Unlock Savings: Your Guide to Flour Mill Suppliers (2025)

Introduction: Navigating the Global Market for flour mill supplier

Navigating the global market for flour mill suppliers can be a daunting task, especially for international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reputable suppliers but also in understanding the various types of flour mills available, their applications, and the intricacies of supplier vetting. This guide aims to demystify the sourcing process, offering a comprehensive overview of the flour milling industry, including equipment specifications, production capacities, and the latest technological advancements.

As you delve into this resource, you will find actionable insights on how to effectively evaluate potential suppliers based on quality standards, pricing structures, and after-sales support. Key considerations such as local regulations, delivery logistics, and market trends will also be covered, ensuring that you are well-equipped to make informed purchasing decisions. This guide is specifically tailored to meet the needs of buyers in emerging markets, providing strategies to optimize procurement processes and enhance supply chain efficiency.

With a focus on empowering B2B buyers, this guide serves as a crucial tool for those looking to establish reliable partnerships in the flour milling sector. Whether you are sourcing equipment for a new plant or upgrading existing facilities, understanding the landscape of flour mill suppliers is essential for achieving your business objectives.

Understanding flour mill supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Flour Mills | Large-scale production, automated processes, high capacity | Food manufacturing, export businesses | Pros: High efficiency, consistent quality. Cons: High initial investment, may require large storage space. |

| Artisanal Flour Mills | Smaller scale, traditional methods, focus on quality ingredients | Local bakeries, specialty food shops | Pros: Unique flavors, local sourcing. Cons: Higher cost per unit, limited production capacity. |

| Mobile Flour Mills | Portable units, on-site milling, flexibility | Remote areas, small-scale farms | Pros: Freshly milled flour, reduced transport costs. Cons: Limited capacity, potential quality variability. |

| Organic Flour Mills | Certification for organic products, sustainable practices | Health food stores, organic bakeries | Pros: Growing market demand, premium pricing. Cons: Higher operational costs, stringent regulations. |

| Custom Flour Suppliers | Tailored milling services, specialized flour blends | Niche markets, specific culinary needs | Pros: Meets specific buyer needs, unique product offerings. Cons: Potentially higher costs, longer lead times. |

What are the characteristics of Industrial Flour Mills?

Industrial flour mills are designed for high-volume production and typically employ automated processes to ensure efficiency and consistency. These mills can produce large quantities of flour rapidly, making them ideal for food manufacturers and export businesses that require bulk supplies. When considering purchasing from industrial suppliers, B2B buyers should evaluate the supplier’s capacity, reliability, and the technology used in their milling processes. While they offer advantages in efficiency and lower costs per unit, the initial investment and need for significant storage can be drawbacks.

How do Artisanal Flour Mills differ from other suppliers?

Artisanal flour mills focus on quality over quantity, often using traditional milling methods and sourcing local grains. These mills cater primarily to local bakeries and specialty food shops that seek unique flavors and high-quality ingredients. Buyers considering artisanal suppliers should assess the mill’s sourcing practices, production capacity, and ability to provide consistent quality. While these mills offer distinct advantages in taste and community support, they typically come with a higher cost per unit and limited production capabilities.

What advantages do Mobile Flour Mills provide?

Mobile flour mills are portable units that allow for on-site milling, offering flexibility to buyers in remote areas or small-scale farms. This approach not only ensures fresh flour but also reduces transportation costs associated with delivering bulk flour. When evaluating mobile suppliers, B2B buyers should consider the mill’s capacity, the range of grains it can process, and the technological aspects of the equipment. Although mobile mills provide unique benefits, such as freshness, they may have limitations in production capacity and could present quality variability.

What makes Organic Flour Mills a viable option for buyers?

Organic flour mills are certified to produce organic products and often emphasize sustainable practices. They cater to health food stores and organic bakeries, which are increasingly in demand as consumers shift toward healthier eating options. Buyers should investigate the certifications held by the supplier, the sourcing of ingredients, and the overall market trends in organic products. While organic flour can command premium pricing and is sought after by health-conscious consumers, it also involves higher operational costs and adherence to strict regulations.

How can Custom Flour Suppliers meet specific buyer needs?

Custom flour suppliers offer tailored milling services and can create specialized flour blends to meet niche market demands. This flexibility is particularly beneficial for businesses with unique culinary needs or specific product formulations. When engaging with custom suppliers, B2B buyers should clarify their requirements, assess the supplier’s capabilities for customization, and consider lead times for orders. While custom milling can provide significant advantages in product differentiation, it may also lead to higher costs and longer turnaround times.

Related Video: Fully Automatic Flour Mill Plant | Shri Viratra Engineering

Key Industrial Applications of flour mill supplier

| Industry/Sector | Specific Application of flour mill supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Production of various types of flour for baked goods | Ensures consistent quality and variety in products | Supplier reliability, milling technology, and certifications |

| Animal Feed Production | Grinding grains for animal feed formulations | Enhances nutritional value and digestibility of feed | Quality control, sourcing of raw materials, and traceability |

| Bakery and Confectionery | Custom flour blends for specialty baked products | Meets unique recipe requirements, improving market competitiveness | Flexibility in order sizes, delivery timelines, and pricing |

| Ethnic Food Production | Milling specific grains for traditional recipes | Supports cultural authenticity and consumer demand | Knowledge of local preferences, quality of grains, and milling expertise |

| Pharmaceutical Industry | Fine milling of starches and other excipients | Ensures precise dosage and effective drug formulation | Compliance with industry regulations and quality standards |

How is Flour Mill Supplier Used in Food Processing?

In the food processing industry, flour mill suppliers play a crucial role by providing high-quality flour for baked goods such as bread, pastries, and pasta. The consistent quality of flour is essential for maintaining the texture and flavor of these products. International buyers, particularly from regions like Africa and South America, must consider suppliers that offer reliable milling processes and adhere to food safety standards. Additionally, local sourcing of grains can enhance flavor profiles and reduce transportation costs.

What are the Benefits of Flour Mill Suppliers in Animal Feed Production?

Flour mill suppliers are instrumental in the animal feed production sector by grinding grains into flour that enhances the nutritional value of feed. This is particularly important for livestock health and growth. Buyers from the Middle East and Europe should prioritize suppliers that offer traceable and high-quality raw materials to ensure the feed meets regulatory standards. Furthermore, suppliers that can provide customized formulations based on specific livestock needs can significantly benefit animal husbandry operations.

How Do Flour Mill Suppliers Assist the Bakery and Confectionery Sector?

In the bakery and confectionery sector, flour mill suppliers provide custom flour blends tailored for specialty baked products, allowing businesses to differentiate themselves in a competitive market. This customization can lead to improved product quality and customer satisfaction. For international B2B buyers, it is essential to find suppliers that can accommodate flexible order sizes and have a strong understanding of local baking trends, particularly in diverse markets such as Europe and Africa.

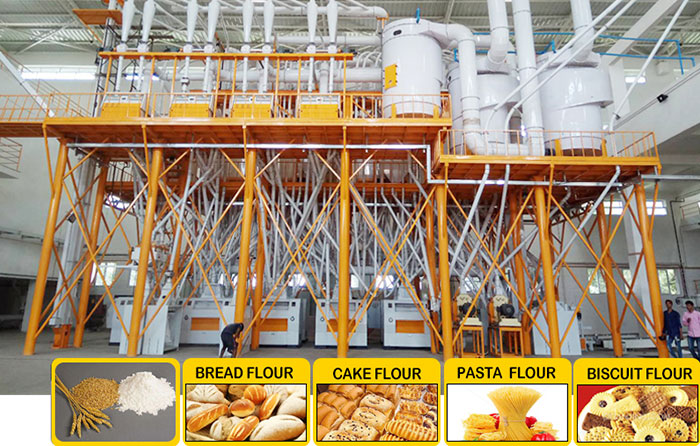

A stock image related to flour mill supplier.

What Role Do Flour Mill Suppliers Play in Ethnic Food Production?

A stock image related to flour mill supplier.

Flour mill suppliers are vital for ethnic food production, where specific grains are milled to create traditional flours used in local recipes. This supports cultural authenticity and meets the growing consumer demand for ethnic foods. Buyers in regions like South America and Africa should seek suppliers with expertise in local grains and milling techniques to ensure high-quality products. Understanding local preferences and quality standards is crucial for maintaining authenticity in ethnic cuisines.

How are Flour Mill Suppliers Important in the Pharmaceutical Industry?

In the pharmaceutical industry, flour mill suppliers provide finely milled starches and excipients necessary for effective drug formulation. The precision of milling ensures accurate dosing and enhances the efficacy of medications. International buyers must ensure that their suppliers comply with stringent pharmaceutical regulations and quality standards. Additionally, suppliers should offer transparency in their milling processes to maintain the integrity of pharmaceutical products.

Related Video: Wheat Flour Mill Plant | How Wheat is Process Inside the Factory | Wheat Processing Line

3 Common User Pain Points for ‘flour mill supplier’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Flour Procurement

The Problem: B2B buyers often face significant challenges in ensuring a consistent supply of flour due to unpredictable supply chain disruptions. Factors such as political instability, economic fluctuations, or natural disasters can lead to sudden shortages or delays. Buyers in regions like Africa or South America may experience these issues more acutely, impacting production schedules and customer satisfaction.

The Solution: To mitigate supply chain risks, international B2B buyers should develop a diversified sourcing strategy. This involves identifying multiple flour mill suppliers across different regions to ensure redundancy. Establish strong relationships with these suppliers and regularly communicate your demand forecasts to help them plan better. Additionally, consider entering into long-term contracts with suppliers who have a proven track record of reliability. This proactive approach not only enhances supply chain resilience but also allows for better negotiation terms, potentially reducing costs in the long run.

Scenario 2: Ensuring Quality Standards in Flour Products

The Problem: Quality assurance is a critical concern for B2B buyers in the flour industry, especially when sourcing from suppliers in different countries. Variations in flour quality can arise from differences in milling processes, grain quality, and regulatory standards. Buyers may struggle to ensure that the flour they receive meets their specifications, which can affect product quality and safety.

The Solution: To ensure consistent quality, buyers should implement a rigorous supplier evaluation process. Start by assessing potential suppliers based on their certifications (such as ISO or HACCP) and production processes. Request samples for quality testing before making bulk purchases, and establish clear quality specifications that suppliers must adhere to. Regular audits and site visits can also help maintain standards. Additionally, fostering a collaborative relationship with suppliers can lead to better quality control practices and transparency, ensuring that the flour consistently meets your business’s requirements.

Scenario 3: Managing Cost Fluctuations in Flour Supply

The Problem: B2B buyers often face the challenge of fluctuating flour prices, which can significantly impact budgeting and financial planning. Factors such as changes in grain prices, transportation costs, and seasonal variations can lead to unpredictable pricing, making it difficult for businesses to maintain profitability.

The Solution: To effectively manage cost fluctuations, buyers should adopt a strategic purchasing approach. One practical solution is to utilize forward contracts, locking in prices for future purchases to shield against sudden price hikes. Additionally, consider sourcing flour from regions with lower production costs or exploring bulk purchasing options to take advantage of economies of scale. Regularly analyze market trends and engage with suppliers to negotiate favorable terms based on your purchasing volume. This strategic approach not only stabilizes costs but also positions your business to react swiftly to market changes, enhancing overall financial control.

Strategic Material Selection Guide for flour mill supplier

When selecting materials for flour mill suppliers, understanding the properties, advantages, and limitations of common materials is essential for international B2B buyers. This guide analyzes four materials frequently used in flour milling applications: stainless steel, carbon steel, aluminum, and plastic composites. Each material has unique characteristics that can significantly affect performance, durability, and compliance with international standards.

What Are the Key Properties of Stainless Steel for Flour Mills?

Stainless steel is renowned for its excellent corrosion resistance, making it ideal for environments where moisture and flour dust are prevalent. It can withstand high temperatures and pressures, which is critical during milling processes. The most common grades used in flour milling are 304 and 316, with 316 offering superior resistance to chlorides, which is beneficial in humid climates.

Pros and Cons of Stainless Steel:

– Pros: High durability, excellent hygiene properties, and resistance to corrosion and heat.

– Cons: Higher initial cost compared to carbon steel and potential for galling if not properly lubricated.

Impact on Application: Stainless steel is compatible with various media, including flour, water, and cleaning agents. Its non-reactive nature ensures that it does not alter the flavor or quality of the flour.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A240 for stainless steel sheets and plates. In regions like Africa and South America, sourcing from local suppliers can reduce costs and improve delivery times.

How Does Carbon Steel Perform in Flour Milling?

Carbon steel is often used in flour mills due to its strength and affordability. It is suitable for structural components and machinery that do not require high corrosion resistance.

Pros and Cons of Carbon Steel:

– Pros: Lower cost and high tensile strength.

– Cons: Susceptible to rust and corrosion, particularly in humid environments, which can lead to contamination.

Impact on Application: Carbon steel is suitable for components that are not in direct contact with flour, such as frames and supports. However, its susceptibility to corrosion limits its use in areas exposed to moisture.

Considerations for International Buyers: Buyers should consider local regulations regarding food safety and materials that come into contact with food. Compliance with standards such as ASTM A36 is essential.

What Are the Advantages of Aluminum in Flour Mills?

Aluminum is lightweight and resistant to corrosion, making it a popular choice for components that require mobility or frequent handling. It is also easy to machine, allowing for intricate designs.

Pros and Cons of Aluminum:

– Pros: Lightweight, good corrosion resistance, and ease of fabrication.

– Cons: Lower strength compared to stainless and carbon steel, and can be more expensive than carbon steel.

Impact on Application: Aluminum is often used for parts like hoppers and covers that require frequent cleaning and maintenance. Its non-reactive nature makes it suitable for food applications.

Considerations for International Buyers: Buyers should verify that aluminum components meet standards such as ASTM B221 for extruded aluminum. In regions with high humidity, additional coatings may be necessary to enhance corrosion resistance.

How Do Plastic Composites Fit into Flour Milling Applications?

Plastic composites offer a unique combination of lightweight properties and resistance to corrosion and chemicals. They are often used in applications requiring flexibility and ease of maintenance.

Pros and Cons of Plastic Composites:

– Pros: Lightweight, resistant to corrosion, and easy to clean.

– Cons: Limited temperature tolerance and can be less durable under heavy loads.

Impact on Application: Plastic composites are suitable for non-structural components like guards and covers. They can withstand flour dust and moisture without degrading.

Considerations for International Buyers: Ensure compliance with food safety standards and regulations, such as FDA approval for food contact materials. In emerging markets, sourcing locally can enhance supply chain efficiency.

Summary Table of Material Selection for Flour Mill Suppliers

| Material | Typical Use Case for flour mill supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Milling equipment and storage containers | High durability and corrosion resistance | Higher initial cost | High |

| Carbon Steel | Structural components and frames | Cost-effective and strong | Prone to rust in humid conditions | Low |

| Aluminum | Hoppers and covers | Lightweight and easy to fabricate | Lower strength compared to steel | Medium |

| Plastic Composites | Guards and non-structural components | Corrosion resistant and easy to clean | Limited temperature tolerance | Medium |

This guide provides actionable insights for international B2B buyers in selecting the appropriate materials for flour milling applications, considering performance, cost, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for flour mill supplier

What Are the Main Stages of Manufacturing for Flour Mill Suppliers?

The manufacturing process for flour mills involves several critical stages that ensure the production of high-quality flour. Understanding these stages can empower international B2B buyers to make informed decisions when sourcing equipment.

-

Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Grains, such as wheat or maize, are sourced from reliable suppliers. This stage often includes cleaning, where impurities like stones, dust, and other foreign materials are removed. The grains may also undergo conditioning, where moisture is added to facilitate easier milling. Effective material preparation is crucial for ensuring the quality of the final product. -

Forming

This stage involves the milling process itself, where grains are ground into flour. Various milling techniques can be employed, including roller milling, stone milling, or hammer milling. Roller mills are the most common, utilizing pairs of rollers to crush and grind the grains. Each method has its benefits and drawbacks, influencing the flour’s texture and quality. Buyers should inquire about the milling techniques used by suppliers to ensure they meet specific production needs. -

Assembly

In the assembly phase, components of the milling equipment are put together. This includes the installation of the milling machinery, sifters, and packaging systems. Quality assembly ensures that the machinery operates efficiently and reduces the risk of breakdowns. For B2B buyers, it’s important to understand the supplier’s assembly practices and the technology used, as this can impact the reliability of the equipment. -

Finishing

The finishing stage includes processes like sifting and blending to achieve the desired flour quality. Flour is sifted to separate fine flour from coarser particles. This stage may also involve the addition of additives to enhance the flour’s baking properties. Buyers should assess the supplier’s capabilities in customizing flour products to meet specific baking or cooking requirements.

How Do Flour Mill Suppliers Ensure Quality Assurance?

Quality assurance (QA) is vital in the flour milling industry, ensuring that the final product meets international standards and customer expectations. Here’s how suppliers typically manage QA:

-

Adherence to International Standards

Suppliers often comply with ISO 9001, which sets the criteria for a quality management system. This certification demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for specific machinery can be essential for certain applications. -

Quality Control Checkpoints

Quality control (QC) checkpoints are implemented at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Monitoring occurs during the manufacturing process to identify and rectify any deviations from quality standards.

– Final Quality Control (FQC): The finished product undergoes thorough testing to ensure it meets customer specifications before shipment. -

Common Testing Methods

Testing methods vary but typically include:

– Moisture Content Analysis: Ensures that the flour has the right moisture level for optimal storage and usage.

– Gluten Quality Testing: Assesses the flour’s suitability for different baking applications.

– Ash Content Testing: Indicates the purity of flour and its milling process.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control measures of flour mill suppliers is crucial to ensure reliability and product quality. Here are several methods to assess supplier QA processes:

-

Audits and Inspections

Conducting on-site audits can provide direct insight into the supplier’s manufacturing processes and quality assurance practices. Buyers should look for transparency in operations and adherence to safety and quality standards. -

Requesting Quality Reports

Suppliers should be able to provide detailed quality assurance reports, including results from testing methods and compliance certificates. Buyers can evaluate these documents to ensure they align with their requirements. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections often follow international standards and can include random sampling and testing of products.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of certain nuances in quality control:

-

Cultural and Regulatory Differences

Different regions may have varying quality standards and regulations. Understanding local requirements and how they align with international standards is essential for compliance. -

Logistics and Supply Chain Considerations

The distance between suppliers and buyers can affect the quality of the product during transit. Buyers should inquire about how suppliers manage logistics to maintain product integrity and quality throughout the shipping process. -

Building Relationships

Establishing strong relationships with suppliers can facilitate better communication and transparency regarding quality assurance practices. This rapport can lead to more favorable terms and conditions, especially when negotiating quality guarantees.

Conclusion

By understanding the manufacturing processes and quality assurance practices of flour mill suppliers, international B2B buyers can make informed decisions that lead to successful partnerships. Emphasizing quality and compliance with international standards not only ensures product reliability but also enhances customer satisfaction in the competitive marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flour mill supplier’

In the competitive landscape of flour milling, sourcing the right supplier is paramount for international B2B buyers. This guide provides a practical checklist to streamline your procurement process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining your requirements for flour milling machinery. This includes production capacity, types of flour to be processed, and any specific features needed for your operation.

– Considerations: Identify whether you need a mill for whole grain, white flour, or specialty flours.

– Importance: A precise specification helps you filter suppliers who can meet your exact needs, reducing the risk of investing in unsuitable equipment.

Step 2: Conduct Market Research on Flour Mill Suppliers

Before selecting a supplier, perform thorough market research to identify potential candidates.

– Sources: Utilize online directories, industry trade shows, and recommendations from other businesses in your region.

– Importance: Understanding the market landscape allows you to compare offerings and pricing, ensuring you find a supplier that fits your budget and quality standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly.

– Actions: Request company profiles, case studies, and references from buyers in a similar industry or region.

– Importance: This step helps you gauge the supplier’s reliability and capacity to deliver according to your specifications, mitigating risks associated with poor supplier performance.

Step 4: ✅ Verify Supplier Certifications and Compliance

Ensure that potential suppliers have the necessary certifications and comply with international standards.

– Look for: ISO certifications, food safety standards, and compliance with local regulations in your target market.

– Importance: Certifications not only assure quality but also indicate the supplier’s commitment to maintaining industry standards, which is vital for food safety and product reliability.

Step 5: Request and Analyze Quotes

Solicit detailed quotations from shortlisted suppliers, including pricing, terms of delivery, and warranties.

– Details to analyze: Pay attention to unit pricing, bulk discounts, shipping costs, and after-sales service conditions.

– Importance: A comprehensive analysis of quotes ensures you understand the total cost of ownership, allowing you to make a financially sound decision.

Step 6: Conduct Site Visits or Virtual Inspections

If possible, visit the supplier’s facility or conduct a virtual inspection to evaluate their operational capabilities.

– What to observe: Assess the state of the machinery, cleanliness of the facility, and adherence to safety protocols.

– Importance: Firsthand observation provides insight into the supplier’s operational efficiency and manufacturing practices, which can significantly impact your supply chain.

Step 7: Establish Clear Communication Channels

Once you select a supplier, establish robust communication channels for ongoing collaboration.

– What to include: Set expectations for response times, reporting formats, and regular updates on order status.

– Importance: Effective communication is key to resolving issues quickly and maintaining a strong business relationship, ensuring smooth operations throughout your partnership.

By following these steps, international B2B buyers can confidently navigate the sourcing process for flour mill suppliers, making informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for flour mill supplier Sourcing

What Are the Key Cost Components in Sourcing Flour Mill Suppliers?

When sourcing flour mill suppliers, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The cost of raw materials, such as wheat, is a significant factor. Prices can fluctuate based on market conditions and geographical factors. Buyers should be aware of these fluctuations and consider sourcing from suppliers who can offer stable pricing or bulk purchasing agreements.

-

Labor: Labor costs vary by region and can significantly influence the overall pricing of flour milling equipment. For instance, labor is typically more expensive in Europe compared to regions like Africa or South America. Understanding local labor markets can help buyers assess total costs accurately.

-

Manufacturing Overhead: This includes costs associated with the production process, such as utilities, rent, and equipment maintenance. Suppliers with efficient manufacturing processes may be able to offer more competitive pricing.

-

Tooling: The initial setup costs for machinery and tools can be substantial, especially for customized flour milling solutions. Buyers should inquire about the tooling costs associated with their specific requirements.

-

Quality Control (QC): Quality assurance processes, including testing and certification, add to the cost. Suppliers with robust QC procedures may charge more, but this investment often results in higher quality products.

-

Logistics: Transporting flour milling equipment can be costly and complex, especially for international shipments. Buyers should consider the logistics costs associated with different suppliers, including shipping fees and potential tariffs.

-

Margin: Suppliers will always include a profit margin in their pricing. Understanding typical margins in the flour milling industry can help buyers evaluate whether they are receiving fair pricing.

How Do Price Influencers Affect Flour Mill Supplier Costs?

Several factors can influence the pricing structure when sourcing flour mill suppliers:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate for favorable terms based on their expected usage.

-

Specifications and Customization: Custom equipment or specific features can significantly raise prices. Buyers should define their needs clearly to avoid unnecessary costs.

-

Materials: The choice of materials used in flour milling machinery can affect both quality and pricing. Buyers should evaluate options carefully, balancing cost with the expected durability and performance.

-

Quality and Certifications: Equipment that meets international quality standards or certifications may come at a premium. However, this often leads to better performance and lower maintenance costs in the long run.

-

Supplier Factors: The reputation, experience, and location of the supplier can influence pricing. Established suppliers may charge more due to their reliability and service quality.

-

Incoterms: Understanding the terms of delivery (Incoterms) is crucial for calculating total costs. Buyers should clarify whether costs include shipping, insurance, and customs duties to avoid unexpected expenses.

What Are Effective Buyer Tips for Negotiating Flour Mill Supplier Prices?

International B2B buyers should consider the following strategies to ensure cost-efficiency and favorable terms when sourcing flour mill suppliers:

-

Negotiate Wisely: Leverage your purchasing volume and long-term potential to negotiate better pricing and terms. Building a strong relationship with suppliers can also lead to more favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, consider the total cost of ownership, which includes maintenance, operational costs, and potential downtime. This holistic view can lead to better purchasing decisions.

-

Understand Pricing Nuances: Prices can vary widely based on regional market conditions. Buyers from Africa, South America, the Middle East, and Europe should research local market trends to inform their negotiations.

-

Request Detailed Quotes: Always ask suppliers for detailed quotes that break down costs. This transparency helps in identifying areas where you can negotiate or seek alternative solutions.

-

Stay Informed About Market Trends: Keeping abreast of global wheat prices, logistics developments, and industry innovations can provide leverage in negotiations and help anticipate price changes.

Disclaimer on Indicative Prices

Prices for flour mill equipment can fluctuate significantly based on market conditions, supplier negotiations, and specific buyer requirements. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing flour mill supplier With Other Solutions

When considering flour milling solutions, it’s essential to evaluate various options available in the market. Different alternatives can offer distinct advantages depending on the specific needs of your business. This analysis compares the traditional flour mill supplier with other viable solutions, helping international B2B buyers make informed decisions.

| Comparison Aspect | Flour Mill Supplier | Alternative 1: Mobile Flour Mill | Alternative 2: Grain Processing Plant |

|---|---|---|---|

| Performance | High capacity for large-scale operations | Moderate capacity, ideal for local markets | High capacity, efficient for large-scale processing |

| Cost | Initial investment can be significant | Lower initial costs, but may require frequent relocations | Higher setup costs but economical for long-term operations |

| Ease of Implementation | Requires site setup and training | Quick setup; can be operational in days | Complex setup involving infrastructure investment |

| Maintenance | Regular maintenance needed for optimal performance | Minimal maintenance; easy to transport | High maintenance due to scale and complexity |

| Best Use Case | Ideal for large bakeries and commercial operations | Suitable for small-scale operations or remote areas | Best for regional processing and distribution centers |

What Are the Advantages and Disadvantages of a Mobile Flour Mill?

Mobile flour mills are an innovative alternative that brings milling capabilities directly to smaller communities or remote areas. They are designed for quick setup and can be operational within days. This solution is cost-effective in terms of initial investment and allows flexibility in location. However, their performance is limited compared to traditional flour mills, making them less suitable for large-scale operations. Regular relocations may lead to logistical challenges and potential downtime.

How Does a Grain Processing Plant Compare?

Grain processing plants are designed for high-capacity operations, making them suitable for large-scale milling and distribution. They can handle various grains and produce multiple products, maximizing efficiency. However, the initial setup cost is significantly higher than that of a flour mill supplier or mobile solutions. The complexity of installation and maintenance can also be a barrier for smaller businesses. Nevertheless, for companies planning long-term operations with a focus on regional distribution, this option can be highly economical.

Conclusion: How Can B2B Buyers Choose the Right Milling Solution?

When selecting a flour milling solution, B2B buyers should consider their specific operational needs, budget constraints, and the scale of their business. For large bakeries or commercial operations, a traditional flour mill supplier is often the best choice due to its high capacity and performance. On the other hand, businesses seeking flexibility and lower initial investment may find mobile flour mills appealing. Lastly, those with a long-term vision focused on regional processing should consider grain processing plants despite their higher setup costs. Each alternative has its unique benefits and drawbacks, making it crucial to align the choice with business goals and operational capabilities.

Essential Technical Properties and Trade Terminology for flour mill supplier

What Are the Key Technical Properties for Flour Mill Suppliers?

When evaluating flour mill suppliers, understanding critical technical properties is essential for making informed purchasing decisions. Here are some of the key specifications to consider:

1. Material Grade

Material grade refers to the quality of the steel or other materials used in the construction of flour mills. High-grade materials ensure durability and longevity, which are crucial for the continuous operation of flour milling equipment. For buyers, selecting suppliers that utilize high-quality materials reduces the risk of equipment failure and maintenance costs.

2. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in dimensions and weight of the mill components. Precise tolerances are vital to ensure the machinery operates smoothly and efficiently. For B2B buyers, understanding tolerance specifications helps in assessing the potential for operational efficiency and product consistency.

3. Capacity Rating

The capacity rating specifies the maximum amount of flour that a mill can process per hour. This specification is crucial for buyers to match equipment capabilities with production needs. Choosing a mill with a suitable capacity prevents bottlenecks in production, ensuring timely delivery of flour to customers.

4. Energy Efficiency

Energy efficiency ratings indicate how much energy the flour mill consumes during operation. Higher efficiency translates to lower operational costs, which can significantly impact profit margins. B2B buyers should prioritize suppliers that provide energy-efficient equipment, especially in regions where energy costs are high.

5. Safety Standards Compliance

Flour milling equipment must comply with specific safety standards, such as ISO or CE certifications. These standards ensure that the equipment is safe to operate, reducing the risk of accidents and liabilities. Buyers should verify that suppliers adhere to these safety standards to protect their workforce and investment.

6. Maintenance Requirements

Understanding the maintenance requirements of the flour mill is critical for ensuring its longevity and performance. This includes the type of lubrication needed, frequency of inspections, and availability of replacement parts. Suppliers that offer clear maintenance guidelines and support can help buyers minimize downtime and operational disruptions.

Which Trade Terms Should B2B Buyers Understand When Sourcing Flour Mills?

Familiarity with industry-specific terminology is equally important for B2B buyers in navigating supplier relationships. Here are some common trade terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of flour mills, sourcing from an OEM can assure buyers of the quality and compatibility of components. Understanding OEM relationships helps buyers evaluate the credibility and reliability of suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers as it impacts inventory management and cash flow. Suppliers with flexible MOQ policies can provide better options for small to medium-sized enterprises looking to minimize upfront costs.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers for specific products or services. For flour mill buyers, issuing an RFQ allows them to compare pricing, terms, and conditions from multiple suppliers, enabling better negotiation and purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping responsibilities, risk management, and costs associated with the transportation of flour milling equipment.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For flour mill buyers, knowing the lead time is essential for planning production schedules and managing supply chains effectively. Suppliers that provide transparent lead time estimates can enhance buyer trust and operational efficiency.

6. Warranty

A warranty is a guarantee provided by the supplier regarding the performance and longevity of their products. Understanding warranty terms is critical for buyers, as it reflects the supplier’s confidence in their equipment and offers protection against defects or failures.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing flour mills, ultimately leading to successful procurement and operational outcomes.

Navigating Market Dynamics and Sourcing Trends in the flour mill supplier Sector

What Are the Current Market Dynamics and Key Trends in the Flour Mill Supplier Sector?

The global flour mill supplier market is currently witnessing transformative dynamics driven by several factors. A key driver is the increasing demand for processed foods, particularly in developing regions such as Africa and South America, where urbanization and changing diets are leading to higher flour consumption. Moreover, technological advancements in milling processes, including automation and digitalization, are enhancing efficiency and lowering operational costs for suppliers. International B2B buyers are increasingly looking for suppliers that can offer not only traditional milling solutions but also innovative technologies that improve yield and quality.

Emerging trends in sourcing include the rise of e-commerce platforms tailored specifically for industrial buyers. These platforms facilitate easier access to a diverse range of products and services, enabling buyers from the Middle East and Europe to compare prices and features more efficiently. Additionally, the integration of IoT in milling equipment is becoming more prevalent, allowing real-time monitoring of production processes, which is essential for maintaining quality standards and optimizing supply chain efficiency.

Another trend is the growing focus on local sourcing. In regions like Africa and South America, where logistics can pose challenges, sourcing flour from local suppliers can significantly reduce costs and lead times. This trend is supported by the increasing availability of local milling technologies, which are becoming more affordable and accessible for small to medium-sized enterprises.

How Important Is Sustainability and Ethical Sourcing in the Flour Mill Supplier Sector?

Sustainability has emerged as a crucial consideration for international B2B buyers in the flour mill supplier sector. The environmental impact of flour production, including energy consumption and waste generation, is prompting buyers to seek suppliers that prioritize sustainable practices. This includes the use of energy-efficient milling equipment and processes that minimize water usage and waste.

Moreover, ethical sourcing is gaining traction as consumers and businesses alike become more aware of the social implications of their purchases. Buyers are increasingly looking for suppliers who can demonstrate a commitment to fair labor practices and community engagement. Certifications such as Fair Trade and organic labels are becoming essential for suppliers aiming to attract conscientious buyers.

The use of ‘green’ materials in the milling process, such as biodegradable packaging and non-toxic lubricants for machinery, is also on the rise. Suppliers that invest in sustainable practices not only contribute to environmental conservation but also enhance their marketability to buyers who prioritize corporate social responsibility.

What Is the Brief Evolution of the Flour Mill Supplier Sector?

The flour mill supplier sector has evolved significantly over the past century. Initially dominated by small, local millers using traditional techniques, the industry began to modernize in the mid-20th century with the introduction of mechanized milling equipment. This shift allowed for higher production capacities and improved flour quality, leading to the establishment of large-scale flour milling companies.

In recent decades, globalization has further transformed the sector, with suppliers expanding their operations internationally to meet rising demand in emerging markets. The advent of digital technologies has now paved the way for a new era of innovation, making it easier for suppliers to optimize their operations and enhance customer engagement through e-commerce and digital marketing strategies. This evolution reflects a broader trend towards efficiency, sustainability, and responsiveness to the needs of diverse international markets.

Frequently Asked Questions (FAQs) for B2B Buyers of flour mill supplier

-

How do I evaluate the quality of flour mill suppliers?

To assess the quality of flour mill suppliers, begin by reviewing their certifications and industry standards compliance, such as ISO or HACCP. Request samples of their flour and inspect the milling process through factory visits or virtual tours. Engage with current clients for testimonials and insights on their reliability and service. Additionally, consider their track record in meeting delivery schedules and their responsiveness to customer feedback. -

What are the key features to look for in a flour mill supplier?

When selecting a flour mill supplier, focus on their milling technology, capacity, and product range. Ensure they offer customization options to meet your specific needs, such as different flour types or packaging sizes. Evaluate their supply chain capabilities, including logistics and lead times. Also, consider their after-sales support, including technical assistance and maintenance services. -

What is the typical minimum order quantity (MOQ) for flour mill suppliers?

Minimum order quantities (MOQ) can vary significantly among flour mill suppliers, often ranging from 1 ton to several tons per order. Suppliers may set MOQs based on production capacity, shipping logistics, and product types. It is advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are starting with a smaller-scale operation or pilot project. -

How can I ensure timely delivery from my flour mill supplier?

To ensure timely delivery, establish clear communication channels with your flour mill supplier and confirm their logistics capabilities. Discuss lead times during the negotiation phase and set realistic delivery schedules. Consider implementing a tracking system for shipments and maintain regular check-ins to address any potential delays proactively. Building a strong relationship with your supplier can also enhance reliability. -

What payment terms should I expect when dealing with flour mill suppliers?

Payment terms for flour mill suppliers can vary, typically involving options like advance payment, letters of credit, or open accounts. It’s crucial to negotiate terms that align with your cash flow and risk management strategies. Discuss payment schedules tied to delivery milestones or product quality checks to minimize financial exposure. Be aware of any additional costs such as shipping or import duties that may impact overall pricing. -

What quality assurance measures should I inquire about with flour mill suppliers?

Inquire about the quality assurance (QA) protocols implemented by flour mill suppliers, including regular testing of raw materials and finished products. Ask about their adherence to food safety standards and certifications. Understanding their QA processes, such as batch tracking and traceability, can provide assurance of product consistency. Request documentation of their QA procedures to evaluate their commitment to maintaining high standards. -

What are the logistics considerations when sourcing flour mill suppliers internationally?

Logistics play a crucial role in sourcing flour mill suppliers internationally. Consider factors such as shipping methods, freight costs, and customs clearance processes. Evaluate the supplier’s location in relation to your operations to minimize shipping times and costs. Additionally, inquire about their experience in handling international shipments and any partnerships with logistics companies to ensure smooth transportation. -

How can I customize my flour orders with suppliers?

To customize flour orders, communicate your specific requirements clearly to the supplier. This includes specifying flour types, protein content, and packaging preferences. Many suppliers offer tailored solutions for different applications, such as bread, pastry, or specialty flours. Discussing your needs upfront allows suppliers to adjust their milling processes accordingly and provide samples for your approval before full-scale production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for flour mill supplier

In the ever-evolving landscape of flour milling, strategic sourcing remains a cornerstone for international B2B buyers aiming to optimize their procurement processes. By focusing on key factors such as supplier reliability, product quality, and cost-effectiveness, businesses can ensure a steady supply of high-quality flour that meets their specific needs. It is essential for buyers in Africa, South America, the Middle East, and Europe to establish strong relationships with suppliers who understand local market dynamics and can provide tailored solutions.

Moreover, leveraging technology and data analytics in the sourcing process can enhance decision-making, allowing companies to forecast demand accurately and manage inventory effectively. As the global market continues to shift, adaptability and foresight in sourcing strategies will be critical in maintaining a competitive edge.

Looking ahead, international B2B buyers should prioritize building resilient supply chains and fostering partnerships that encourage innovation and sustainability. Embrace these strategic sourcing principles to not only meet current demands but also to position your business for future growth and success in the flour milling industry. Take the next step today—evaluate your sourcing strategies and explore new supplier relationships that can drive your business forward.