Unlocking Opportunities: Hydrogen Fuel Cell Cars China (2025)

Introduction: Navigating the Global Market for hydrogen fuel cell cars china

In the rapidly evolving landscape of sustainable transportation, sourcing hydrogen fuel cell cars from China presents a unique challenge for international B2B buyers. As the global demand for cleaner energy solutions intensifies, understanding the intricacies of the hydrogen fuel cell vehicle market becomes essential for businesses aiming to stay competitive. This comprehensive guide delves into the various types of hydrogen fuel cell cars available, their applications across different industries, and the critical aspects of supplier vetting.

From assessing production capabilities to evaluating cost structures, this resource empowers international buyers—particularly those from Africa, South America, the Middle East, and Europe—to make informed purchasing decisions. With China’s dominance in hydrogen technology and manufacturing, navigating this market requires a strategic approach to identify reliable partners and secure the best value for investments.

Additionally, the guide will cover essential insights into regulatory considerations, technological advancements, and market trends that shape the hydrogen fuel cell sector. By equipping B2B buyers with the knowledge they need, this resource not only simplifies the procurement process but also enhances the potential for successful partnerships and sustainable growth in the burgeoning hydrogen economy. Understanding these dynamics is key to harnessing the full potential of hydrogen fuel cell cars and driving a sustainable future.

Understanding hydrogen fuel cell cars china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fuel Cell Electric Vehicles (FCEVs) | Uses hydrogen to generate electricity for propulsion | Public transportation, logistics, fleet management | Pros: Zero emissions, quick refueling. Cons: Limited infrastructure, higher initial costs. |

| Hydrogen Internal Combustion Engine (HICE) | Combines traditional combustion engines with hydrogen | Heavy-duty transport, construction equipment | Pros: Familiar technology, easier integration. Cons: Lower efficiency than FCEVs, emissions still present. |

| Hybrid Hydrogen Vehicles | Combines hydrogen fuel cells with battery systems | Urban commuting, delivery services | Pros: Extended range, versatile applications. Cons: More complex systems, potentially higher maintenance. |

| Hydrogen-Powered Buses | Specifically designed for public transit systems | Urban public transport, tourism | Pros: Large passenger capacity, environmentally friendly. Cons: High initial investment, dependency on refueling stations. |

| Hydrogen-Powered Trucks | Designed for heavy-duty logistics and transport | Freight transport, long-haul logistics | Pros: Significant range, reduced fuel costs over time. Cons: Infrastructure challenges, weight considerations. |

What are Fuel Cell Electric Vehicles (FCEVs) and Their B2B Relevance?

Fuel Cell Electric Vehicles (FCEVs) are a primary category of hydrogen-powered cars that convert hydrogen into electricity to power an electric motor. These vehicles are particularly suitable for public transportation and logistics due to their zero-emission profile and rapid refueling capabilities. B2B buyers should consider the initial investment against the long-term operational savings, especially in regions with established hydrogen infrastructure. The growing emphasis on sustainability in corporate responsibility makes FCEVs an appealing option.

How Do Hydrogen Internal Combustion Engines (HICE) Work for B2B Applications?

Hydrogen Internal Combustion Engines (HICE) utilize hydrogen as fuel in a modified traditional combustion engine. This technology is particularly relevant for heavy-duty transport and construction equipment, where businesses are looking to transition to cleaner alternatives without completely overhauling existing systems. HICE offers familiarity for operators, but companies should weigh the lower efficiency and remaining emissions against potential regulatory benefits and public perception.

What Are the Benefits of Hybrid Hydrogen Vehicles for Businesses?

Hybrid Hydrogen Vehicles integrate hydrogen fuel cells with battery systems, offering a versatile solution for urban commuting and delivery services. These vehicles allow for greater range and flexibility, making them suitable for businesses that require both short and long-distance travel. While the complexity of hybrid systems can lead to higher maintenance costs, the adaptability and efficiency gains often justify the investment for B2B buyers looking to enhance their fleet’s sustainability.

Why Choose Hydrogen-Powered Buses for Urban Transport?

Hydrogen-Powered Buses are specifically designed for public transit, providing an eco-friendly alternative to traditional diesel buses. They can accommodate large passenger capacities, making them ideal for urban public transport and tourism sectors. Despite the high initial investment and reliance on a robust refueling infrastructure, the potential for reduced operational costs and compliance with increasingly stringent emissions regulations makes these buses a compelling option for city planners and transit authorities.

How Do Hydrogen-Powered Trucks Fit into the Logistics Sector?

Hydrogen-Powered Trucks are engineered for heavy-duty logistics, offering significant range and efficiency for freight transport and long-haul logistics. These vehicles can help businesses reduce fuel costs over time, making them a strategic investment for companies focused on sustainability and operational efficiency. However, buyers must consider the current challenges related to hydrogen infrastructure and weight regulations, which can impact overall fleet performance.

Key Industrial Applications of hydrogen fuel cell cars china

| Industry/Sector | Specific Application of Hydrogen Fuel Cell Cars China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Hydrogen-powered buses and taxis | Reduced emissions and operational costs | Infrastructure for refueling, maintenance expertise |

| Logistics and Freight | Hydrogen fuel cell delivery vehicles | Longer range and faster refueling times | Vehicle durability, service network availability |

| Mining and Heavy Industries | Hydrogen fuel cell trucks for material transport | Enhanced efficiency and lower carbon footprint | Load capacity, ruggedness, and safety standards |

| Agricultural Transport | Hydrogen fuel cell vehicles for farm equipment | Sustainability and reduced fuel costs | Compatibility with existing equipment, maintenance support |

| Emergency Services | Hydrogen fuel cell emergency response vehicles | Quick deployment and reduced environmental impact | Reliability under pressure, training for operators |

How Can Public Transportation Benefit from Hydrogen Fuel Cell Cars in China?

Public transportation in China is increasingly adopting hydrogen-powered buses and taxis to meet stringent emission regulations. These vehicles provide a cleaner alternative to traditional fossil fuel options, significantly reducing greenhouse gas emissions. For international buyers, particularly from regions like Africa and South America, sourcing these vehicles can lead to cost savings in the long run due to lower operational costs. However, buyers must consider the availability of refueling infrastructure and the need for specialized maintenance services.

What Advantages Do Hydrogen Fuel Cell Delivery Vehicles Offer in Logistics?

In the logistics and freight sector, hydrogen fuel cell delivery vehicles are becoming essential due to their extended range and rapid refueling capabilities. This is particularly beneficial for businesses that require frequent long-distance transportation. For B2B buyers, such as those in the Middle East and Europe, investing in these vehicles can enhance operational efficiency and reduce dependency on traditional fuels. Buyers should evaluate the vehicle’s durability and the availability of a robust service network to ensure smooth operations.

How Are Hydrogen Fuel Cell Trucks Transforming Mining and Heavy Industries?

Mining and heavy industries in China are leveraging hydrogen fuel cell trucks for transporting materials within sites. These trucks not only improve operational efficiency but also lower the carbon footprint, aligning with global sustainability goals. For international buyers, especially in regions like Australia and Kenya, it’s crucial to ensure that the trucks meet load capacity requirements and ruggedness standards. Additionally, buyers should assess safety standards to protect workers in challenging environments.

What Role Do Hydrogen Fuel Cell Vehicles Play in Agricultural Transport?

In agriculture, hydrogen fuel cell vehicles are being utilized for transporting goods and equipment, promoting sustainability within the sector. These vehicles help farmers reduce fuel costs and emissions, which is increasingly important in regions facing climate challenges. Buyers from Africa and South America should consider compatibility with existing agricultural equipment and the availability of maintenance support when sourcing these vehicles.

How Can Emergency Services Enhance Operations with Hydrogen Fuel Cell Vehicles?

Emergency services in China are incorporating hydrogen fuel cell vehicles to ensure rapid response times while minimizing environmental impact. The reliability and quick deployment capabilities of these vehicles are critical during emergencies. For B2B buyers in the Middle East and Europe, investing in hydrogen fuel cell emergency response vehicles can enhance service efficiency. However, it is vital to ensure that operators are adequately trained to handle these advanced vehicles under pressure.

Related Video: Hydrogen Fuel Cell: How It Works

3 Common User Pain Points for ‘hydrogen fuel cell cars china’ & Their Solutions

Scenario 1: Limited Infrastructure for Hydrogen Fuel Cell Cars in Emerging Markets

The Problem: One of the most significant challenges faced by B2B buyers considering hydrogen fuel cell cars in regions like Africa and South America is the limited availability of refueling infrastructure. Many businesses are hesitant to invest in hydrogen vehicles due to the scarcity of hydrogen stations, which can deter potential users from adopting this technology. This situation creates a frustrating catch-22: companies are reluctant to invest without a refueling network, while the lack of investment in infrastructure slows its development.

The Solution: To effectively navigate this issue, international B2B buyers should engage in partnerships with local governments and private investors to advocate for the development of hydrogen refueling stations. This can include participating in public-private partnerships that share the financial burden of establishing this infrastructure. Additionally, companies can explore collaborations with existing fuel providers to integrate hydrogen fueling options into their operations. Another practical approach is to leverage mobile refueling solutions that can temporarily provide hydrogen until a more permanent infrastructure is in place. By actively participating in infrastructure development discussions, B2B buyers can help shape a supportive ecosystem for hydrogen fuel cell cars.

Scenario 2: High Initial Costs of Hydrogen Fuel Cell Vehicles

The Problem: The upfront costs associated with hydrogen fuel cell cars can be a significant barrier for businesses in regions like the Middle East and Europe. Many B2B buyers find that the price of these vehicles is considerably higher than traditional combustion engine vehicles or even battery electric vehicles. This cost disparity can make it difficult for companies to justify the switch to hydrogen fuel technology, especially when budgets are tight or when immediate returns on investment are expected.

The Solution: To address the high initial costs, B2B buyers should look into government subsidies and incentives available for the adoption of hydrogen technology. Many countries offer financial assistance for businesses transitioning to cleaner technologies. Additionally, buyers can focus on total cost of ownership (TCO) analyses, which consider long-term savings on fuel and maintenance compared to traditional vehicles. Working with manufacturers to negotiate bulk purchasing deals can also lead to significant discounts, making the investment more feasible. Lastly, exploring leasing options can provide a lower barrier to entry, allowing businesses to adopt hydrogen fuel cell cars without the heavy initial financial burden.

Scenario 3: Uncertainty About Hydrogen Technology Reliability

The Problem: Many B2B buyers are uncertain about the reliability and long-term performance of hydrogen fuel cell technology compared to more established vehicle technologies. This skepticism can stem from concerns over the durability of fuel cells, their efficiency under various operating conditions, and the availability of skilled technicians for maintenance and repairs. Such uncertainties can lead to hesitation in adopting this innovative solution, hindering potential partnerships or purchases.

The Solution: To alleviate concerns about reliability, B2B buyers should conduct thorough research and engage with manufacturers who can provide robust warranties and service agreements. Requesting detailed case studies or testimonials from other businesses that have successfully integrated hydrogen fuel cell vehicles into their fleets can also provide reassurance. Additionally, buyers should consider investing in training programs for their maintenance staff to ensure they are equipped to handle hydrogen technology effectively. Collaborating with manufacturers to establish a dedicated support line or service network can further enhance confidence in the technology’s reliability. By taking proactive steps to educate themselves and their teams, buyers can mitigate concerns and embrace the advantages of hydrogen fuel cell vehicles.

Strategic Material Selection Guide for hydrogen fuel cell cars china

When selecting materials for hydrogen fuel cell cars in China, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of these vehicles, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions like Africa, South America, the Middle East, and Europe.

What are the Key Properties of Metal Alloys in Hydrogen Fuel Cell Cars?

Metal alloys, particularly stainless steel and aluminum, are widely used in hydrogen fuel cell vehicles due to their strength and corrosion resistance. Stainless steel offers excellent durability and can withstand high temperatures and pressures, making it suitable for fuel cell components. Aluminum, while lighter, is also resistant to corrosion but may not handle extreme conditions as well as stainless steel.

Pros & Cons:

– Stainless Steel: Highly durable and resistant to corrosion; however, it is heavier and more expensive than aluminum.

– Aluminum: Lightweight and cost-effective, but it may require additional treatments to enhance its strength under high pressure.

Impact on Application:

Metal alloys are crucial for structural components, storage tanks, and piping systems, where integrity under pressure is vital.

Considerations for International Buyers:

Compliance with international standards like ASTM and DIN is essential, especially for buyers in Europe and the Middle East. Buyers should also consider local manufacturing capabilities and the availability of these materials in their regions.

How Do Composite Materials Enhance Performance in Hydrogen Fuel Cell Vehicles?

Composite materials, such as carbon fiber reinforced polymers (CFRP), are increasingly being utilized in hydrogen fuel cell cars. These materials are known for their high strength-to-weight ratio and excellent fatigue resistance, making them ideal for lightweight vehicle components.

Pros & Cons:

– Advantages: CFRP is exceptionally lightweight, which can enhance vehicle efficiency and range.

– Disadvantages: The manufacturing process is complex and can be costly, which may deter some manufacturers.

Impact on Application:

CFRP is particularly effective in applications where weight reduction is critical, such as in body panels and structural components.

Considerations for International Buyers:

Buyers should be aware of the different manufacturing standards and certifications that may apply to composite materials, especially in regions with stringent automotive regulations.

What Role Do Polymers Play in Hydrogen Fuel Cell Systems?

Polymers, particularly ion-exchange membranes like Nafion, are vital for the functionality of hydrogen fuel cells. These membranes facilitate the movement of protons while preventing the passage of gases, which is essential for the fuel cell’s operation.

Pros & Cons:

– Advantages: Polymers are generally lightweight and can be produced at a lower cost than metals.

– Disadvantages: They may have limitations in temperature and pressure resistance compared to metals.

Impact on Application:

Polymers are critical in the fuel cell stack, where their performance directly influences the efficiency and longevity of the fuel cell system.

Considerations for International Buyers:

Understanding the specific grades of polymers and their compliance with international standards is crucial for ensuring compatibility and performance in various climates, particularly in regions like Africa and South America.

How Do Ceramics Contribute to the Durability of Hydrogen Fuel Cell Cars?

Ceramics are often used in high-temperature applications within hydrogen fuel cells, such as in solid oxide fuel cells (SOFC). They exhibit excellent thermal stability and resistance to corrosion.

Pros & Cons:

– Advantages: Ceramics can withstand extreme temperatures and harsh environments, making them suitable for specific applications.

– Disadvantages: They can be brittle, making them less suitable for components that experience mechanical stress.

Impact on Application:

Ceramics are primarily used in fuel cell stacks and components that require high thermal resistance.

Considerations for International Buyers:

Buyers should evaluate the availability of ceramic materials and their compliance with local and international standards, especially in regions with different thermal management requirements.

Summary Table of Material Selection for Hydrogen Fuel Cell Cars in China

| Material | Typical Use Case for hydrogen fuel cell cars china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal Alloys | Structural components, storage tanks | High durability and corrosion resistance | Heavier and more expensive than alternatives | High |

| Composite Materials | Body panels, lightweight structural components | Exceptional strength-to-weight ratio | Complex and costly manufacturing | Medium |

| Polymers | Fuel cell stacks, ion-exchange membranes | Lightweight and lower cost | Limited temperature and pressure resistance | Low |

| Ceramics | High-temperature applications in fuel cells | Excellent thermal stability | Brittle and less suitable for mechanical stress | Medium |

This strategic material selection guide provides international B2B buyers with critical insights into the various materials used in hydrogen fuel cell cars, enabling informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hydrogen fuel cell cars china

What Are the Main Stages of Manufacturing Hydrogen Fuel Cell Cars in China?

Manufacturing hydrogen fuel cell vehicles (HFCVs) in China involves a series of carefully coordinated processes. The production is typically divided into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing and preparing high-quality materials such as hydrogen fuel cell membranes, bipolar plates, and storage tanks. The focus is on using lightweight and durable materials to enhance the vehicle’s efficiency and performance. Suppliers must ensure that materials meet industry standards, which is crucial for the overall durability of the final product.

-

Forming: During this phase, materials are shaped into the necessary components for the fuel cell stack and vehicle chassis. Techniques such as stamping, molding, and extrusion are commonly employed. Advanced manufacturing technologies, including computer numerical control (CNC) machining, help achieve precision in forming complex shapes that are essential for performance and safety.

-

Assembly: The assembly process is where individual components come together to form the complete vehicle. This stage requires a high degree of skill and precision. Automated assembly lines are increasingly used to improve efficiency and reduce human error. Each vehicle undergoes thorough inspections at various points during assembly to ensure all parts fit correctly and meet design specifications.

-

Finishing: The finishing stage includes painting, quality checks, and final adjustments. Aesthetic and functional coatings are applied to protect the vehicle from environmental factors. This stage also involves rigorous testing to ensure that every vehicle meets safety and performance standards before it leaves the factory.

How Is Quality Assurance Implemented in Hydrogen Fuel Cell Vehicle Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of hydrogen fuel cell cars, as the technology is still evolving and requires adherence to stringent safety standards. Various international and industry-specific standards guide QA practices.

-

Relevant International Standards: Manufacturers typically adhere to ISO 9001, which sets out the criteria for a quality management system. This certification indicates that a company consistently provides products that meet customer and regulatory requirements. Additionally, compliance with CE marking and American Petroleum Institute (API) standards is essential, particularly for components related to fuel storage and handling.

-

Quality Control Checkpoints: Effective quality control is implemented at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Materials and components are inspected upon arrival at the manufacturing facility to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, random inspections are conducted to identify defects early, reducing rework and waste.

– Final Quality Control (FQC): Before the vehicle is dispatched, it undergoes a comprehensive final inspection and testing to ensure it meets all performance and safety criteria. -

Common Testing Methods: Various testing methods are employed to assess the quality of components and finished vehicles. These include pressure testing for fuel tanks, performance testing for fuel cells, and crash testing for safety. Each test aims to validate the integrity and reliability of the vehicle under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control in China?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers in China is critical. Here are several actionable strategies:

-

Conducting Supplier Audits: Regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Audits should assess adherence to international standards, production capabilities, and quality management practices.

-

Reviewing Quality Control Reports: Requesting detailed QC reports from suppliers can offer a clearer picture of their quality management system. These reports should include data on defect rates, inspection results, and compliance with relevant standards.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection services can ensure impartial evaluation of manufacturing processes and quality control. These services can conduct on-site inspections, review documentation, and provide certification of compliance with international standards.

-

Understanding Quality Control Nuances for International Buyers: Different regions may have specific quality expectations and regulatory requirements. B2B buyers should familiarize themselves with these nuances to ensure that the products they import meet local standards. For instance, CE marking is important for European buyers, while African markets may have their own certification needs.

What Challenges Do International Buyers Face with Quality Assurance in Hydrogen Fuel Cell Vehicles?

While the potential for hydrogen fuel cell vehicles is vast, international buyers face several challenges when it comes to quality assurance.

-

Language and Cultural Barriers: Communication issues may arise due to language differences and varying business practices. Buyers should establish clear communication channels and possibly work with local intermediaries who understand both the market and the suppliers.

-

Variability in Standards: Different countries have differing standards for vehicle safety and emissions. Buyers must ensure that the products they import not only meet their local regulations but also align with international quality benchmarks.

-

Supply Chain Reliability: The hydrogen fuel cell supply chain is still developing, and disruptions can impact quality and availability. Buyers should evaluate the reliability of suppliers and their ability to maintain consistent quality over time.

-

Evolving Technology: As hydrogen fuel cell technology advances, buyers need to stay updated on the latest innovations and standards. Engaging with industry experts and participating in relevant trade shows can help buyers keep abreast of technological changes.

Conclusion: Ensuring Quality in the Hydrogen Fuel Cell Vehicle Supply Chain

For B2B buyers looking to invest in hydrogen fuel cell cars from China, understanding the manufacturing processes and quality assurance practices is essential. By focusing on supplier audits, reviewing quality reports, and leveraging third-party inspections, buyers can mitigate risks and ensure that they receive high-quality products that meet international standards. As the market for hydrogen fuel cell vehicles continues to grow, maintaining a strong emphasis on quality will be key to success in this innovative automotive sector.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydrogen fuel cell cars china’

Introduction

In the rapidly evolving landscape of sustainable transportation, hydrogen fuel cell cars represent a promising solution for reducing carbon emissions. For international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—sourcing these vehicles from China requires a strategic approach. This checklist provides actionable insights to help you navigate the complexities of procurement, ensuring you make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for hydrogen fuel cell cars. This includes vehicle range, fuel efficiency, and compliance with local regulations. By defining these specifications, you ensure that potential suppliers can meet your operational needs and adhere to industry standards.

Step 2: Research the Market Landscape

Conduct thorough research on the current market for hydrogen fuel cell cars in China. Identify key players, market trends, and emerging technologies. Understanding the landscape helps you to pinpoint potential suppliers who are at the forefront of innovation and can offer competitive pricing.

- Key Considerations:

- Analyze the performance of existing models in the market.

- Keep abreast of government policies promoting hydrogen fuel technology.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Don’t just rely on their website; engage in direct communication to assess their credibility and reliability.

- What to Look For:

- Certifications from recognized standards (ISO, etc.).

- Experience in exporting vehicles to your region.

Step 4: Assess Supply Chain Capabilities

Understanding the supplier’s supply chain capabilities is essential for ensuring timely delivery and consistent product quality. Evaluate their logistics, warehousing, and distribution networks. This insight will help mitigate risks associated with delays or shortages.

- Key Questions:

- What is their lead time for production and delivery?

- How do they manage inventory and quality control?

Step 5: Verify Compliance with Regulations

Ensure that the hydrogen fuel cell cars comply with both Chinese export regulations and the import regulations of your home country. Non-compliance can lead to costly delays and legal challenges, so confirm that all vehicles meet safety, emissions, and technical standards.

- Documentation to Request:

- Certificates of conformity.

- Test reports from accredited laboratories.

Step 6: Negotiate Terms and Conditions

Once you’ve shortlisted potential suppliers, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment terms, warranty policies, and after-sales service. Clear agreements will help prevent misunderstandings and ensure a smooth procurement process.

- Negotiation Tips:

- Be transparent about your budget and expectations.

- Don’t hesitate to ask for discounts on bulk orders.

Step 7: Plan for Logistics and After-Sales Support

Consider the logistics involved in transporting the vehicles from China to your location. Additionally, ensure that your supplier offers adequate after-sales support, including maintenance and spare parts availability. This consideration is vital for minimizing downtime and enhancing customer satisfaction.

- Logistics Planning:

- Choose reliable shipping partners.

- Confirm the availability of service centers in your region.

By following this step-by-step checklist, international B2B buyers can effectively navigate the complexities of sourcing hydrogen fuel cell cars from China, ensuring they make informed and strategic decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for hydrogen fuel cell cars china Sourcing

What Are the Key Cost Components for Sourcing Hydrogen Fuel Cell Cars from China?

When considering the procurement of hydrogen fuel cell cars from China, understanding the cost structure is paramount. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The sourcing of high-quality materials, such as hydrogen tanks, fuel cells, and electric motors, significantly impacts overall costs. Prices for these components can fluctuate based on global supply chain dynamics and availability.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and specialization. Skilled labor for assembly and quality control may command higher wages, affecting the overall cost.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, but buyers should assess the manufacturing capabilities of potential suppliers.

-

Tooling: Custom tooling for specialized components can be a substantial upfront investment. Depending on the complexity of the parts required, this can add significant costs to the initial procurement phase.

-

Quality Control (QC): Ensuring that the hydrogen fuel cell vehicles meet international quality standards is essential. Investing in robust QC processes can prevent costly returns and enhance product reliability.

-

Logistics: Shipping costs can vary greatly depending on the mode of transportation, distance, and urgency. Given the global nature of supply chains, incorporating logistics into the total cost is crucial.

-

Margin: Supplier profit margins can vary widely based on competition and product uniqueness. It is essential to negotiate terms that are beneficial for both parties.

How Do Price Influencers Affect the Sourcing of Hydrogen Fuel Cell Cars?

Several factors can influence the pricing of hydrogen fuel cell vehicles, including volume, specifications, material quality, and supplier reliability.

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate favorable terms and pricing.

-

Specifications/Customization: Tailoring vehicles to specific needs can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials: The choice of materials impacts not only the cost but also the vehicle’s performance and safety. Higher quality materials may come at a premium but can enhance longevity and reduce Total Cost of Ownership (TCO).

-

Quality/Certifications: Products that meet international standards (ISO, CE) may have higher upfront costs but can lead to savings in the long run through reduced warranty claims and improved reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may command higher prices but can also offer better service and support.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for pricing clarity. These terms dictate responsibilities for shipping, insurance, and tariffs, which can affect the overall cost.

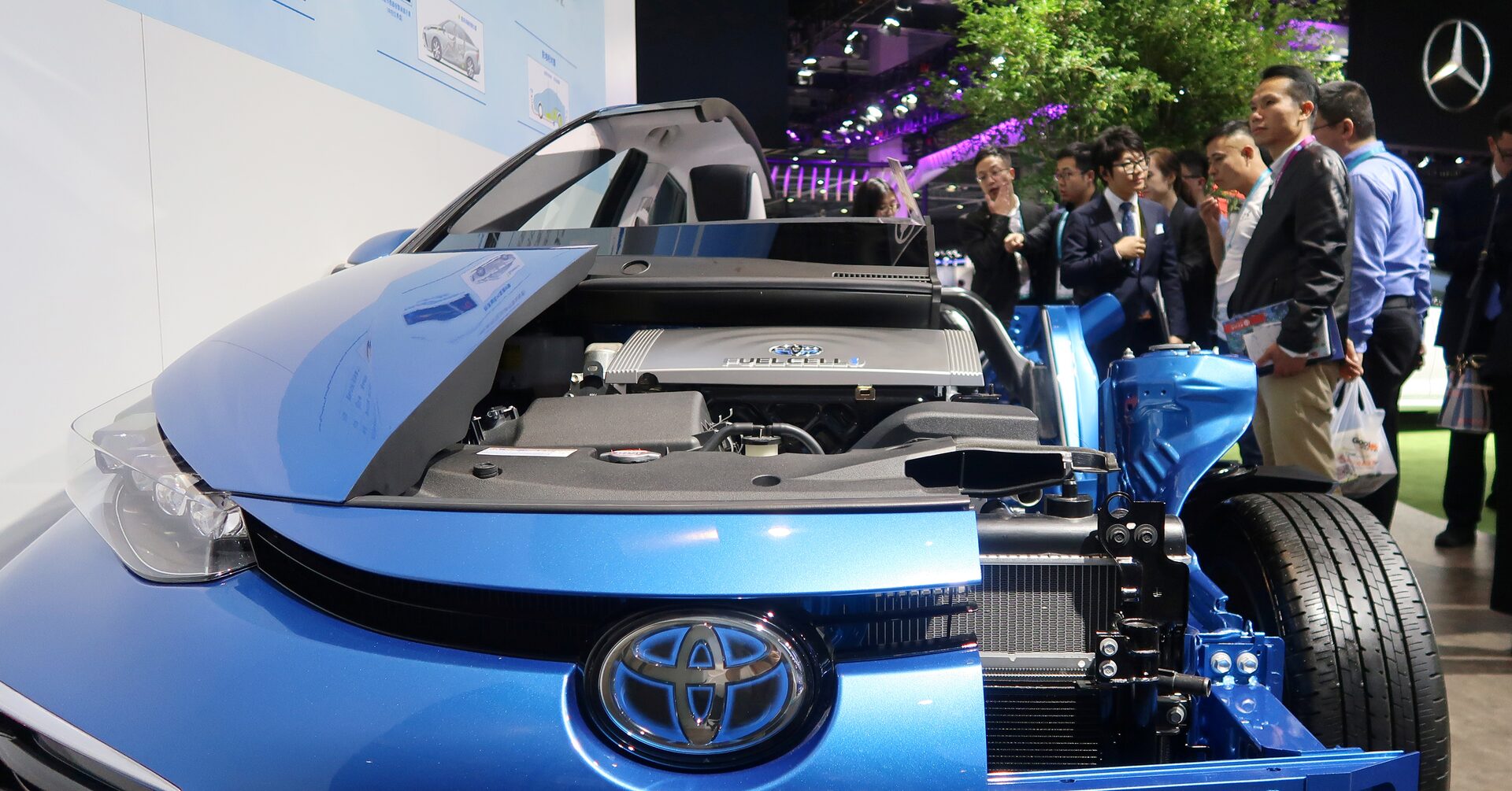

A stock image related to hydrogen fuel cell cars china.

What Negotiation Strategies Should B2B Buyers Consider?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings.

-

Research and Comparison: Conduct thorough market research to compare prices from different suppliers. Leverage this information in negotiations to secure better terms.

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just the initial purchase price. Consider factors like maintenance, fuel efficiency, and potential resale value to make a more informed decision.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable negotiations.

-

Be Prepared to Walk Away: Being willing to explore other options can strengthen your negotiating position. Suppliers are often more flexible when they know you have alternatives.

-

Clarify Payment Terms: Negotiating favorable payment terms can improve cash flow. Consider options such as extended payment periods or discounts for early payment.

Conclusion: What Should B2B Buyers Keep in Mind?

While sourcing hydrogen fuel cell cars from China presents various opportunities, it also comes with complexities in cost and pricing. By understanding the key cost components, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions that align with their business objectives. Always remember to account for indicative prices and fluctuations in the market, and tailor your approach to suit the unique dynamics of your region.

Alternatives Analysis: Comparing hydrogen fuel cell cars china With Other Solutions

Understanding the Importance of Comparing Hydrogen Fuel Cell Cars in China with Alternative Solutions

As the automotive industry evolves, B2B buyers must consider various technologies when evaluating transportation solutions. Hydrogen fuel cell cars in China offer a promising alternative to traditional vehicles, but understanding how they stack up against other options is crucial for informed decision-making. This analysis will compare hydrogen fuel cell cars with battery electric vehicles (BEVs) and internal combustion engine (ICE) vehicles, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Hydrogen Fuel Cell Cars and Alternatives

| Comparison Aspect | Hydrogen Fuel Cell Cars China | Battery Electric Vehicles (BEVs) | Internal Combustion Engine (ICE) Vehicles |

|---|---|---|---|

| Performance | High range, quick refueling | Limited range, longer charging times | High power output and range |

| Cost | Higher initial investment, potential for lower operating costs | Moderate initial cost, lower operating costs | Lower initial cost, higher fuel costs |

| Ease of Implementation | Requires hydrogen infrastructure | Growing charging infrastructure | Established fueling infrastructure |

| Maintenance | Low maintenance, fewer moving parts | Moderate maintenance, battery replacement | Higher maintenance due to complex engines |

| Best Use Case | Commercial fleets, long-distance travel | Urban commuting, light-duty applications | Long-distance travel, existing market dominance |

What Are the Pros and Cons of Hydrogen Fuel Cell Cars?

Hydrogen fuel cell cars offer significant benefits, particularly in terms of performance. They can achieve a range similar to that of gasoline vehicles, with quick refueling capabilities that can be completed in under five minutes. However, the initial investment is higher than both BEVs and ICE vehicles, and the hydrogen infrastructure is still developing, especially in regions outside of China. Maintenance is relatively low due to fewer moving parts, making it an attractive option for fleets focused on minimizing downtime.

How Do Battery Electric Vehicles Compare?

Battery electric vehicles (BEVs) are becoming increasingly popular, particularly in urban settings where charging stations are more prevalent. They typically have lower operating costs due to less expensive energy sources and fewer mechanical components. However, BEVs face challenges related to range and charging times, which can be a disadvantage for long-distance travel. The initial investment is moderate, but the growing infrastructure for charging stations is making them more accessible, particularly in Europe and North America.

What Are the Strengths and Weaknesses of Internal Combustion Engine Vehicles?

Internal combustion engine (ICE) vehicles have dominated the market for decades due to their established fueling infrastructure and lower initial costs. They provide high power output and a familiar driving experience. However, they face increasing scrutiny due to environmental concerns and higher fuel costs. Maintenance can be more demanding, with complex engine systems requiring regular servicing. Despite these drawbacks, ICE vehicles remain a viable option for long-distance travel, especially in regions where electric or hydrogen infrastructure is still developing.

How Can B2B Buyers Choose the Right Solution?

When selecting the right vehicle solution, B2B buyers should consider their specific operational needs, including the type of usage, distance requirements, and existing infrastructure. For businesses focused on urban commuting or short distances, BEVs might be the most cost-effective and environmentally friendly option. Conversely, companies with long-distance logistics or fleet operations may find hydrogen fuel cell cars to be more suitable. ICE vehicles may still serve niche markets, particularly where infrastructure for alternative fuels is lacking. Ultimately, the choice will depend on balancing initial costs with long-term operational efficiency and sustainability goals.

Essential Technical Properties and Trade Terminology for hydrogen fuel cell cars china

What Are the Key Technical Properties of Hydrogen Fuel Cell Cars in China?

Understanding the technical properties of hydrogen fuel cell cars is crucial for international B2B buyers looking to invest in this emerging market. Here are some essential specifications that buyers should consider:

1. Fuel Cell Efficiency

Fuel cell efficiency refers to the ratio of electrical energy produced to the chemical energy contained in the hydrogen fuel. Typically measured in percentage terms, high efficiency indicates better performance and lower operational costs. B2B buyers should prioritize vehicles with efficiency ratings above 60%, as this can significantly impact long-term profitability and sustainability.

2. Range and Refueling Time

The range of a hydrogen fuel cell vehicle (FCV) denotes how far it can travel on a full tank of hydrogen, while refueling time indicates how quickly the vehicle can be replenished. Most FCVs can achieve a range of 300 to 400 kilometers and can be refueled in about 3 to 5 minutes. This is particularly relevant for fleet operators who need vehicles that minimize downtime.

3. Material Grade of Components

The materials used in hydrogen fuel cells, such as membrane electrode assemblies (MEAs) and bipolar plates, are critical for performance and durability. High-grade materials not only improve the lifespan of the vehicle but also enhance its overall efficiency. Buyers should look for vehicles utilizing materials with proven performance metrics to ensure reliability and lower maintenance costs.

4. Operating Temperature Range

Hydrogen fuel cells operate efficiently within a specific temperature range, typically between -20°C and 40°C. Understanding this property is essential for buyers in regions with extreme climates, as it directly affects vehicle performance. Buyers should assess the vehicle’s ability to function effectively in their local conditions to avoid operational challenges.

5. Durability and Longevity

Durability metrics refer to the expected lifespan and maintenance intervals of fuel cell components. High durability means fewer replacements and repairs, resulting in lower total cost of ownership. B2B buyers should inquire about warranty periods and maintenance schedules to evaluate the long-term viability of their investments.

What Are the Common Trade Terms in the Hydrogen Fuel Cell Car Industry?

Familiarizing oneself with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some key terms relevant to hydrogen fuel cell cars:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or complete vehicles that are marketed under another company’s brand. Understanding the role of OEMs is critical for buyers looking to establish partnerships or source components for their own vehicle production.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers as it affects inventory costs and logistics. Buyers should negotiate favorable MOQs to optimize their supply chain and minimize upfront investments.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. This is an essential step in sourcing hydrogen fuel cell vehicles or components, enabling buyers to compare offers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and insurance responsibilities, which are vital for smooth cross-border trade.

5. FCA (Free Carrier)

FCA is an Incoterm indicating that the seller delivers the goods to a carrier nominated by the buyer at a specified location. This term is significant for B2B buyers as it determines the point at which the risk and cost transfer from seller to buyer, impacting logistics and financing decisions.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the hydrogen fuel cell vehicle market in China with greater confidence and make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the hydrogen fuel cell cars china Sector

What Are the Key Market Dynamics and Trends in the Hydrogen Fuel Cell Cars Sector in China?

The hydrogen fuel cell car sector in China is witnessing rapid growth, driven by government policies aimed at reducing carbon emissions and promoting clean energy technologies. As of late 2023, China’s commitment to achieving carbon neutrality by 2060 has led to increased investments in hydrogen infrastructure and vehicle production. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, this presents a unique opportunity to engage with a market that is not only burgeoning but also heavily supported by national policies.

Emerging B2B tech trends include advancements in hydrogen production technologies, such as electrolysis and steam methane reforming. These innovations are making hydrogen more accessible and affordable, thereby enhancing the feasibility of hydrogen fuel cell vehicles (FCVs) for a broader range of applications. Additionally, the integration of digital technologies like IoT and AI in supply chain management is streamlining operations, improving efficiency, and reducing costs. Buyers should be aware of the competitive landscape, which includes not only local manufacturers but also international players looking to penetrate the Chinese market.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Hydrogen Fuel Cell Sector?

A stock image related to hydrogen fuel cell cars china.

Sustainability is a cornerstone of the hydrogen fuel cell industry, significantly influencing B2B sourcing decisions. The environmental impact of hydrogen production methods is a critical consideration for buyers. Opting for suppliers that utilize renewable energy sources for hydrogen production can enhance the overall sustainability profile of the end product. This is particularly relevant for buyers in regions like Europe, where regulatory frameworks increasingly favor green technologies.

Ethical sourcing is equally vital, as stakeholders are increasingly scrutinizing supply chains for transparency and social responsibility. Buyers should look for partners who adhere to recognized standards and certifications, such as ISO 14001 for environmental management and ISO 26000 for social responsibility. Additionally, the use of green materials in the production of hydrogen fuel cell vehicles not only meets regulatory requirements but also appeals to environmentally conscious consumers. By prioritizing suppliers committed to ethical practices, B2B buyers can strengthen their market position and align with global sustainability goals.

What is the Evolution of the Hydrogen Fuel Cell Car Industry in China?

The hydrogen fuel cell car industry in China has evolved significantly over the past two decades. Initially, development was slow, with limited government support and technological advancements. However, the turning point came in the mid-2010s when the Chinese government recognized the potential of hydrogen as a clean energy source. Policies were introduced to incentivize research and development, leading to a surge in investments from both domestic and international stakeholders.

By 2020, China had established itself as a global leader in hydrogen fuel cell technology, with numerous manufacturers producing a range of vehicles, from passenger cars to heavy-duty trucks. Today, the focus has shifted towards building a comprehensive hydrogen infrastructure, including refueling stations and supply chains. For B2B buyers, understanding this historical context is essential for making informed sourcing decisions, as it highlights the rapid pace of innovation and the increasing importance of partnerships within the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of hydrogen fuel cell cars china

-

How do I ensure the reliability of suppliers for hydrogen fuel cell cars in China?

To ensure the reliability of suppliers, start by researching their background, including company history, production capacity, and market reputation. Utilize platforms like Alibaba or Made-in-China for reviews and ratings. Request references from previous clients and verify their credibility. Additionally, consider visiting the manufacturing facility if possible, or hiring a third-party inspection service to assess quality control processes and production standards. -

What are the key factors to consider when sourcing hydrogen fuel cell cars from China?

Key factors include supplier certification, compliance with international safety and environmental standards, and the technological capabilities of the vehicles. Analyze the supplier’s experience in exporting to your region, as well as their ability to customize vehicles to meet local regulations. It’s also important to evaluate the total cost of ownership, including maintenance and fuel efficiency, to ensure long-term viability. -

What is the typical minimum order quantity (MOQ) for hydrogen fuel cell cars from Chinese manufacturers?

The MOQ for hydrogen fuel cell cars can vary widely depending on the manufacturer and the specific model. Typically, it ranges from 10 to 50 units for standard models. Customizations may increase the MOQ, so it’s advisable to discuss your specific needs with suppliers. Negotiation may also lead to lower MOQs, especially if you are considering a long-term partnership. -

What payment terms should I expect when purchasing hydrogen fuel cell cars from China?

Payment terms can vary by supplier but typically include a mix of upfront deposits (often 30-50%) and the balance due upon shipment or delivery. Be cautious of suppliers requesting full payment upfront. Utilize secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify terms in writing to avoid misunderstandings. -

How can I verify the quality assurance processes of Chinese manufacturers for hydrogen fuel cell cars?

To verify quality assurance processes, request documentation of their quality management systems, such as ISO 9001 certifications. Conduct audits or inspections, either personally or through third-party services, to assess production facilities and quality control measures. Ask for samples to evaluate build quality and performance before committing to larger orders. -

What logistics considerations should I take into account when importing hydrogen fuel cell cars from China?

Logistics considerations include shipping methods, customs regulations, and potential tariffs in your country. Determine whether you will use air freight for faster delivery or sea freight for cost efficiency. Engage a freight forwarder experienced in automotive imports to navigate complex logistics and ensure compliance with import regulations, which can vary significantly by region. -

Are there customization options available for hydrogen fuel cell cars sourced from China?

Yes, many Chinese manufacturers offer customization options for hydrogen fuel cell cars, including modifications for specific regional standards, branding, and design features. Discuss your requirements with potential suppliers early in the negotiation process. Keep in mind that extensive customization may lead to longer lead times and higher costs, so factor this into your planning. -

What are the potential challenges of sourcing hydrogen fuel cell cars from China?

Potential challenges include language barriers, cultural differences in business practices, and varying standards of quality and service. Additionally, navigating the regulatory environment for vehicle imports can be complex. It’s vital to establish clear communication and build strong relationships with suppliers. Engaging local experts or consultants familiar with the Chinese market can also help mitigate these challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hydrogen fuel cell cars china

As the global automotive landscape shifts towards sustainable energy solutions, the strategic sourcing of hydrogen fuel cell cars in China presents a unique opportunity for international B2B buyers. Key takeaways highlight the importance of understanding local supply chains, forming partnerships with reliable manufacturers, and leveraging China’s advanced technological capabilities. These factors not only enhance product quality but also significantly reduce costs and lead times.

International buyers from Africa, South America, the Middle East, and Europe should focus on establishing long-term relationships with Chinese suppliers, ensuring that they are well-versed in both market trends and regulatory frameworks. This proactive approach to sourcing can mitigate risks associated with supply chain disruptions while optimizing procurement strategies.

Looking ahead, the hydrogen fuel cell vehicle market in China is poised for exponential growth, driven by governmental support and increasing environmental awareness. Now is the time for B2B buyers to engage with this evolving sector. By aligning with innovative suppliers and embracing strategic sourcing practices, businesses can not only enhance their competitive edge but also contribute to a more sustainable future. Take the initiative today to explore partnerships that will position your business at the forefront of this transformative market.