Unlock Value with the 1972 C10 Custom: A Complete Guide (2025)

Introduction: Navigating the Global Market for 1972 c10 custom

Navigating the global market for a 1972 C10 custom presents a unique set of challenges for international B2B buyers, especially when considering the need for authentic parts, reliable suppliers, and competitive pricing. As businesses in regions such as Africa, South America, the Middle East, and Europe seek to source these iconic vehicles, understanding the nuances of the market becomes crucial. This guide aims to demystify the procurement process for the 1972 C10 custom, covering key aspects such as the various types of modifications available, potential applications for these vehicles, and effective strategies for vetting suppliers.

By delving into the complexities of sourcing, this comprehensive resource equips buyers with actionable insights to make informed purchasing decisions. From assessing the quality of customizations to evaluating the total cost of ownership, the guide will illuminate the critical factors that influence the successful acquisition of a 1972 C10 custom. International buyers will find valuable information tailored to their unique market conditions, ensuring they can navigate the complexities of cross-border transactions with confidence. Whether you’re in Australia, Argentina, or elsewhere, this guide is your roadmap to making strategic choices that align with your business objectives in the classic vehicle marketplace.

Understanding 1972 c10 custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 1972 C10 Custom Deluxe | Enhanced trim and features, often includes upgraded upholstery and chrome accents. | Restoration projects, classic vehicle dealerships. | Pros: Aesthetic appeal, higher resale value. Cons: Higher initial investment. |

| 1972 C10 Stepside | Features a distinctive stepside bed, providing a unique look and functionality. | Small business logistics, personal use for craftspeople. | Pros: Versatile cargo space, unique design. Cons: Limited bed space compared to fleetside. |

| 1972 C10 Fleetside | Offers a smooth-sided bed design, maximizing cargo capacity. | Transportation companies, tradesmen. | Pros: Greater cargo capacity, easier loading. Cons: More common design may reduce uniqueness. |

| 1972 C10 Short Bed | Compact size with a shorter bed, ideal for urban settings. | Urban delivery services, contractors. | Pros: Maneuverability in tight spaces, stylish look. Cons: Less storage capacity for larger loads. |

| 1972 C10 Long Bed | Extended bed length for maximum cargo capacity. | Construction, landscaping businesses. | Pros: Increased cargo capacity, ideal for heavy loads. Cons: Reduced maneuverability in urban areas. |

What are the Key Characteristics of the 1972 C10 Custom Deluxe?

The 1972 C10 Custom Deluxe is notable for its upgraded trim, which often includes enhanced upholstery and chrome accents. This type is well-suited for restoration projects, especially for businesses focused on classic vehicles. B2B buyers should consider the aesthetic appeal and potential for higher resale value, although the initial investment may be higher than standard models.

How Does the 1972 C10 Stepside Stand Out?

The 1972 C10 Stepside is characterized by its unique bed design, which features a step along the sides. This design is particularly appealing for small businesses and craftspeople who require versatility in cargo space. While it offers a distinctive look, buyers should weigh the benefits of its unique design against the limited bed space compared to the Fleetside option.

What Makes the 1972 C10 Fleetside a Popular Choice?

The Fleetside model features a smooth-sided bed that maximizes cargo capacity, making it ideal for transportation companies and tradesmen. Its larger cargo area allows for easier loading and transportation of goods. However, B2B buyers may find that its more common design could reduce its uniqueness in a competitive marketplace.

What Advantages Does the 1972 C10 Short Bed Offer?

The 1972 C10 Short Bed is designed for urban settings, providing excellent maneuverability in tight spaces. This model is particularly suitable for urban delivery services and contractors who prioritize a stylish look. While it excels in maneuverability, buyers should consider its reduced storage capacity for larger loads.

Why Choose the 1972 C10 Long Bed?

The Long Bed variant is tailored for maximum cargo capacity, making it an excellent choice for construction and landscaping businesses. Its extended length allows for the transportation of heavy loads, which is a significant advantage for B2B applications. However, potential buyers should be aware that the increased length may compromise maneuverability in urban environments.

Related Video: 1972 Chevrolet C10 Custom | [4K] | REVIEW SERIES | “The Custom Custom”

Key Industrial Applications of 1972 c10 custom

| Industry/Sector | Specific Application of 1972 c10 custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Restoration | Classic car restoration and customization | High resale value and niche market appeal | Authentic parts sourcing, skilled labor availability |

| Logistics and Transportation | Versatile delivery vehicle for local businesses | Cost-effective and reliable transport solution | Vehicle condition, maintenance history, and customization options |

| Agriculture | Farming vehicle for small to medium-sized farms | Enhanced mobility and utility in rural areas | Engine performance, load capacity, and fuel efficiency |

| Event Management | Mobile display or promotional vehicle | Unique branding opportunity and customer engagement | Customization for branding, interior layout flexibility |

| Construction | On-site tool and material transport vehicle | Improved efficiency in project execution | Load capacity, vehicle durability, and maintenance support |

How is the 1972 C10 Custom Used in Automotive Restoration?

The 1972 C10 Custom is a sought-after model in the classic car restoration industry. Buyers, especially from regions like Europe and South America, often look for authentic parts to maintain the vehicle’s originality. The restoration process not only enhances the aesthetic appeal but also significantly increases the vehicle’s resale value. For B2B buyers, sourcing original or high-quality aftermarket parts is crucial, along with ensuring skilled labor is available for restoration.

What Role Does the 1972 C10 Custom Play in Logistics and Transportation?

In logistics, the 1972 C10 Custom serves as a versatile delivery vehicle for local businesses, especially in urban areas. Its compact size and reliable engine make it ideal for navigating tight spaces while providing a cost-effective transport solution. International buyers, particularly in Africa and the Middle East, should consider the vehicle’s condition and maintenance history when sourcing, as well as potential customization options to meet specific logistical needs.

How Can the 1972 C10 Custom Benefit Agricultural Operations?

For small to medium-sized farms, the 1972 C10 Custom can be an invaluable asset, providing enhanced mobility and utility. Its robust build allows it to transport tools, materials, and even small livestock across rural terrains. Buyers in agricultural sectors should focus on engine performance, load capacity, and fuel efficiency when sourcing this vehicle, ensuring it meets the demands of their farming operations.

In What Ways is the 1972 C10 Custom Utilized in Event Management?

Event management companies often utilize the 1972 C10 Custom as a mobile display or promotional vehicle. Its classic design offers a unique branding opportunity that can attract attention at events and fairs. B2B buyers in this sector should prioritize customization options that allow for branding and flexible interior layouts, enhancing customer engagement during events.

How is the 1972 C10 Custom Applied in the Construction Industry?

In construction, the 1972 C10 Custom is frequently used as an on-site vehicle for transporting tools and materials. Its durability and load capacity make it a practical choice for improving efficiency in project execution. Buyers in this industry should consider the vehicle’s overall durability and maintenance support when sourcing, ensuring it can withstand the rigors of construction environments.

Related Video: Chevrolet C10 Pickup | Buyer’s Guide

3 Common User Pain Points for ‘1972 c10 custom’ & Their Solutions

Scenario 1: Difficulty Sourcing Authentic Parts for 1972 C10 Custom Restoration

The Problem: One of the significant challenges faced by B2B buyers in the automotive aftermarket, particularly those focused on restoring classic vehicles like the 1972 C10 Custom, is sourcing authentic and high-quality replacement parts. Many buyers, especially those in regions like Africa and South America, encounter issues with counterfeit products or parts that do not meet the original specifications. This can lead to increased costs, delays in project completion, and ultimately dissatisfaction with the restoration process.

The Solution: To mitigate this issue, B2B buyers should establish relationships with reputable suppliers who specialize in classic car parts. Conduct thorough research to identify manufacturers or distributors with a proven track record in the classic vehicle market. Engage in industry forums, attend automotive trade shows, and leverage social media platforms to connect with trusted suppliers. It’s also beneficial to request samples or detailed specifications before placing bulk orders. Buyers should prioritize vendors who offer warranties and return policies, ensuring they receive authentic parts that align with their restoration goals.

Scenario 2: Managing Customization Challenges in 1972 C10 Builds

The Problem: Customizing a 1972 C10 can be a complex process, especially when dealing with unique specifications from clients or market trends that require specific modifications. B2B buyers often struggle with balancing customization requests with the technical limitations of parts and accessories available in the market. This challenge can lead to project overruns, unsatisfied clients, and potential loss of business.

The Solution: To effectively manage customization challenges, B2B buyers should invest in comprehensive project planning and communication with clients. Before starting a project, conduct a detailed consultation to understand the client’s vision and expectations. Create a flexible design plan that allows for adjustments as parts are sourced. Additionally, utilize CAD (Computer-Aided Design) software to visualize modifications and ensure all parties are aligned on the final look and functionality. Establishing partnerships with customization experts or local fabrication shops can also provide valuable insights into feasible modifications, ensuring projects are delivered on time and within budget.

Scenario 3: Navigating Regulatory Compliance for Classic Vehicle Modifications

The Problem: B2B buyers often face significant regulatory hurdles when modifying classic vehicles like the 1972 C10, especially when it comes to emissions and safety standards that vary by region. Buyers from Europe and the Middle East may encounter stringent regulations that can complicate their projects and result in penalties if not adhered to. This scenario can lead to costly delays and frustration during the restoration or customization process.

The Solution: To navigate regulatory compliance successfully, B2B buyers should stay informed about the specific regulations applicable to their region. This involves researching local automotive regulations, consulting with legal experts in automotive compliance, and engaging with local automotive associations that can provide guidance. Buyers should also work closely with their suppliers to ensure that all parts sourced comply with the necessary standards. Documenting all modifications and ensuring that any necessary inspections are conducted before the vehicle is put back on the road can help mitigate risks and streamline the approval process, ensuring a smoother project completion and customer satisfaction.

Strategic Material Selection Guide for 1972 c10 custom

What Are the Key Materials for 1972 C10 Custom Builds?

When selecting materials for the 1972 C10 custom builds, international B2B buyers must consider various factors including performance, cost, and compliance with regional standards. Below, we analyze four common materials used in the construction of these vehicles, providing insights that can guide purchasing decisions.

Steel: The Backbone of Durability

Key Properties: Steel is known for its high tensile strength and durability, making it ideal for structural components. It can withstand high temperatures and pressures, which is crucial for engine parts and chassis.

Pros & Cons: The primary advantage of steel is its robustness and cost-effectiveness. However, it is susceptible to corrosion unless properly treated or coated. This can lead to increased maintenance costs over time.

Impact on Application: Steel is compatible with various media, including oils and fuels, making it suitable for engine components. However, its weight can affect overall vehicle performance and fuel efficiency.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel complies with local standards such as ASTM or ISO. Corrosion resistance treatments may be necessary in humid climates.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and offers excellent corrosion resistance, making it a popular choice for body panels and components that require reduced weight.

Pros & Cons: The main advantage of aluminum is its low weight, which can improve fuel efficiency and handling. However, it is generally more expensive than steel and may require specialized welding techniques.

Impact on Application: Aluminum is compatible with various automotive fluids, including antifreeze and oils, but it may not be suitable for high-stress applications without proper engineering.

Considerations for International Buyers: In Europe and the Middle East, aluminum components must meet specific standards (e.g., DIN or JIS). Buyers should also consider the availability of specialized welding services.

Composite Materials: Innovation in Performance

Key Properties: Composites, such as fiberglass and carbon fiber, provide high strength-to-weight ratios and excellent resistance to corrosion and environmental degradation.

Pros & Cons: Composites can significantly enhance vehicle performance and aesthetics. However, they tend to be more expensive and may require specialized manufacturing processes.

Impact on Application: Composites are ideal for body kits and interior components but may not be suitable for load-bearing applications without reinforcement.

Considerations for International Buyers: Buyers in South America and Africa should be aware of the limited availability of composite materials and the potential need for specialized labor to work with these materials.

Rubber: Essential for Sealing and Vibration Damping

Key Properties: Rubber is flexible and provides excellent sealing properties, making it essential for gaskets and seals in various automotive applications.

Pros & Cons: The primary advantage of rubber is its ability to absorb vibrations and provide a tight seal. However, it can degrade over time due to exposure to UV light and extreme temperatures.

Impact on Application: Rubber components are crucial for preventing leaks in fuel and oil systems. Their performance can significantly affect engine efficiency and longevity.

Considerations for International Buyers: Compliance with local standards for rubber materials is essential, especially in regions with extreme weather conditions. Buyers should also consider sourcing from reputable manufacturers to ensure quality.

Summary Table of Material Selection

| Material | Typical Use Case for 1972 C10 Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, engine components | High strength and durability | Susceptible to corrosion | Low |

| Aluminum | Body panels, lightweight components | Lightweight, corrosion-resistant | Higher cost, requires special welding | Medium |

| Composite | Body kits, interior components | High strength-to-weight ratio | Expensive, specialized manufacturing | High |

| Rubber | Gaskets, seals | Excellent sealing and vibration damping | Degrades over time | Low |

This comprehensive analysis of materials used in the 1972 C10 custom builds provides actionable insights for international B2B buyers, ensuring they make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 1972 c10 custom

What Are the Main Stages in Manufacturing a 1972 C10 Custom?

Manufacturing a 1972 C10 custom involves several key stages that ensure the vehicle meets quality standards while also allowing for customization. The primary stages include:

-

Material Preparation: The process begins with sourcing high-quality materials, including steel, aluminum, and plastic components. Suppliers should provide material certifications to ensure compliance with international standards. For B2B buyers, verifying the origin and quality of these materials is crucial, as they directly impact the vehicle’s durability and performance.

-

Forming: This stage involves shaping the raw materials into specific parts of the truck, such as the body, chassis, and interior components. Techniques like stamping, bending, and welding are employed to create the desired shapes. Advanced CNC machining may also be used for precision components. International buyers should inquire about the machinery and technology used in this process to ensure it aligns with modern manufacturing practices.

-

Assembly: The assembly phase integrates various components, including the engine, transmission, and electrical systems. This stage often involves both manual and automated processes. For customization, options may include performance upgrades, aesthetic modifications, and unique interior features. B2B buyers should consider the supplier’s flexibility in accommodating custom requests during this phase.

-

Finishing: The final touches, such as painting and detailing, occur in this stage. High-quality finishes not only enhance the vehicle’s appearance but also protect against corrosion. Buyers should assess the paint processes and materials used, as these can vary significantly between manufacturers.

How Is Quality Assurance Implemented in 1972 C10 Custom Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing to ensure that every vehicle meets both safety and performance standards. Here are the components of a robust QA process:

-

Adherence to International Standards: Manufacturers should comply with standards like ISO 9001, which outlines requirements for a quality management system. This certification demonstrates a commitment to consistent quality and continuous improvement. B2B buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with ISO certifications to mitigate risks associated with quality issues.

-

Industry-Specific Certifications: Depending on the market, additional certifications may be necessary. For example, CE marking is essential for products sold in the European Economic Area, while API certifications might be relevant for components like engines. Understanding these requirements is vital for international buyers to ensure regulatory compliance.

-

Quality Control Checkpoints: A well-structured QA process includes several checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to identify and rectify issues early.

– Final Quality Control (FQC): Comprehensive testing of the finished vehicle, including performance, safety, and aesthetic evaluations.

What Common Testing Methods Are Used in the Manufacturing of 1972 C10 Customs?

Testing methods are essential for verifying the quality and safety of the final product. Common methods include:

- Visual Inspection: Simple yet effective, visual checks help identify defects in finish and assembly.

- Functional Testing: This involves assessing the vehicle’s performance, including engine operation, braking, and electrical systems.

- Durability Testing: Vehicles may undergo stress testing to evaluate their ability to withstand various conditions over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensure they receive a reliable product. Here are some effective strategies:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s QA processes. This includes checking compliance with international standards and internal quality protocols.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control measures, including inspection reports and certification documents. This transparency is a positive indicator of their commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality systems. These organizations can conduct random checks and provide detailed reports, offering additional assurance to buyers.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is essential for B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe. Key considerations include:

-

Cultural Differences: Different regions may have varying expectations regarding quality and standards. Buyers should familiarize themselves with local regulations and market expectations to ensure compliance.

-

Language Barriers: Documentation and communication may present challenges. Buyers should ensure that all quality documentation is available in a language they understand to avoid misinterpretations.

-

Post-Purchase Support: Establishing clear agreements regarding warranty and after-sales support is crucial. Buyers should verify that suppliers have robust systems in place for addressing any quality issues that may arise post-purchase.

By focusing on these aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when sourcing 1972 C10 customs, ensuring they receive high-quality vehicles that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1972 c10 custom’

The following is a practical sourcing guide designed to assist international B2B buyers in procuring a ‘1972 C10 Custom’. This guide provides a structured checklist to ensure a successful sourcing process.

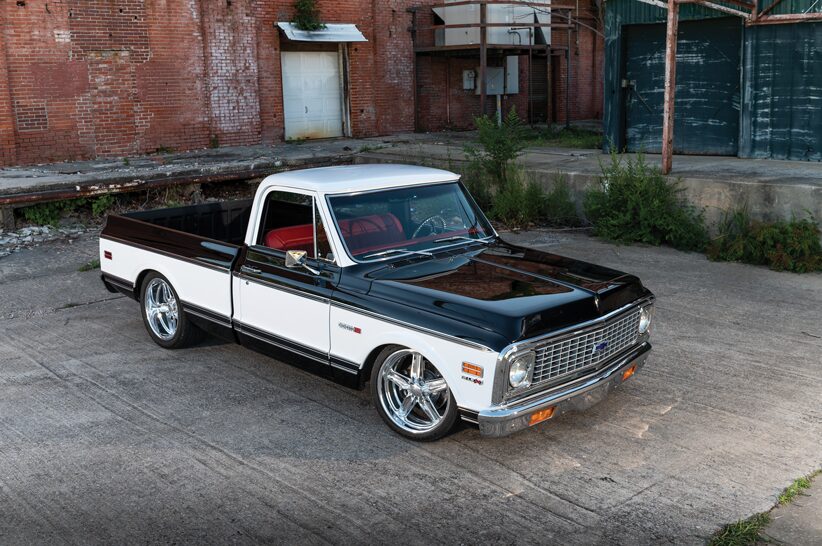

A stock image related to 1972 c10 custom.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the specific technical specifications you require for the ‘1972 C10 Custom’. This includes details such as engine type, body modifications, and any custom features that are essential for your market. A well-defined specification will not only guide your search but will also facilitate better communication with potential suppliers.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for ‘1972 C10 Custom vehicles is crucial. Analyze data from various regions, particularly in Africa, South America, the Middle East, and Europe. This will help you set a realistic budget and identify competitive pricing, ensuring you do not overpay for your custom vehicle.

- Tip: Utilize online platforms and automotive trade shows to gather insights on pricing models and consumer preferences.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request comprehensive company profiles, including their production capabilities, quality assurance processes, and customer testimonials. It’s beneficial to connect with other buyers who have sourced similar vehicles from the suppliers you are considering.

- Tip: Look for suppliers with a proven track record in exporting to your region, as they will be familiar with the logistics and compliance requirements.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers possess the necessary certifications and comply with international trade regulations. This may include ISO certifications, quality management systems, and environmental standards. Compliance not only guarantees product quality but also mitigates risks associated with international transactions.

- Tip: Check if suppliers are members of relevant trade associations, which can be a good indicator of credibility.

Step 5: Request Samples or Prototypes

Before making a bulk purchase, request samples or prototypes of the ‘1972 C10 Custom. This allows you to assess the quality, craftsmanship, and adherence to your specifications. A hands-on evaluation can reveal details that may not be apparent in product descriptions or photos.

- Tip: Be specific about what you want to test in the samples, such as material quality, finish, and functionality.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to establish favorable terms and conditions. Discuss payment terms, delivery schedules, warranty conditions, and after-sales support. Clear agreements will help prevent misunderstandings later in the process.

- Tip: Don’t hesitate to ask for flexibility in payment terms, especially if you are ordering in larger quantities.

Step 7: Plan for Logistics and Shipping

Finally, develop a comprehensive logistics plan for the delivery of your ‘1972 C10 Custom. Consider factors such as shipping methods, customs clearance, and local regulations in your destination country. Effective planning can significantly reduce lead times and ensure that your vehicles arrive in optimal condition.

- Tip: Collaborate with logistics experts who have experience in automotive shipments to navigate the complexities of international transport.

By following this structured checklist, B2B buyers can streamline their sourcing process for ‘1972 C10 Custom vehicles, ensuring a successful procurement experience tailored to their specific needs and market conditions.

Comprehensive Cost and Pricing Analysis for 1972 c10 custom Sourcing

What Are the Key Cost Components in Sourcing a 1972 C10 Custom?

When considering the sourcing of a 1972 C10 custom, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact the overall cost. This includes the steel for the chassis, body panels, and various components such as suspension and braking systems. High-quality, certified materials can lead to a higher upfront cost but may reduce long-term maintenance expenses.

-

Labor: Labor costs can vary based on the region of sourcing. In countries with lower labor costs, such as certain regions in South America or Africa, buyers may find more competitive pricing. However, skilled labor is essential for custom builds, so sourcing from regions with experienced craftsmen may increase costs but improve quality.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as factory utilities, equipment depreciation, and administrative expenses. Understanding how overhead is calculated can provide insights into pricing.

-

Tooling: Custom parts may require specialized tooling. The initial investment in tooling can be significant, but it is often amortized over larger production runs. Buyers should inquire about the tooling costs and how they affect pricing for lower volumes.

-

Quality Control (QC): Implementing quality control measures can increase costs but ensures that the final product meets specifications. This is particularly important for custom builds where precision is critical.

-

Logistics: Shipping costs can vary widely based on the shipping method, distance, and any applicable tariffs or taxes. Buyers should consider the total logistics cost, including insurance and customs duties, when sourcing internationally.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the market rates for similar products can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of a 1972 C10 Custom?

Several factors can influence the pricing of a 1972 C10 custom:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to volume discounts, while small orders may incur higher per-unit costs. Buyers should assess their needs and potential future orders to negotiate better pricing.

-

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should clearly define their needs upfront to avoid unexpected expenses during production.

-

Materials and Quality Certifications: The choice of materials and any required certifications (such as ISO or safety standards) can impact pricing. High-quality materials may come with a premium but can lead to better performance and durability.

-

Supplier Factors: The supplier’s reputation, experience, and location can all affect pricing. Established suppliers with a track record of quality may charge higher prices but offer greater reliability.

-

Incoterms: Understanding the agreed Incoterms is vital, as they determine who is responsible for shipping, insurance, and tariffs. This can significantly affect the total cost.

What Tips Can Help International B2B Buyers Negotiate Better Prices?

International buyers, especially from Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiate Terms Upfront: Clear communication about expectations and needs can help set the stage for better pricing. Discussing payment terms, lead times, and other factors can lead to more favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the total cost, including maintenance, logistics, and potential repair costs. This can lead to better long-term decisions.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to labor costs, material availability, and market competition. Understanding these nuances can help buyers make informed choices.

-

Build Relationships with Suppliers: Establishing long-term partnerships can lead to better pricing, especially if suppliers recognize a consistent order pattern or a reliable payment history.

Conclusion

Sourcing a 1972 C10 custom involves a complex interplay of costs and pricing factors. By understanding the key components, price influencers, and negotiation strategies, international B2B buyers can make informed decisions that align with their business needs while ensuring quality and reliability. Always remember to verify indicative prices with suppliers to account for the latest market conditions and fluctuations.

Alternatives Analysis: Comparing 1972 c10 custom With Other Solutions

Understanding Alternatives for the 1972 C10 Custom

When evaluating the 1972 C10 Custom, it is crucial for international B2B buyers to consider alternative solutions that can meet their specific needs. This comparison focuses on assessing how the C10 Custom stacks up against other vehicles and modifications that may offer similar utility or performance.

Comparison Table of the 1972 C10 Custom and Alternatives

| Comparison Aspect | 1972 C10 Custom | Alternative 1: Chevrolet Silverado 1500 | Alternative 2: Ford F-150 |

|---|---|---|---|

| Performance | Classic V8 engine, solid torque for hauling | Modern engines with better fuel efficiency | Powerful engines, excellent towing capacity |

| Cost | Typically lower acquisition cost for vintage models | Higher initial cost due to modern features | Competitive pricing, varies with trims |

| Ease of Implementation | Requires restoration and customization | Ready to use with less immediate work needed | Simple to acquire and modify for personal needs |

| Maintenance | Higher maintenance due to age; parts may be scarce | Lower maintenance, more readily available parts | Generally low maintenance, robust support network |

| Best Use Case | Classic car enthusiasts, custom builds | Daily driving, light to moderate hauling | Versatile for work and personal use, off-road capabilities |

Pros and Cons of Alternatives

Chevrolet Silverado 1500

The Chevrolet Silverado 1500 is a modern pickup that offers improved fuel efficiency, advanced safety features, and a range of engine options. Its design caters to both work and leisure, making it an attractive option for businesses needing a reliable vehicle. However, the higher acquisition cost and potential depreciation may deter some buyers, particularly those looking for classic aesthetics.

Ford F-150

The Ford F-150 stands out with its diverse lineup of engines and configurations, allowing buyers to choose the best fit for their needs. Known for its strong towing capacity and off-road capabilities, the F-150 is a practical choice for various industries, including construction and logistics. However, its pricing can be competitive, which may be a consideration for budget-conscious buyers.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right vehicle or modification for your business hinges on understanding your specific requirements. For buyers in Africa, South America, the Middle East, and Europe, the choice between a vintage model like the 1972 C10 Custom and modern alternatives like the Chevrolet Silverado 1500 or Ford F-150 will depend on factors such as budget, desired performance, and maintenance capabilities. Assessing these elements will ensure that you invest in a solution that aligns with your operational needs and long-term objectives.

Essential Technical Properties and Trade Terminology for 1972 c10 custom

What Are the Key Technical Properties of the 1972 C10 Custom?

When considering the procurement of a 1972 C10 Custom, understanding its technical specifications is crucial for ensuring compatibility and performance in various applications. Here are several critical specifications:

-

Material Grade

The 1972 C10 is predominantly made from high-strength steel, particularly for the chassis and body. This material grade is significant because it affects the vehicle’s durability and weight capacity. Buyers should consider the implications of material strength when assessing the vehicle for commercial use, particularly in rugged environments typical in markets across Africa or South America. -

Engine Type and Displacement

The standard engine for the C10 Custom is a 350-cubic inch V8 engine. Engine displacement is a vital metric as it directly impacts power output and fuel efficiency. B2B buyers should evaluate the engine’s compatibility with local fuel types and availability, especially in regions where diesel options may be preferred. -

Payload Capacity

The payload capacity of the 1972 C10 Custom is approximately 1,500 lbs. Understanding this capacity is essential for businesses that plan to use the vehicle for transporting goods. Buyers need to ensure that the payload meets their operational requirements without risking damage to the vehicle. -

Towing Capacity

The towing capacity for the 1972 C10 is around 5,000 lbs. This specification is critical for businesses involved in logistics or those requiring vehicles for hauling trailers. Knowing the towing capacity helps buyers determine if the vehicle can handle their specific operational needs. -

Suspension Type

The truck features a leaf spring suspension system, which enhances load-bearing capabilities. Understanding the suspension type is important for buyers looking for vehicles that can endure rough terrain and heavy loads, which is especially relevant in developing markets. -

Fuel Economy

The C10 typically achieves 10-12 miles per gallon (MPG). Fuel economy is a key consideration for B2B buyers, as it affects operational costs. In regions with fluctuating fuel prices, understanding the vehicle’s efficiency can influence purchasing decisions.

Which Trade Terminology Should International Buyers Know?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to purchasing a 1972 C10 Custom:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the original manufacturer of the vehicle. When sourcing parts for the C10, buyers should look for OEM parts to ensure compatibility and maintain the vehicle’s value. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for buyers who may need to order parts or vehicles in bulk, as it can significantly affect pricing and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers should use RFQs to gather competitive pricing for parts or vehicles, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Knowledge of Incoterms is essential for buyers to understand shipping costs, delivery responsibilities, and risk management in cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. For B2B buyers, understanding lead times is crucial for planning and managing inventory, especially in regions where supply chains can be unpredictable. -

Warranty Terms

Warranty terms outline the conditions under which a vehicle or part is covered for defects. Buyers should carefully review warranty terms to protect their investment and ensure they have recourse in the event of issues arising post-purchase.

By understanding these technical properties and industry terms, international B2B buyers can make informed decisions regarding the procurement of the 1972 C10 Custom, ensuring it meets their operational needs and aligns with market conditions.

Navigating Market Dynamics and Sourcing Trends in the 1972 c10 custom Sector

What Are the Current Market Dynamics and Key Trends in the 1972 C10 Custom Sector?

The 1972 C10 custom market has witnessed significant transformation driven by various global factors. The resurgence of interest in classic vehicles, particularly in regions like Africa, South America, the Middle East, and Europe, has been fueled by a growing appreciation for vintage aesthetics and the unique driving experience they offer. This trend is further supported by a rising number of automotive enthusiasts and collectors, which has created a robust demand for parts, restorations, and custom modifications.

Emerging B2B technologies, such as online marketplaces and digital supply chain management systems, are reshaping how international buyers source components for the 1972 C10. Platforms that connect buyers with suppliers across continents simplify the procurement process, making it easier to find high-quality parts and services. Additionally, the integration of advanced analytics and AI-driven tools allows buyers to make data-informed decisions, optimizing inventory and reducing costs.

A stock image related to 1972 c10 custom.

Another notable trend is the shift towards customization and personalization. B2B buyers are increasingly looking for unique features that reflect individual tastes and preferences. This demand has led to a rise in suppliers offering tailored solutions, from custom paint jobs to bespoke interior designs. International buyers should be aware of these dynamics to stay competitive and meet the evolving expectations of their customers.

How Is Sustainability and Ethical Sourcing Impacting the 1972 C10 Custom Sector?

In today’s market, sustainability and ethical sourcing have become paramount concerns for B2B buyers, including those in the 1972 C10 custom sector. The environmental impact of automotive production, including resource depletion and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recycled materials and implementing energy-efficient production methods.

Ethical supply chains are critical in ensuring that materials used in modifications and restorations are sourced responsibly. Certifications such as the Forest Stewardship Council (FSC) for wood products or the Global Recycled Standard (GRS) for recycled materials provide assurance that suppliers adhere to sustainable practices. B2B buyers should prioritize partnerships with certified suppliers to enhance their brand reputation and appeal to environmentally conscious consumers.

Moreover, as regulations around emissions and waste management tighten globally, it is essential for buyers to consider the long-term implications of their sourcing decisions. Investing in sustainable materials not only meets regulatory requirements but also positions businesses as leaders in the growing market for green products. This proactive approach can lead to cost savings and improved customer loyalty in the competitive landscape of vintage automotive customization.

What Is the Historical Context of the 1972 C10 Custom?

The 1972 C10 custom, part of Chevrolet’s C/K series, has a rich history that significantly influences its current market. Launched during a period of economic change and cultural shifts in the early 1970s, the C10 was designed to cater to a diverse audience, from commercial users to everyday families. Its versatile design and robust performance made it a favorite among truck enthusiasts.

Over the decades, the C10 has evolved from a utilitarian vehicle into a symbol of American automotive culture. The rise of the classic car restoration movement in the late 20th century further cemented its status, as enthusiasts sought to preserve and enhance these vehicles. Today, the 1972 C10 custom is not just a nostalgic relic; it represents a thriving market where innovation and tradition coexist. Understanding this historical context allows international B2B buyers to appreciate the value and potential of sourcing parts and services for this iconic vehicle.

Frequently Asked Questions (FAQs) for B2B Buyers of 1972 c10 custom

-

How do I ensure the quality of a 1972 C10 custom before purchasing?

To ensure quality, request detailed photographs and a comprehensive history of the vehicle, including previous modifications and repairs. Establish communication with the seller to ask specific questions about the truck’s condition, parts used in customization, and any warranties. If possible, arrange for a third-party inspection by a qualified mechanic familiar with classic vehicles. This step is crucial for international buyers to mitigate risks associated with purchasing remotely. -

What are the best customization options for a 1972 C10 custom?

The best customization options depend on your specific needs and preferences. Popular modifications include engine upgrades (like LS swaps), suspension enhancements, and modernized interiors for comfort. Additionally, consider aesthetic changes such as paint jobs, wheel upgrades, and custom lighting. Discuss your requirements with suppliers who specialize in vintage vehicles to find tailored solutions that align with your vision. -

What is the typical minimum order quantity (MOQ) for sourcing parts for a 1972 C10 custom?

The MOQ for sourcing parts can vary significantly depending on the supplier and the specific components required. Generally, for custom parts, MOQs can range from one to several units. It’s advisable to communicate directly with potential suppliers about your needs, as many are willing to accommodate smaller orders for international buyers looking to customize a single vehicle. -

What payment terms should I expect when sourcing a 1972 C10 custom?

Payment terms can vary by supplier but typically include options such as a deposit upfront (often 30-50%) followed by the balance upon completion or before shipping. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms before finalizing any agreements to avoid misunderstandings. -

How can I vet suppliers for a 1972 C10 custom in international markets?

To vet suppliers, start by researching their reputation through online reviews, testimonials, and ratings on B2B platforms. Request references from previous customers and contact them to inquire about their experiences. Additionally, evaluate the supplier’s experience in handling international orders and their familiarity with customs regulations in your country. It’s also beneficial to visit the supplier’s facility if possible. -

What logistics considerations should I keep in mind when importing a 1972 C10 custom?

Logistics for importing a vintage vehicle involve understanding shipping methods, customs regulations, and import duties in your country. Choose a reliable freight forwarder experienced in handling classic cars to ensure proper handling during transit. Be aware of the documentation required for customs clearance, including the bill of lading, invoice, and any necessary certifications. Plan for potential delays due to customs inspections or paperwork processing. -

How do I handle potential issues with customs when importing a 1972 C10 custom?

To handle customs issues, ensure all required documents are complete and accurate before shipping. Familiarize yourself with your country’s import regulations regarding vintage vehicles, as some may have specific requirements or restrictions. Engaging a customs broker can be beneficial, as they can navigate complex regulations and help resolve any issues that arise during the import process. -

What should I know about warranties and after-sales support for a 1972 C10 custom?

Warranties for custom vehicles can vary widely based on the supplier and the extent of the modifications. Always inquire about warranty coverage for both parts and workmanship before purchasing. Some suppliers may offer limited warranties on specific components, while others may not provide any coverage for custom modifications. Ensure you have clear agreements regarding after-sales support, including availability for maintenance and repairs, to safeguard your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 1972 c10 custom

What Are the Key B2B Insights for Sourcing 1972 C10 Custom Parts?

In conclusion, the strategic sourcing of 1972 C10 custom parts offers significant opportunities for international B2B buyers. Understanding the complexities of this market—ranging from sourcing authentic parts to navigating regional suppliers—can enhance supply chain efficiency and reduce costs. Buyers from Africa, South America, the Middle East, and Europe should prioritize establishing relationships with reputable suppliers who can ensure quality and timely delivery, while also considering local regulations and import duties that may affect pricing.

How Can Strategic Sourcing Drive Value for Your Business?

Effective strategic sourcing not only mitigates risks but also enhances competitiveness in the marketplace. By leveraging local expertise and fostering partnerships, buyers can access a wider range of products and services tailored to their unique needs. This approach is especially vital in the custom vehicle market, where personalization and quality are paramount.

What’s Next for International B2B Buyers in the Custom Vehicle Market?

Looking forward, international B2B buyers should remain proactive in exploring emerging trends, such as the rise of electric vehicle components and sustainable sourcing practices. Engaging with global networks and attending industry trade shows can provide valuable insights and opportunities for collaboration. Embrace the potential of the 1972 C10 custom market to drive your business growth and innovation. Your next strategic partnership could be the key to unlocking new possibilities.