Guide for pocket custom

When selecting materials for pocket custom applications, international B2B buyers must consider various factors, including the specific properties of materials, their advantages and disadvantages, and how these attributes align with the intended application. Below is an analysis of four common materials used in pocket custom manufacturing, tailored to the needs and considerations of buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel for Pocket Custom Applications?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it a popular choice for pocket custom applications. It can withstand high temperatures and pressures, which is critical in industries such as oil and gas, food processing, and pharmaceuticals. Additionally, stainless steel complies with various international standards, including ASTM and DIN, ensuring its suitability for global markets.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to wear and tear. However, it tends to be more expensive than other materials and may require complex manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for applications in harsh environments.

Considerations for International Buyers: Buyers from regions like Saudi Arabia and Colombia should ensure that the selected stainless steel grades meet local compliance standards, which may vary significantly.

How Does Aluminum Compare as a Material for Pocket Custom?

Aluminum is lightweight and offers excellent corrosion resistance, making it suitable for applications where weight reduction is a priority. It is also highly malleable, allowing for intricate designs and shapes in pocket custom products.

Pros & Cons: The key advantage of aluminum is its low weight, which can lead to reduced shipping costs and easier handling. However, it may not perform as well under high temperatures or pressures compared to stainless steel, making it less suitable for certain industrial applications.

Impact on Application: Aluminum is often used in automotive and aerospace applications, where weight is critical, but it may not be ideal for applications involving aggressive chemicals.

Considerations for International Buyers: Buyers from Europe should be aware of the EU’s stringent regulations on aluminum quality, ensuring compliance with standards like EN and ISO.

What Are the Benefits of Using Polypropylene in Pocket Custom Manufacturing?

Polypropylene is a thermoplastic polymer known for its chemical resistance and flexibility. It is often used in applications that require a lightweight, cost-effective solution.

Pros & Cons: The main advantage of polypropylene is its affordability and ease of manufacturing, which can significantly lower production costs. However, it has a lower temperature resistance compared to metals, which may limit its application in high-heat environments.

Impact on Application: Polypropylene is suitable for applications involving non-aggressive chemicals, making it ideal for packaging and consumer goods.

Considerations for International Buyers: Buyers from South America should consider local regulations regarding plastic use and recycling, as these can impact the long-term viability of polypropylene products.

Why Choose Brass for Pocket Custom Applications?

Brass is an alloy of copper and zinc, offering excellent machinability and corrosion resistance. It is commonly used in plumbing, electrical, and decorative applications.

Pros & Cons: One of the significant advantages of brass is its aesthetic appeal and ease of machining, which can lead to intricate designs. However, it is generally more expensive than other materials and may not be suitable for high-stress applications.

Impact on Application: Brass is compatible with water and various chemicals, making it a good choice for plumbing fixtures and decorative elements.

Considerations for International Buyers: Buyers in the Middle East should be mindful of the specific grades of brass that comply with local standards, especially in plumbing applications.

Summary Table of Material Selection for Pocket Custom

| Material | Typical Use Case for pocket custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, food processing | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Automotive, aerospace | Lightweight and malleable | Limited high-temperature performance | Medium |

| Polypropylene | Packaging, consumer goods | Cost-effective and flexible | Lower temperature resistance | Low |

| Brass | Plumbing, electrical, decorative | Aesthetic appeal and machinability | Higher cost, not for high-stress applications | Medium |

By carefully evaluating these materials, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements, ensuring successful procurement and application of pocket custom products.

In-depth Look: Manufacturing Processes and Quality Assurance for pocket custom

What are the Key Stages in the Manufacturing Process of Pocket Custom?

The manufacturing process for pocket custom products involves several critical stages, each ensuring that the final product meets both functional and aesthetic requirements. Understanding these stages is essential for international B2B buyers seeking reliable suppliers.

1. Material Preparation

The first stage in the manufacturing process is material preparation. This involves sourcing high-quality raw materials that meet specific industry standards. For pocket custom, materials might include various fabrics, metals, and plastics, depending on the product’s intended use. Buyers should request material certifications to ensure compliance with international standards, such as REACH for chemicals in the EU or ISO 14001 for environmental management.

2. Forming Techniques: How are Pocket Custom Products Shaped?

Once materials are prepared, the next step is forming, where raw materials are shaped into the desired product form. Common techniques include:

- Cutting and Die-Cutting: Precision cutting tools ensure that materials are shaped accurately.

- Sewing and Stitching: For fabric-based products, advanced sewing techniques are employed to enhance durability and aesthetics.

- Injection Molding: For plastic components, this method allows for complex shapes and designs while maintaining consistency.

B2B buyers should inquire about the technologies used and whether they have capabilities for custom designs, as this can significantly impact the product’s final quality.

3. Assembly: What are the Best Practices for Assembly in Pocket Custom Manufacturing?

The assembly stage combines the various components into a final product. Best practices during assembly include:

- Automated Assembly Lines: Utilizing automation can improve efficiency and reduce human error.

- Hand Assembly for Customization: For bespoke orders, skilled labor may be employed to ensure precision and attention to detail.

Buyers should assess a supplier’s assembly capabilities and their ability to handle both high-volume and custom orders.

4. Finishing: How is the Final Touch Applied?

Finishing processes add the final touches that enhance the product’s appearance and functionality. Common finishing techniques include:

- Quality Control Coatings: Applying coatings can protect against wear and enhance aesthetic appeal.

- Labeling and Branding: This step is crucial for market differentiation and should comply with local regulations regarding labeling.

B2B buyers should verify that the finishing processes align with their branding requirements and regulatory compliance.

What International Quality Standards are Relevant for Pocket Custom Manufacturing?

Quality assurance is paramount in ensuring that pocket custom products meet both buyer expectations and regulatory requirements. Several international standards are relevant, including:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring consistent quality and customer satisfaction.

- CE Marking: Important for products sold in the European market, this mark indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for products used in the petroleum and natural gas industries, ensuring safety and reliability.

B2B buyers should prioritize suppliers who are certified to these standards, as it reflects their commitment to quality.

How are Quality Control Checkpoints Implemented in Pocket Custom Manufacturing?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process to ensure that products meet specified standards. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections help identify defects early in the process.

- Final Quality Control (FQC): After production, a thorough inspection ensures that the final products meet all specifications before shipping.

B2B buyers should request detailed QC reports from suppliers, which can provide insights into the effectiveness of their quality management systems.

What Common Testing Methods are Used to Ensure Product Quality?

To guarantee product quality, various testing methods are employed, including:

- Mechanical Testing: Evaluates strength, flexibility, and durability of materials.

- Chemical Testing: Ensures compliance with safety standards, especially for products that may come into contact with skin or food.

- Dimensional Testing: Confirms that products meet specified measurements and tolerances.

B2B buyers should inquire about the specific testing methods used by suppliers and request access to testing reports.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international buyers, verifying a supplier’s quality control measures is crucial. Effective methods include:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and quality control processes firsthand.

- Requesting Quality Assurance Reports: Suppliers should provide documentation of their quality control processes, including testing results and certifications.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased assessment of the supplier’s quality practices and compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality control and certification:

- Cultural Expectations: Different regions may have varying expectations regarding product quality and standards. Understanding these cultural differences can help in negotiations and supplier selection.

- Regulatory Compliance: Ensure that suppliers can navigate local regulations and provide necessary certifications, as these can differ significantly from one region to another.

- Logistics and Supply Chain Considerations: Quality assurance practices may also be influenced by logistical challenges. Buyers should evaluate how suppliers manage their supply chains to mitigate risks.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing pocket custom products, ensuring they partner with reliable and compliant suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pocket custom’

Introduction

Sourcing ‘pocket custom’ products effectively requires a structured approach to ensure you select the right suppliers and secure high-quality goods. This guide provides a practical checklist tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and mitigate potential risks.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of successful sourcing. This includes dimensions, materials, and any specific features or functionalities that your ‘pocket custom’ products must have.

- Why it’s important: Precise specifications help suppliers understand your needs and reduce the likelihood of miscommunication.

- What to look for: Ensure that your specifications are detailed and unambiguous to avoid costly mistakes later.

Step 2: Conduct Market Research for Suppliers

Identifying potential suppliers is crucial for effective sourcing. Research suppliers who specialize in ‘pocket custom’ products across your target regions.

- Why it’s important: A broad market research approach allows you to compare options and identify suppliers who can meet your requirements.

- What to look for: Evaluate their market reputation, customer reviews, and product range to shortlist viable candidates.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet your potential suppliers. Request comprehensive company profiles, product catalogs, and references from existing clients in similar industries.

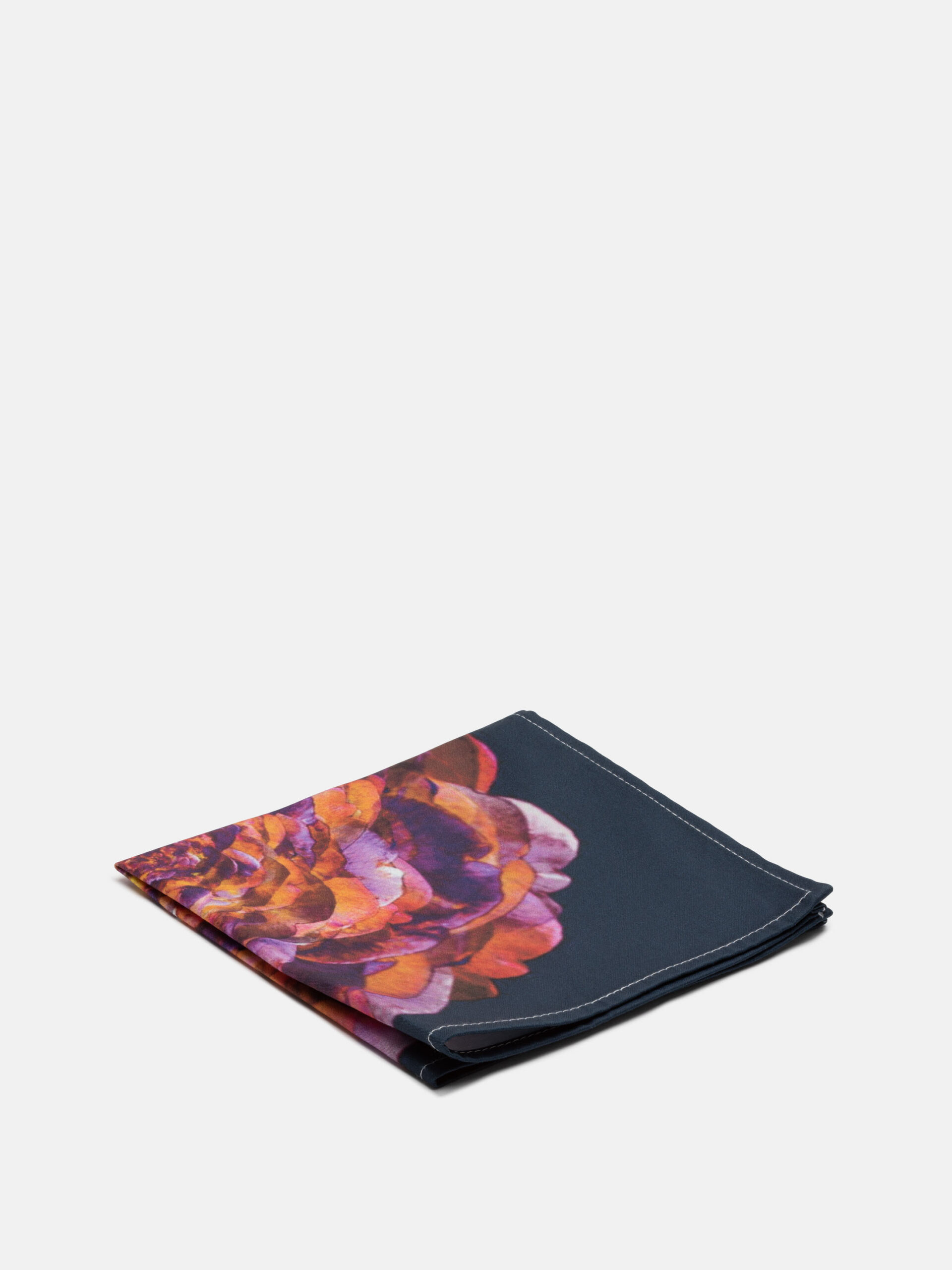

A stock image related to pocket custom.

- Why it’s important: A thorough evaluation reduces the risk of partnering with unreliable suppliers.

- What to look for: Check for industry certifications, production capabilities, and past project case studies to gauge their reliability and expertise.

Step 4: Request Samples for Quality Assessment

Requesting samples is a critical step in the sourcing process. It allows you to assess the quality of the products before placing a bulk order.

- Why it’s important: Samples provide a tangible representation of what you can expect, helping to ensure that the final products meet your standards.

- What to look for: Pay attention to craftsmanship, material quality, and adherence to your specifications.

Step 5: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, it’s time to negotiate terms, including pricing, delivery timelines, and payment conditions.

- Why it’s important: Effective negotiation can lead to better pricing and terms that can significantly impact your bottom line.

- What to look for: Be clear about your budget constraints and consider the total cost of ownership, including shipping and customs fees.

Step 6: Verify Supplier Certifications and Compliance

Ensure that your chosen supplier complies with industry standards and regulations relevant to your market.

- Why it’s important: Compliance with regulations is crucial to avoid legal issues and ensure product safety and quality.

- What to look for: Verify certifications such as ISO, CE, or other relevant quality assurance marks that indicate adherence to industry standards.

Step 7: Establish Clear Communication Channels

Once you’ve selected a supplier, establish effective communication channels to facilitate smooth interactions throughout the sourcing process.

- Why it’s important: Clear communication helps to address any issues promptly and keeps the project on track.

- What to look for: Ensure that you have access to key contacts and agree on preferred communication methods and response times.

By following this checklist, international B2B buyers can navigate the complexities of sourcing ‘pocket custom’ products with greater confidence and efficiency, leading to successful partnerships and high-quality outcomes.

Comprehensive Cost and Pricing Analysis for pocket custom Sourcing

What Are the Key Cost Components in Pocket Custom Sourcing?

When sourcing pocket custom products, understanding the cost structure is crucial for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The choice of materials significantly impacts overall costs. Premium fabrics, specialized coatings, or eco-friendly materials may increase initial costs but can enhance the product’s marketability and durability.

-

Labor: Labor costs vary by region and are influenced by the skill level required for production. Countries with higher wages may offer more skilled labor, which can justify higher prices due to enhanced quality.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and indirect labor. Efficient production processes can mitigate overhead costs.

-

Tooling: Custom tooling is often necessary for unique designs. The initial investment in tooling can be substantial, but it can be amortized over larger production runs.

-

Quality Control (QC): Implementing rigorous QC measures ensures product reliability but adds to the overall cost. Buyers should weigh the costs of QC against potential returns from enhanced product quality.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can fluctuate based on destination and shipping method. Understanding local regulations and potential tariffs is essential for accurate budgeting.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Pocket Custom Sourcing?

Numerous factors influence the final pricing of pocket custom products:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often result in lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to balance inventory costs against unit pricing.

-

Specifications and Customization: The complexity of design specifications and the degree of customization required can significantly affect pricing. More intricate designs may incur higher costs for both materials and labor.

-

Materials Quality and Certifications: High-quality materials and certifications (e.g., organic, fair trade) can justify higher prices and appeal to specific market segments. Buyers should consider the long-term benefits of investing in quality.

-

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more but offer benefits like better service, reliability, and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the risk and costs at various stages of the shipping process. This knowledge can prevent unexpected expenses.

What Tips Can Help Buyers Optimize Costs in Pocket Custom Sourcing?

International B2B buyers can enhance cost-efficiency through strategic approaches:

-

Negotiation: Develop a clear negotiation strategy based on comprehensive market research. Understanding the supplier’s cost structure can provide leverage in negotiations.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider factors like maintenance, shipping, and potential returns when assessing overall costs.

-

Pricing Nuances for Different Regions: Buyers from Africa, South America, the Middle East, and Europe may encounter varied pricing structures due to local economic conditions and supply chain dynamics. Familiarity with regional market trends can facilitate better decision-making.

-

Leverage Technology: Utilize digital platforms and tools for sourcing to streamline the process and reduce costs. Online marketplaces often provide comparative pricing and supplier reviews.

-

Build Strong Supplier Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and tailored solutions, ultimately enhancing the sourcing experience.

Disclaimer on Indicative Prices

Prices for pocket custom sourcing can vary widely based on the factors discussed. The information provided is for guidance and should not be considered definitive. Always conduct thorough due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing pocket custom With Other Solutions

In the landscape of B2B solutions, understanding the alternatives to a product like ‘pocket custom’ is essential for making informed purchasing decisions. This analysis compares ‘pocket custom’ with other viable solutions, helping international buyers identify the best fit for their specific business needs. The alternatives presented here will focus on performance, cost, ease of implementation, maintenance, and best use cases to provide a comprehensive overview.

Comparison Table of Pocket Custom and Alternatives

| Comparison Aspect | Pocket Custom | Alternative 1: Standard Customization Services | Alternative 2: Off-the-Shelf Solutions |

|---|---|---|---|

| Performance | High | Moderate to High | Moderate |

| Cost | Moderate | High | Low to Moderate |

| Ease of Implementation | Moderate | Low | High |

| Maintenance | Moderate | High | Low |

| Best Use Case | Unique, tailored solutions for niche markets | Businesses needing extensive customization | Businesses with standard requirements |

What Are the Pros and Cons of Standard Customization Services?

Standard customization services offer a tailored approach similar to ‘pocket custom’, but they often come with higher costs. They are suitable for businesses that need highly specialized solutions but can afford a significant investment. The implementation can be lengthy and complex, requiring expert input and resources. Maintenance can also be a challenge, as updates or changes may require professional support. This makes them ideal for companies in sectors like manufacturing or tech, where specific adaptations are crucial for product success.

How Do Off-the-Shelf Solutions Compare?

Off-the-shelf solutions provide a cost-effective alternative to ‘pocket custom’. They are typically easy to implement and maintain, making them attractive for businesses with standard requirements. However, the performance may not meet the unique needs of every organization, especially those in niche markets. While they can be a great fit for small to medium enterprises looking for quick deployment and lower initial costs, the lack of customization may limit their effectiveness in addressing specific challenges.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting the right solution between ‘pocket custom’ and its alternatives, B2B buyers should evaluate their specific requirements, budget constraints, and long-term goals. Companies seeking unique, tailored solutions that cater to specialized markets may find ‘pocket custom’ to be the most effective choice, despite its moderate implementation and maintenance demands. Conversely, those needing cost-effective, readily available solutions may benefit from off-the-shelf options. Finally, businesses that can afford a higher budget and seek extensive customization may lean towards standard customization services. By carefully considering these factors, buyers can make a well-informed decision that aligns with their operational objectives and market demands.

Essential Technical Properties and Trade Terminology for pocket custom

What Are the Key Technical Properties of Pocket Custom Products?

Understanding the technical specifications of pocket custom products is crucial for B2B buyers, as these properties directly impact the product’s performance, durability, and suitability for specific applications. Here are some essential technical properties to consider:

-

Material Grade

– The material grade determines the strength, flexibility, and overall quality of the pocket custom product. Common materials include various grades of metals (like stainless steel or aluminum), plastics, and composites. Selecting the appropriate material grade is vital for ensuring the product meets industry standards and customer expectations. -

Tolerance Levels

– Tolerance refers to the permissible limits of variation in a physical dimension or measured value. High tolerance levels ensure that parts fit together correctly, which is especially important in applications requiring precision. In B2B transactions, understanding tolerance levels helps buyers avoid costly errors and rework. -

Surface Finish

– The surface finish affects not only the aesthetic quality but also the functionality of the product. It can influence factors such as corrosion resistance, friction, and wear. Buyers should specify the desired surface finish to ensure compatibility with their operational environments, especially in industries like automotive and aerospace. -

Load Capacity

– Load capacity indicates the maximum weight a pocket custom product can safely support. This property is critical in applications such as construction and manufacturing, where structural integrity is paramount. B2B buyers must assess load requirements to ensure safety and compliance with regulations. -

Temperature Resistance

– The ability of a pocket custom product to withstand various temperatures is essential for applications in extreme environments. Buyers should consider temperature resistance specifications to avoid product failure, especially in sectors like oil and gas or food processing. -

Lifecycle and Durability

– This property assesses how long a product will last under normal operating conditions. A longer lifecycle can significantly reduce the total cost of ownership, making it a key factor in purchasing decisions. Understanding durability helps buyers choose products that align with their maintenance and replacement strategies.

What Are Common Trade Terminology and Their Importance in Pocket Custom Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common trade terms relevant to pocket custom:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for reliable suppliers who can provide high-quality components tailored to specific needs. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or missed opportunities. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing information for specific products. It is a critical step in the procurement process, allowing buyers to compare costs and terms from multiple vendors. Crafting a clear RFQ can lead to better pricing and service agreements. -

Incoterms (International Commercial Terms)

– These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for buyers to clarify shipping responsibilities, insurance, and risk transfer, thus preventing disputes and ensuring smooth logistics. -

Lead Time

– Lead time is the duration from placing an order to receiving the product. It is a crucial factor in supply chain management, impacting inventory levels and production schedules. Buyers should account for lead time when planning purchases to ensure timely project completion. -

Certification Standards

– These are benchmarks that products must meet to ensure safety and reliability. Familiarity with relevant certification standards helps buyers ensure that the products comply with local and international regulations, reducing the risk of legal issues and enhancing marketability.

A stock image related to pocket custom.

By understanding these essential technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance their procurement processes and ensure successful partnerships in the pocket custom sector.

Navigating Market Dynamics and Sourcing Trends in the pocket custom Sector

What Are the Key Market Dynamics Influencing the Pocket Custom Sector?

The pocket custom sector is experiencing significant shifts driven by globalization, technological advancements, and changing consumer preferences. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should pay close attention to these dynamics to stay competitive. One of the primary drivers is the rise of e-commerce, which has made sourcing more accessible and streamlined. Businesses can now leverage online platforms to connect with manufacturers and suppliers globally, reducing costs and time spent on procurement.

Emerging technologies, such as artificial intelligence and machine learning, are transforming sourcing strategies. These tools can analyze vast amounts of data to identify trends, optimize inventory management, and predict market demands. Additionally, the integration of blockchain technology is enhancing transparency in supply chains, making it easier for buyers to track the origin of materials and ensure compliance with ethical standards.

Furthermore, the demand for customization is growing, as businesses strive to differentiate themselves in competitive markets. This trend is particularly pronounced in regions like Colombia and Saudi Arabia, where local cultures and preferences influence product design. Buyers must adapt to these trends by sourcing flexible manufacturing solutions that can accommodate bespoke requests without compromising on lead times or costs.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in the Pocket Custom Sector?

Sustainability is no longer just a buzzword; it has become a crucial factor influencing purchasing decisions in the pocket custom sector. International B2B buyers must recognize the environmental impact of their sourcing choices. The shift towards eco-friendly materials and processes is driven by both regulatory pressures and consumer demand for ethical products. Buyers should seek suppliers who prioritize sustainable practices, such as using recycled materials or implementing waste reduction strategies in their production processes.

Ethical sourcing is equally important, as it ensures that supply chains are free from exploitation and adhere to fair labor practices. Buyers can enhance their sourcing strategies by partnering with manufacturers that hold certifications like Fair Trade or Global Organic Textile Standard (GOTS). These certifications not only provide assurance of ethical practices but also appeal to a growing segment of consumers who prioritize sustainability in their purchasing decisions.

Investing in ‘green’ certifications and materials can also lead to long-term cost savings. By reducing waste and energy consumption, companies can lower operational costs while enhancing their brand image. Buyers should conduct thorough due diligence when evaluating suppliers, focusing on their sustainability credentials and commitment to ethical practices.

How Has the Pocket Custom Sector Evolved Over Time?

The evolution of the pocket custom sector can be traced back to the growing demand for personalized products, which has been fueled by advances in technology and manufacturing processes. Initially, pocket custom items were primarily handcrafted, limiting scalability and accessibility. However, with the advent of digital printing and advanced manufacturing techniques, businesses can now produce customized products at scale.

This evolution has been particularly significant in regions like Europe and the Middle East, where consumers are increasingly seeking unique and tailored items. The rise of online marketplaces has also democratized access to pocket custom products, enabling smaller businesses to compete with larger brands. As a result, the sector has expanded beyond traditional markets, creating new opportunities for international B2B buyers to explore diverse sourcing options and meet the evolving demands of their customers.

By understanding these historical shifts, B2B buyers can better navigate the complexities of the current market landscape and make informed decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of pocket custom

-

How do I find reliable suppliers for pocket custom products?

To find reliable suppliers for pocket custom products, start by leveraging online B2B marketplaces like Alibaba, Global Sources, and TradeIndia. It’s crucial to check supplier credentials, including certifications, production capabilities, and customer reviews. Networking at industry trade shows and using platforms like LinkedIn can also connect you with reputable suppliers. Additionally, consider sourcing agents who specialize in your target regions, as they can provide valuable insights and facilitate communication. -

What is the minimum order quantity (MOQ) for pocket custom products?

Minimum order quantities (MOQs) for pocket custom products can vary significantly based on the supplier and the complexity of the customization. Typically, MOQs range from 100 to 1,000 units. Before engaging with a supplier, clarify their MOQ policies and see if they offer flexibility for smaller orders or trial runs. Negotiating MOQs can also be possible, especially if you are willing to establish a long-term relationship or place larger orders in the future. -

What payment terms should I expect when ordering pocket custom products?

Payment terms for pocket custom products generally depend on the supplier’s policies and your negotiation. Common terms include a 30% upfront deposit with the balance paid before shipment, or payment via letter of credit for larger orders. Always discuss payment methods that work best for your financial operations, such as bank transfers, PayPal, or escrow services. Ensure that you have a clear agreement to avoid misunderstandings that could impact your cash flow. -

How can I ensure quality assurance when sourcing pocket custom products?

To ensure quality assurance, establish clear specifications and standards before production begins. Request samples to evaluate product quality and craftsmanship. It’s also beneficial to conduct factory audits, either in person or through third-party inspection services. Regular communication with the supplier during the production process can help address any quality concerns proactively. Consider implementing a quality control checklist to verify that all products meet your expectations before shipment. -

What are the key logistics considerations for importing pocket custom products?

When importing pocket custom products, consider logistics factors such as shipping methods, customs duties, and lead times. Choose between air freight for speed or sea freight for cost-effectiveness based on your urgency. Understand the customs regulations in your country to avoid delays or unexpected fees. Collaborating with a freight forwarder can streamline the process, as they can assist with documentation and ensure compliance with international shipping laws. -

How does customization impact pricing for pocket custom products?

Customization typically increases the price of pocket custom products due to additional design, material, and labor costs. The complexity and scale of customization will significantly affect pricing; for instance, intricate designs or unique materials may incur higher fees. To manage costs, discuss customization options with suppliers and explore cost-effective alternatives, such as using standard materials or simpler designs. Be transparent about your budget to help suppliers propose suitable solutions. -

What are the risks associated with sourcing pocket custom products internationally?

Sourcing pocket custom products internationally carries risks, including quality discrepancies, shipping delays, and compliance issues with local regulations. To mitigate these risks, conduct thorough supplier vetting, including checking references and past performance. Establish clear contracts that outline responsibilities, quality standards, and timelines. Additionally, consider purchasing insurance for high-value shipments to protect against loss or damage during transit. -

How can I build a long-term relationship with my pocket custom supplier?

Building a long-term relationship with your pocket custom supplier involves consistent communication, trust, and collaboration. Regularly provide feedback on product quality and service, and be open to discussing improvements. Consider offering incentives for loyalty, such as larger orders or long-term contracts. Engage in discussions about future projects, which can help align your goals and create a mutually beneficial partnership. Regular visits to the supplier’s facilities can also strengthen the relationship and foster goodwill.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pocket custom

In navigating the complexities of strategic sourcing for pocket custom solutions, international B2B buyers must prioritize understanding their unique market dynamics. Key takeaways include the importance of establishing strong supplier relationships, leveraging data analytics for informed decision-making, and continuously evaluating supplier performance to ensure quality and cost-effectiveness. By embracing these practices, companies can optimize their sourcing strategies, ultimately enhancing their competitive advantage in diverse markets such as Africa, South America, the Middle East, and Europe.

How Can Strategic Sourcing Drive Long-Term Success?

The value of strategic sourcing cannot be overstated; it is a critical component in mitigating risks and enhancing operational efficiency. Buyers should focus on building a resilient supply chain that can adapt to changing market conditions while also being mindful of sustainability practices that resonate with consumers today.

What Are the Future Trends in Pocket Custom Sourcing?

Looking ahead, the demand for customized solutions is expected to grow, driven by consumer preferences for personalization. B2B buyers should remain agile and open to innovation, exploring partnerships that can facilitate new product developments and market expansions.

In conclusion, now is the time for international buyers, especially those from Colombia, Saudi Arabia, and beyond, to actively engage in strategic sourcing initiatives. Embrace the opportunities that lie ahead, and position your organization for sustained growth in the evolving landscape of pocket custom solutions.