Unlock Savings: Your Guide to Metal Parts Supplier (2025)

Introduction: Navigating the Global Market for metal parts supplier

Navigating the complex landscape of sourcing metal parts suppliers can be daunting for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. As businesses strive to enhance their operational efficiency and product quality, the challenge of finding reliable suppliers who can provide high-quality metal parts at competitive prices becomes increasingly critical. This guide offers a comprehensive overview of the global metal parts supplier market, detailing various types of metal components, their applications across different industries, and strategies for effectively vetting suppliers.

In this resource, buyers will gain insights into essential factors such as cost considerations, quality assurance processes, and the latest trends in metal manufacturing. We will also explore regional nuances and cultural factors that can influence purchasing decisions, particularly for buyers in regions like Mexico and Argentina, where local market conditions may differ significantly. By leveraging the actionable information presented in this guide, B2B buyers will be empowered to make informed purchasing decisions, optimize their supply chains, and ultimately drive business growth. Whether you are a startup or an established enterprise, understanding the dynamics of sourcing metal parts can be a game-changer in achieving your business objectives.

Understanding metal parts supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Metal Fabricators | Tailored solutions, specialized machining processes | Aerospace, automotive, construction | Pros: High precision, tailored designs. Cons: Longer lead times, potentially higher costs. |

| Stock Metal Suppliers | Wide variety of pre-manufactured parts | General manufacturing, retail, construction | Pros: Quick delivery, lower costs. Cons: Limited customization options. |

| Specialty Metal Suppliers | Focused on specific materials (e.g., titanium, alloys) | Medical devices, aerospace, defense | Pros: Expertise in niche markets, high quality. Cons: May have higher prices due to material costs. |

| Distributors of Metal Components | Broad inventory, often including multiple brands | OEMs, repair services, industrial sectors | Pros: One-stop shopping, competitive pricing. Cons: Varying quality among brands. |

| Recycling Metal Suppliers | Sourced from scrap, eco-friendly options | Construction, manufacturing, automotive | Pros: Cost-effective, sustainable. Cons: Quality may vary, less control over specifications. |

What are the characteristics of Custom Metal Fabricators?

Custom metal fabricators specialize in producing bespoke metal parts tailored to specific client requirements. They utilize advanced machining techniques and technologies to achieve high precision. This type of supplier is particularly suited for industries such as aerospace and automotive, where exact specifications are critical. When purchasing from custom fabricators, buyers should consider lead times and the potential for higher costs due to the customization involved.

How do Stock Metal Suppliers differ from others?

Stock metal suppliers provide a diverse range of pre-manufactured metal parts readily available for immediate shipment. They cater to a wide array of applications in general manufacturing, retail, and construction. The main advantage for buyers is quick delivery and competitive pricing, though the trade-off is often a lack of customization options. When selecting a stock supplier, it’s important for buyers to assess the breadth of inventory and quality assurance processes.

What makes Specialty Metal Suppliers unique?

Specialty metal suppliers focus on specific materials, such as titanium or various alloys, providing expertise in niche markets like medical devices and aerospace. Their deep knowledge ensures that they can meet stringent quality standards required in these industries. Buyers should weigh the benefits of specialized knowledge against potentially higher costs due to the materials and processes involved. It’s crucial to evaluate certifications and compliance with industry standards when sourcing from these suppliers.

Why choose Distributors of Metal Components?

Distributors of metal components offer a wide inventory that includes various brands and products, making them a convenient option for OEMs and industrial sectors needing quick access to parts. The primary advantage is the ability to source multiple components from a single supplier, which can streamline procurement processes. However, buyers must be cautious about the quality consistency among different brands represented by the distributor, necessitating thorough vetting.

What are the benefits of working with Recycling Metal Suppliers?

Recycling metal suppliers focus on sourcing metal from scrap, promoting sustainability in manufacturing. They can provide cost-effective solutions for businesses in construction and automotive sectors. While these suppliers may offer lower prices, the quality of recycled materials can vary, which may affect product performance. Buyers should ensure that the recycled materials meet their specific requirements and consider certifications that validate the quality of the recycled metal.

Related Video: Metal Plating Process | A Complete Guide To Its Types And Technique.

Key Industrial Applications of metal parts supplier

| Industry/Sector | Specific Application of metal parts supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Manufacturing engine components | Enhanced performance and durability | Quality certifications, material specifications |

| Aerospace | Production of structural components | Weight reduction and increased safety | Compliance with international standards, traceability |

| Construction | Supply of metal frameworks and reinforcements | Improved structural integrity and longevity | Local availability, cost-effectiveness |

| Electronics | Fabrication of housing and chassis parts | Enhanced thermal management and aesthetics | Precision machining capabilities, lead times |

| Oil & Gas | Creation of drilling equipment parts | Increased efficiency and reduced downtime | Material resistance to corrosion, supplier reliability |

How Are Metal Parts Suppliers Used in the Automotive Industry?

In the automotive sector, metal parts suppliers play a crucial role in manufacturing engine components such as pistons, crankshafts, and cylinder heads. These parts must meet high-performance standards for durability and efficiency. International buyers from regions like Africa and South America should prioritize suppliers that offer quality certifications and adhere to stringent material specifications to ensure reliable performance. Additionally, understanding the supplier’s ability to provide just-in-time delivery can significantly enhance supply chain efficiency.

What Role Do Metal Parts Suppliers Play in Aerospace Manufacturing?

Metal parts suppliers are essential in the aerospace industry, where they provide structural components that must be lightweight yet strong. Parts such as fuselage frames and wing structures are often fabricated from specialized alloys to ensure safety and performance. Buyers from Europe and the Middle East should focus on suppliers that comply with international aerospace standards and can provide traceability for materials used, as this is vital for meeting regulatory requirements and ensuring product integrity.

How Are Metal Parts Suppliers Impacting the Construction Sector?

In construction, metal parts suppliers provide critical materials like steel frameworks and reinforcements. These components are vital for ensuring structural integrity and longevity in buildings and infrastructure projects. Buyers should consider local availability and cost-effectiveness when sourcing metal parts, as logistics can significantly impact project timelines. Additionally, suppliers should demonstrate their capacity for large-scale production to meet the demands of extensive construction projects.

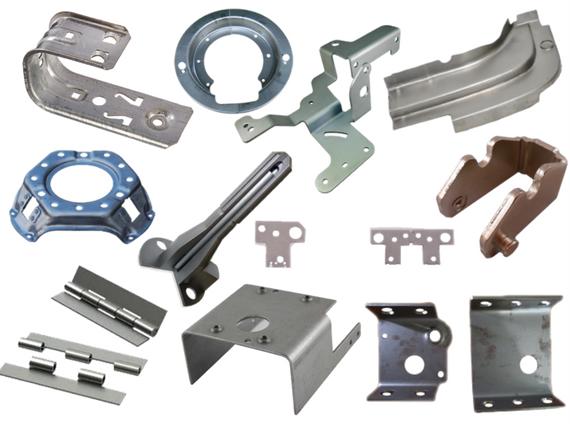

A stock image related to metal parts supplier.

Why Are Metal Parts Suppliers Important in Electronics Manufacturing?

In the electronics industry, metal parts suppliers are integral to fabricating housings and chassis for devices. These components often require precision machining to ensure proper fit and function, as well as enhanced thermal management for performance. Buyers should seek suppliers that offer advanced machining capabilities and can meet tight lead times, particularly for projects requiring rapid prototyping or mass production. Additionally, understanding the supplier’s experience with specific materials can be beneficial in achieving desired aesthetics and performance.

How Do Metal Parts Suppliers Support the Oil & Gas Industry?

In the oil and gas sector, metal parts suppliers provide essential components for drilling equipment, such as drill bits and casing pipes. These parts must withstand extreme conditions, requiring materials that are resistant to corrosion and wear. International buyers need to prioritize suppliers with a proven track record of reliability and performance under challenging conditions. Additionally, evaluating the supplier’s ability to offer customized solutions can be vital for meeting specific operational requirements in various geographical locations.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

3 Common User Pain Points for ‘metal parts supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Metal Parts

The Problem:

B2B buyers often face significant challenges related to the inconsistent quality of metal parts supplied by vendors. This issue can lead to production delays, increased costs, and product failures. For instance, a manufacturer in South America may order steel components for machinery only to discover that the parts do not meet the required specifications, resulting in costly rework or even equipment downtime. Such discrepancies not only strain relationships with end customers but also compromise the supplier’s reputation.

The Solution:

To mitigate quality issues, buyers should establish a rigorous supplier evaluation process before placing orders. This includes requesting certifications such as ISO 9001 or industry-specific standards that demonstrate the supplier’s commitment to quality management. Additionally, conducting initial sample tests or audits can help ensure that the metal parts meet the required specifications before full-scale production. Building a long-term partnership with a reliable supplier that offers transparent quality control processes can also help in maintaining consistent standards. Regular communication regarding specifications and expectations can further solidify the relationship and reduce the likelihood of receiving subpar products.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem:

Long lead times for metal parts can severely disrupt production schedules, especially in fast-paced industries like automotive or aerospace. For example, a company in Africa may face delays when waiting for critical metal components that are essential for assembly lines. These delays can lead to missed deadlines, dissatisfied customers, and lost revenue, creating a ripple effect throughout the supply chain.

The Solution:

To combat long lead times, international buyers should prioritize establishing relationships with local suppliers or those with robust logistics capabilities. Assessing the supply chain logistics of potential suppliers can provide insights into their ability to meet deadlines. Utilizing Just-In-Time (JIT) inventory strategies can also help mitigate the impact of long lead times. By closely collaborating with suppliers to forecast demand and plan orders, buyers can ensure that necessary parts are available when needed. Additionally, exploring dual-sourcing strategies—where a company sources the same parts from multiple suppliers—can create a safety net that helps reduce reliance on a single source and enhances flexibility in meeting production needs.

Scenario 3: Difficulty in Understanding Technical Specifications

The Problem:

B2B buyers often struggle with understanding the technical specifications and requirements for metal parts, which can lead to incorrect orders and project delays. A buyer in Europe, for instance, may not fully grasp the differences between various metal grades, finishes, or treatment processes required for specific applications, resulting in purchasing unsuitable components that fail to meet their project requirements.

The Solution:

To navigate the complexities of metal specifications, buyers should invest time in collaborating with engineering teams and suppliers to gain a deeper understanding of the materials and processes involved. Organizing training sessions or workshops with suppliers can be beneficial in educating the purchasing team about different metal types, their properties, and best-use cases. Moreover, creating detailed specification sheets that outline the exact requirements for each project can help ensure clarity in communication with suppliers. Leveraging resources such as technical datasheets, industry standards, and consulting with experts can provide valuable insights and lead to more informed purchasing decisions, ultimately reducing the risk of errors and enhancing project outcomes.

Strategic Material Selection Guide for metal parts supplier

What Are the Key Properties of Common Metals Used in B2B Applications?

When selecting materials for metal parts, international B2B buyers must consider a variety of factors that impact product performance and application suitability. Below, we analyze four common metals: Steel, Aluminum, Brass, and Titanium, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Steel: A Versatile Choice for Metal Parts

Key Properties: Steel is renowned for its high tensile strength, durability, and ability to withstand high temperatures and pressures. It offers excellent wear resistance and can be treated for enhanced corrosion resistance.

Pros & Cons: Steel is relatively cost-effective and widely available, making it a popular choice for various applications. However, its weight can be a disadvantage in applications where lightweight materials are preferred. Additionally, certain grades of steel may require additional treatments to prevent rust, especially in humid environments.

Impact on Application: Steel is suitable for a wide range of media, including heavy machinery and structural components. Its strength makes it ideal for load-bearing applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN, especially when sourcing steel from different regions. Understanding local regulations regarding material properties and certifications is crucial.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, has excellent corrosion resistance, and offers good thermal and electrical conductivity. It is also non-magnetic, making it suitable for applications where magnetic interference is a concern.

Pros & Cons: The primary advantage of aluminum is its low weight, which reduces transportation costs and energy consumption in applications like aerospace and automotive. However, aluminum is generally more expensive than steel and may not provide the same level of strength, making it less suitable for heavy-duty applications.

Impact on Application: Aluminum is ideal for applications requiring lightweight materials, such as in the automotive and aerospace industries. Its corrosion resistance makes it suitable for marine environments.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum (such as 6061 or 7075) and their respective properties. Compliance with standards like JIS or ASTM is essential, particularly when exporting to regions with stringent regulations.

Brass: The Choice for Corrosion Resistance and Machinability

Key Properties: Brass, an alloy of copper and zinc, is known for its excellent corrosion resistance and machinability. It also has good thermal and electrical conductivity.

Pros & Cons: Brass is easy to machine, making it a favorite for precision components. However, it is more expensive than both steel and aluminum, which can be a limiting factor for large-scale production.

Impact on Application: Brass is commonly used in plumbing fittings, electrical connectors, and decorative applications due to its aesthetic appeal and resistance to tarnishing.

Considerations for International Buyers: Buyers should consider the specific alloy used, as different brass compositions can affect performance. Compliance with local standards and regulations is necessary, especially in plumbing applications where safety is paramount.

Titanium: The Premium Option for High-Performance Applications

Key Properties: Titanium is known for its exceptional strength-to-weight ratio and outstanding corrosion resistance, particularly in harsh environments. It can withstand extreme temperatures and is biocompatible, making it ideal for medical applications.

Pros & Cons: While titanium offers remarkable performance, it is significantly more expensive than other metals, which can be a barrier for some applications. Its machining can also be complex, requiring specialized tools and techniques.

Impact on Application: Titanium is often used in aerospace, medical implants, and high-performance automotive applications where strength and weight are critical.

Considerations for International Buyers: Buyers must ensure compliance with stringent international standards, particularly in aerospace and medical sectors. Understanding the specific grades of titanium and their applications is essential for making informed decisions.

Summary Table of Material Selection for Metal Parts

| Material | Typical Use Case for Metal Parts Supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, heavy machinery | High strength and durability | Heavier than alternatives | Medium |

| Aluminum | Aerospace, automotive parts | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Brass | Plumbing fittings, electrical connectors | Excellent machinability and corrosion resistance | More expensive than steel/aluminum | High |

| Titanium | Aerospace, medical implants | Exceptional strength-to-weight ratio | Very high cost and complex machining | High |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for metal parts, ensuring informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for metal parts supplier

What Are the Key Stages in the Manufacturing Process of Metal Parts?

When sourcing metal parts, understanding the manufacturing process is crucial for B2B buyers. The typical stages involved include material preparation, forming, assembly, and finishing. Each stage is pivotal in ensuring that the final product meets the required specifications and quality standards.

Material Preparation: How Is Raw Material Processed?

The first step in the manufacturing process involves preparing the raw materials. This can include cutting, shearing, or machining metal sheets to the required dimensions. Techniques such as laser cutting and water jet cutting are commonly employed for precision. The choice of material—be it aluminum, steel, or titanium—affects not only the cost but also the properties of the final product. Buyers should verify the supplier’s sourcing of materials to ensure quality and compliance with international standards.

Forming: What Techniques Are Used to Shape Metal Parts?

Once the materials are prepared, they undergo forming processes. Common techniques include stamping, forging, and casting. Stamping is often used for mass production of components, while forging provides superior strength through deformation. Casting, on the other hand, allows for complex shapes but may require additional finishing. Each method has implications for cost and lead time, which are critical considerations for international buyers.

Assembly: How Are Metal Parts Joined Together?

After forming, the next stage is assembly, where various components are joined. Techniques such as welding, riveting, and adhesive bonding are employed. The choice of assembly method can impact the durability and performance of the final product. B2B buyers should inquire about the specific assembly techniques used and their implications for the end product’s strength and reliability.

Finishing: What Processes Enhance the Final Product?

The finishing stage involves processes that enhance the product’s aesthetic and functional characteristics. Techniques such as powder coating, anodizing, and electroplating are used to improve corrosion resistance and surface quality. For international buyers, understanding the finishing options available can help in selecting products that meet specific environmental or regulatory standards.

What Quality Assurance Practices Are Essential for Metal Parts Suppliers?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures the final products meet required specifications. B2B buyers should be familiar with both international standards and specific industry certifications relevant to their needs.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most recognized international standards for quality management systems. Suppliers adhering to ISO 9001 demonstrate a commitment to quality processes and continuous improvement. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for the oil and gas sector, can be significant indicators of a supplier’s capability.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining product quality throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this ensures that any deviations are caught early.

- Final Quality Control (FQC): This final inspection verifies that the finished product meets all specifications before shipment.

International buyers should confirm that their suppliers have robust QC processes in place at each of these checkpoints.

What Testing Methods Are Commonly Used in Metal Parts Manufacturing?

Testing methods employed during the manufacturing process can vary based on the application and material used. Common methods include:

- Mechanical Testing: Assessing properties such as tensile strength, hardness, and ductility.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing, radiographic testing, and magnetic particle inspection allow for evaluation of the material without damaging it.

- Dimensional Inspection: Using tools such as calipers and coordinate measuring machines (CMM) to ensure that parts meet dimensional specifications.

Understanding these testing methods helps buyers evaluate the reliability and safety of the metal parts they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verification of a supplier’s QC processes is essential for mitigating risks associated with sourcing. Here are some effective strategies for B2B buyers:

- Conducting Audits: Regular audits can provide insights into the supplier’s quality management system and adherence to standards. Buyers should request access to audit reports.

- Reviewing Quality Control Reports: Suppliers should provide documentation detailing their QC processes, including results from testing and inspections.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality practices and product compliance.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control:

- Regulatory Compliance: Different regions may have varying compliance requirements. Understanding local regulations and ensuring that the supplier meets these is crucial.

- Cultural Differences in Quality Standards: Quality expectations can differ based on cultural perceptions of manufacturing and quality assurance. Engaging in clear communication about quality expectations can help bridge these gaps.

- Logistical Challenges: Ensure that quality control measures take into account the logistics involved in shipping and handling products internationally, as these can affect quality post-manufacturing.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting metal parts suppliers, ensuring that they receive high-quality products that meet their specifications and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal parts supplier’

A stock image related to metal parts supplier.

In this practical sourcing guide, international B2B buyers will find a step-by-step checklist designed to streamline the process of procuring metal parts from suppliers. This guide aims to help buyers from regions such as Africa, South America, the Middle East, and Europe (including Mexico and Argentina) make informed decisions and secure high-quality materials efficiently.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to have a clear understanding of the technical specifications required for your metal parts. This includes dimensions, tolerances, materials (such as steel, aluminum, or titanium), and surface finishes. Defining these specifications helps ensure that potential suppliers can meet your exact needs, reducing the risk of miscommunication or product returns.

Step 2: Conduct Market Research

Perform thorough research on the metal parts market to identify potential suppliers. Look for companies that specialize in the type of metal parts you need and have a proven track record in your industry. Utilize online platforms, industry trade shows, and local business directories to gather a list of potential suppliers. This foundational step is crucial for ensuring you have a range of options to evaluate.

Step 3: Evaluate Supplier Certifications and Standards

Verify that potential suppliers hold relevant certifications and comply with industry standards. Certifications like ISO 9001 for quality management and ISO 14001 for environmental management indicate a commitment to quality and sustainability. Checking for compliance with local regulations and industry-specific standards (such as ASTM or EN standards) can help mitigate risks associated with material quality and supplier reliability.

Step 4: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the metal parts. This allows you to assess the quality, workmanship, and overall suitability of the products for your application. Evaluate the samples against your defined specifications and consider conducting tests to ensure they meet your performance criteria. This step is vital for preventing costly mistakes later in the procurement process.

Step 5: Review Pricing and Payment Terms

Once you’ve narrowed down your list of suppliers, request detailed quotations that include pricing, lead times, and payment terms. Compare these factors among potential suppliers to identify the best value for your needs. Be aware of additional costs such as shipping, duties, and taxes, especially for international transactions. Understanding payment terms can also help manage cash flow effectively.

Step 6: Assess Supplier Communication and Support

Effective communication is key to a successful supplier relationship. Evaluate how responsive and transparent potential suppliers are during your inquiry process. Consider their willingness to provide technical support, answer questions, and offer solutions to potential issues. A supplier that prioritizes clear communication can significantly enhance your procurement experience and ensure smooth project execution.

Step 7: Establish a Long-Term Relationship

After selecting a supplier, focus on building a long-term relationship. Regular communication and feedback will help ensure ongoing quality and service improvements. Consider setting up periodic reviews to discuss performance, address any issues, and explore opportunities for collaboration. A strong partnership can lead to better pricing, priority service, and innovation tailored to your evolving needs.

By following this checklist, B2B buyers can navigate the complexities of sourcing metal parts more effectively, ensuring they find reliable suppliers that meet their specific requirements.

Comprehensive Cost and Pricing Analysis for metal parts supplier Sourcing

What Are the Key Cost Components in Sourcing Metal Parts?

Understanding the cost structure for sourcing metal parts is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of metal (e.g., steel, aluminum, titanium) significantly impacts pricing. Fluctuations in global commodity prices can cause variability in material costs.

-

Labor: Labor costs vary by region and are influenced by local wage standards and skill levels. In countries with higher labor costs, such as those in Europe, it may be beneficial to consider outsourcing to regions with lower wage expectations.

-

Manufacturing Overhead: This includes fixed and variable costs associated with production facilities. Buyers should inquire about overhead rates to understand how they affect overall pricing.

-

Tooling: Custom tooling can lead to significant upfront costs, especially for unique parts. Understanding tooling costs is essential when evaluating total project costs.

-

Quality Control (QC): Investments in QC ensure that the parts meet specified standards. Suppliers may charge more for stringent QC processes, which can be a worthwhile expense for critical applications.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and Incoterms. Understanding logistics costs is vital for accurate pricing assessments.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on competition, market demand, and the supplier’s business strategy.

How Do Price Influencers Impact Metal Parts Sourcing?

Several factors can influence the pricing of metal parts:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate MOQ to optimize pricing.

-

Specifications and Customization: Custom parts often incur additional costs. Clear specifications can help suppliers provide accurate quotes and avoid unexpected costs.

-

Materials: The choice of materials not only affects cost but also the part’s performance and longevity. Buyers should weigh the cost against the material’s suitability for the application.

-

Quality and Certifications: Parts that require specific certifications (e.g., ISO, ASTM) may come with higher costs. Understanding the necessary certifications can aid in supplier selection.

-

Supplier Factors: The supplier’s reputation, experience, and operational efficiency can impact pricing. Evaluating potential suppliers on these metrics can lead to better purchasing decisions.

-

Incoterms: The terms of shipping can significantly affect overall costs. Understanding Incoterms (e.g., FOB, CIF) helps buyers anticipate shipping costs and responsibilities.

What Are Effective Buyer Tips for Cost-Efficiency in Metal Parts Sourcing?

International B2B buyers can adopt several strategies to optimize costs:

-

Negotiation: Establishing strong relationships with suppliers can lead to better pricing and terms. Negotiating not only on price but also on payment terms can enhance cash flow.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. TCO includes maintenance, durability, and potential downtime costs, which can influence the overall economic impact of the purchase.

-

Pricing Nuances for International Buyers: Currency fluctuations can affect costs. Consider locking in prices or negotiating contracts in stable currencies to mitigate risks.

-

Market Research: Conduct thorough research on suppliers in different regions. Understanding regional market dynamics can provide leverage in negotiations and uncover potential cost-saving opportunities.

Disclaimer on Indicative Prices

Prices for metal parts can vary significantly based on the aforementioned factors. Buyers should always request detailed quotes and consider all cost components to ensure accurate budgeting and financial planning.

Alternatives Analysis: Comparing metal parts supplier With Other Solutions

When considering sourcing options for metal parts, international B2B buyers must evaluate various alternatives that can meet their operational needs and specifications. Understanding the strengths and weaknesses of each solution can help businesses make informed decisions that align with their manufacturing goals and budget constraints. Below, we compare ‘Metal Parts Supplier’ with two viable alternatives: 3D Printing and CNC Machining.

| Comparison Aspect | Metal Parts Supplier | 3D Printing | CNC Machining |

|---|---|---|---|

| Performance | High precision; suitable for bulk orders | Good for prototypes; less precision for functional parts | Very high precision; excellent for complex geometries |

| Cost | Competitive pricing for large volumes | Lower initial cost for small runs, but expensive for mass production | Higher setup costs; cost-effective for large quantities |

| Ease of Implementation | Straightforward procurement process | Requires expertise in design and printing | Requires skilled labor and setup time |

| Maintenance | Minimal; depends on supplier reliability | Minimal; depends on printer maintenance | Regular maintenance needed for machinery |

| Best Use Case | Mass production of standardized parts | Prototyping and custom designs | High-volume production with complex designs |

What Are the Advantages and Disadvantages of 3D Printing as an Alternative?

3D printing has revolutionized the way businesses approach manufacturing. It allows for rapid prototyping and customization without the need for extensive tooling. The primary advantages include lower initial costs for small runs and the ability to create complex geometries that would be difficult with traditional methods. However, it may not be suitable for high-volume production due to longer print times and potential inconsistencies in material properties. Businesses may find it most beneficial for developing prototypes or small batches of specialized components.

How Does CNC Machining Compare to Metal Parts Suppliers?

CNC machining is a highly precise method of manufacturing that can produce complex shapes with tight tolerances. It is ideal for high-volume production runs where uniformity and accuracy are critical. While the initial setup costs can be high, the long-term savings on labor and material waste can make it an attractive option. However, CNC machining requires skilled operators and regular maintenance of equipment, which may not be feasible for smaller businesses. This method is best suited for companies needing consistent, high-quality parts at scale.

How Can International B2B Buyers Choose the Right Solution for Their Needs?

When selecting a solution for metal parts sourcing, international B2B buyers should consider several factors: the scale of production, the complexity of the parts required, and budget constraints. For high-volume and precise manufacturing, a traditional metal parts supplier or CNC machining may be more appropriate. Conversely, for smaller runs or innovative designs, 3D printing could provide the necessary flexibility. Additionally, assessing the supplier’s reliability and the technology’s adaptability to changing needs will help ensure that the chosen method aligns with the company’s strategic objectives. By analyzing these alternatives, businesses can optimize their supply chain and enhance their production capabilities.

Essential Technical Properties and Trade Terminology for metal parts supplier

What Are the Essential Technical Properties for Metal Parts?

Understanding the technical specifications of metal parts is crucial for international B2B buyers, especially when sourcing from regions like Africa, South America, the Middle East, and Europe. Here are some key properties that buyers should prioritize:

1. Material Grade: Why Does It Matter?

Material grade refers to the classification of a metal based on its mechanical and chemical properties. Common grades include stainless steel (e.g., 304, 316) and aluminum (e.g., 6061, 7075). The grade affects corrosion resistance, strength, and durability, which are vital for applications ranging from automotive to aerospace. Buyers must ensure that the metal parts meet industry-specific standards to guarantee performance and longevity.

2. Tolerance: How Precise Should Your Parts Be?

Tolerance indicates the permissible limit of variation in a physical dimension. For example, a tolerance of ±0.01 mm means that the actual measurement can deviate by that amount. Precise tolerances are essential for parts that must fit together accurately, such as in machinery or assembly lines. Inaccurate tolerances can lead to increased production costs and project delays, making it crucial for buyers to communicate their tolerance requirements clearly.

3. Surface Finish: What Is Its Impact on Performance?

The surface finish of a metal part refers to its texture and smoothness, which can significantly influence its performance and aesthetics. Common finishes include anodized, polished, or sandblasted. A proper surface finish can enhance corrosion resistance and reduce friction in moving parts. Buyers should specify the desired finish based on the part’s application to ensure optimal functionality.

4. Yield Strength: How Much Can Your Parts Withstand?

Yield strength is the maximum stress that a material can withstand while still returning to its original shape. It is crucial for determining how a metal part will perform under load. Understanding yield strength helps buyers select materials that can endure specific conditions without deforming, which is essential for safety-critical applications.

5. Hardness: Why Is It Important for Durability?

Hardness measures a material’s resistance to deformation or scratching. It is vital in applications where wear and tear are expected. For instance, harder materials are often used in tooling and manufacturing processes. Buyers should consider hardness values when selecting parts that will face significant mechanical stress or abrasion.

What Are the Common Trade Terms in Metal Parts Supply?

Familiarity with trade terminology can streamline the procurement process and minimize misunderstandings. Here are some essential terms:

1. OEM (Original Equipment Manufacturer): What Role Do They Play?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure that they are sourcing genuine parts that meet quality standards.

2. MOQ (Minimum Order Quantity): How Does It Affect Your Purchase?

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is crucial for buyers to know the MOQ to manage inventory costs effectively. Understanding this term can help in negotiating better purchasing agreements and aligning supply with demand.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It usually includes details like specifications, quantities, and delivery timelines. Crafting a well-structured RFQ can lead to more accurate quotes and better supplier relationships.

4. Incoterms (International Commercial Terms): Why Are They Important?

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps buyers clarify who is responsible for shipping costs, insurance, and risk during transport. This knowledge is essential for effective contract negotiation and supply chain management.

5. Lead Time: What Should You Expect?

Lead time refers to the time taken from placing an order to receiving it. Knowing the lead time helps buyers plan their inventory and production schedules. It is critical to communicate lead time expectations upfront to ensure timely delivery and prevent operational disruptions.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing metal parts, ultimately enhancing their procurement strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the metal parts supplier Sector

What Are the Current Market Dynamics and Sourcing Trends for Metal Parts Suppliers?

The metal parts supplier sector is witnessing significant transformations driven by various global factors. Key trends include the increased adoption of advanced manufacturing technologies, such as additive manufacturing (3D printing) and automation. These technologies not only enhance production efficiency but also allow for greater customization, catering to the specific needs of diverse industries, including automotive, aerospace, and construction. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the rising trend towards digital procurement platforms that streamline sourcing processes, reduce lead times, and enhance transparency in supply chains.

Moreover, geopolitical factors, such as trade agreements and tariffs, are influencing sourcing strategies. For example, buyers from Latin America may find opportunities in sourcing from nearby suppliers to mitigate risks associated with long-distance logistics and fluctuating tariffs. The demand for high-quality, durable metal parts is also pushing suppliers to innovate and invest in materials technology, which is crucial for sectors that prioritize performance and safety. As a result, buyers are encouraged to evaluate potential suppliers not only based on price but also on their technological capabilities and ability to meet stringent quality standards.

How Is Sustainability Shaping Sourcing Decisions in the Metal Parts Industry?

The importance of sustainability and ethical sourcing is becoming increasingly paramount in the metal parts supplier sector. International B2B buyers are now more conscious of the environmental impact of their supply chains. This shift is driven by both regulatory pressures and consumer preferences, particularly in Europe and North America, where businesses are expected to adopt greener practices.

To address these concerns, suppliers are increasingly adopting sustainable manufacturing processes and offering eco-friendly materials. Certifications such as ISO 14001 for environmental management and adherence to the ResponsibleSteel standard are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. Buyers should prioritize suppliers who provide transparency regarding their sourcing practices and environmental impact, including the use of recycled metals and energy-efficient manufacturing processes.

Furthermore, the transition towards circular economy principles is encouraging companies to develop products that are not only durable but also recyclable at the end of their lifecycle. This trend presents an opportunity for B2B buyers to engage with suppliers who align with their sustainability goals, enhancing their brand reputation while contributing to global environmental initiatives.

What Is the Historical Context of the Metal Parts Supplier Sector?

The evolution of the metal parts supplier sector can be traced back to the industrial revolution, which marked the beginning of mass production techniques. Over the decades, advancements in metallurgy and manufacturing processes have significantly influenced the sector’s growth. The introduction of computer-aided design (CAD) and computer numerical control (CNC) technologies in the late 20th century revolutionized production capabilities, allowing for higher precision and efficiency.

In recent years, the sector has experienced a shift towards digitalization and automation, driven by Industry 4.0 principles. This evolution is crucial for B2B buyers to understand, as it highlights the increasing importance of technological capabilities in evaluating potential suppliers. As the industry continues to adapt to modern challenges, including sustainability and global competition, understanding its historical context provides valuable insights for making informed sourcing decisions in today’s dynamic market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of metal parts supplier

-

How do I evaluate a metal parts supplier for my business needs?

When evaluating a metal parts supplier, consider factors such as their industry experience, product quality certifications (like ISO), and customer reviews. Request samples to assess material quality and tolerances. It’s also beneficial to inquire about their manufacturing processes, lead times, and capacity to meet your specific requirements. Building a relationship with suppliers through visits or communication can provide insights into their operational standards and reliability. -

What are the most critical quality assurance practices for metal parts?

Quality assurance in metal parts manufacturing includes rigorous testing methods like dimensional checks, material composition analysis, and performance testing under specified conditions. Suppliers should adhere to industry standards and have documented processes for quality control. Regular audits and certifications from recognized bodies can further ensure that the parts meet safety and performance requirements, which is crucial for maintaining your product integrity. -

What customization options should I look for in a metal parts supplier?

A good metal parts supplier should offer a range of customization options, including material selection, dimensions, surface finishes, and coatings. Ask about their ability to handle prototyping, as this can significantly reduce lead times and costs for custom parts. Additionally, inquire about their design capabilities, as some suppliers may provide engineering support to help refine your specifications. -

What are typical minimum order quantities (MOQ) for metal parts?

Minimum order quantities (MOQ) can vary significantly between suppliers and depend on factors such as the complexity of the part and production processes. Generally, MOQs for metal parts can range from a few units for simple components to thousands for more complex or specialized items. Always discuss MOQs upfront to ensure they align with your production needs and budget constraints. -

What payment terms should I expect from international metal parts suppliers?

Payment terms can vary widely, but common practices include a deposit upfront (typically 30-50%) and the remainder upon delivery or prior to shipping. Some suppliers may offer credit terms based on your relationship and order history. Be sure to clarify payment methods accepted, as international transactions can involve additional fees and currency exchange considerations. -

How can I ensure timely logistics and delivery for my metal parts?

To ensure timely logistics and delivery, establish clear communication with your supplier regarding shipping timelines and expected lead times. Discuss their logistics partners and their track record for on-time deliveries. It’s also advisable to use tracking systems to monitor shipments and consider placing orders well in advance to account for potential delays, especially when sourcing internationally. -

What are the best practices for international trade compliance when sourcing metal parts?

Compliance with international trade regulations is crucial when sourcing metal parts. Familiarize yourself with import/export laws in your country and the supplier’s location. Ensure that your supplier provides necessary documentation, such as certificates of origin and compliance with safety standards. Additionally, consider engaging customs brokers to facilitate smoother transactions and avoid potential legal issues. -

How do I handle disputes with my metal parts supplier?

Handling disputes requires clear communication and documentation. Start by addressing the issue directly with your supplier to seek an amicable resolution. If necessary, refer to any contracts or agreements that outline dispute resolution processes. Consider mediation or arbitration if direct negotiations fail, and always keep a record of communications and agreements to support your position.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal parts supplier

The landscape of metal parts sourcing is evolving rapidly, influenced by global trends and regional demands. For international B2B buyers from Africa, South America, the Middle East, and Europe, strategic sourcing is essential for maximizing efficiency and reducing costs. By developing strong partnerships with reliable metal parts suppliers, businesses can ensure high-quality materials while navigating the complexities of international trade.

Emphasizing the importance of local market insights, B2B buyers should leverage regional strengths and supplier capabilities to enhance their supply chain resilience. This approach not only mitigates risks associated with geopolitical tensions and fluctuating market conditions but also fosters innovation through collaboration.

As we look to the future, the integration of advanced technologies in the metal parts industry presents new opportunities for buyers. Embracing automation, machine learning, and sustainable practices will be crucial in staying competitive. Therefore, now is the time for B2B buyers to engage actively with suppliers, explore innovative solutions, and align their sourcing strategies with long-term business goals.

In conclusion, the path to successful strategic sourcing in the metal parts sector is paved with collaboration, technology, and a keen understanding of market dynamics. Engage with your suppliers today to build a robust foundation for tomorrow’s success.