Upgrade Your Ride: The Ultimate 99 Chevy Silverado Custom Guide (2025)

Introduction: Navigating the Global Market for 99 chevy silverado custom

Navigating the global market for a 1999 Chevy Silverado custom can present unique challenges, particularly for international B2B buyers seeking reliable suppliers. One of the key hurdles is identifying trustworthy vendors who can provide high-quality custom parts and services tailored to specific needs. This guide is designed to streamline the sourcing process, offering insights into various customization options, applications, and the latest trends in the aftermarket industry.

In this comprehensive resource, we will explore a range of topics, including the types of customizations available for the 1999 Chevy Silverado, effective supplier vetting strategies, and an overview of pricing structures. Additionally, we will delve into the importance of understanding regional market differences, particularly for buyers from Africa, South America, the Middle East, and Europe, including key markets like Turkey and Mexico.

By equipping B2B buyers with the necessary knowledge and tools, this guide empowers you to make informed purchasing decisions that enhance your business operations. Whether you’re looking for performance upgrades, aesthetic modifications, or reliable repair parts, understanding the landscape of the global market for custom Chevy Silverados will help you navigate potential pitfalls and capitalize on opportunities for growth.

Understanding 99 chevy silverado custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 99 Chevy Silverado Custom 1500 | Standard features with options for enhanced payload and towing capabilities. | Construction, logistics, and transportation services. | Pros: Good balance of power and efficiency. Cons: Limited off-road capabilities compared to other models. |

| 99 Chevy Silverado Custom 2500 | Heavy-duty construction with increased towing capacity and payload. | Heavy machinery transport and commercial hauling. | Pros: Exceptional durability and power. Cons: Higher initial cost and lower fuel efficiency. |

| 99 Chevy Silverado Custom 3500 | Dual rear wheels for maximum stability and towing capacity. | Large-scale logistics and fleet operations. | Pros: Best-in-class towing capabilities. Cons: Bulkier size may limit maneuverability. |

| 99 Chevy Silverado Custom Sport | Sporty design with upgraded suspension and performance features. | Fleet services requiring a blend of utility and style. | Pros: Enhanced handling and aesthetics. Cons: Compromised cargo capacity for style. |

| 99 Chevy Silverado Custom LT | Luxury trim with advanced comfort features and technology. | Executive transport and high-end service industries. | Pros: Superior comfort and features. Cons: Higher maintenance costs and less rugged for heavy-duty use. |

What Are the Key Characteristics of the 99 Chevy Silverado Custom 1500?

The 99 Chevy Silverado Custom 1500 is a versatile pickup that balances performance with efficiency. It features a robust V8 engine, making it suitable for light to moderate hauling tasks. B2B buyers in construction or logistics can benefit from its payload capacity, which is ideal for transporting tools and materials. However, its off-road capabilities are limited compared to heavier-duty models, which may be a consideration for buyers in rugged environments.

How Does the 99 Chevy Silverado Custom 2500 Stand Out?

The Custom 2500 variant is designed for heavy-duty applications, offering superior towing capacity and payload capabilities. This model is particularly suitable for businesses involved in heavy machinery transport or commercial hauling, where reliability and strength are paramount. B2B buyers should note that while this model is powerful, it comes with a higher initial purchase price and lower fuel efficiency, which could impact operating costs.

Why Consider the 99 Chevy Silverado Custom 3500 for Your Business?

The Custom 3500 model features dual rear wheels, enhancing its stability and towing capacity, making it ideal for large-scale logistics and fleet operations. Its ability to handle substantial loads makes it a favorite among businesses that require robust transportation solutions. However, its larger size can make maneuvering in tight spaces challenging, which is an important consideration for urban deliveries.

What Are the Advantages of the 99 Chevy Silverado Custom Sport?

The Custom Sport variant offers a sporty design with upgraded suspension and performance features, appealing to B2B buyers who need a vehicle that combines utility with aesthetic appeal. It’s well-suited for fleet services that require a mix of style and functionality. Nonetheless, buyers should be aware that the focus on performance may compromise cargo capacity, making it less ideal for heavy hauling.

How Does the 99 Chevy Silverado Custom LT Enhance Executive Transport?

The Custom LT is the luxury trim of the Silverado, equipped with advanced comfort features and technology, making it suitable for executive transport and high-end service industries. B2B buyers will appreciate its superior comfort and amenities, which can enhance the client experience. However, potential buyers should consider the higher maintenance costs associated with luxury vehicles, as well as its reduced ruggedness compared to more utilitarian models.

Related Video: Silverado CUSTOM TRAIL BOSS vs LT TRAIL BOSS ~ What’s the difference?

Key Industrial Applications of 99 chevy silverado custom

| Industry/Sector | Specific Application of 99 Chevy Silverado Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty transport for materials and tools | Increases operational efficiency and reduces downtime | Ensure compatibility with local terrain and load capacities |

| Agriculture | Farming equipment transport and utility vehicle | Enhances productivity and mobility on farms | Evaluate engine performance and fuel efficiency for rural areas |

| Logistics & Freight | Delivery vehicle for goods and services | Streamlines logistics processes and reduces costs | Focus on payload capacity and reliability for long-distance transport |

| Oil & Gas | Field service vehicle for remote locations | Improves access to hard-to-reach sites | Assess durability and off-road capability for rugged environments |

| Tourism & Recreation | Shuttle service for tourists and outdoor activities | Boosts customer satisfaction and expands service offerings | Consider passenger capacity and comfort features for diverse clientele |

How is the 99 Chevy Silverado Custom Used in Construction?

In the construction sector, the 99 Chevy Silverado Custom serves as a heavy-duty transport vehicle, crucial for moving materials and tools to and from job sites. Its robust design allows for the transport of significant loads, which is essential for maintaining project timelines and reducing downtime. For international B2B buyers, particularly from regions with challenging terrains, sourcing vehicles that meet local regulations and have appropriate load capacities is vital to ensure operational efficiency.

What Role Does the 99 Chevy Silverado Custom Play in Agriculture?

The Silverado Custom is increasingly popular in agriculture as a versatile utility vehicle, adept at transporting farming equipment and supplies. Its adaptability allows farmers to navigate various terrains, enhancing productivity and mobility on expansive farms. Buyers in regions like Africa and South America should prioritize models with strong engine performance and fuel efficiency to maximize operational effectiveness in rural settings, where access to resources can be limited.

How is the 99 Chevy Silverado Custom Applied in Logistics & Freight?

In logistics, the 99 Chevy Silverado Custom acts as an efficient delivery vehicle, capable of transporting goods and services across urban and rural landscapes. This capability streamlines logistics processes, leading to reduced operational costs and improved service delivery. For international buyers, it’s crucial to assess payload capacity and reliability, especially for long-distance transport in diverse climates, ensuring that the vehicle can withstand varying conditions.

How Does the 99 Chevy Silverado Custom Support the Oil & Gas Industry?

The oil and gas industry utilizes the Silverado Custom as a field service vehicle, essential for accessing remote locations where traditional vehicles may struggle. Its durability and off-road capabilities make it ideal for rugged environments, facilitating the transport of personnel and equipment to hard-to-reach sites. Buyers from the Middle East and other oil-rich regions should focus on sourcing models that are equipped for extreme conditions, ensuring longevity and reliability in field operations.

What Advantages Does the 99 Chevy Silverado Custom Offer to the Tourism Sector?

In the tourism and recreation sector, the 99 Chevy Silverado Custom is frequently used as a shuttle service vehicle, enhancing the experience for tourists and outdoor enthusiasts. Its spacious interior and comfort features make it suitable for transporting groups, which can significantly boost customer satisfaction. For European buyers, especially in countries with a high influx of tourists, considering passenger capacity and additional comfort features is essential to cater to diverse clientele needs and preferences.

Related Video: How We Built the Ultimate Cammed / Supercharged NBS Silverado Street Truck

3 Common User Pain Points for ’99 chevy silverado custom’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Replacement Parts for ’99 Chevy Silverado Custom

The Problem:

B2B buyers often encounter challenges when sourcing high-quality replacement parts for the ’99 Chevy Silverado Custom. This vehicle is over two decades old, which complicates the availability of OEM (Original Equipment Manufacturer) parts. Buyers may face issues such as counterfeit products, inconsistent quality, and inflated prices from unreliable suppliers. These challenges not only affect repair timelines but can also compromise vehicle performance, leading to increased operational costs.

The Solution:

To effectively source quality replacement parts, B2B buyers should establish relationships with reputable suppliers who specialize in classic truck parts. Start by identifying suppliers with a strong reputation in the industry, evidenced by customer reviews and ratings. It’s beneficial to attend automotive trade shows or join online forums dedicated to classic vehicles, where buyers can connect with trusted vendors.

Additionally, consider using certified aftermarket parts, which can offer similar quality to OEM parts at lower prices. Always request warranties on parts to ensure reliability. Implementing a systematic approach to part procurement, such as maintaining a database of reliable suppliers and regularly reviewing their performance, can significantly streamline the sourcing process. Furthermore, leveraging bulk purchasing agreements can provide cost savings and ensure a steady supply of parts.

Scenario 2: Ensuring Compliance with International Vehicle Standards

The Problem:

International B2B buyers of the ’99 Chevy Silverado Custom frequently face compliance issues related to different vehicle regulations and standards. Countries in Africa, South America, the Middle East, and Europe have varying emissions, safety, and import standards. Non-compliance can lead to costly delays, fines, and even the rejection of shipments, which directly impacts business operations and customer satisfaction.

The Solution:

To navigate these regulatory challenges, buyers should conduct thorough research on the specific vehicle regulations in their target markets. This includes understanding emissions requirements, safety standards, and import tariffs. Collaborating with local automotive compliance consultants or legal experts can provide valuable insights into the applicable regulations.

Furthermore, when importing vehicles or parts, ensure that all necessary documentation is in order, including compliance certificates and proof of emissions testing. Establishing a robust compliance checklist before shipments can minimize risks associated with regulatory violations. By proactively addressing compliance issues, buyers can streamline their operations and avoid potential setbacks in their business dealings.

Scenario 3: Managing Customization Needs for Diverse Markets

The Problem:

B2B buyers may struggle to meet the diverse customization needs of clients for the ’99 Chevy Silverado Custom. Different markets have varying preferences for vehicle features, aesthetics, and functionalities, which can make it challenging to deliver tailored solutions that satisfy all customer demands. Failure to address these needs can result in lost sales opportunities and dissatisfied customers.

The Solution:

To effectively manage customization requirements, B2B buyers should conduct market research to understand the specific preferences of their target audience in different regions. Utilizing surveys, focus groups, or customer feedback can provide insights into what features are most sought after in each market.

Once these preferences are identified, buyers should collaborate with skilled automotive customization specialists who can help design and implement modifications that cater to these needs. This may involve partnerships with local workshops or manufacturers that understand regional tastes and requirements. Additionally, keeping an inventory of popular customization options can allow for quicker turnaround times and enhance customer satisfaction. By being responsive to market demands and offering tailored solutions, buyers can differentiate themselves in a competitive landscape and build long-lasting customer relationships.

Strategic Material Selection Guide for 99 chevy silverado custom

What Are the Key Materials for the 1999 Chevy Silverado Custom?

When selecting materials for the 1999 Chevy Silverado Custom, it is essential to consider various properties that affect performance, durability, and overall suitability for specific applications. Here, we analyze four common materials used in the manufacturing and customization of this vehicle, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Which Metals Are Commonly Used in the 1999 Chevy Silverado Custom?

Steel

Steel is a widely used material in the construction of the Silverado’s frame and body panels due to its strength and durability.

- Key Properties: High tensile strength, good impact resistance, and weldability. It can withstand high pressures and temperatures, making it suitable for various automotive applications.

- Pros & Cons: Steel is relatively inexpensive and provides excellent durability. However, it is prone to corrosion if not properly treated or coated, which can lead to increased maintenance costs.

- Impact on Application: Steel’s strength makes it ideal for structural components, but its weight can affect fuel efficiency.

- Considerations for International Buyers: Compliance with standards such as ASTM A36 (for structural steel) is crucial. Buyers should also consider local corrosion resistance requirements, especially in humid or coastal regions.

Aluminum

Aluminum is increasingly popular in automotive applications due to its lightweight nature.

- Key Properties: Excellent corrosion resistance, lightweight, and good thermal conductivity. Aluminum can handle moderate temperatures but may not be suitable for high-pressure applications without proper alloying.

- Pros & Cons: The primary advantage of aluminum is its weight reduction, which can enhance fuel efficiency. However, it is generally more expensive than steel and may require specialized welding techniques.

- Impact on Application: Aluminum is ideal for body panels and components where weight savings are critical. It performs well in environments where corrosion is a concern.

- Considerations for International Buyers: Compliance with standards like ASTM B221 (for aluminum extrusions) is important. Additionally, buyers should be aware of the availability of aluminum alloys in their region.

What Are the Benefits of Using Composites in the 1999 Chevy Silverado Custom?

Fiberglass Reinforced Plastics (FRP)

FRP is used in various applications, including body kits and interior components.

- Key Properties: Lightweight, high strength-to-weight ratio, and excellent corrosion resistance. FRP can be molded into complex shapes, making it ideal for custom designs.

- Pros & Cons: FRP is durable and resistant to environmental factors. However, it can be more expensive to manufacture and repair compared to traditional materials.

- Impact on Application: FRP is suitable for aesthetic components and parts exposed to moisture. It does not conduct heat or electricity, making it safe for various applications.

- Considerations for International Buyers: Buyers should consider the manufacturing capabilities in their region for FRP and ensure compliance with relevant standards like ASTM D638 (for tensile properties of plastics).

How Does Rubber Play a Role in the 1999 Chevy Silverado Custom?

Rubber

Rubber is essential for various seals, gaskets, and suspension components in the Silverado.

- Key Properties: Excellent flexibility, resilience, and resistance to wear and tear. Rubber can withstand a range of temperatures, though it may degrade under extreme conditions.

- Pros & Cons: Rubber provides effective sealing and vibration dampening. However, it can be susceptible to degradation from UV exposure and certain chemicals.

- Impact on Application: Rubber is crucial for maintaining vehicle integrity by preventing leaks and providing a smooth ride.

- Considerations for International Buyers: Compliance with standards such as ASTM D2000 (for rubber materials) is essential. Buyers should also consider the climate in their region, as extreme temperatures can affect rubber performance.

Summary Table of Material Selection for 1999 Chevy Silverado Custom

| Material | Typical Use Case for 99 Chevy Silverado Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and body panels | High strength and durability | Prone to corrosion | Low |

| Aluminum | Body panels and lightweight components | Lightweight, enhances fuel efficiency | Higher cost and specialized welding | Medium |

| Fiberglass Reinforced Plastics | Body kits and interior components | Lightweight and corrosion resistant | More expensive to manufacture | High |

| Rubber | Seals, gaskets, and suspension components | Effective sealing and vibration dampening | Degradation under UV exposure | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing materials for the 1999 Chevy Silverado Custom. Understanding the properties, advantages, and limitations of each material is crucial for ensuring compliance with local standards and optimizing performance.

In-depth Look: Manufacturing Processes and Quality Assurance for 99 chevy silverado custom

What Are the Main Stages of Manufacturing for the 1999 Chevy Silverado Custom?

The manufacturing process for the 1999 Chevy Silverado Custom involves several critical stages, each contributing to the overall quality and functionality of the vehicle. Understanding these stages is essential for B2B buyers who are looking to source parts or complete vehicles.

1. Material Preparation

The first stage in manufacturing begins with the selection and preparation of raw materials. High-strength steel, aluminum alloys, and composite materials are commonly used in the Silverado’s construction. Suppliers must ensure that materials meet specific standards for durability and weight efficiency. This preparation often involves cutting, shaping, and treating materials to enhance their properties, such as corrosion resistance.

2. Forming Techniques

Once the materials are prepared, various forming techniques are employed. This includes stamping, bending, and machining operations that shape the vehicle’s components. For the Silverado, processes like hydroforming and press forming are vital for creating complex shapes that enhance both aesthetics and structural integrity. Utilizing advanced CNC (Computer Numerical Control) machines allows for precise shaping, which is essential for maintaining consistent quality across batches.

3. Assembly Process

The assembly stage is where the Silverado comes to life. Components such as the chassis, body, and engine are brought together on an assembly line. This process is highly automated, often using robotic arms for tasks like welding and painting. The precision of these machines ensures that parts fit together seamlessly, reducing the risk of defects. Additionally, assembly lines typically incorporate lean manufacturing principles to minimize waste and improve efficiency.

4. Finishing Touches

After assembly, the vehicle undergoes finishing processes, which include painting and quality checks. The paint application is crucial, not just for aesthetics but also for protection against environmental factors. B2B buyers should pay attention to the types of paints and coatings used, as these can affect the vehicle’s longevity and maintenance needs.

How Is Quality Assurance Implemented in the Manufacturing of the 1999 Chevy Silverado Custom?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that each vehicle meets international standards and customer expectations. For B2B buyers, understanding these QA processes can aid in making informed purchasing decisions.

International Standards and Certifications

Manufacturers of the 1999 Chevy Silverado Custom typically adhere to international quality standards, such as ISO 9001. This standard focuses on continuous improvement and customer satisfaction, requiring manufacturers to establish quality management systems. Additionally, industry-specific certifications, such as CE marking for compliance with European safety standards, may also be relevant.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet predetermined specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, various inspections and tests are conducted to monitor quality at different stages, ensuring that any deviations are addressed immediately.

- Final Quality Control (FQC): Once the vehicle is fully assembled, a comprehensive inspection is performed. This may include functional tests, aesthetic evaluations, and safety checks to ensure the vehicle is ready for the market.

What Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are employed to verify the quality of the 1999 Chevy Silverado Custom. These methods help in assessing both the performance and safety of the vehicle:

- Destructive Testing: While not commonly used on finished vehicles, this method can be employed on prototypes to assess material strength and durability.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and radiographic testing are utilized to detect internal flaws without damaging the components.

- Performance Testing: This includes road testing to evaluate handling, braking, and overall drivability under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is crucial for ensuring product reliability. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess a supplier’s manufacturing processes, quality management systems, and adherence to standards.

- Quality Reports: Requesting detailed QC reports can provide insight into a supplier’s testing methods, defect rates, and overall performance metrics.

- Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance, providing unbiased evaluations of the supplier’s products before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be challenging for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here are some nuances to consider:

- Regulatory Compliance: Different regions have varying regulatory requirements. For instance, vehicles exported to Europe must comply with stricter emissions and safety regulations compared to those in other markets.

- Cultural Factors: Understanding local business practices and cultural nuances can facilitate better communication and negotiation with suppliers.

- Language Barriers: Language differences can complicate the verification of quality standards. It may be beneficial to work with local partners or translators who can bridge this gap.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make more informed decisions when sourcing the 1999 Chevy Silverado Custom, ensuring they select suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ’99 chevy silverado custom’

In the competitive landscape of sourcing parts for the ’99 Chevy Silverado Custom, international B2B buyers must navigate various considerations to ensure a successful procurement process. This step-by-step checklist provides actionable insights to streamline your sourcing efforts, particularly for buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before initiating the sourcing process. Determine the specific parts or features required for the ’99 Chevy Silverado Custom, including engine specifications, body styles, and additional customizations. This clarity will help you communicate effectively with suppliers and avoid unnecessary costs or delays.

- Key Considerations:

- Identify OEM (Original Equipment Manufacturer) versus aftermarket parts.

- Specify any compatibility requirements with existing vehicle systems.

Step 2: Conduct Market Research on Suppliers

Understanding the market landscape is essential for identifying potential suppliers. Research reputable suppliers who specialize in automotive parts, specifically for the ’99 Chevy Silverado Custom. Utilize online platforms, trade shows, and industry publications to gather information.

- Recommended Actions:

- Check online marketplaces and directories for verified suppliers.

- Explore forums and social media groups for recommendations and reviews.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, thorough evaluation is necessary. Look for suppliers with a proven track record in the automotive industry. Request company profiles, case studies, and references from buyers in similar regions or industries to assess their credibility.

- What to Look For:

- Supplier certifications (ISO, IATF, etc.).

- Customer testimonials that demonstrate reliability and quality.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request detailed quotes for the required parts. Ensure that the quotes include shipping costs, lead times, and payment terms. This comparison will help you identify the best value for your investment.

- Important Factors to Compare:

- Total cost of ownership, including shipping and potential duties.

- Payment terms and conditions to avoid cash flow issues.

Step 5: Verify Quality Assurance Processes

Quality assurance is vital when sourcing automotive parts. Inquire about the quality control measures suppliers have in place to ensure that all parts meet industry standards and specifications. This step minimizes the risk of defects or compatibility issues.

- Quality Assurance Checks:

- Request documentation of testing procedures.

- Confirm that parts comply with relevant regulations in your region.

Step 6: Assess Logistics and Shipping Options

Understanding the logistics involved in shipping is critical for timely delivery. Assess the shipping options offered by suppliers, including transit times and tracking capabilities. This insight helps you plan your inventory management more effectively.

- Key Logistics Considerations:

- Evaluate shipping methods (air freight vs. sea freight).

- Confirm the supplier’s ability to handle customs and import regulations.

Step 7: Establish a Communication Plan

Effective communication with your supplier is essential throughout the sourcing process. Establish a clear communication plan that includes regular updates and points of contact. This approach fosters a strong working relationship and ensures that any issues are addressed promptly.

- Best Practices:

- Schedule regular check-ins to discuss progress and concerns.

- Utilize collaborative tools for tracking orders and feedback.

By following this checklist, B2B buyers can enhance their sourcing strategy for the ’99 Chevy Silverado Custom, ensuring a smoother procurement process and better overall satisfaction with their suppliers.

Comprehensive Cost and Pricing Analysis for 99 chevy silverado custom Sourcing

What Are the Key Cost Components for Sourcing a 1999 Chevy Silverado Custom?

When sourcing a 1999 Chevy Silverado custom, understanding the cost structure is critical for B2B buyers. The main components of cost include:

-

Materials: The selection of materials significantly impacts the overall cost. High-quality steel, aluminum, and custom parts can drive prices higher. Buyers should consider sourcing from local suppliers to minimize costs associated with shipping and tariffs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In areas with higher labor costs, such as Europe, negotiating labor rates or considering outsourcing to countries with lower labor expenses could be beneficial.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Understanding the overhead costs of potential suppliers can help buyers assess total pricing accurately.

-

Tooling: Custom parts may require specialized tooling, which can be a significant upfront cost. Buyers should discuss tooling costs upfront to avoid surprises later in the production process.

-

Quality Control (QC): Implementing strict QC processes can increase costs but is essential for maintaining product quality. Buyers should inquire about the QC measures suppliers have in place.

-

Logistics: Transportation costs can vary widely based on distance and shipping methods. For international shipments, consider Incoterms that outline shipping responsibilities and costs.

-

Margin: Suppliers will typically include a margin to ensure profitability. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Impact the Sourcing of a Custom Silverado?

Several factors influence the pricing of a custom Silverado:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Buyers should assess their needs and consider negotiating MOQs with suppliers to achieve better pricing.

-

Specifications and Customization: The more customized the vehicle, the higher the price. Be clear about your specifications to avoid unexpected costs. If possible, standardize certain elements to keep costs down.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO) can lead to higher prices but ensure durability and compliance with safety standards. Buyers should weigh the long-term benefits against initial costs.

-

Supplier Factors: Supplier reputation, experience, and reliability can impact pricing. Conducting due diligence on potential suppliers can help identify those who provide the best value for money.

-

Incoterms: Understanding the terms of shipping (like FOB, CIF, etc.) can affect the final landed cost of the vehicle. These terms dictate who is responsible for transportation costs and risks, influencing the overall budget.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

When negotiating for a 1999 Chevy Silverado custom, consider the following strategies:

-

Establish Relationships: Building a rapport with suppliers can lead to better pricing and terms. Long-term relationships often yield favorable negotiations.

-

Understand Total Cost of Ownership (TCO): Buyers should look beyond the initial purchase price and consider maintenance, warranty, and potential resale value. A higher upfront cost may lead to lower overall costs in the long run.

-

Be Transparent About Budgets: Sharing budget constraints with suppliers can encourage them to propose more tailored solutions that meet your needs while staying within financial limits.

-

Leverage Competitive Quotes: Obtaining multiple quotes can provide leverage in negotiations. Use this information to negotiate better terms and pricing with your preferred supplier.

-

Timing and Flexibility: Being flexible with timelines can lead to better pricing. Suppliers may offer discounts for orders that fit their production schedules.

What Should International Buyers from Africa, South America, the Middle East, and Europe Consider?

International buyers face unique challenges and opportunities:

-

Currency Fluctuations: Be aware of currency exchange rates and their potential impact on pricing. Locking in rates or using forward contracts can mitigate risks.

-

Regulatory Compliance: Understand the import regulations and tariffs that apply in your region. Compliance can affect total costs and timelines.

-

Cultural Differences: Familiarize yourself with cultural nuances in negotiations. This can help build trust and facilitate smoother transactions.

-

Local Partnerships: Establishing partnerships with local agents or distributors can simplify the sourcing process and improve logistics management.

Are Prices Indicative and Subject to Change?

It’s essential to note that prices for sourcing a 1999 Chevy Silverado custom are indicative and can fluctuate based on market conditions, supplier pricing strategies, and changes in material costs. Buyers should conduct thorough market research and remain adaptable in their sourcing strategies to ensure they secure the best possible deals.

Alternatives Analysis: Comparing 99 chevy silverado custom With Other Solutions

When considering the purchase of a vehicle for commercial purposes, evaluating alternatives to the 1999 Chevy Silverado Custom can provide valuable insights. This section explores two viable alternatives, enabling international B2B buyers to make informed decisions based on their specific needs and operational requirements.

Comparison Table of Alternatives

| Comparison Aspect | ’99 Chevy Silverado Custom | Ford F-150 (1999) | Dodge Ram 1500 (1999) |

|---|---|---|---|

| Performance | Reliable V8 engine, good towing capacity | Strong V8 engine, best-in-class towing | Capable V8 engine, rugged performance |

| Cost | Moderate upfront cost, good resale value | Slightly higher initial cost | Competitive pricing, excellent warranty |

| Ease of Implementation | Standard features, easy to customize | User-friendly features, extensive aftermarket support | Versatile configurations, good aftermarket options |

| Maintenance | Low maintenance, widespread parts availability | Moderate maintenance, good parts support | Moderate maintenance, solid parts availability |

| Best Use Case | General commercial use, light to medium hauling | Heavy-duty hauling, off-road use | Versatile for work and leisure |

In-Depth Analysis of Alternatives

Ford F-150 (1999): What Makes It a Strong Contender?

The Ford F-150 of the same year is renowned for its strong performance, particularly in towing capabilities. It features a robust V8 engine that outperforms many competitors in terms of power and reliability. The F-150 also has a slightly higher upfront cost but offers extensive aftermarket support, making it easier to customize for specific business needs. However, its maintenance can be moderate, requiring attention to keep it in peak condition. This vehicle is best suited for businesses that require heavy-duty hauling or have off-road needs.

Dodge Ram 1500 (1999): How Does It Compare?

The Dodge Ram 1500 stands out for its rugged performance and competitive pricing. It offers a capable V8 engine that delivers solid power for various tasks, making it a versatile choice for many businesses. The Ram 1500 provides good warranty options, which can be a significant advantage for B2B buyers concerned about long-term reliability. However, maintenance can be moderate, and potential buyers should consider the availability of parts in their region. This vehicle is well-suited for companies looking for a reliable workhorse that can also double as a leisure vehicle.

Conclusion: How to Choose the Right Vehicle for Your Needs

In selecting the right vehicle, B2B buyers should assess their specific operational requirements and budget constraints. The ’99 Chevy Silverado Custom is an excellent option for general commercial use, but alternatives like the Ford F-150 and Dodge Ram 1500 may offer superior performance in specific areas such as towing and customization. By weighing the benefits and drawbacks of each vehicle, buyers can make a well-informed choice that aligns with their business goals and operational demands.

Essential Technical Properties and Trade Terminology for 99 chevy silverado custom

What Are the Essential Technical Properties of the 1999 Chevy Silverado Custom?

When considering the 1999 Chevy Silverado Custom for international trade, understanding its technical properties is crucial for B2B buyers. Here are several key specifications that should be on your radar:

-

Material Grade

The Silverado utilizes high-strength steel for its frame and body components. This material grade ensures durability and resistance to corrosion, which is particularly important for vehicles operating in diverse climates across Africa, South America, and the Middle East. Understanding the material properties can help buyers assess the longevity and maintenance needs of the vehicle. -

Engine Specifications

The 1999 model comes with a variety of engine options, including a 4.3L V6 and a 5.7L V8. The choice of engine impacts performance, fuel efficiency, and maintenance costs. Buyers should evaluate which engine configuration aligns with their operational requirements and local fuel availability. -

Towing Capacity

With a towing capacity of up to 7,200 lbs (3,266 kg), the Silverado is well-suited for businesses needing to transport heavy loads. This specification is vital for logistics companies and tradespeople who require reliable towing capabilities for trailers or heavy equipment. -

Payload Capacity

The payload capacity of the Silverado Custom ranges from 1,500 lbs to 2,200 lbs (680 kg to 998 kg), depending on the configuration. For B2B buyers, knowing the payload capacity is essential for ensuring that the vehicle can handle daily operational demands without compromising performance. -

Fuel Economy

The Silverado averages 15-20 miles per gallon (mpg), depending on engine choice and driving conditions. Fuel economy is a significant factor for international buyers, as it directly influences operational costs and environmental impact, especially in regions with fluctuating fuel prices. -

Safety Ratings

The 1999 Chevy Silverado received favorable safety ratings, which can be a crucial selling point for companies prioritizing employee safety. Understanding the safety features and ratings can help buyers make informed decisions when selecting vehicles for their fleet.

What Trade Terminology Should B2B Buyers Understand for the 1999 Chevy Silverado Custom?

Navigating the complexities of international trade requires familiarity with specific jargon. Here are essential terms relevant to the procurement of the 1999 Chevy Silverado Custom:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the parts that are used in the vehicle. For B2B buyers, working with OEM parts ensures compatibility and reliability, which is crucial for fleet maintenance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ helps buyers negotiate better terms and manage inventory levels effectively, especially when dealing with multiple vehicle purchases. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products. It is essential for comparing prices and securing the best deals when purchasing multiple units of the Silverado. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers avoid misunderstandings and ensure smooth transactions. -

Lead Time

This term refers to the time taken from placing an order to receiving the goods. For international buyers, understanding lead times is critical for planning and logistics, especially when coordinating with local markets. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the vehicle and its parts. Knowing the warranty terms can help buyers assess the long-term value and support available for their investment.

Understanding these technical properties and trade terms not only aids in making informed purchasing decisions but also enhances the efficiency of operations across diverse markets.

Navigating Market Dynamics and Sourcing Trends in the 99 chevy silverado custom Sector

What Are the Current Market Dynamics for the 99 Chevy Silverado Custom Sector?

The market for the 1999 Chevy Silverado Custom is influenced by several global drivers, including the rising demand for customization and the increasing availability of aftermarket parts. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking tailored solutions that enhance vehicle performance and aesthetics. Current trends indicate a shift towards e-commerce platforms that offer a wide range of parts and accessories, allowing buyers to compare prices and features easily. Additionally, the integration of advanced technology such as augmented reality (AR) for visualizing custom modifications is gaining traction, enhancing the shopping experience.

Emerging sourcing trends include the use of digital marketplaces that connect buyers directly with suppliers, thereby reducing lead times and costs. Businesses are also leveraging data analytics to forecast demand and optimize inventory levels, which is particularly crucial for parts that are specific to the 1999 Chevy Silverado Custom. Furthermore, sustainability is becoming a priority, with manufacturers focusing on eco-friendly materials and production processes to meet the expectations of socially conscious consumers.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the 99 Chevy Silverado Custom Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the automotive sector. The environmental impact of vehicle customization can be significant, particularly concerning the materials used and the waste generated during the modification process. Buyers should prioritize suppliers who adopt sustainable practices, such as using recycled materials or eco-friendly coatings for parts.

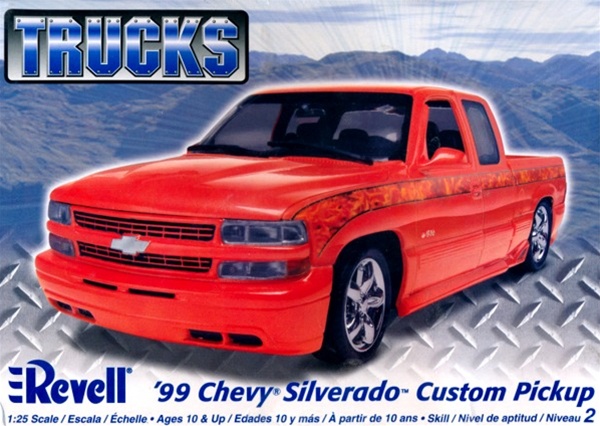

A stock image related to 99 chevy silverado custom.

Certifications such as ISO 14001 for environmental management systems and SFI (Sustainable Forestry Initiative) for wood-based materials are indicators of a supplier’s commitment to sustainability. By opting for suppliers with these certifications, buyers can ensure that their sourcing decisions align with global sustainability goals. Additionally, investing in local suppliers can reduce transportation emissions and support community economies.

Ethical sourcing is equally important. Buyers should conduct due diligence to ensure that their suppliers adhere to fair labor practices and do not exploit workers. This includes verifying that suppliers provide safe working conditions and fair wages. By fostering ethical supply chains, B2B buyers can enhance their brand reputation and appeal to a growing segment of environmentally and socially conscious consumers.

How Has the 99 Chevy Silverado Custom Evolved Over Time?

The 1999 Chevy Silverado Custom is part of a lineage that has seen significant evolution in both design and functionality. Initially introduced as a reliable workhorse, the Silverado quickly gained popularity for its versatility and customization options. Over the years, the aftermarket industry has expanded, offering a plethora of parts that cater to various preferences, from performance upgrades to aesthetic enhancements.

This evolution has been marked by the introduction of advanced materials and technologies, allowing for lighter, stronger components that improve vehicle performance. As customization became a cultural trend, the Silverado has transformed from a utilitarian vehicle into a canvas for personal expression, appealing to a broad range of consumers—from contractors to car enthusiasts. This historical context underlines the importance of understanding market trends and sourcing strategies for B2B buyers looking to capitalize on the Silverado’s enduring popularity.

Frequently Asked Questions (FAQs) for B2B Buyers of 99 chevy silverado custom

-

How do I choose the right supplier for sourcing a 99 Chevy Silverado custom?

Selecting the right supplier involves thorough research and vetting. Begin by evaluating suppliers’ reputations through online reviews and testimonials from previous clients. Ensure they specialize in custom vehicles and have experience with the 1999 Chevy Silverado. Request references and verify their quality assurance processes. Additionally, assess their ability to meet your specific customization needs and their compliance with international shipping regulations. -

What customization options are available for the 1999 Chevy Silverado?

Customization options for the 1999 Chevy Silverado can include modifications to the body, engine, suspension, and interior. Buyers can select enhancements such as aftermarket wheels, paint jobs, upgraded audio systems, and performance tuning. It’s important to communicate your specific requirements to the supplier and confirm their capability to deliver the desired modifications while adhering to safety standards. -

What are the minimum order quantities (MOQ) for purchasing 99 Chevy Silverado customs?

Minimum order quantities can vary significantly between suppliers, typically ranging from one unit for specialized custom orders to larger quantities for bulk purchases. When engaging with suppliers, clarify their MOQ policies, as this will impact your purchasing strategy. It’s beneficial to negotiate terms that align with your business model, especially if you plan to serve a diverse clientele in multiple regions. -

What payment terms should I expect when sourcing a 99 Chevy Silverado custom?

Payment terms can vary widely among suppliers. Most will require a deposit upfront, often between 30-50%, with the balance due upon delivery or before shipping. Ensure to discuss and negotiate terms that are favorable for your cash flow, such as installment payments or net terms. Additionally, confirm accepted payment methods, as international transactions may involve currency conversion fees. -

How can I ensure quality assurance when sourcing a custom vehicle?

To ensure quality, ask suppliers about their quality control processes, including inspections and testing of vehicles before shipment. Request detailed documentation of these procedures and, if possible, arrange for third-party inspections. Establishing a clear agreement on quality standards and expectations in your contract can also help safeguard your investment and ensure compliance with your specifications.

A stock image related to 99 chevy silverado custom.

-

What logistics considerations should I keep in mind when importing a custom Silverado?

Logistics are crucial when importing custom vehicles. Consider the shipping methods, such as container shipping or roll-on/roll-off services, and understand the associated costs. Research customs regulations in your destination country to avoid delays and additional fees. Collaborating with a logistics partner experienced in automotive imports can streamline the process and ensure compliance with all legal requirements. -

How do tariffs and duties affect the cost of importing a 99 Chevy Silverado custom?

Tariffs and duties can significantly impact the total cost of importing vehicles. Each country has different regulations regarding vehicle imports, and it’s essential to research applicable tariffs in your region. Contact local customs authorities or consult with a customs broker to understand these costs and factor them into your overall budget. Being informed can prevent unexpected expenses and delays. -

What are the best practices for negotiating with suppliers of custom vehicles?

Effective negotiation requires preparation and understanding of your needs and the supplier’s capabilities. Start by researching market prices and understanding the supplier’s cost structure. Clearly articulate your requirements and be open to compromises that still meet your needs. Building a relationship based on trust can also facilitate better terms and conditions, potentially leading to long-term partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 99 chevy silverado custom

How Can Strategic Sourcing Enhance Your Supply Chain for 99 Chevy Silverado Custom Parts?

In conclusion, strategic sourcing for the 99 Chevy Silverado custom presents a vital opportunity for international B2B buyers to optimize their supply chains. By leveraging local suppliers from regions such as Africa, South America, the Middle East, and Europe, businesses can enhance cost efficiency, reduce lead times, and ensure the availability of high-quality parts. The importance of establishing strong supplier relationships cannot be overstated; it fosters collaboration and innovation, which are essential for meeting the evolving demands of the automotive market.

What Are the Key Takeaways for B2B Buyers in Global Markets?

B2B buyers should prioritize a comprehensive analysis of their sourcing strategies, focusing on factors such as supplier reliability, quality assurance, and regulatory compliance. Additionally, embracing digital tools for sourcing can streamline procurement processes, making it easier to manage vendor relationships and track inventory levels.

What Does the Future Hold for B2B Sourcing of Chevy Silverado Parts?

Looking ahead, the landscape of automotive sourcing will continue to evolve with advancements in technology and shifts in consumer preferences. Buyers are encouraged to remain agile and adaptable, ready to explore new markets and innovative sourcing strategies. Engage with suppliers who share your commitment to quality and sustainability, and position your business for success in the competitive automotive industry.