Top 25 Wire Stripping Machine Companies Reviewed

Are you tired of dealing with unreliable wire stripping machines that just don’t cut it? You’re not alone! Many businesses struggle to find a trustworthy supplier that delivers quality and efficiency. Finding the right wire stripping machine can significantly boost your productivity and reduce downtime. With so many manufacturers out there, how do you choose the best? Imagine having a machine that’s not only reliable but also tailored to your specific needs.

The right factory can make all the difference in your operations. Ready to discover the top 30 wire stripping machine manufacturers? Dive into our article to find the perfect partner for your business success!

Top 25 Wire Stripping Machine Company Manufacturers

Bluerock Tools – Wire Stripping Machines

Domain: bluerocktools.com

Registered: 2011 ( 14 years )

Introduction: Blue Rock Tools offers a range of wire stripping machines designed for efficient and effective wire processing.

Bluedog Wire Stripper – Industrial Wire Stripping Machines

Domain: bluedogwirestripper.com

Registered: 2013 ( 12 years )

Introduction: Industrial wire stripping machines and recycling equipment including models like BWS-50 SAR, BWS-80 HD, BDG-8L Granulator, and BMC-10 Motor Recycling Machine.

CopperMine – Industrial Copper Wire Stripping Machines

Domain: copperminetools.com

Registered: 2013 ( 12 years )

Introduction: CopperMine offers industrial grade powered copper wire stripping machines designed to increase workplace efficiency and safety.

Stripmeister – Products

Domain: stripmeister.com

Registered: 2013 ( 12 years )

Introduction: StripMeister™ Original Drill Powered Wire Stripping Machine is engineered for superior performance, durability, and long-lasting reliability, capable of stripping 100% of household wires from #18 wire to 250 MCM.

Schleuniger – Wire Stripping and Processing Solutions

Domain: schleuniger.com

Registered: 1997 ( 28 years )

Introduction: Komax Group’s semi-automatic wire stripping machines handle wire stripping, jacket and shield processing, multilayer, laser, and fiber stripping. They offer high precision, flexibility, and repeatability — ideal for small to mid-sized batch production across diverse applications.

Genscoequip – Automatic Wire Stripping Machines

Domain: genscoequip.com

Registered: 1996 ( 29 years )

Introduction: Gensco offers a range of Automatic Wire Stripping Machines, specifically the CSX range, which includes table-top and self-standing models capable of stripping various types of wire and cable, including copper, aluminum, steel, and lead.

Eraser – Wire and Cable Stripping Solutions

Domain: eraser.com

Registered: 1995 ( 30 years )

Introduction: Eraser offers a range of wire and cable strippers, including thermal strippers, portable rotary strippers, and wheel strippers, designed for various insulation types and wire sizes.

Cozpalace – Automatic Wire Stripping Machines

Domain: cozpalace.com

Registered: 2020 ( 5 years )

Introduction: Automatic wire stripper machines designed for efficient and precise wire stripping.

Solidequip – Industrial Wire Stripping Machines

Domain: solidequip.com

Registered: 2016 ( 9 years )

Introduction: Solid Equip is a supplier of industrial wire strippers and wire stripping machines in the USA, offering a range of equipment for wire recycling and processing.

Creworks Equipment – Wire Stripping Machines Solutions

Domain: creworksequipment.com

Registered: 2021 ( 4 years )

Introduction: Creworks Equipment offers a range of manual and automotive wire stripping machines designed for efficient wire processing.

Komaxgroup – Semi-Automatic Wire Stripping Machines

Domain: komaxgroup.com

Registered: 2004 ( 21 years )

Introduction: Komax offers semi-automatic wire stripping machines that process a wide range of wires and cables with precision and repeatability, ensuring consistent stripping quality across various cross sections and materials.

Eubanks – Precision Wire Stripping Solutions

Domain: eubanks.com

Registered: 1996 ( 29 years )

Introduction: Eubanks Engineering offers a range of wire strippers including programmable machines, high-speed pneumatic wire strippers, and semi-automatic wire strippers.

Dmctools – Precision Wire Strippers

Domain: dmctools.com

Registered: 1997 ( 28 years )

Introduction: Wire strippers designed for various wire sizes and applications, offering precision and ease of use.

Speed Tech Engineering – Automatic Wire Stripping Machines

Domain: speedtechengg.com

Registered: 2022 ( 3 years )

Introduction: Automatic Wire Stripping Machine – Wire Stripping Machine B 13 manufactured by Speed Tech Engineering Co.

Stryker Machinery – Wire Stripping Machines

Domain: strykermachinery.com

Registered: 2024 ( 1 years )

Introduction: The company offers a range of wire stripping machines, which are compact devices designed for the quick and easy separation of valuable wire from its protective casing and insulation.

ACCE Machinery – Wire Stripping Machines

Domain: accemachinery.com

Registered: 2022 ( 3 years )

Introduction: ACCE Machinery offers a range of wire stripping machines designed for efficient and effective wire processing. Their product line includes various models such as the V-KOF, V-038M, V-918-B, V-025M, V-120, V-200M, V-120M, V-025, and V-009, catering to different wire stripping needs.

Ew Wirestripping – Automatic Wire Stripping Machines

Domain: ew-wirestripping.com

Registered: 2014 ( 11 years )

Introduction: EW-10UT-3 Automatic Wire Stripping Machine (OD: 10-50mm) – Wire Stripping Machine, Wire Crimping Machine, Wire Cutting Stripping Machine, Cable Stripping Machine.

Knipex – Wire Strippers and Stripping Tools

Domain: knipex.com

Registered: 1997 ( 28 years )

Introduction: KNIPEX offers a range of wire strippers and stripping tools designed for various applications, including electrical, plumbing, electronics, automotive, and more.

JCWelec – Wire Stripping and Crimping Machines

Domain: jcw-wirestripping.com

Registered: 2021 ( 4 years )

Introduction: JCWelec offers a range of wire stripping and crimping machines, including fully automatic and semi-automatic options, as well as specialized machines for cutting, stripping, and processing various types of cables.

Itascaautosys – Wire Stripping and Automation Equipment

Domain: itascaautosys.com

Registered: 2006 ( 19 years )

Introduction: Itasca offers a variety of wire stripping machines and related automation equipment, including single spindle and multi-spindle coil winders, custom machine designs, and accessories such as wire guides and wire tension units.

Ideal Industries – Precision Wire Stripping Solutions

Domain: idealind.com

Registered: 2012 ( 13 years )

Introduction: Ideal Industries offers a range of wire strippers designed for various wire sizes and types, focusing on precision and ease of use.

Yescomusa – Automatic Wire Stripping Machines

Domain: yescomusa.com

Registered: 2002 ( 23 years )

Introduction: Yescom Automatic Wire Stripping Machine for stripping copper cables.

KNIPEX – Wire Strippers and Dismantling Tools

Domain: knipex-tools.com

Registered: 2005 ( 20 years )

Introduction: KNIPEX offers a range of wire strippers and dismantling tools, including automatic wire strippers, dismantling tools, electronics wire stripping shears, and fiber optic wire strippers.

Vevor – Wire Stripping Machines

Domain: vevor.com

Registered: 2009 ( 16 years )

Introduction: CO-Z Wire Stripping Machine designed for efficient wire stripping.

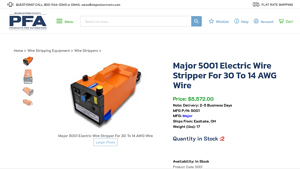

Productsforautomation – Electric Wire Strippers

Domain: productsforautomation.com

Registered: 2007 ( 18 years )

Introduction: Major 5001 Electric Wire Stripper For 30 To 14 AWG Wire

Category Information

The category of “wire stripping machine company” encompasses businesses that design, manufacture, and sell machines specifically engineered to remove insulation from electrical wires. These machines are essential in various industries, including electronics, automotive, and telecommunications, where efficient wire processing is crucial for production and assembly. Companies in this sector provide a range of solutions, from manual devices for small operations to fully automated systems for large-scale manufacturing.

The significance of wire stripping machines lies in their ability to enhance productivity and ensure precision in wire preparation. By automating the stripping process, companies can reduce labor costs, minimize waste, and improve safety in the workplace. As the demand for electrical components continues to grow, wire stripping machine companies play a vital role in supporting innovation and efficiency across multiple sectors.

Application Information

Wire stripping machines are essential in various industries where efficient and precise handling of electrical wires is crucial. One key application area is the electrical manufacturing sector, where these machines are used to prepare wires for assembly in devices such as circuit boards and appliances. This ensures reliable connections and enhances product performance. Another significant area is automotive manufacturing, where wire stripping machines facilitate the production of wiring harnesses.

These harnesses are critical for the electrical systems of vehicles, ensuring safety and functionality. Additionally, the recycling industry employs wire stripping machines to extract valuable metals from insulated cables, contributing to sustainable practices by enabling the recovery of copper and aluminum. In construction, these machines are utilized for preparing electrical installations, ensuring that wires are ready for safe and effective use in various building projects.

Production Process Information

The production process for a wire stripping machine typically involves several key stages. First, design and engineering is crucial, where engineers create detailed plans and specifications for the machine. This phase includes selecting the right materials and components to ensure durability and efficiency. Next comes the manufacturing stage, where the various parts of the machine are produced. This can include cutting, shaping, and assembling components like blades, motors, and frames.

Quality control is vital during this stage to ensure that each part meets the required standards. Finally, the assembly and testing phase takes place. In this stage, all parts are brought together to form the complete machine, followed by rigorous testing to ensure it operates correctly. After passing quality checks, the machines are either packaged for sale or customized for specific customer needs. Throughout the process, customer feedback and market trends are considered to improve the product continually.

Related Video

Frequently Asked Questions (FAQs)

What should I look for when choosing a wire stripping machine manufacturer?

When selecting a wire stripping machine manufacturer, consider their experience in the industry, the range of machines they offer, and their reputation among customers. Look for manufacturers that provide detailed specifications and demonstrate innovation in their designs. It’s also important to check if they offer after-sales support, warranty options, and spare parts availability. Customer reviews and testimonials can provide valuable insights into their reliability and service quality.

How can I verify the quality of a wire stripping machine?

To verify the quality of a wire stripping machine, request samples or demonstrations of the equipment in action. Check for certifications such as ISO, CE, or other relevant industry standards that indicate quality assurance. It’s also helpful to ask about the materials used in manufacturing and the testing processes the machines undergo before delivery. Engaging with current users of the machines can also give you a clearer picture of their performance and durability.

What are the benefits of purchasing from a local manufacturer versus an overseas one?

Purchasing from a local manufacturer can offer several advantages, including easier communication, quicker shipping times, and the ability to inspect the machines in person before buying. Local suppliers may also provide better customer service and support, as they are in the same time zone and can respond to inquiries more promptly. On the other hand, overseas manufacturers might offer lower prices or a wider range of options, but consider the potential challenges of longer lead times and shipping costs.

How do I determine the right capacity and features for my wire stripping needs?

To determine the right capacity and features for your wire stripping machine, start by assessing the volume of wire you need to process and the types of materials you’ll be working with. Consider the wire sizes and insulation types, as different machines have varying capabilities. It’s also beneficial to think about the automation level you desire—manual, semi-automatic, or fully automatic—based on your production needs and budget. Consulting with manufacturers can help you find a machine that aligns perfectly with your requirements.

What is the typical lead time for ordering a wire stripping machine?

The lead time for ordering a wire stripping machine can vary significantly based on the manufacturer, the complexity of the machine, and whether it is a standard model or a custom order. Generally, you can expect lead times to range from a few weeks to several months. It’s a good idea to ask the manufacturer directly about their production schedule and delivery timelines when you place your order. This way, you can plan accordingly and ensure that you receive your machine when you need it.