Unlock Savings: Your Guide to Electric Car Suppliers (2025)

Introduction: Navigating the Global Market for electric car supplier

Navigating the global market for electric car suppliers presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With the surge in demand for electric vehicles (EVs), sourcing reliable suppliers who offer quality products at competitive prices can be daunting. This guide aims to demystify the process of selecting the right electric car suppliers, addressing critical factors such as types of electric vehicles, their applications, supplier vetting processes, and cost considerations.

Understanding the diverse landscape of electric car suppliers is essential for making informed purchasing decisions. By exploring various supplier options, including manufacturers, distributors, and innovative startups, B2B buyers can identify partners that align with their operational needs and sustainability goals. This guide also emphasizes the importance of due diligence in supplier selection, providing actionable insights on evaluating supplier credibility, assessing product quality, and negotiating favorable terms.

For international buyers from regions like Africa, South America, the Middle East, and Europe, this comprehensive resource empowers you to navigate the complexities of the electric vehicle market effectively. By leveraging the insights offered, you can enhance your procurement strategy, reduce risks, and ultimately contribute to a greener future through informed investments in electric mobility solutions.

Understanding electric car supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Electric Vehicle Suppliers | Manufacturers that produce electric vehicles under their own brand. | Fleet purchases, partnerships with local governments. | Pros: High reliability, brand recognition. Cons: Higher costs, limited customization. |

| Component Suppliers | Companies providing essential parts such as batteries, motors, and charging systems. | Automotive assembly, aftermarket services. | Pros: Specialized expertise, competitive pricing. Cons: Dependency on OEMs, potential supply chain issues. |

| Charging Infrastructure Providers | Firms that design and install charging stations and networks. | Urban development, fleet charging solutions. | Pros: Essential for EV adoption, scalable solutions. Cons: High initial investment, regulatory hurdles. |

| Electric Vehicle Conversion Kits Suppliers | Businesses that offer kits to convert traditional vehicles to electric. | Small fleet operators, eco-conscious businesses. | Pros: Cost-effective for existing fleets, sustainability. Cons: Technical challenges, variable quality. |

| Electric Mobility-as-a-Service (MaaS) Providers | Companies offering electric vehicles on a subscription or sharing basis. | Corporate mobility solutions, urban transport. | Pros: Flexibility, reduced ownership costs. Cons: Limited availability in some regions, potential service variability. |

What Are OEM Electric Vehicle Suppliers and Their B2B Relevance?

OEM electric vehicle suppliers are manufacturers that produce electric vehicles under their own brand names, such as Tesla, Nissan, and BMW. These suppliers are crucial for B2B buyers looking for reliable fleet purchases or partnerships with local governments for public transport initiatives. While they offer high reliability and brand recognition, the higher costs and limited customization options can be a drawback for some businesses.

How Do Component Suppliers Contribute to the Electric Vehicle Ecosystem?

Component suppliers provide essential parts like batteries, electric motors, and charging systems, playing a vital role in the electric vehicle supply chain. B2B buyers in automotive assembly and aftermarket services benefit from their specialized expertise and competitive pricing. However, these suppliers often depend on OEMs for demand, which can lead to potential supply chain issues, making it essential for buyers to assess the reliability of their partners.

Why Are Charging Infrastructure Providers Essential for B2B Buyers?

Charging infrastructure providers design and install the necessary charging stations and networks for electric vehicles. They are particularly relevant for urban development projects and businesses with fleet operations requiring charging solutions. While their offerings are essential for the widespread adoption of electric vehicles, buyers should be aware of the high initial investment and potential regulatory hurdles that may affect deployment.

What Are the Advantages of Electric Vehicle Conversion Kits for Businesses?

Electric vehicle conversion kits allow businesses to convert traditional internal combustion engine vehicles to electric. This option is attractive for small fleet operators or eco-conscious businesses seeking a cost-effective way to transition to electric mobility. While these kits promote sustainability and can be more affordable than purchasing new electric vehicles, buyers must consider technical challenges and the variable quality of available kits.

How Does Electric Mobility-as-a-Service (MaaS) Benefit B2B Buyers?

Electric Mobility-as-a-Service (MaaS) providers offer electric vehicles on a subscription or sharing basis, catering to corporate mobility needs and urban transport solutions. This model provides flexibility and reduced ownership costs, making it appealing to businesses looking to minimize their fleet expenses. However, limited availability in certain regions and potential variability in service quality should be taken into account when considering this option.

Related Video: GM-Wuling tiny car overtakes Tesla to lead China’s EV market

Key Industrial Applications of electric car supplier

| Industry/Sector | Specific Application of Electric Car Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric Buses and Shuttles | Reduced operational costs and lower emissions | Battery capacity, charging infrastructure, maintenance services |

| Logistics and Delivery | Electric Delivery Vans | Improved fuel efficiency and reduced urban congestion | Range, payload capacity, and vehicle durability |

| Tourism and Hospitality | Electric Shuttle Services | Enhanced guest experience and sustainability image | Fleet scalability, charging solutions, and local regulations |

| Construction | Electric Construction Vehicles | Lower emissions and compliance with environmental regulations | Equipment compatibility, power requirements, and service support |

| Agriculture | Electric Farm Vehicles | Cost savings on fuel and reduced noise pollution | Terrain adaptability, battery life, and agricultural regulations |

How Can Electric Buses and Shuttles Transform Public Transportation?

Electric buses and shuttles are increasingly being adopted in urban areas to provide sustainable public transportation solutions. These vehicles help municipalities reduce operational costs significantly while contributing to lower emissions and improved air quality. For international buyers, especially from Africa and South America, understanding local infrastructure for charging stations and maintenance support is crucial. Additionally, ensuring that the electric buses meet regional regulations regarding passenger capacity and safety standards is essential.

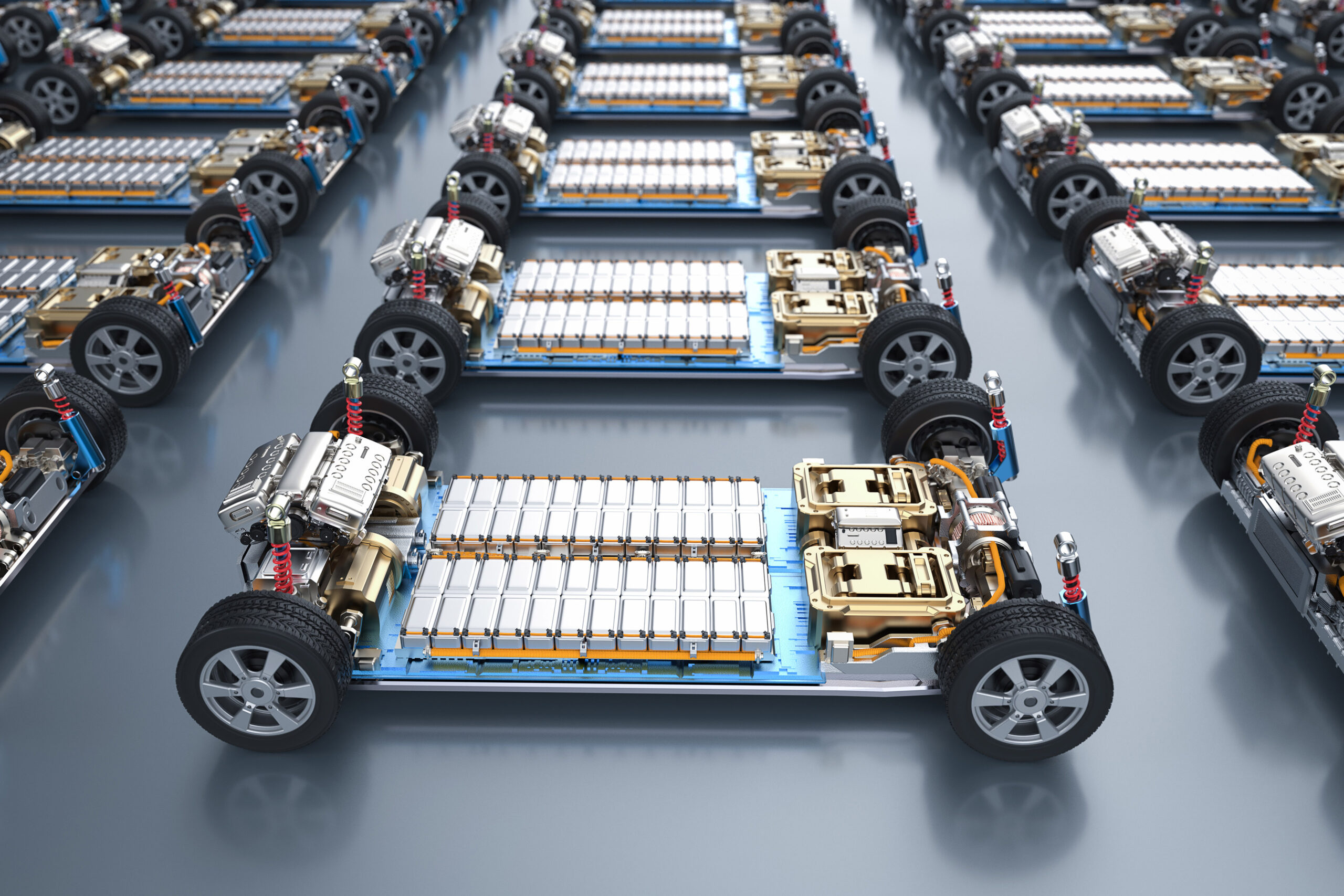

A stock image related to electric car supplier.

What Are the Benefits of Using Electric Delivery Vans in Logistics?

Electric delivery vans are transforming the logistics and delivery sector by providing a cost-effective alternative to traditional fuel-powered vehicles. These electric vans offer improved fuel efficiency, significantly reducing the total cost of ownership over time. For international B2B buyers, particularly from Europe and the Middle East, it’s vital to consider the vehicle’s range and payload capacity, as well as the availability of charging infrastructure in urban delivery zones. Compliance with local emissions regulations can also influence sourcing decisions.

How Can Electric Shuttle Services Enhance Tourism and Hospitality?

Electric shuttle services are becoming a popular choice in the tourism and hospitality industry, allowing hotels and resorts to offer eco-friendly transportation options for their guests. This not only enhances the guest experience but also helps establishments build a sustainable brand image. For buyers in regions like Spain and Mexico, factors such as fleet scalability, local charging solutions, and adherence to tourism regulations are crucial when sourcing electric shuttle services.

Why Are Electric Construction Vehicles Important for Sustainable Building Practices?

Electric construction vehicles are gaining traction due to their ability to lower emissions and comply with increasingly strict environmental regulations in the construction industry. These vehicles can be used for various tasks, from site preparation to material transport, making them versatile assets. Buyers from diverse regions must consider equipment compatibility with existing machinery, power requirements, and the availability of service support when sourcing these vehicles.

How Do Electric Farm Vehicles Contribute to Sustainable Agriculture?

Electric farm vehicles are revolutionizing the agricultural sector by offering a sustainable alternative to traditional fuel-powered machinery. These vehicles not only provide cost savings on fuel but also contribute to reducing noise pollution in rural areas. For international buyers, particularly in regions with specific agricultural regulations, it is essential to evaluate the terrain adaptability and battery life of these vehicles to ensure they meet operational needs effectively.

3 Common User Pain Points for ‘electric car supplier’ & Their Solutions

Scenario 1: Navigating Supply Chain Uncertainties in Electric Vehicle Components

The Problem: International B2B buyers often face significant challenges in sourcing reliable components for electric vehicles (EVs). Supply chain disruptions, particularly due to geopolitical tensions or global pandemics, can lead to delays and increased costs. This is especially problematic for buyers from regions like Africa and South America, where local supply chains may be less established, resulting in a heavy reliance on international suppliers. Buyers may find themselves scrambling to find alternative sources, risking project timelines and budgets.

The Solution: To mitigate supply chain uncertainties, B2B buyers should establish relationships with multiple suppliers across different regions. Diversifying the supplier base not only reduces dependency on a single source but also allows for competitive pricing. Buyers should conduct thorough due diligence on potential suppliers, assessing their reliability, production capacity, and quality control processes. Additionally, leveraging technology, such as supply chain management software, can enhance visibility into inventory levels and lead times. Regular communication with suppliers can also provide insights into potential disruptions before they impact operations, allowing buyers to proactively adjust their strategies.

Scenario 2: Ensuring Compliance with Local Regulations for Electric Vehicles

The Problem: Different regions have varying regulations concerning electric vehicles, including emissions standards, safety requirements, and tax incentives. For B2B buyers from Europe, the Middle East, and Africa, navigating these regulations can be daunting. Non-compliance can lead to costly fines, shipment delays, and reputational damage, making it crucial for buyers to stay informed about local laws and regulations.

The Solution: B2B buyers should invest in understanding the regulatory landscape of their target markets. This can be achieved through partnerships with local consultants who specialize in automotive regulations. Suppliers themselves can also be a valuable resource; many have compliance teams that can guide buyers through the process. Additionally, buyers should consider integrating compliance checks into their procurement processes, ensuring that all suppliers meet the necessary regulations before finalizing contracts. This proactive approach not only avoids penalties but also enhances the overall quality and acceptance of the electric vehicles in local markets.

Scenario 3: Addressing the Skills Gap in Electric Vehicle Technology

The Problem: The transition to electric vehicles often requires a workforce skilled in new technologies, including battery management systems and electric drivetrains. However, many regions, particularly in developing markets, struggle with a lack of trained personnel. This skills gap can hinder the successful implementation and maintenance of electric vehicle technologies, creating a barrier for B2B buyers looking to invest in electric car supply chains.

The Solution: To bridge the skills gap, B2B buyers should consider investing in training programs for their workforce. Collaborating with educational institutions or technical training centers can help create tailored programs that focus on the specific skills required for electric vehicle technologies. Furthermore, buyers can partner with their suppliers to gain access to training resources and workshops. Engaging in knowledge-sharing initiatives and industry conferences can also help buyers stay abreast of the latest technologies and best practices. By prioritizing workforce development, buyers can enhance their operational capabilities and ensure a smoother transition to electric vehicle adoption.

Strategic Material Selection Guide for electric car supplier

What Are the Key Materials Used in Electric Vehicle Production?

When selecting materials for electric vehicles (EVs), suppliers must consider various factors that affect performance, cost, and compliance with international standards. Here, we analyze four common materials used in EV manufacturing: aluminum, steel, carbon fiber, and lithium-ion batteries. Each material has distinct properties and implications for B2B buyers in different regions.

How Does Aluminum Benefit Electric Vehicle Manufacturing?

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for various components in electric vehicles. It can withstand high temperatures and pressures, essential for battery enclosures and structural components.

Pros & Cons: The primary advantage of aluminum is its low weight, which enhances vehicle efficiency and range. However, it can be more expensive than traditional steel and may require specialized manufacturing processes, increasing complexity.

Impact on Application: Aluminum’s compatibility with various media, such as coolant fluids, makes it ideal for battery cooling systems. Its lightweight nature helps improve overall vehicle dynamics.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with regional standards such as ASTM and DIN. In regions with high humidity, corrosion resistance is particularly crucial, making aluminum a preferred choice.

What Role Does Steel Play in Electric Vehicle Production?

Key Properties: Steel is known for its high strength and durability. It can be treated to enhance corrosion resistance and withstand high stress and pressure, making it suitable for structural components.

Pros & Cons: Steel is generally more affordable than aluminum and offers excellent strength-to-weight ratios. However, it is heavier, which can negatively impact the vehicle’s efficiency and range.

Impact on Application: Steel’s robustness makes it ideal for chassis and body structures. Its compatibility with various coatings can enhance corrosion resistance, especially in regions with harsh climates.

Considerations for International Buyers: Buyers should be aware of the need for compliance with local steel standards, such as JIS in Japan or EN in Europe. Additionally, the availability of high-strength steel grades may vary by region, affecting sourcing decisions.

How Does Carbon Fiber Enhance Electric Vehicle Performance?

Key Properties: Carbon fiber is known for its exceptional strength-to-weight ratio and rigidity. It can withstand high temperatures and is resistant to corrosion, making it suitable for high-performance applications.

Pros & Cons: The main advantage of carbon fiber is its lightweight nature, which significantly improves vehicle performance and efficiency. However, it is costly and requires specialized manufacturing techniques, which can complicate production.

Impact on Application: Carbon fiber is often used in high-performance EVs for components like body panels and structural reinforcements. Its lightweight properties contribute to better acceleration and handling.

Considerations for International Buyers: Buyers should consider the cost implications and availability of carbon fiber in their regions. Compliance with international standards for composite materials is also essential.

What Are the Key Features of Lithium-Ion Batteries in Electric Vehicles?

Key Properties: Lithium-ion batteries offer high energy density and are lightweight compared to other battery types. They perform well under varying temperature conditions and have a long lifecycle.

Pros & Cons: The primary advantage of lithium-ion batteries is their efficiency and ability to store significant energy in a compact form. However, they can be expensive and require careful management to ensure safety and longevity.

Impact on Application: These batteries are crucial for electric vehicles, providing the necessary power for propulsion. Their compatibility with various charging systems is vital for widespread adoption.

Considerations for International Buyers: International buyers must ensure compliance with safety standards and regulations regarding battery transportation and disposal. Understanding local market conditions for battery sourcing is also critical.

Summary Table of Material Selection for Electric Vehicle Suppliers

| Material | Typical Use Case for Electric Car Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Battery enclosures, structural components | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | High |

| Steel | Chassis, body structures | Affordable, strong | Heavier, less efficient | Medium |

| Carbon Fiber | Body panels, structural reinforcements | Exceptional strength-to-weight ratio | High cost, specialized manufacturing | High |

| Lithium-Ion Battery | Power source for propulsion | High energy density, lightweight | Expensive, requires careful management | High |

This comprehensive analysis of materials provides actionable insights for international B2B buyers, helping them make informed decisions in the electric vehicle supply chain.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car supplier

What Are the Main Stages of Manufacturing for Electric Car Suppliers?

Manufacturing electric cars involves several critical stages, each designed to optimize efficiency, quality, and safety. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with the selection and preparation of raw materials, which often include metals, plastics, and advanced composites. Suppliers must ensure that these materials meet specific standards for strength, durability, and weight. This stage often involves sourcing materials from certified suppliers to guarantee quality.

-

Forming: This stage involves shaping the materials into the required components. Techniques such as stamping, extrusion, and molding are commonly used. Advanced methods like additive manufacturing (3D printing) are gaining traction for creating complex parts that reduce waste and enhance design flexibility. The choice of forming technique can significantly impact the overall production efficiency and the final product’s performance.

-

Assembly: Once the components are formed, they are assembled into the vehicle. This stage requires precision and often employs automated assembly lines to ensure consistency and speed. Robotics play a significant role in this process, especially in tasks that demand high accuracy, such as welding and fitting. The integration of smart technologies in assembly processes helps in monitoring production in real-time, ensuring that any issues are addressed immediately.

-

Finishing: The final stage involves painting, coating, and quality checks. Finishing processes not only enhance the vehicle’s aesthetic appeal but also protect it from environmental factors. Techniques such as electrostatic painting and powder coating are popular for their durability. This stage often includes the installation of electronic systems, battery packs, and other essential components.

How Is Quality Assurance Implemented in Electric Car Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of electric vehicles, where safety and performance standards are paramount. Several international and industry-specific standards guide QA processes.

-

International Standards: Adherence to ISO 9001, the international standard for quality management systems, is vital for electric car manufacturers. This certification demonstrates a commitment to maintaining high-quality processes and products. Other relevant standards include ISO 14001 for environmental management and ISO 45001 for occupational health and safety.

-

Industry-Specific Standards: In addition to general quality standards, electric car manufacturers often comply with industry-specific regulations such as the CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards. Similarly, certifications like API (American Petroleum Institute) are critical for suppliers dealing with components that interface with fuel systems.

What Are the Key Quality Control Checkpoints in Electric Car Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that the manufacturing process meets the desired quality standards. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. Rigorous testing and documentation help verify that suppliers meet the required specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are performed to ensure that each stage adheres to quality standards. This can include real-time monitoring of critical parameters, such as dimensions and material properties, to catch defects early.

-

Final Quality Control (FQC): Once assembly is complete, the vehicle undergoes a series of tests to ensure it meets all specifications. This includes performance testing, safety inspections, and compliance checks with regulatory standards.

What Testing Methods Are Commonly Used in Electric Car Manufacturing?

Testing methods are vital in validating the quality and safety of electric vehicles. Common methods include:

- Functional Testing: Ensures that all vehicle systems operate correctly, including battery management systems, electric drive systems, and safety features.

- Durability Testing: Simulates long-term usage conditions to assess the vehicle’s performance over time. This often involves stress tests and environmental exposure tests.

- Safety Testing: Involves crash tests and assessments of electrical safety to ensure compliance with global safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their electric car suppliers adhere to stringent quality control measures. Here are actionable steps to verify supplier QC:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality management systems, and compliance with international standards. Audits can reveal insights into the supplier’s operational capabilities and quality culture.

-

Quality Reports: Request detailed quality reports that outline the supplier’s QC processes, including metrics related to defect rates, inspection results, and corrective actions taken. These reports can provide transparency into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing capabilities and quality compliance. This can be especially useful for buyers in regions with varied regulatory environments, such as Africa and South America.

What QC and Certification Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers must navigate various QC and certification nuances when sourcing from electric car suppliers, especially from regions like Africa, South America, the Middle East, and Europe. Key considerations include:

-

Regional Standards: Different regions may have unique compliance requirements. For example, while CE marking is crucial in Europe, other markets may prioritize different certifications. Understanding these regional nuances helps in selecting compliant suppliers.

-

Supply Chain Transparency: Buyers should seek suppliers who demonstrate transparency in their supply chains. This includes clear documentation of sourcing practices, production processes, and quality control measures.

-

Cultural and Regulatory Differences: Awareness of cultural differences in business practices and regulatory frameworks can impact supplier relationships and quality expectations. Establishing clear communication channels and expectations can mitigate potential misunderstandings.

A stock image related to electric car supplier.

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when selecting electric car suppliers, ensuring they partner with reliable and quality-driven manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car supplier’

Introduction

Sourcing an electric car supplier requires a strategic approach to ensure that your investment aligns with your business objectives and sustainability goals. This checklist is designed to guide international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, through the essential steps to identify and secure a reliable electric car supplier.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Determine the type of electric vehicles (EVs) you need—consider aspects such as battery capacity, range, vehicle type (passenger, commercial, etc.), and any specific features required for your market.

- What to consider: Focus on industry standards and local regulations that may affect vehicle performance and compliance.

Step 2: Conduct Market Research on Suppliers

Identifying potential suppliers begins with thorough market research. Utilize industry reports, online directories, and trade shows to compile a list of manufacturers and distributors of electric vehicles that align with your needs.

- Where to look: Explore platforms like Alibaba or Global Sources, and consider local suppliers in your region to support local economies.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to evaluate their capabilities and track record. Request company profiles, case studies, and references from buyers in similar industries or regions.

- Key criteria: Assess their production capacity, quality control processes, and experience in exporting to your specific region.

Step 4: Verify Supplier Certifications and Compliance

Compliance with international standards is critical when sourcing electric vehicles. Ensure that potential suppliers hold relevant certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management.

- Why it matters: Certifications are indicators of a supplier’s commitment to quality and sustainability, which are crucial for long-term partnerships.

Step 5: Request Samples and Conduct Quality Assessments

Before finalizing your supplier choice, request samples of the electric vehicles or components you plan to procure. Conduct thorough quality assessments to ensure they meet your technical specifications and performance expectations.

- What to look for: Pay attention to the vehicle’s build quality, battery performance, and safety features during your evaluation.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate terms. Discuss pricing, payment options, delivery timelines, and after-sales support to ensure that both parties have a clear understanding of expectations.

- Focus on: Establishing a mutually beneficial agreement that includes warranties and service commitments for the vehicles.

Step 7: Establish a Communication Plan

Effective communication is vital for a successful partnership. Set up a communication plan that outlines how often you will interact with the supplier, preferred communication channels, and key contacts.

- Why this is important: A solid communication plan fosters transparency and helps address potential issues proactively, ensuring a smoother procurement process.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing electric car suppliers effectively and secure partnerships that drive their business success.

Comprehensive Cost and Pricing Analysis for electric car supplier Sourcing

What Are the Key Cost Components in Electric Car Supplier Sourcing?

When sourcing electric cars, understanding the cost structure is paramount for international B2B buyers. The primary cost components include:

-

Materials: The cost of materials, including batteries, electric motors, and body components, significantly affects the overall pricing. High-quality materials can lead to better vehicle performance and longevity, influencing buyer decisions.

-

Labor: Labor costs vary by region and can impact pricing. Countries with higher labor costs might offer better-skilled workers, which can enhance production quality.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities and facility maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Investments in specialized tools and machinery are necessary for producing electric vehicles. These costs are often amortized over the production volume, affecting pricing strategies.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and safety, which is crucial for electric vehicles. Higher QC standards can lead to increased costs but are essential for maintaining brand reputation.

-

Logistics: Transportation and handling costs play a critical role in the total cost structure, especially for international shipments. Factors like distance, mode of transport, and customs duties can all influence logistics costs.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on competition and market demand.

How Do Price Influencers Affect Electric Car Sourcing?

Several factors influence the pricing of electric cars:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing due to economies of scale. Buyers should negotiate MOQs to align with their purchasing strategy.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can significantly affect pricing. Buyers should assess the balance between cost and quality to ensure value.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can influence pricing. It’s advisable to conduct thorough due diligence on potential suppliers.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for clarifying responsibilities and costs associated with shipping. Different terms can impact the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency in Electric Car Sourcing?

To optimize sourcing strategies, buyers should consider the following actionable tips:

-

Negotiation: Engage in effective negotiation with suppliers to secure better pricing and terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Total Cost of Ownership (TCO): Evaluate TCO instead of just upfront costs. This includes maintenance, operation, and depreciation, providing a clearer picture of long-term expenses.

-

Pricing Nuances for International Buyers: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import taxes, and local regulations that may affect pricing.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing, improved service, and priority in production schedules.

Conclusion

Understanding the comprehensive cost and pricing landscape when sourcing electric cars is essential for international B2B buyers. By focusing on key cost components, price influencers, and actionable buyer tips, companies can make informed decisions that align with their financial and operational goals. It is crucial to remember that prices can vary significantly based on various factors, and it is advisable to request indicative prices and quotes directly from suppliers to obtain the most accurate information.

Alternatives Analysis: Comparing electric car supplier With Other Solutions

In the evolving landscape of transportation solutions, businesses are increasingly exploring alternatives to traditional electric car suppliers. These alternatives can range from hybrid vehicles to public transport systems, each offering unique benefits and challenges. This analysis aims to provide B2B buyers with a comparative overview of electric car suppliers against other viable solutions, enabling informed decision-making.

| Comparison Aspect | Electric Car Supplier | Hybrid Vehicle Supplier | Public Transport Solutions |

|---|---|---|---|

| Performance | High torque, quick acceleration, lower emissions | Moderate performance, improved fuel efficiency | Variable based on infrastructure; generally lower emissions per passenger |

| Cost | Higher upfront cost; potential savings in fuel and maintenance | Moderate upfront cost; better fuel economy than traditional vehicles | Lower individual cost; dependent on ticketing and subscription models |

| Ease of Implementation | Requires charging infrastructure and training | Easier integration with existing fuel infrastructure | Limited by regional availability and quality of service |

| Maintenance | Lower maintenance costs due to fewer moving parts | Moderate maintenance; some components still require traditional servicing | Minimal maintenance for users; depends on service reliability |

| Best Use Case | Ideal for businesses with fleet operations and eco-conscious branding | Suitable for mixed-use transportation needs; flexibility for long trips | Best for urban areas with high population density and established routes |

What Are the Pros and Cons of Hybrid Vehicles Compared to Electric Cars?

Hybrid vehicles combine an internal combustion engine with an electric motor, providing a versatile transportation solution. One of the significant advantages of hybrids is their flexibility; they can operate on gasoline when electric power is insufficient, making them ideal for long-distance travel without the need for charging infrastructure. However, they still rely on fossil fuels, which may not align with businesses aiming for complete sustainability. Additionally, while maintenance costs are generally moderate, they can still be higher than those of fully electric vehicles due to the complexity of their systems.

How Do Public Transport Solutions Stack Up Against Electric Car Suppliers?

Public transport solutions offer a cost-effective and environmentally friendly alternative for businesses with employees commuting to centralized locations. The primary advantage of public transport is its lower individual cost per passenger and reduced carbon footprint when utilized at scale. However, the effectiveness of public transport can vary significantly based on the quality of the service and existing infrastructure. In regions with limited public transport options, reliance on this solution may not be practical, potentially leading to employee dissatisfaction and logistical challenges.

How Can B2B Buyers Choose the Right Transportation Solution for Their Needs?

When selecting the right transportation solution, B2B buyers should evaluate their specific operational needs, budget constraints, and sustainability goals. Electric car suppliers may offer the best performance and eco-friendly branding for businesses focused on reducing their carbon footprint and operating in urban environments with suitable charging infrastructure. In contrast, hybrid vehicles might serve well in scenarios requiring longer travel without extensive planning for charging. Public transport could be the most economical choice in densely populated urban areas, provided that the service quality meets the needs of the workforce.

Ultimately, the decision should align with the business’s strategic goals, operational needs, and the environmental impact they wish to have. By carefully assessing each option’s advantages and challenges, international B2B buyers can make informed choices that benefit their operations and the planet.

Essential Technical Properties and Trade Terminology for electric car supplier

What Are the Essential Technical Properties of Electric Car Supplies?

In the electric vehicle (EV) industry, understanding the technical specifications of components is crucial for B2B buyers. Here are some key properties that you should consider when sourcing electric car supplies:

-

Material Grade

– The material grade refers to the quality and type of materials used in manufacturing EV components, such as lithium for batteries or aluminum for body frames. High-grade materials ensure durability, safety, and efficiency. For international buyers, knowing the material grade can help in assessing the reliability of suppliers, especially when considering different standards across regions like Africa and Europe. -

Tolerance

– Tolerance indicates the permissible limits of variation in a physical dimension. In electric vehicle manufacturing, precise tolerances are essential for components like motors and battery packs to ensure compatibility and performance. A tight tolerance can lead to better energy efficiency, while loose tolerances may result in operational failures. B2B buyers should prioritize suppliers who can consistently meet specified tolerances. -

Battery Capacity

– Battery capacity is a critical specification for electric vehicles, measured in kilowatt-hours (kWh). It determines the range an electric vehicle can travel on a single charge. For buyers, understanding battery capacity helps in evaluating vehicle performance and matching it with market needs, especially in regions with vast distances between urban centers. -

Power-to-Weight Ratio

– This property compares the power output of the vehicle to its weight. A higher power-to-weight ratio often translates to better acceleration and overall performance. B2B buyers should consider this metric when assessing suppliers, as it can impact the vehicle’s competitiveness in the market. -

Charging Time

– Charging time is the duration required to recharge an electric vehicle’s battery. It varies based on the battery’s capacity and the type of charger used. Understanding the charging time is crucial for B2B buyers, especially in markets where charging infrastructure may be limited or underdeveloped.

Which Trade Terminology Should International Buyers Understand?

Familiarity with industry jargon can streamline communication and negotiations. Here are several key terms that every B2B buyer in the electric vehicle sector should know:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from established OEMs can ensure quality and compatibility with existing vehicle systems. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for international buyers to manage inventory and cash flow effectively. Buyers should negotiate MOQs that align with their operational capabilities and market demand. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a price quote for specific products. This process is crucial for B2B buyers to gather competitive pricing and terms, allowing them to make informed purchasing decisions. -

Incoterms

– Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which is particularly important when dealing with cross-border suppliers. -

Lead Time

– Lead time is the period from placing an order to receiving the product. It is vital for B2B buyers to consider lead times when planning inventory and production schedules, especially in industries where timely delivery can significantly affect market competitiveness.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing electric car supplies, ensuring that their investments align with market demands and operational capabilities.

Navigating Market Dynamics and Sourcing Trends in the electric car supplier Sector

What Are the Current Market Dynamics and Sourcing Trends in the Electric Car Supplier Sector?

The electric car supplier sector is experiencing rapid growth driven by several global factors. The urgent need to combat climate change has led governments and corporations to commit to reducing carbon emissions, which is significantly boosting the demand for electric vehicles (EVs). This shift is particularly noticeable in regions such as Africa, South America, the Middle East, and Europe, where policy incentives and consumer interest are rising. For international B2B buyers, understanding local regulations, market entry barriers, and regional demand patterns is essential for successful sourcing.

Emerging technologies are reshaping the sourcing landscape within this sector. For instance, advancements in battery technology, such as solid-state batteries, are leading to increased efficiency and reduced costs, making EVs more accessible. Additionally, digital platforms are streamlining procurement processes, allowing suppliers and manufacturers to connect more effectively. Buyers should be aware of these trends, as they can leverage technology to enhance their supply chain management and drive down costs.

Market dynamics are also influenced by geopolitical factors. For example, trade agreements between countries can open up new sourcing opportunities or create barriers. Buyers from regions like Europe may face different challenges compared to those in Africa or South America, such as varying levels of infrastructure development and market maturity. Therefore, conducting thorough market research is crucial for navigating these complexities.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategy?

Sustainability has become a cornerstone of the electric car supplier sector, influencing sourcing decisions across the globe. The environmental impact of battery production, particularly lithium extraction, has raised concerns about the ethical implications of sourcing materials. For B2B buyers, prioritizing suppliers who adhere to sustainable practices is not just a trend; it’s a necessity for maintaining brand reputation and compliance with emerging regulations.

Ethical sourcing also extends to the supply chain transparency, which is increasingly demanded by consumers and stakeholders alike. Buyers should seek suppliers who can provide verifiable information regarding their sourcing practices, including certifications related to environmental and social governance (ESG). Certifications like ISO 14001 for environmental management systems or Fair Trade certifications for materials can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of sustainable materials, such as recycled metals and bio-based plastics, is gaining traction. Suppliers that incorporate ‘green’ materials into their production processes not only contribute to reduced environmental footprints but also appeal to a growing segment of eco-conscious consumers. By integrating sustainability into sourcing strategies, B2B buyers can enhance their competitive advantage and align with global sustainability goals.

What Is the Brief Evolution of the Electric Car Supplier Sector?

The electric car supplier sector has evolved significantly over the past few decades. Initially, the market was characterized by limited options and high costs, primarily due to nascent technology and low consumer demand. However, the 2000s marked a pivotal turning point with advancements in battery technology and the emergence of key players in the automotive industry.

By the 2010s, governments worldwide began implementing stricter emissions regulations and offering incentives for EV adoption, further propelling market growth. Today, the sector is defined by a diverse array of suppliers offering innovative components, from batteries to charging infrastructure. This evolution has created a dynamic environment for international B2B buyers, who now have access to a broader range of sustainable and technologically advanced products that align with their strategic goals. Understanding this evolution is crucial for making informed sourcing decisions in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car supplier

-

How do I evaluate the reliability of an electric car supplier?

To evaluate the reliability of an electric car supplier, consider their industry experience, customer reviews, and product certifications. Request references from previous clients and check their track record in delivering quality products on time. Additionally, assess their production capabilities and supply chain management practices. A reliable supplier should have transparent communication and be willing to share information about their manufacturing processes, quality assurance measures, and compliance with international standards. -

What are the key factors to consider when sourcing electric vehicles for my business?

When sourcing electric vehicles, key factors include the supplier’s reputation, product quality, customization options, pricing, and after-sales support. Additionally, consider the supplier’s compliance with local regulations and environmental standards. Assess the availability of spare parts and service networks in your region. It’s also essential to evaluate the total cost of ownership, including maintenance, charging infrastructure, and potential incentives for electric vehicle adoption in your market. -

What minimum order quantities (MOQ) should I expect from electric car suppliers?

Minimum order quantities (MOQ) for electric cars can vary significantly among suppliers, typically ranging from 10 to 50 units for smaller manufacturers to larger quantities for established brands. When negotiating MOQs, consider your market demand and potential sales volume. Some suppliers may offer flexible MOQs for first-time buyers or pilot projects, so it’s worthwhile to discuss your specific needs to reach a mutually beneficial agreement. -

What payment terms are common when dealing with electric car suppliers?

Common payment terms when working with electric car suppliers include a deposit upfront (typically 30-50%), with the balance due upon delivery or prior to shipment. Some suppliers may offer financing options or extended payment terms based on your creditworthiness and order size. It’s crucial to clarify payment terms in the contract to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance when sourcing electric vehicles?

To ensure quality assurance, ask suppliers about their quality control processes, including inspections and testing procedures for their vehicles. Request documentation of certifications, such as ISO standards or local compliance certificates. Consider conducting factory audits or hiring third-party inspection services to verify product quality before shipment. Establishing a clear return policy for defective products can also safeguard your investment. -

What logistics considerations should I keep in mind when importing electric cars?

Logistics considerations when importing electric cars include transportation costs, customs duties, and compliance with local regulations. Work closely with your supplier to understand shipping options and lead times. Ensure that the vehicles are compliant with the destination country’s safety and emissions standards. Partnering with a reliable freight forwarder can help navigate the complexities of international shipping, ensuring timely delivery and minimizing delays. -

Can I customize electric vehicles to meet my specific business needs?

Many electric car suppliers offer customization options to meet specific business requirements, such as branding, interior configurations, or additional features. Discuss your needs during the initial conversations with potential suppliers and inquire about the extent of their customization capabilities. Be aware that customization may affect lead times and pricing, so it’s essential to factor these elements into your decision-making process. -

What should I know about warranty and after-sales support for electric vehicles?

Understanding warranty terms and after-sales support is crucial when sourcing electric vehicles. Most suppliers offer warranties that cover defects in materials and workmanship, typically ranging from 2 to 5 years. Inquire about the specifics of the warranty, including what it covers and any limitations. Additionally, assess the availability of after-sales support, including service centers, spare parts availability, and technical assistance. A strong after-sales support system can significantly enhance your experience and reduce downtime for your fleet.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric car supplier

In the rapidly evolving landscape of electric vehicle (EV) supply chains, strategic sourcing remains a cornerstone for international B2B buyers. By focusing on long-term partnerships with reliable suppliers, businesses can enhance their competitiveness while mitigating risks associated with fluctuating raw material prices and regulatory changes. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate sustainability practices, innovation in technology, and responsiveness to market demands.

Leveraging data analytics and market intelligence tools can further streamline sourcing processes, enabling companies to identify emerging trends and make informed decisions. Additionally, fostering relationships with local suppliers can provide advantages in terms of logistics and compliance with regional regulations.

As the global shift towards electric vehicles accelerates, now is the time for international B2B buyers to reassess their sourcing strategies. Embrace the opportunities presented by this transition to secure a competitive edge in the EV market. Engage with suppliers who align with your strategic goals and invest in partnerships that will drive innovation and sustainability. The future of mobility is electric, and your sourcing decisions today will shape your success tomorrow.